clock Hyundai Getz 2003 Service Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2003, Model line: Getz, Model: Hyundai Getz 2003Pages: 444, PDF Size: 13.82 MB

Page 398 of 444

6- 8 DO-IT-YOURSELF MAINTENANCE

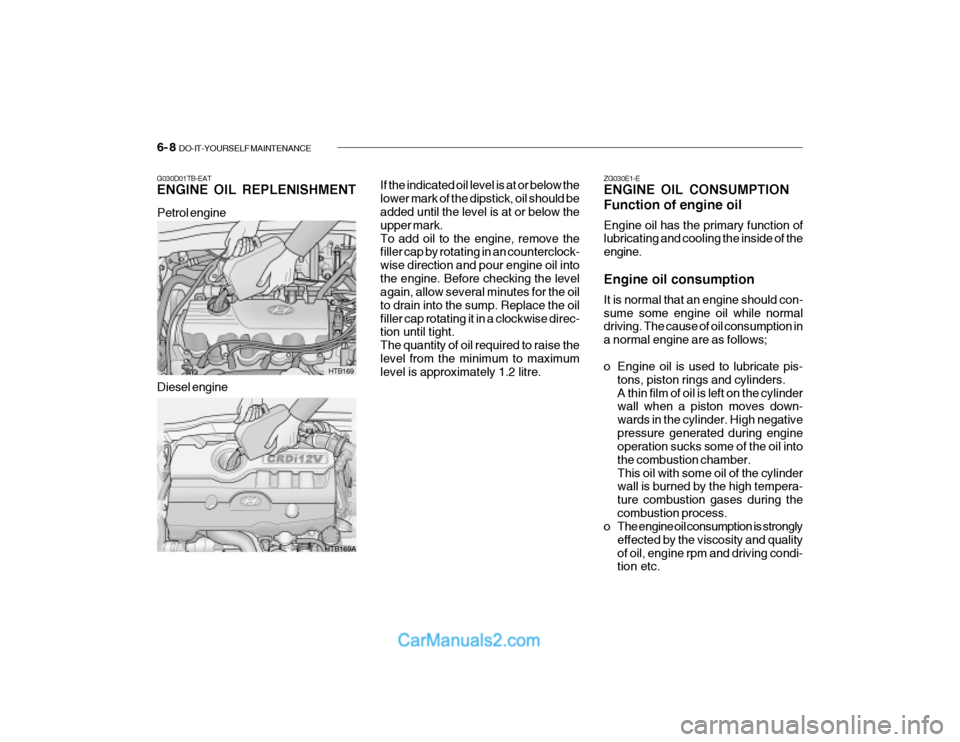

Petrol engine

HTB169

HTB169A

Diesel engine

G030D01TB-EAT ENGINE OIL REPLENISHMENT

If the indicated oil level is at or below the lower mark of the dipstick, oil should be added until the level is at or below the upper mark.To add oil to the engine, remove the filler cap by rotating in an counterclock- wise direction and pour engine oil intothe engine. Before checking the level again, allow several minutes for the oil to drain into the sump. Replace the oilfiller cap rotating it in a clockwise direc- tion until tight. The quantity of oil required to raise thelevel from the minimum to maximum level is approximately 1.2 litre.ZG030E1-E ENGINE OIL CONSUMPTION Function of engine oil Engine oil has the primary function of lubricating and cooling the inside of the engine. Engine oil consumption It is normal that an engine should con- sume some engine oil while normal driving. The cause of oil consumption in a normal engine are as follows;

o Engine oil is used to lubricate pis-

tons, piston rings and cylinders. A thin film of oil is left on the cylinder wall when a piston moves down- wards in the cylinder. High negativepressure generated during engine operation sucks some of the oil into the combustion chamber.This oil with some oil of the cylinder wall is burned by the high tempera- ture combustion gases during thecombustion process.

o The engine oil consumption is strongly

effected by the viscosity and qualityof oil, engine rpm and driving condi- tion etc.

Page 400 of 444

6- 10 DO-IT-YOURSELF MAINTENANCE

!

!

HTB170

Petrol engine SG050A1-E ENGINE COOLANT CHECKING AND REPLACING

SG050B1-E Coolant recommendations WARNING:

Do not remove the radiator cap when the engine is hot, since the system is pressurized and coolant may be ejected from the radiator resulting inscalding.

3. Prepare a suitable receptacle to col-

lect the displaced oil and remove thedrain plug from the sump.

4. When the oil has drained from the sump, replace the drain plug using anew washer ensuring that the plug is not over tightened. Tightening torque is: 3.5 ~ 4.5 kgf.m

5. Remove the oil filter by rotating coun- terclockwise, using a proprietary oil filter removal tool if necessary. Notethat the oil filter will contain approxi- mately 0.5 litres of oil and this should be collected in a suitable receptacle.

6. Install a new oil filter having smeared the sealing ring with clean oil androtating clockwise until the filter con-tacts the mounting and then a further one half turn. Do not over-tighten CAUTION:

The oil being drained from the en- gine will be hot. Care should beexercised to prevent scalding.

! Tightening torque: Petrol -

1.2 ~ 1.6 kgf.m

Diesel(RHD) - 2.3 ~ 2.5 kgf.m

7. Pour the specified quantity of the recommended oil into the engine and replace the filler cap. Start the en- gine and ensure that no oil leaks exist. Turn off the engine and after acouple minutes, recheck the oil level.

WARNING:

Prolonged and repeated contact with used engine oils may result in seri- ous skin disorders including derma- titis and cancer. Avoid contact with skin as far as possible and alwayswash thoroughly after any contact. Keep used oils out of reach of chil- dren. It is illegal to pollute drains,water courses and soil. Use only authorized waste collection facili- ties including civic amenity sitesand garages for the disposal of used oil and oil filters. If in doubt, contact the local authority for disposal in-structions.

Page 403 of 444

DO-IT-YOURSELF MAINTENANCE 6- 13

SG060A1-E SPARKING PLUG REPLACE- MENT

G060A01L

0.039 ~ 0.043 in. (1.0 ~ 1.1 mm )

This operation should only be performed when the engine is cold.

1. Remove the centre cover from the engine rocker cover.

2. Remove plug lead from the sparking plug to be replaced, pulling the lead by the rubber cap. (Pulling the lead may damage the carbon conductor).

3. Clean around the base of the plug to be removed, and install the plugsocket ensuring that the ceramicinsulator does not become damaged. Turn the socket counterclockwise to remove the plug. CAUTION:

Sparking plugs must only be cleaned using purpose designed equipment. Wire brushing may damage the cen-tre electrodein-sulator causing mis- firing to occur. Only the correct grade of sparking plug should be used.Use of an incorrect grade may result in serious engine damage. Prior to installing a sparking plug, the gap between the centre and outer elec- trodes must be checked and adjusted as necessary. Adjustment is facilitated by bending the outer electrode towards or away fromthe centre electrode. Under no circum- stances should attempts be made to adjust the position of the centre elec-trode.

4. Insert the sparking plug into the cyl- inder head and screw by the wrench and until the plug contacts the seat- ing area. Tighten the plug with the socket by a further 1/2 to 3/4 of a turnonly. 5. Replace the plug lead ensuring that

the cap is pushed firmly into place.Confirm that the cap is correctlyseated by lightly pulling upon it.

NOTE: When replacing the spark plug, al- ways use the genuine parts recom- mended. Recommended Spark Plugs

CHAMPION NGK RC10YCBKR5ES

Unleaded

engine Leaded

engine

RC10YC4 BKR5ES-11

!

Page 441 of 444

10- 2 INDEX

A AIR BAG ................................................................... 1-29

AIR CONDITIONING SWITCH .................................1-74

AIR CONDITIONING SYSTEM MAINTENANCE ..... 6-19

AIR CLEANER FILTER ............................................. 6-14

ANTENNA ................................................................. 1-81

ANTI-LOCK BRAKE SYSTEM .................................. 2-13

ANTI-THEFT ALARM SYSTEM .................................. 1-7

ASHTRAY ................................................................. 1-52

AUTO FUEL CUT SWITCH...................................... 1-66

AUTOMATIC TRANSAXLE ......................................... 2-9AUTOMATIC TRANSAXLE FLUID ...........................6-16

BBATTERY MAINTENANCE ......................................6-25

BEFORE STARTING THE ENGINE ...........................2-3

BONNET RELEA SE .................................................. 1-60

BRAKE PEDAL FREEPLAY .....................................6-22

BRAKE SYSTEM CHECKING ..................................6-18

CCARE OF DISC ......................................................... 1-79

CARE OF SEAT BELTS ....... ....................................1-17

CARGO AREA COVER ............................................ 1-63

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ...................................................... 7-3

CENTRAL DOOR LOCKS .......................................... 1-5

CHANGING A FLAT TYRE ......................................... 3-6 CHILD-PROOF REAR DOOR

LOCK .......................... 1-5

CHILD RESTRAINT SYSTEM ..................................1-21

CIGAR LIGHTER ...................................................... 1-51

CLUTCH PEDAL FREEPLAY................................... 6-22

COMBINATION IGNITION SWITCH AND STEERING LOCK ................................................... 2-3

CONSOLE TRAY ...................................................... 1-52

COOLANT TEMPERATURE GAUGE .......................1-42

DDAILY OPERATING CHECKS .................................... 6-6

DIGITAL CLOCK ....................................................... 1-51

DOOR LOCK S ............................................................ 1-5

DOOR WINDOWS .................................................... 1-10

DRINK HOLDER ....................................................... 1-52

DRIVE BELTS ........................................................... 6-23

DRIVING FOR ECONOMY .......................................2-14

E

EFFECTIVE BRAKING ............................................. 2-13

ELECTRIC COOLING FANS ....................................6-25

EMERGENCY TOWING ........................................... 3-12

EMISSION CONTROL SYSTEM ................................ 7-2

ENGINE COMPARTMENT .................... ..................... 6-2

ENGINE COOLANT CHECKING AND REPLACING ......................................................... 6-10

ENGINE OIL AND FILTER REPLACEMENT .............. 6-9

ENGINE OIL CONSUMPTION ................................... 6-8