cooling Hyundai Genesis 2014 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: Genesis, Model: Hyundai Genesis 2014Pages: 546, PDF Size: 13.59 MB

Page 459 of 546

7-23

7

Maintenance

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

We recommend that the air cleaner

filter be replaced by an authorized

HYUNDAI dealer.

Spark plugs

Make sure to install new spark plugs

of the correct heat range.

Valve clearance

(3.0L / 3.3L / 3.8L)

Inspect excessive valve noise and/or

engine vibration and adjust if neces-

sary. We recommend that the system

be serviced by an authorized

HYUNDAI dealer.

Cooling system

Check the cooling system parts,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule. Do not disconnect and inspect

spark plugs when the engine is

hot. You may burn yourself.

WARNING

Page 464 of 546

7-28

Maintenance

ENGINE COOLANT

The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant concentration level at least

once a year, at the beginning of the

winter season, and before traveling

to a colder climate.Checking the coolant level

Removing radiator

cap

•

Never attempt to remove the

radiator cap while the engine

is operating or hot. Doing so

might lead to cooling system

and engine damage and could

result in serious personal

injury from escaping hot

coolant or steam.

•Turn the engine off and wait

until it cools down. Use

extreme care when removing

the radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to

the first stop. Step back while

the pressure is released from

the cooling system.

(Continued)

WARNING

(Continued)

When you are sure all the

pressure has been released,

press down on the cap, using

a thick towel, and continue

turning counterclockwise to

remove it.

•Even if the engine is not oper-

ating, do not remove the radi-

ator cap or the drain plug

while the engine and radiator

are hot. Hot coolant and

steam may still blow out

under pressure, causing seri-

ous injury.

•When the engine overheats

from low engine coolant, sud-

denly adding engine coolant

may cause cracks in the

engine. To prevent damage,

add engine coolant slowly in

small quantities.

•Do not drive with no engine

coolant. It may cause water

pump failure and engine

seizure, etc.

CAUTION

Page 465 of 546

7-29

7

Maintenance

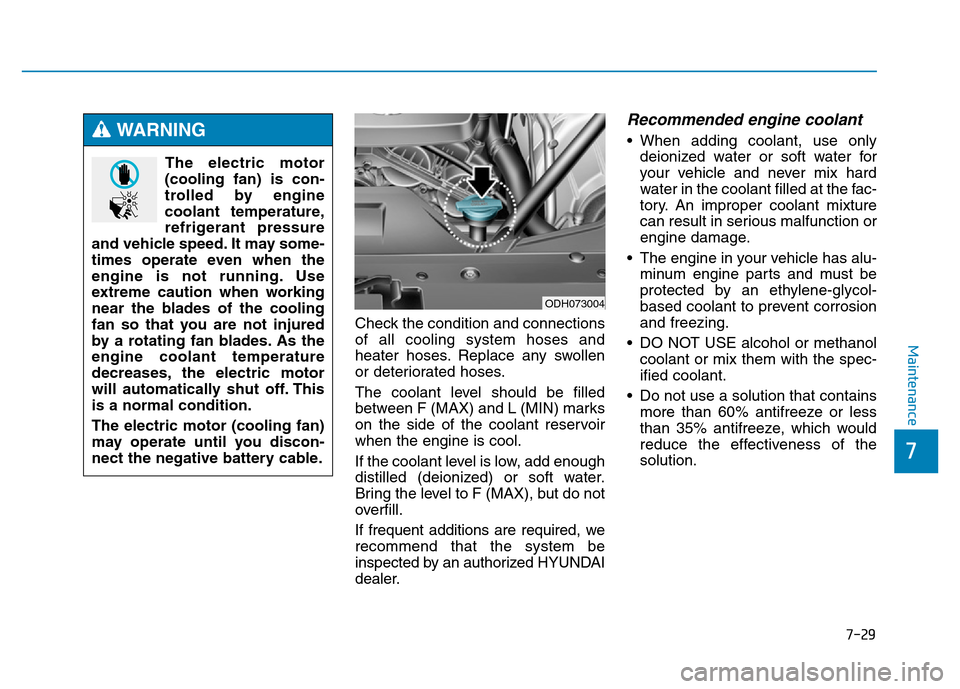

Check the condition and connections

of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between F (MAX) and L (MIN) marks

on the side of the coolant reservoir

when the engine is cool.

If the coolant level is low, add enough

distilled (deionized) or soft water.

Bring the level to F (MAX), but do not

overfill.

If frequent additions are required, we

recommend that the system be

inspected by an authorized HYUNDAI

dealer.

Recommended engine coolant

• When adding coolant, use only

deionized water or soft water for

your vehicle and never mix hard

water in the coolant filled at the fac-

tory. An improper coolant mixture

can result in serious malfunction or

engine damage.

• The engine in your vehicle has alu-

minum engine parts and must be

protected by an ethylene-glycol-

based coolant to prevent corrosion

and freezing.

• DO NOT USE alcohol or methanol

coolant or mix them with the spec-

ified coolant.

• Do not use a solution that contains

more than 60% antifreeze or less

than 35% antifreeze, which would

reduce the effectiveness of the

solution.

ODH073004

The electric motor

(cooling fan) is con-

trolled by engine

coolant temperature,

refrigerant pressure

and vehicle speed. It may some-

times operate even when the

engine is not running. Use

extreme caution when working

near the blades of the cooling

fan so that you are not injured

by a rotating fan blades. As the

engine coolant temperature

decreases, the electric motor

will automatically shut off. This

is a normal condition.

The electric motor (cooling fan)

may operate until you discon-

nect the negative battery cable.

WARNING

Page 501 of 546

7-65

7

Maintenance

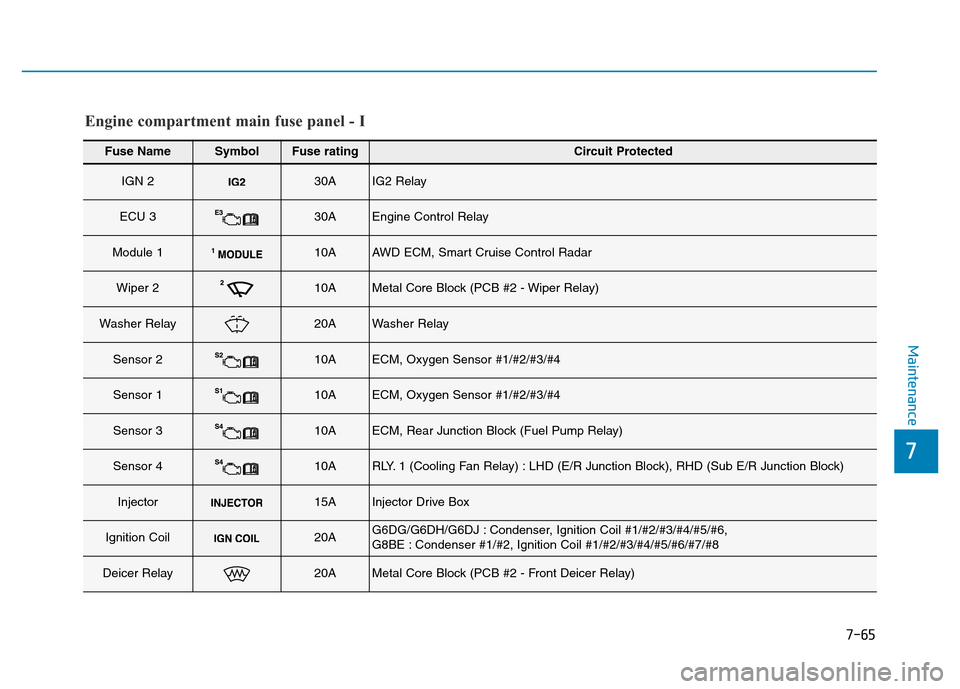

Fuse NameSymbolFuse ratingCircuit Protected

IGN 230AIG2 Relay

ECU 330AEngine Control Relay

Module 110AAWD ECM, Smart Cruise Control Radar

Wiper 210AMetal Core Block (PCB #2 - Wiper Relay)

Washer Relay20AWasher Relay

Sensor 210AECM, Oxygen Sensor #1/#2/#3/#4

Sensor 110AECM, Oxygen Sensor #1/#2/#3/#4

Sensor 310AECM, Rear Junction Block (Fuel Pump Relay)

Sensor 410ARLY. 1 (Cooling Fan Relay) : LHD (E/R Junction Block), RHD (Sub E/R Junction Block)

Injector15AInjector Drive Box

Ignition Coil20AG6DG/G6DH/G6DJ : Condenser, Ignition Coil #1/#2/#3/#4/#5/#6,

G8BE : Condenser #1/#2, Ignition Coil #1/#2/#3/#4/#5/#6/#7/#8

Deicer Relay20AMetal Core Block (PCB #2 - Front Deicer Relay)

Engine compartment main fuse panel - I

Page 504 of 546

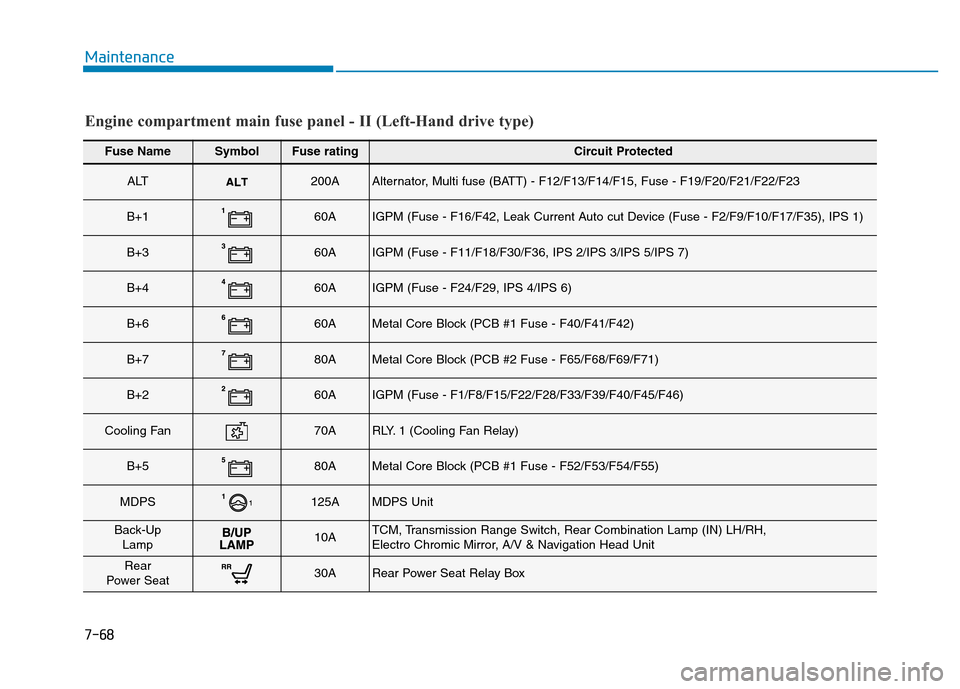

7-68

Maintenance

Fuse NameSymbolFuse ratingCircuit Protected

ALT200AAlternator, Multi fuse (BATT) - F12/F13/F14/F15, Fuse - F19/F20/F21/F22/F23

B+160AIGPM (Fuse - F16/F42, Leak Current Auto cut Device (Fuse - F2/F9/F10/F17/F35), IPS 1)

B+360AIGPM (Fuse - F11/F18/F30/F36, IPS 2/IPS 3/IPS 5/IPS 7)

B+460AIGPM (Fuse - F24/F29, IPS 4/IPS 6)

B+660AMetal Core Block (PCB #1 Fuse - F40/F41/F42)

B+780AMetal Core Block (PCB #2 Fuse - F65/F68/F69/F71)

B+260AIGPM (Fuse - F1/F8/F15/F22/F28/F33/F39/F40/F45/F46)

Cooling Fan70ARLY. 1 (Cooling Fan Relay)

B+580AMetal Core Block (PCB #1 Fuse - F52/F53/F54/F55)

MDPS125AMDPS Unit

Back-Up

Lamp10ATCM, Transmission Range Switch, Rear Combination Lamp (IN) LH/RH,

Electro Chromic Mirror, A/V & Navigation Head Unit

Rear

Power Seat30ARear Power Seat Relay Box

Engine compartment main fuse panel - II (Left-Hand drive type)

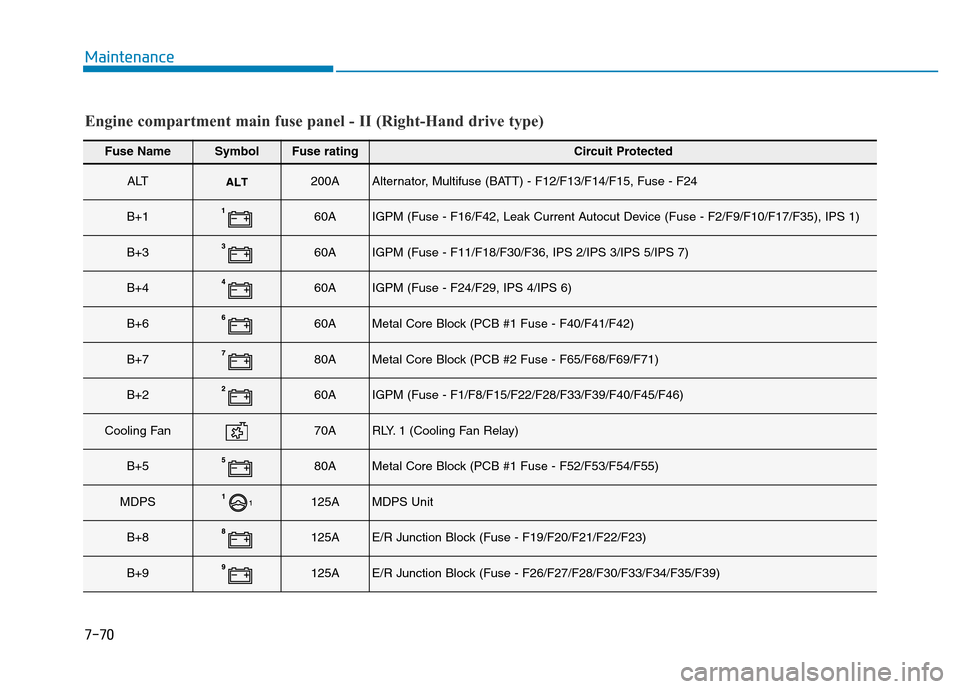

Page 506 of 546

7-70

Maintenance

Fuse NameSymbolFuse ratingCircuit Protected

ALT200AAlternator, Multifuse (BATT) - F12/F13/F14/F15, Fuse - F24

B+160AIGPM (Fuse - F16/F42, Leak Current Autocut Device (Fuse - F2/F9/F10/F17/F35), IPS 1)

B+360AIGPM (Fuse - F11/F18/F30/F36, IPS 2/IPS 3/IPS 5/IPS 7)

B+460AIGPM (Fuse - F24/F29, IPS 4/IPS 6)

B+660AMetal Core Block (PCB #1 Fuse - F40/F41/F42)

B+780AMetal Core Block (PCB #2 Fuse - F65/F68/F69/F71)

B+260AIGPM (Fuse - F1/F8/F15/F22/F28/F33/F39/F40/F45/F46)

Cooling Fan70ARLY. 1 (Cooling Fan Relay)

B+580AMetal Core Block (PCB #1 Fuse - F52/F53/F54/F55)

MDPS125AMDPS Unit

B+8125AE/R Junction Block (Fuse - F19/F20/F21/F22/F23)

B+9125AE/R Junction Block (Fuse - F26/F27/F28/F30/F33/F34/F35/F39)

Engine compartment main fuse panel - II (Right-Hand drive type)