maintenance schedule Hyundai Grand Santa Fe 2013 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2013, Model line: Grand Santa Fe, Model: Hyundai Grand Santa Fe 2013Pages: 718, PDF Size: 13.5 MB

Page 593 of 718

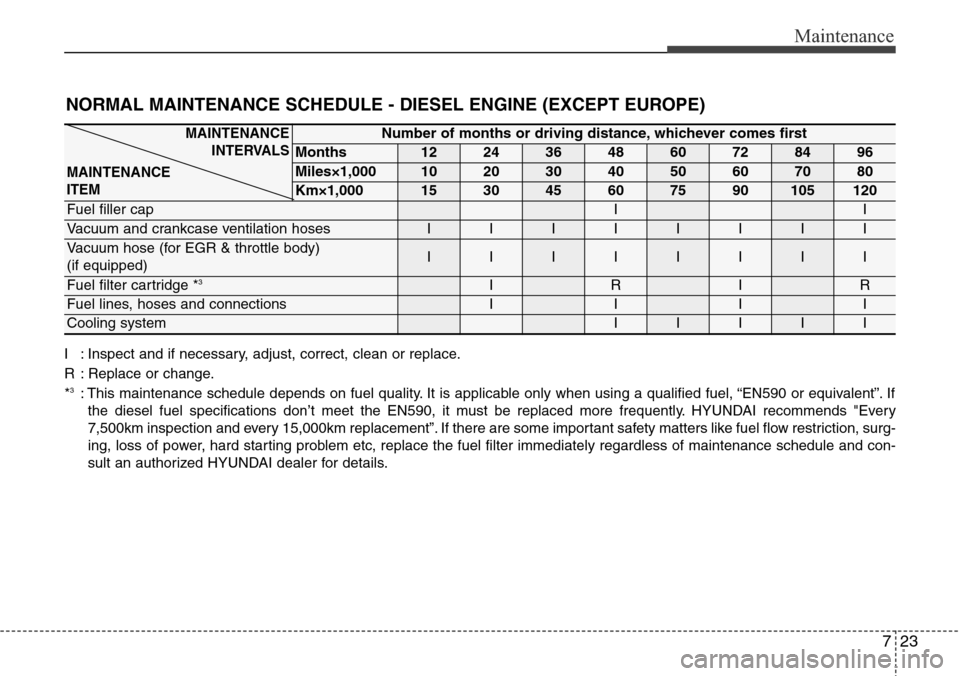

Number of months or driving distance, whichever comes first

Months1224364860728496

Miles×1,0001020304050607080

Km×1,000153045607590105120

Fuel filler capII

Vacuum and crankcase ventilation hosesIIIIIIII

Vacuum hose (for EGR & throttle body)

(if equipped)IIIIIIII

Fuel filter cartridge *3IRIR

Fuel lines, hoses and connectionsIIII

Cooling systemIIIII

723

Maintenance

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (EXCEPT EUROPE)

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

3: This maintenance schedule depends on fuel quality. It is applicable only when using a qualified fuel, “EN590 or equivalent”. If

the diesel fuel specifications don’t meet the EN590, it must be replaced more frequently. HYUNDAI recommends "Every

7,500km inspection and every 15,000km replacement”. If there are some important safety matters like fuel flow restriction, surg-

ing, loss of power, hard starting problem etc, replace the fuel filter immediately regardless of maintenance schedule and con-

sult an authorized HYUNDAI dealer for details.

Page 594 of 718

Maintenance

24 7

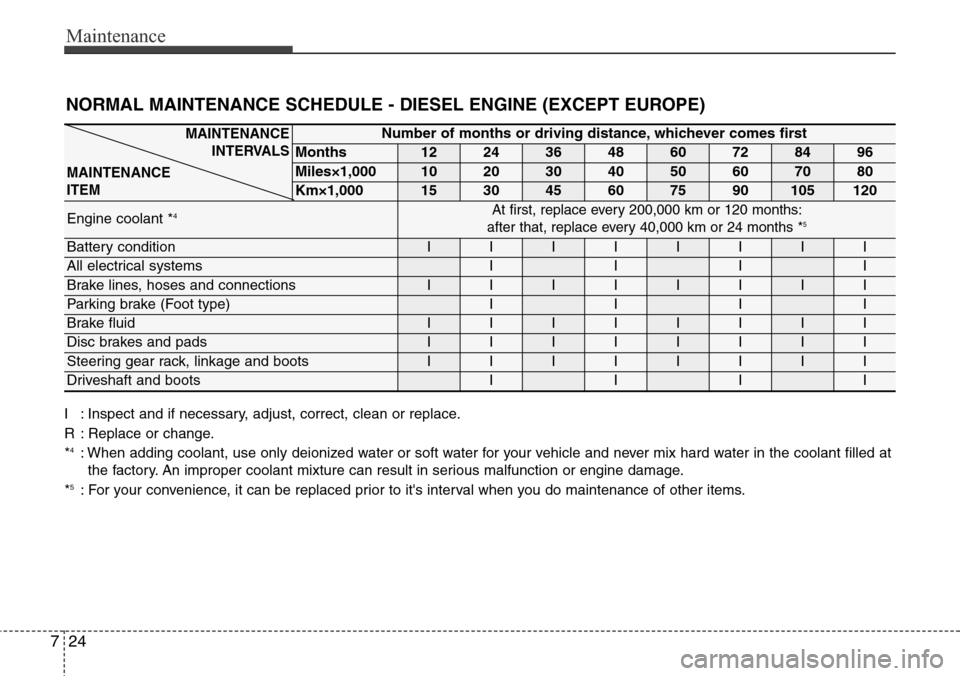

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*

4: When adding coolant, use only deionized water or soft water for your vehicle and never mix hard water in the coolant filled at

the factory. An improper coolant mixture can result in serious malfunction or engine damage.

*

5: For your convenience, it can be replaced prior to it's interval when you do maintenance of other items.

Number of months or driving distance, whichever comes first

Months1224364860728496

Miles×1,0001020304050607080

Km×1,000153045607590105120

Engine coolant *4At first, replace every 200,000 km or 120 months:

after that, replace every 40,000 km or 24 months *5

Battery conditionIIIIIIII

All electrical systemsIIII

Brake lines, hoses and connectionsIIIIIIII

Parking brake (Foot type)IIII

Brake fluidIIIIIIII

Disc brakes and padsIIIIIIII

Steering gear rack, linkage and bootsIIIIIIII

Driveshaft and bootsIIII

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (EXCEPT EUROPE)

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Page 595 of 718

725

Maintenance

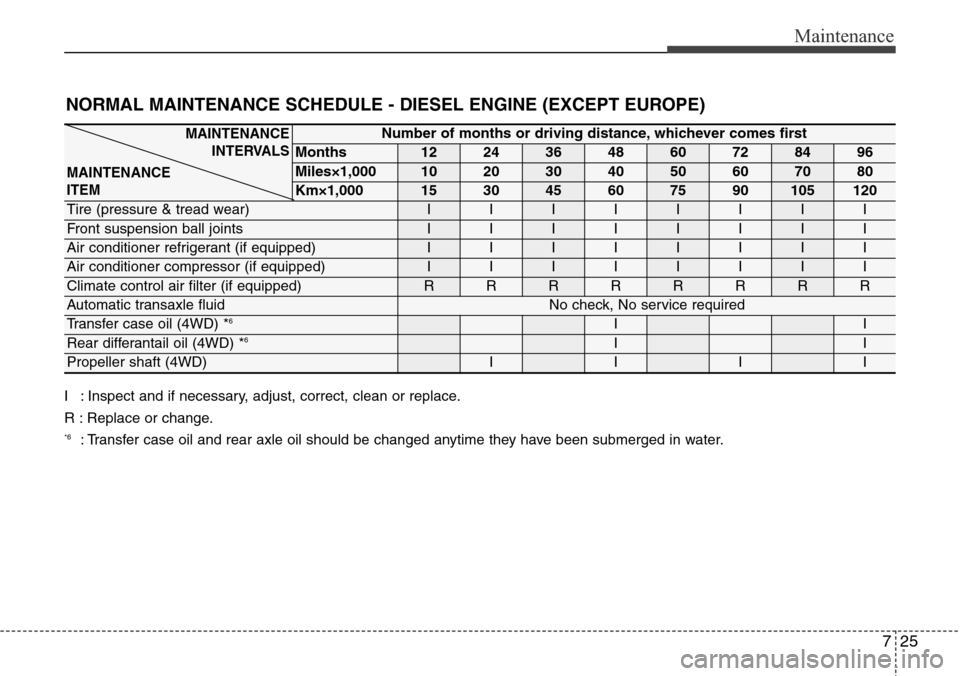

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (EXCEPT EUROPE)

Number of months or driving distance, whichever comes first

Months1224364860728496

Miles×1,0001020304050607080

Km×1,000153045607590105120

Tire (pressure & tread wear) IIIIIIII

Front suspension ball jointsIIIIIIII

Air conditioner refrigerant (if equipped)IIIIIIII

Air conditioner compressor (if equipped)IIIIIIII

Climate control air filter (if equipped)RRRRRRRR

Automatic transaxle fluid No check, No service required

Transfer case oil (4WD) *6II

Rear differantail oil (4WD) *6II

Propeller shaft (4WD)IIII

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.

*6: Transfer case oil and rear axle oil should be changed anytime they have been submerged in water.

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Page 598 of 718

Maintenance

28 7

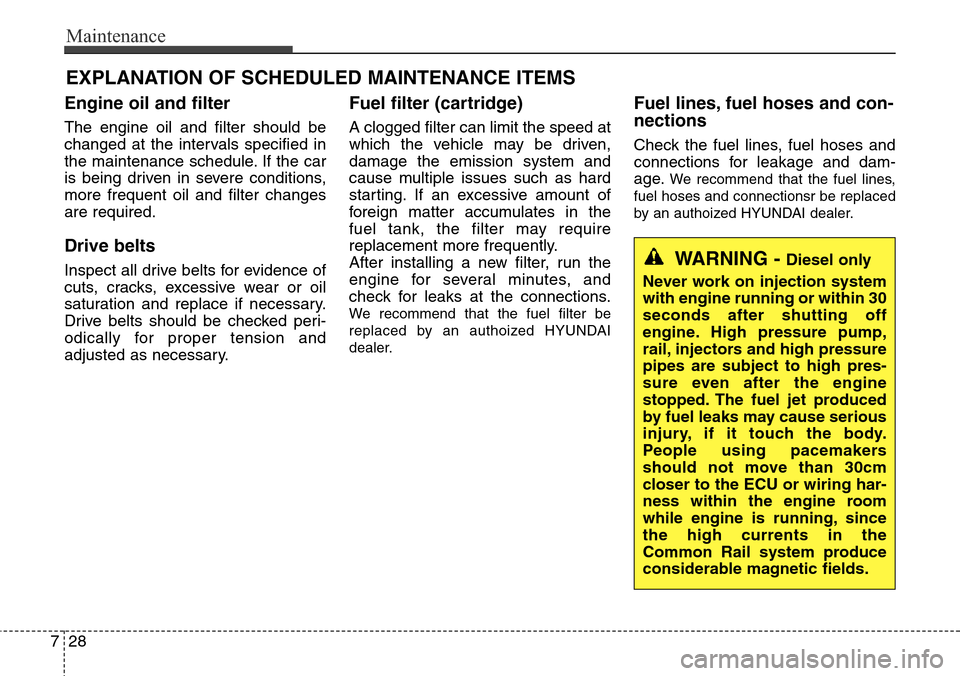

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven,

damage the emission system and

cause multiple issues such as hard

starting. If an excessive amount of

foreign matter accumulates in the

fuel tank, the filter may require

replacement more frequently.

After installing a new filter, run the

engine for several minutes, and

check for leaks at the connections.

We recommend that the fuel filter be

replaced by an authoized HYUNDAI

dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age.

We recommend that the fuel lines,

fuel hoses and connectionsr be replaced

by an authoized HYUNDAI dealer.

WARNING - Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off

engine. High pressure pump,

rail, injectors and high pressure

pipes are subject to high pres-

sure even after the engine

stopped. The fuel jet produced

by fuel leaks may cause serious

injury, if it touch the body.

People using pacemakers

should not move than 30cm

closer to the ECU or wiring har-

ness within the engine room

while engine is running, since

the high currents in the

Common Rail system produce

considerable magnetic fields.

Page 599 of 718

729

Maintenance

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-

rectly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Air cleaner filter

We recommend that the air cleaner

filter be replaced by an authoized

HYUNDAI dealer.

Spark plugs

(for gasoline engine)

Make sure to install new spark plugs

of the correct heat range.

Valve clearance

(for gasoline engine)

Inspect excessive valve noise and/or

engine vibration and adjust if neces-

sary. We recommend that the system

be serviced by an authorized

HYUNDAI dealer.

Page 600 of 718

Maintenance

30 7

Cooling system

Check the cooling system parts,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Automatic transaxle fluid

Automatic transaxle fluid should not

be checked under normal usage

conditions.

We recommend that the automatic

transaxle fluid changed by an author-

ized HYUNDAI dealer according to

the maintenance schedule.

✽NOTICE

Automatic transaxle fluid color is

basically red.

As the vehicle is driven, the auto-

matic transaxle fluid will begin to

look darker.

It is normal condition and you

should not judge the need to replace

the fluid based upon the changed

color.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake fluid

Check brake fluid level in the brake

fluid reservoir. The level should be

between “MIN” and “MAX” marks on

the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Parking brake

Inspect the parking brake system

including the EPB actuator, wiring

and connectors.

CAUTION

The use of a non-specified fluid

could result in transaxle mal-

function and failure. Use only

specified automatic transaxle

fluid. (Refer to “Recommended

lubricants and capacities” in

section 8.)

Page 612 of 718

Maintenance

42 7

Replace the filter according to the

Maintenance Schedule.

If the vehicle is operated in extremely

dusty or sandy areas, replace the

element more often than the usual

recommended intervals. (Refer to

“Maintenance under severe usage

conditions” in this section.)

CAUTION

• Do not drive with the air clean-

er removed; this will result in

excessive engine wear.

• When removing the air cleaner

filter, be careful that dust or

dirt does not enter the air

intake, or damage may result.

• We recommend that you use

parts for replacement from an

authorized HYUNDAI dealer.

Page 613 of 718

743

Maintenance

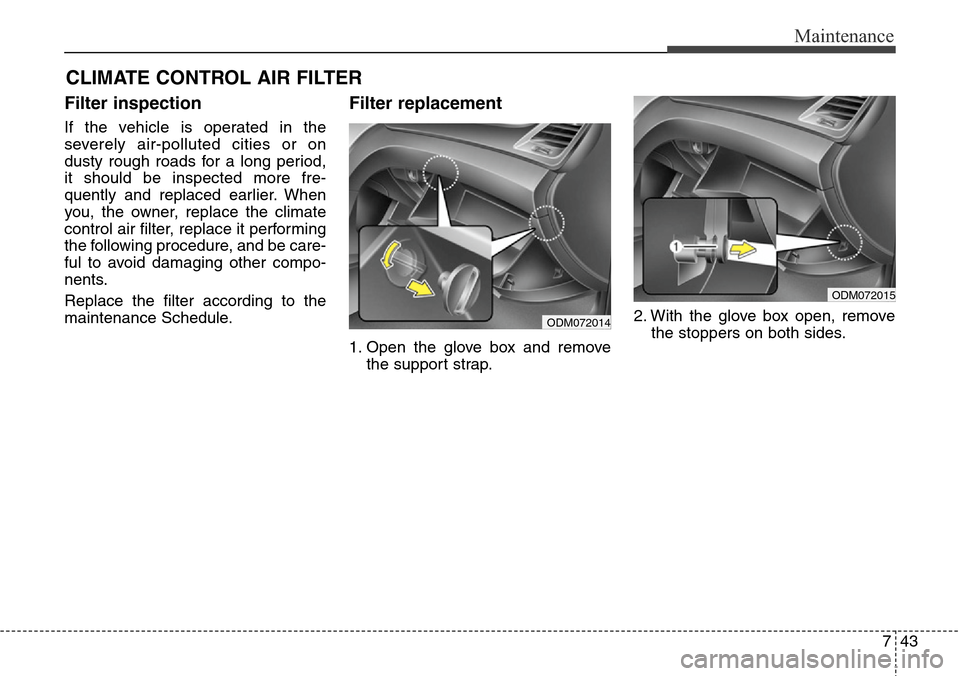

CLIMATE CONTROL AIR FILTER

Filter inspection

If the vehicle is operated in the

severely air-polluted cities or on

dusty rough roads for a long period,

it should be inspected more fre-

quently and replaced earlier. When

you, the owner, replace the climate

control air filter, replace it performing

the following procedure, and be care-

ful to avoid damaging other compo-

nents.

Replace the filter according to the

maintenance Schedule.

Filter replacement

1. Open the glove box and remove

the support strap.2. With the glove box open, remove

the stoppers on both sides.

ODM072015

ODM072014

Page 674 of 718

Maintenance

104 7

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

emission regulations.

There are three emission control

systems which are as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys-

tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

car inspected and maintained by an

authorized HYUNDAI dealer in

accordance with the maintenance

schedule in this manual.Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

• To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Contol (ESC) system off by

pressing the ESC switch.

• After dynamometer testing is

completed, turn the ESC system

back on by pressing the ESC

switch again.

1. Crankcase emission control

system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-

trol System

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surge

tank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.