AIr HYUNDAI I30 2012 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2012, Model line: I30, Model: HYUNDAI I30 2012Pages: 635, PDF Size: 40.66 MB

Page 370 of 635

753

Maintenance

FUSES

G210000AFD

A vehicle’s electrical system is protected

from electrical overload damage by

fuses. This vehicle has 2 (or 3) fuse panels, one

located in the driver’s side panel bolster,

the other in the engine compartment

near the battery.

If any of your vehicle’s lights, acces-

sories, or controls do not work, check the

appropriate circuit fuse. If a fuse has

blown, the element inside the fuse will bemelted.

If the electrical system does not work,

first check the driver’s side fuse panel.

Always replace a blown fuse with one of

the same rating.

If the replacement fuse blows, this indi-

cates an electrical problem. Avoid using

the system involved and immediately

consult an authorized HYUNDAI dealer.

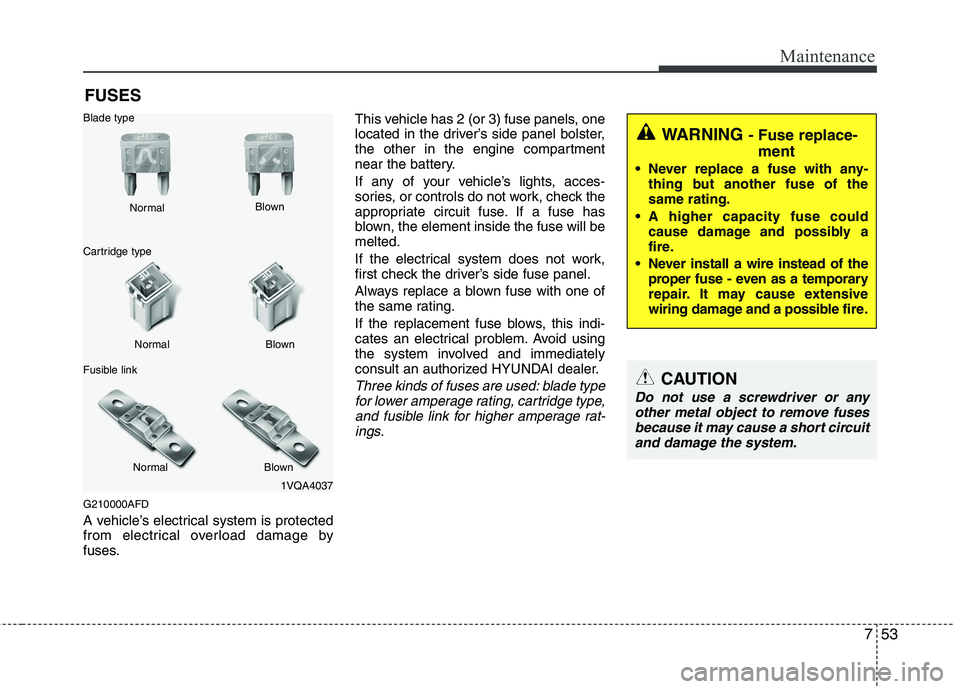

Three kinds of fuses are used: blade type

for lower amperage rating, cartridge type,

and fusible link for higher amperage rat-ings.

1VQA4037

Normal

Normal

Blade type

Cartridge type

Fusible link Blown

Blown

Normal Blown

WARNING - Fuse replace-

ment

Never replace a fuse with any- thing but another fuse of the same rating.

A higher capacity fuse could cause damage and possibly a

fire.

Never install a wire instead of the proper fuse - even as a temporary

repair. It may cause extensive

wiring damage and a possible fire.

CAUTION

Do not use a screwdriver or any

other metal object to remove fuses because it may cause a short circuitand damage the system.

Page 375 of 635

Maintenance

58

7

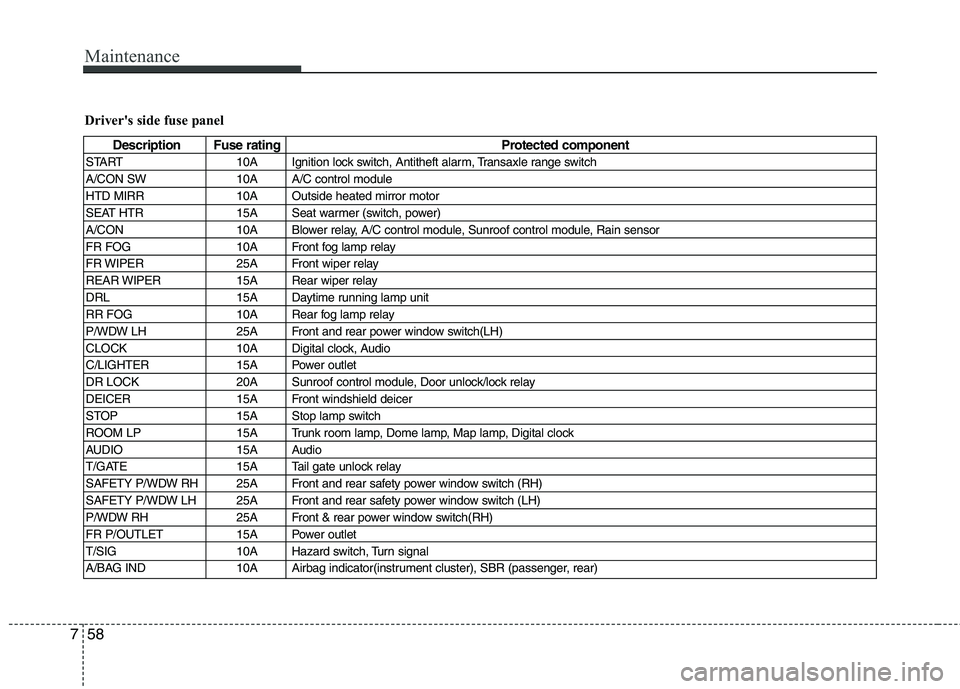

Driver's side fuse panel

Description Fuse rating Protected component

START 10A Ignition lock switch, Antitheft alarm, Transaxle range switch

A/CON SW 10A A/C control module

HTD MIRR 10A Outside heated mirror motor

SEAT HTR 15A Seat warmer (switch, power)

A/CON 10A Blower relay, A/C control module, Sunroof control module, Rain sensor

FR FOG 10A Front fog lamp relay

FR WIPER 25A Front wiper relay

REAR WIPER 15A Rear wiper relay

DRL 15A Daytime running lamp unit

RR FOG 10A Rear fog lamp relay

P/WDW LH 25A Front and rear power window switch(LH)

CLOCK 10A Digital clock, Audio

C/LIGHTER 15A Power outlet

DR LOCK 20A Sunroof control module, Door unlock/lock relay

DEICER 15A Front windshield deicer

STOP 15A Stop lamp switch

ROOM LP 15A Trunk room lamp, Dome lamp, Map lamp, Digital clock

AUDIO 15A Audio

T/GATE 15A Tail gate unlock relay

SAFETY P/WDW RH 25A Front and rear safety power window switch (RH)

SAFETY P/WDW LH 25A Front and rear safety power window switch (LH)

P/WDW RH 25A Front & rear power window switch(RH)

FR P/OUTLET 15A Power outlet

T/SIG 10A Hazard switch, Turn signal

A/BAG IND 10A Airbag indicator(instrument cluster), SBR (passenger, rear)

Page 378 of 635

761

Maintenance

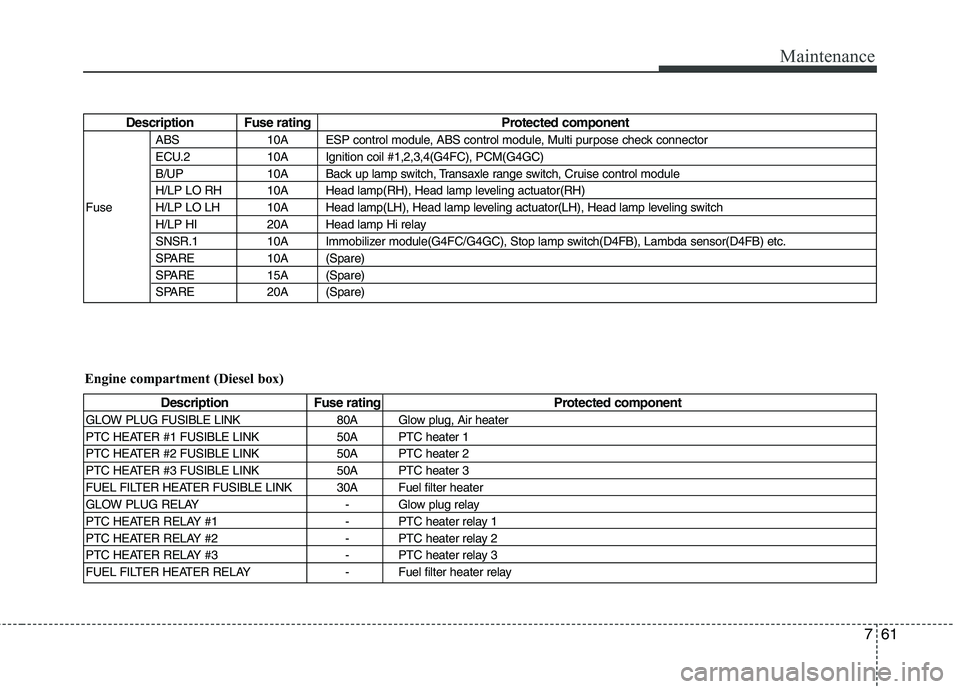

Description Fuse rating Protected componentABS 10A ESP control module, ABS control module, Multi purpose check connector

ECU.2 10A Ignition coil #1,2,3,4(G4FC), PCM(G4GC)

B/UP 10A Back up lamp switch, Transaxle range switch, Cruise control module

H/LP LO RH 10A Head lamp(RH), Head lamp leveling actuator(RH)

Fuse H/LP LO LH 10A Head lamp(LH), Head lamp leveling actuator(LH), Head lamp leveling switch H/LP HI 20A Head lamp Hi relay

SNSR.1 10A Immobilizer module(G4FC/G4GC), Stop lamp switch(D4FB), Lambda sensor(D4FB) etc.

SPARE 10A (Spare)

SPARE 15A (Spare)

SPARE 20A (Spare)

Description Fuse rating Protected component

GLOW PLUG FUSIBLE LINK 80A Glow plug, Air heater

PTC HEATER #1 FUSIBLE LINK 50A PTC heater 1

PTC HEATER #2 FUSIBLE LINK 50A PTC heater 2

PTC HEATER #3 FUSIBLE LINK 50A PTC heater 3

FUEL FILTER HEATER FUSIBLE LINK 30A Fuel filter heater

GLOW PLUG RELAY - Glow plug relay

PTC HEATER RELAY #1 - PTC heater relay 1

PTC HEATER RELAY #2 - PTC heater relay 2

PTC HEATER RELAY #3 - PTC heater relay 3

FUEL FILTER HEATER RELAY - Fuel filter heater relay

Engine compartment (Diesel box)

Page 385 of 635

Maintenance

68

7

APPEARANCE CARE

Exterior care

G230101AUN

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning andcaution statements that appear on thelabel. G230102CUN

Finish maintenance

Washing

To help protect your vehicle’s finish from

rust and deterioration, wash it thoroughlyand frequently at least once a month with

lukewarm or cold water.

If you use your vehicle for off-road driv-

ing, you should wash it after each off-

road trip. Pay special attention to the

removal of any accumulation of salt, dirt,

mud, and other foreign materials. Make

sure the drain holes in the lower edges of

the doors and rocker panels are keptclear and clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar deposits

can damage your vehicle’s finish if not

removed immediately.

Even prompt washing with plain water

may not completely remove all these

deposits. A mild soap, safe for use on

painted surfaces, may be used. After washing, rinse the vehicle thor-

oughly with lukewarm or cold water. Do

not allow soap to dry on the finish.

WARNING -

Wet brakes

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

CAUTION

Do not use strong soap, chemical detergents or hot water, and donot wash the vehicle in direct

sunlight or when the body of the vehicle is warm.

Be careful when washing the side windows of your vehicle.

Especially, with high-pressurewater. Water may leak through thewindows and wet the interior.

To prevent damage to the plastic parts, do not clean with chemical

solvents or strong detergents.

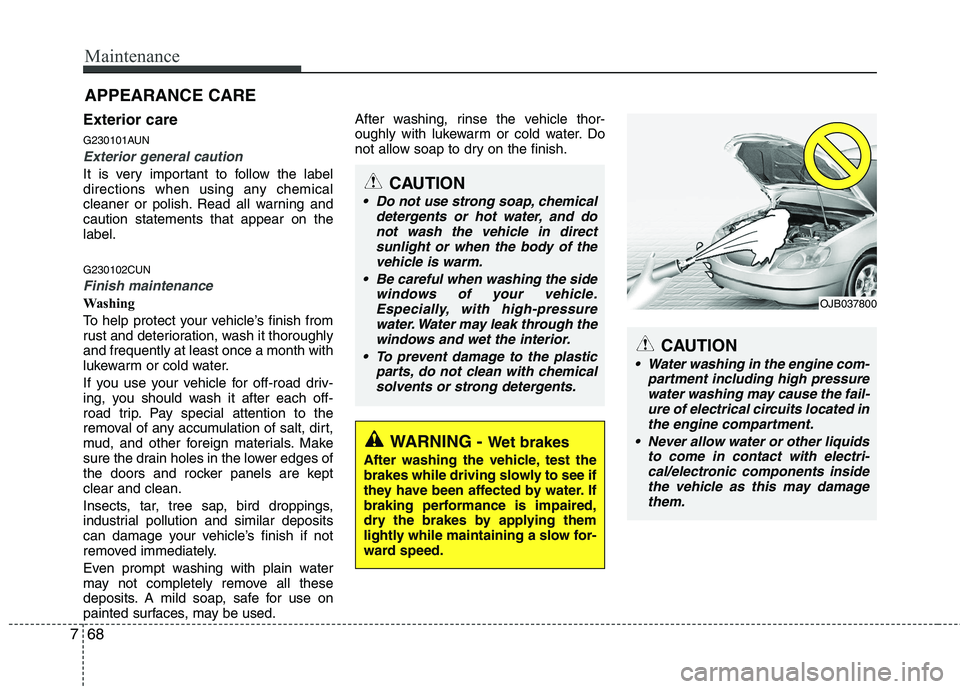

CAUTION

Water washing in the engine com- partment including high pressurewater washing may cause the fail-

ure of electrical circuits located in the engine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components inside

the vehicle as this may damage them.

OJB037800

Page 386 of 635

769

Maintenance

Waxing

Wax the vehicle when water will no longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.G230103AUN

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.

✽✽

NOTICE

If your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

B230104AUN

Bright-metal maintenance

To remove road tar and insects, use a tar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

CAUTION

Wiping dust or dirt off the body

with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline or

caustic agents on chrome-platedor anodized aluminum parts. This may result in damage to the pro- tective coating and cause discol-

oration or paint deterioration.

Page 387 of 635

Maintenance

70

7

G230105AUN

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Payspecial attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting. G230106AUN

Aluminum wheel maintenance

The aluminum wheels are coated with a

clear protective finish.

Do not use any abrasive cleaner, pol-

ishing compound, solvent, or wire

brushes on aluminum wheels. They

may scratch or damage the finish.

Use only a mild soap or neutral deter- gent, and rinse thoroughly with water.

Also, be sure to clean the wheels after

driving on salted roads. This helps pre-

vent corrosion.

Avoid washing the wheels with high- speed car wash brushes.

Do not use any acid detergent. It may damage and corrode the aluminum

wheels coated with a clear protectivefinish.

WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.

Page 388 of 635

771

Maintenance

G230107AUN

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corro-

sion, we produces cars of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's cooperation and assistance isalso required.

Common causes of corrosion The most common causes of corrosion

on your car are:

allowed to accumulate underneath the

car.

Removal of paint or protective coatings by stones, gravel, abrasion or minor

scrapes and dents which leave unpro-

tected metal exposed to corrosion. High-corrosion areas

If you live in an area where your car is

regularly exposed to corrosive materials,

corrosion protection is particularly impor-

tant. Some of the common causes of

accelerated corrosion are road salts,

dust control chemicals, ocean air and

industrial pollution.

Moisture breeds corrosion Moisture creates the conditions in which

corrosion is most likely to occur. For

example, corrosion is accelerated by

high humidity, particularly when tempera-

tures are just above freezing. In such

conditions, the corrosive material is kept

in contact with the car surfaces by mois-

ture that is slow to evaporate.

Mud is particularly corrosive because it is

slow to dry and holds moisture in contact

with the vehicle. Although the mud

appears to be dry, it can still retain themoisture and promote corrosion.

High temperatures can also accelerate

corrosion of parts that are not properly

ventilated so the moisture can be dis-

persed. For all these reasons, it is par-

ticularly important to keep your car clean

and free of mud or accumulations of

other materials. This applies not only to

the visible surfaces but particularly to the

underside of the car.

Page 391 of 635

Maintenance

74

7

EMISSION CONTROL SYSTEM

G270000AFD

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis- sion control system to meet all emission

regulations. There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system(3) Exhaust emission control system In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by an author-

ized HYUNDAI dealer in accordance with

the maintenance schedule in this manu-al. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Program (ESP) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability

Program (ESP) system off by press-

ing the ESP switch.

After dynamometer testing is com- pleted, turn the ESP system back on

by pressing the ESP switch again.

G270100AUN

1. Crankcase emission control system

The positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valveinto the induction system. G270200AFD

2. Evaporative emission control

System

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

G270201AUN

Canister

Fuel vapors generated inside the fuel tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

G270202AUN

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

Page 392 of 635

775

Maintenance

G270300AUN

3. Exhaust emission control system

The Exhaust Emission Control System is

a highly effective system which controls

exhaust emissions while maintaining

good vehicle performance.

G270301AUN

Vehicle modifications

This vehicle should not be modified.

Modification of your vehicle could affect

its performance, safety or durability and

may even violate governmental safety

and emissions regulations.

In addition, damage or performance

problems resulting from any modification

may not be covered under warranty.

G270302AUN

Engine exhaust gas precautions (car- bon monoxide)

Carbon monoxide can be present with other exhaust fumes. Therefore, if you

smell exhaust fumes of any kind inside

your vehicle, have it inspected and

repaired immediately. If you ever sus-

pect exhaust fumes are coming into

your vehicle, drive it only with all the

windows fully open. Have your vehicle

checked and repaired immediately. Do not operate the engine in confined

or closed areas (such as garages) any

more than what is necessary to move

the vehicle in or out of the area.

When the vehicle is stopped in an open area for more than a short time

with the engine running, adjust the

ventilation system (as needed) to draw

outside air into the vehicle.

Never sit in a parked or stopped vehi- cle for any extended time with the

engine running.

When the engine stalls or fails to start, excessive attempts to restart the

engine may cause damage to theemission control system. G270303BFD

Operating precautions for catalytic

converters (if equipped)

Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL for gaso- line engine.

Do not operate the vehicle when there are signs of engine malfunction, such

as misfire or a noticeable loss of per-

formance.

Do not misuse or abuse the engine. Examples of misuse are coasting withthe ignition off and descending steep

grades in gear with the ignition off.

Do not operate the engine at high idle speed for extended periods (5 minutesor more).

WARNING - Exhaust

Engine exhaust gases contain car-

bon monoxide (CO). Though color-

less and odorless, it is dangerousand could be lethal if inhaled.

Follow the instructions following to

avoid CO poisoning.

WARNING - Fire

A hot exhaust system can ignite

flammable items under your vehi-

cle. Do not park, idle, or drive the

vehicle over or near flammable

objects, such as dry grass, paper,

leaves, etc.

Page 393 of 635

Maintenance

76

7

Do not modify or tamper with any part

of the engine or emission control sys-

tem. All inspections and adjustments

must be made by an authorized

HYUNDAI dealer.

Avoid driving with a very low fuel level. If you run out of gasoline, it couldcause the engine to misfire and result

in excessive loading of the catalytic

converter.

Failure to observe these precautionscould result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void your

warranties.Diesel Particulate Filter (if equipped)

The Diesel Particulate Filter (DPF) sys-

tem removes the soot emitted from the

vehicle.

Unlike a disposable air filter, the DPF

system automatically burns (oxidizes)

and removes the accumulated soot

according to the driving condition. In

other words, the active burning by engine

control system and high exhaust gas

temperature caused by normal/high driv-

ing condition burns and removes the

accumulated soot.

However, if the vehicle continues to be

driven at low speed for long time, the

accumulated soot may not be automati-

cally removed because of low exhaust

gas temperature. In this particular case,the amount of soot is out of detection

limit, the soot oxidation process by

engine control system may not happen

and the malfunction indicator light may

blink.When the malfunction indicator light

blinks, it may stop blinking by driving the

vehicle at more than 60km/h (37 mph) orat more than second gear with 1500 ~

2000 engine rpm for a certain time (for

about 25 minutes). If the malfunction indicator light contin-

ues to be blinked in spite of the proce-

dure, please visit an authorized

HYUNDAI dealer and then check theDPF system.

If you continue to drive with the malfunc-

tion indicator light blinking for a long

time, the DPF system can be damaged

and fuel consumption can be worsen.

CAUTION -

Diesel Fuel

(if equipped with DPF)

It is recommended to use the regu- lated automotive diesel fuel for

diesel vehicle equipped with the DPF system.

If you use diesel fuel including highsulfur (more than 50 ppm sulfur) and unspecified additives, it can

cause the DPF system to be dam-aged and white smoke can be emit- ted.