HYUNDAI I30 2022 Owners Manual

Manufacturer: HYUNDAI, Model Year: 2022, Model line: I30, Model: HYUNDAI I30 2022Pages: 659, PDF Size: 17.14 MB

Page 591 of 659

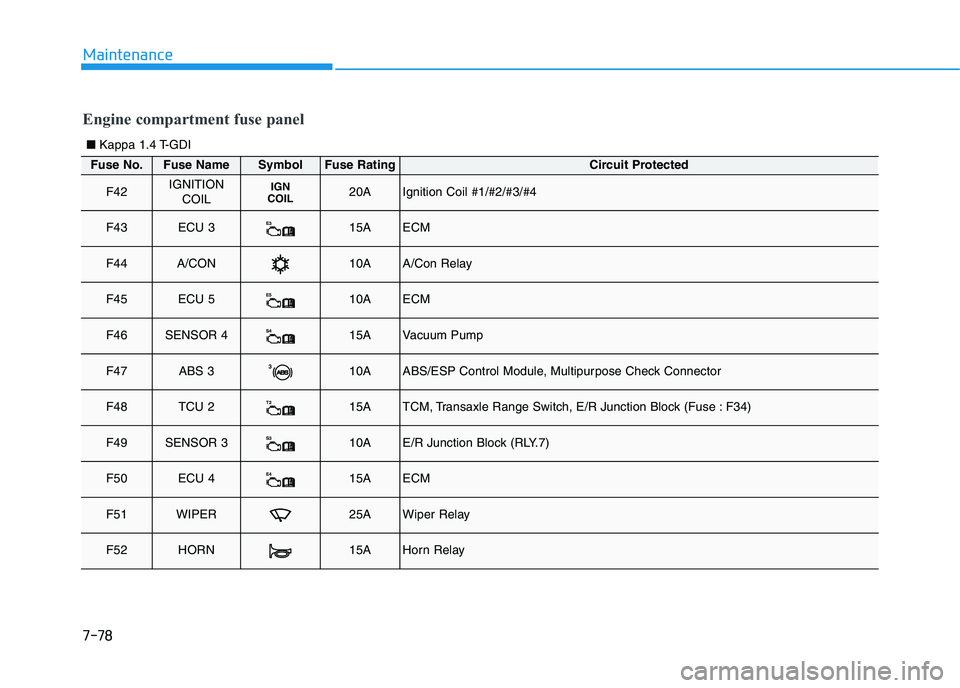

7-78

Maintenance

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F42IGNITIONCOILIGN

COIL20AIgnition Coil #1/#2/#3/#4

F43ECU 3E 315AECM

F44A/CON10AA/Con Relay

F45ECU 5E510AECM

F46SENSOR 4S415AVacuum Pump

F47ABS 3310AABS/ESP Control Module, Multipurpose Check Connector

F48TCU 2T215ATCM, Transaxle Range Switch, E/R Junction Block (Fuse : F34)

F49SENSOR 3S310AE/R Junction Block (RLY.7)

F50ECU 4E415AECM

F51WIPER25AWiper Relay

F52HORN15AHorn Relay

Engine compartment fuse panel

■ Kappa 1.4 T-GDI

Page 592 of 659

7-79

7

Maintenance

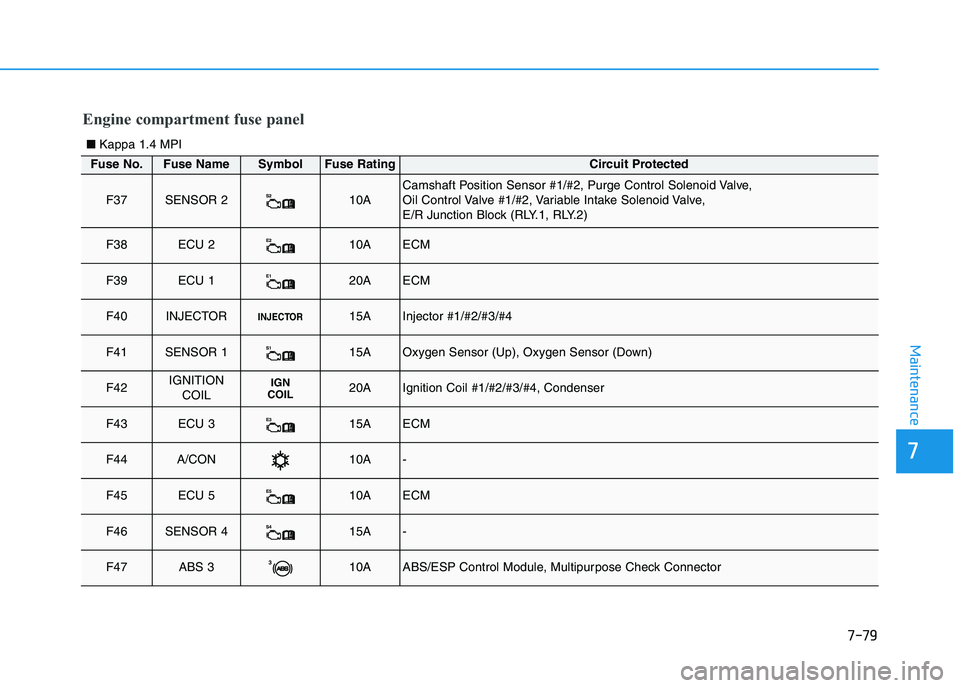

Engine compartment fuse panel

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F37SENSOR 2S210ACamshaft Position Sensor #1/#2, Purge Control Solenoid Valve,

Oil Control Valve #1/#2, Variable Intake Solenoid Valve,

E/R Junction Block (RLY.1, RLY.2)

F38ECU 2E210AECM

F39ECU 1E120AECM

F40INJECTORINJECTOR15AInjector #1/#2/#3/#4

F41SENSOR 1S115AOxygen Sensor (Up), Oxygen Sensor (Down)

F42IGNITION

COILIGN

COIL20AIgnition Coil #1/#2/#3/#4, Condenser

F43ECU 3E 315AECM

F44A/CON10A-

F45ECU 5E510AECM

F46SENSOR 4S415A-

F47ABS 3310AABS/ESP Control Module, Multipurpose Check Connector

■ Kappa 1.4 MPI

Page 593 of 659

7-80

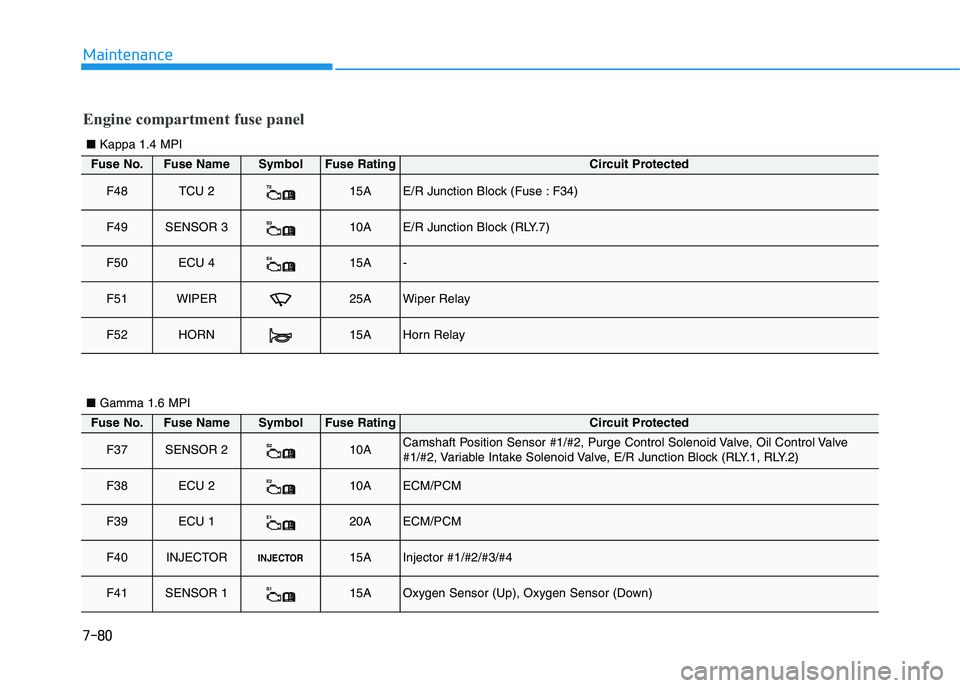

Maintenance

Engine compartment fuse panel

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F48TCU 2T215AE/R Junction Block (Fuse : F34)

F49SENSOR 3S310AE/R Junction Block (RLY.7)

F50ECU 4E415A-

F51WIPER25AWiper Relay

F52HORN15AHorn Relay

■ Kappa 1.4 MPI

■ Gamma 1.6 MPI

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F37SENSOR 2S210ACamshaft Position Sensor #1/#2, Purge Control Solenoid Valve, Oil Control Valve

#1/#2, Variable Intake Solenoid Valve, E/R Junction Block (RLY.1, RLY.2)

F38ECU 2E210AECM/PCM

F39ECU 1E120AECM/PCM

F40INJECTORINJECTOR15AInjector #1/#2/#3/#4

F41SENSOR 1S115AOxygen Sensor (Up), Oxygen Sensor (Down)

Page 594 of 659

7-81

7

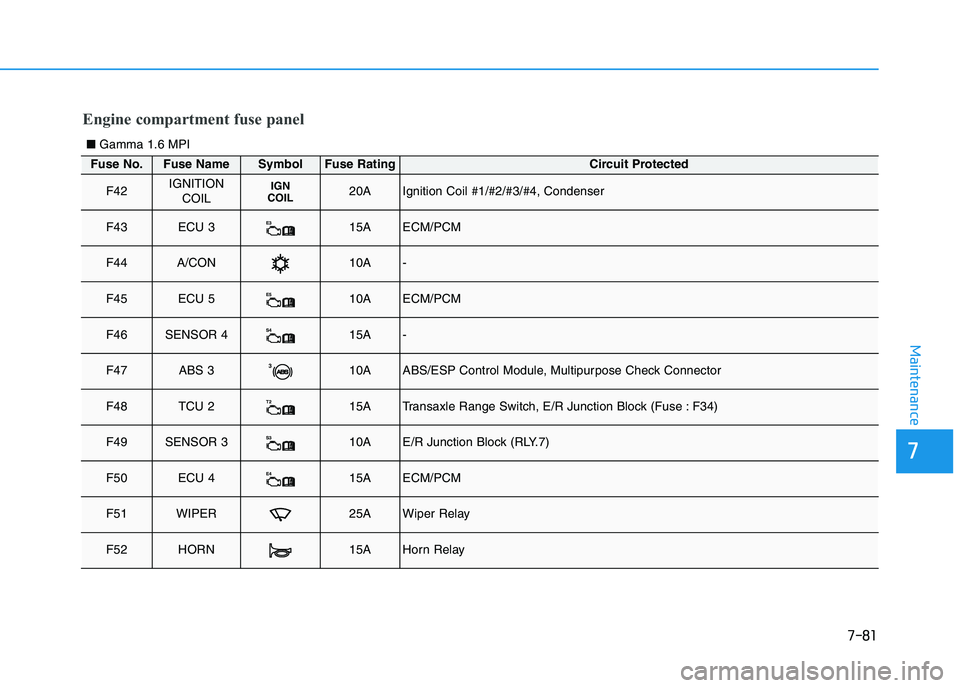

Maintenance

Engine compartment fuse panel

■ Gamma 1.6 MPI

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F42IGNITION

COILIGN

COIL20AIgnition Coil #1/#2/#3/#4, Condenser

F43ECU 3E 315AECM/PCM

F44A/CON10A-

F45ECU 5E510AECM/PCM

F46SENSOR 4S415A-

F47ABS 3310AABS/ESP Control Module, Multipurpose Check Connector

F48TCU 2T215ATransaxle Range Switch, E/R Junction Block (Fuse : F34)

F49SENSOR 3S310AE/R Junction Block (RLY.7)

F50ECU 4E415AECM/PCM

F51WIPER25AWiper Relay

F52HORN15AHorn Relay

Page 595 of 659

7-82

Maintenance

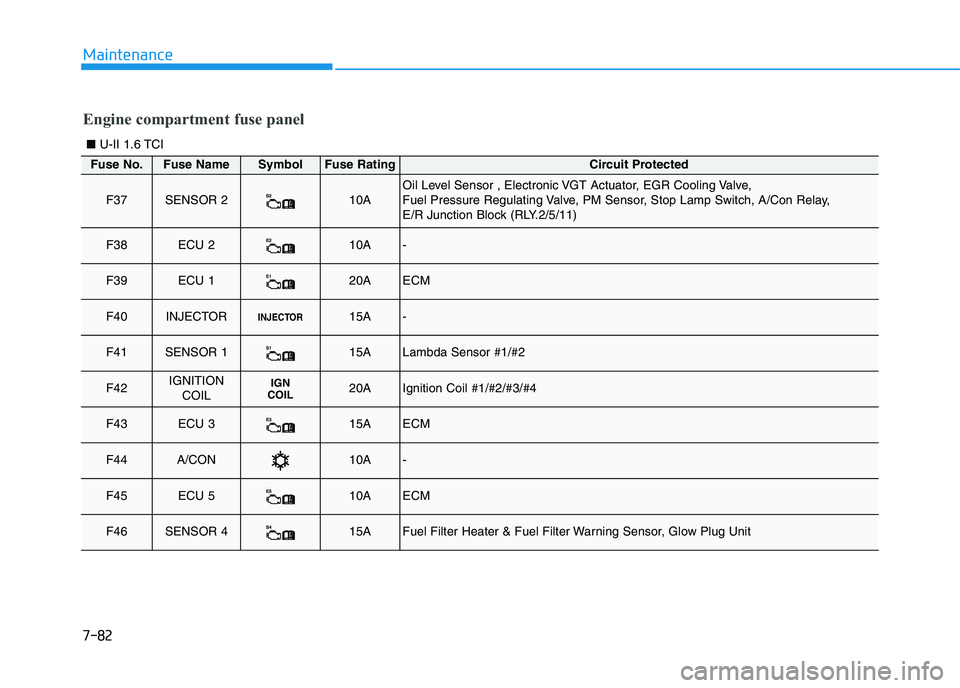

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F37SENSOR 2S210AOil Level Sensor , Electronic VGT Actuator, EGR Cooling Valve,

Fuel Pressure Regulating Valve, PM Sensor, Stop Lamp Switch, A/Con Relay,

E/R Junction Block (RLY.2/5/11)

F38ECU 2E210A-

F39ECU 1E120AECM

F40INJECTORINJECTOR15A-

F41SENSOR 1S115ALambda Sensor #1/#2

F42IGNITION

COILIGN

COIL20AIgnition Coil #1/#2/#3/#4

F43ECU 3E 315AECM

F44A/CON10A-

F45ECU 5E510AECM

F46SENSOR 4S415AFuel Filter Heater & Fuel Filter Warning Sensor, Glow Plug Unit

■ U-II 1.6 TCI

Engine compartment fuse panel

Page 596 of 659

7-83

7

Maintenance

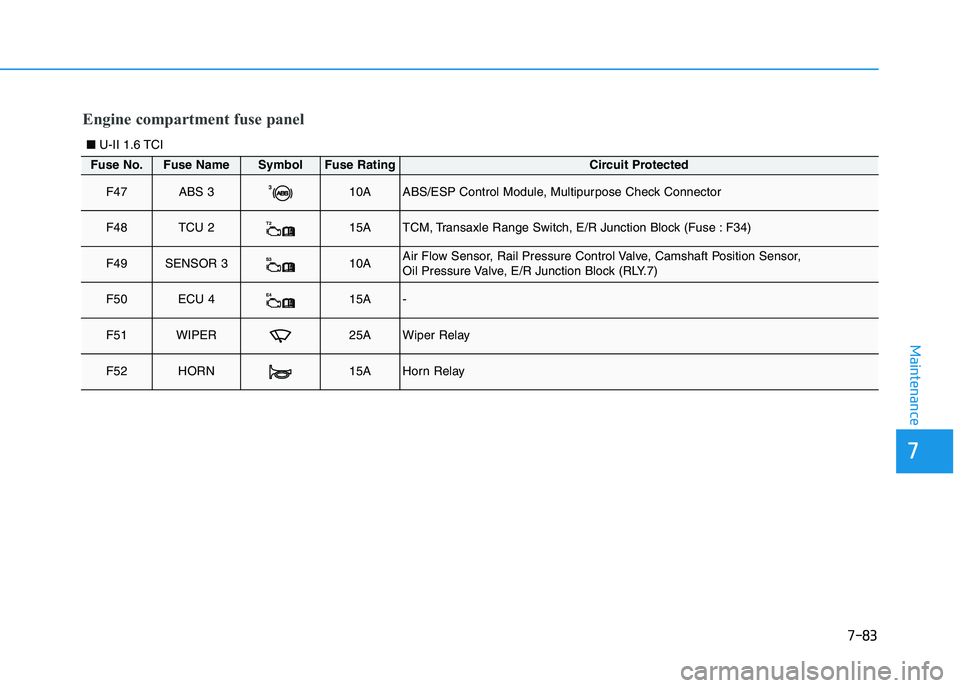

Fuse No.Fuse NameSymbolFuse RatingCircuit Protected

F47ABS 3310AABS/ESP Control Module, Multipurpose Check Connector

F48TCU 2T215ATCM, Transaxle Range Switch, E/R Junction Block (Fuse : F34)

F49SENSOR 3S310AAir Flow Sensor, Rail Pressure Control Valve, Camshaft Position Sensor,

Oil Pressure Valve, E/R Junction Block (RLY.7)

F50ECU 4E415A-

F51WIPER25AWiper Relay

F52HORN15AHorn Relay

Engine compartment fuse panel

■ U-II 1.6 TCI

Page 597 of 659

7-84

Maintenance

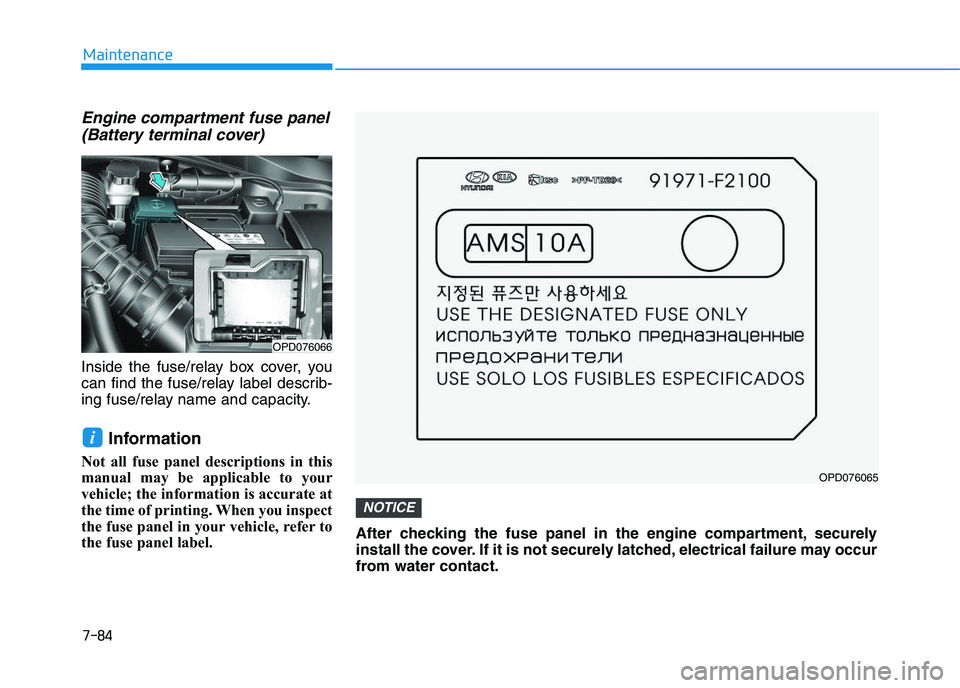

Engine compartment fuse panel(Battery terminal cover)

Inside the fuse/relay box cover, you

can find the fuse/relay label describ-

ing fuse/relay name and capacity.

Information

Not all fuse panel descriptions in this

manual may be applicable to your

vehicle; the information is accurate at

the time of printing. When you inspect

the fuse panel in your vehicle, refer to

the fuse panel label.

i

OPD076066

OPD076065

After checking the fuse panel in the engine compartment, securely

install the cover. If it is not securely latched, electrical failure may occur

from water contact.

NOTICE

Page 598 of 659

7-85

7

Maintenance

L

L I

I G

G H

H T

T

B

B U

U L

L B

B S

S

Consult an authorized HYUNDAI

dealer to replace most vehicle light

bulbs. It is difficult to replace vehicle

light bulbs because other parts of the

vehicle must be removed before you

can get to the bulb. This is especially

true for removing the headlamp

assembly to get to the bulb(s).

Removing/installing the headlamp

assembly can result in damage to

the vehicle. Be sure to replace the burned-out

bulb with one of the same wattage

rating. Otherwise, it may cause

damage to the fuse or electric

wiring system.

Information

After heavy driving, rain or washing,

headlamp and tail lamp lenses could

appear frosty. This condition is caused

by the temperature difference between

the lamp inside and outside. This is

similar to the condensation on your

windows inside your vehicle during the

rain and doesn’t indicate a problem

with your vehicle. If the water leaks

into the lamp bulb circuitry, we rec-

ommend that the system be checked

by an authorized HYUNDAI dealer.

Information

The headlamp aiming should be adjust-

ed after an accident or after the head-

lamp assembly is reinstalled at an

authorized HYUNDAI dealer.

Information - Traffic Change

(for Europe)

The low beam light distribution is

asymmetric. If you go abroad to a coun-

try with opposite traffic direction, this

asymmetric part will dazzle oncoming

car driver. To prevent dazzle, ECE reg-

ulation demand several technical solu-

tions (ex. automatic change system,

adhesive sheet, down aiming). These

headlamps are designed not to dazzle

opposite drivers. So, you need not

change your headlamps in a country

with opposite traffic direction.i

i

i

NOTICE

Prior to working on the light,

firmly apply the parking brake,

ensure that the ignition switch is

in the LOCK/OFF position and

turn off the lights to avoid sud-

den movement of the vehicle and

burning your fingers or receiving

an electric shock.

WARNING

Page 599 of 659

7-86

Maintenance

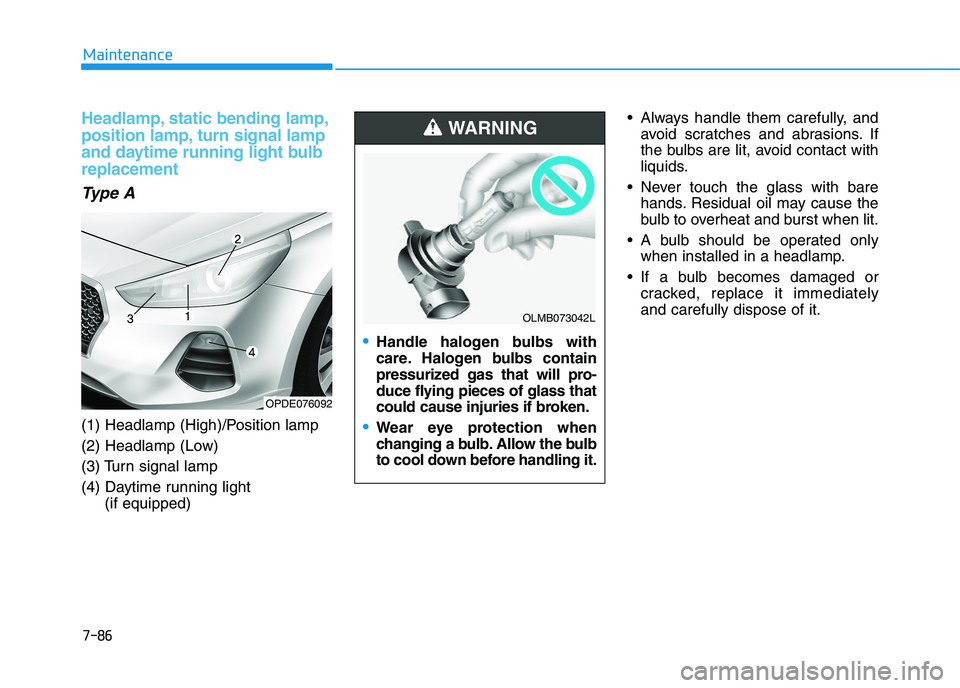

Headlamp, static bending lamp,

position lamp, turn signal lamp

and daytime running light bulb

replacement

Ty p e A

(1) Headlamp (High)/Position lamp

(2) Headlamp (Low)

(3) Turn signal lamp

(4) Daytime running light (if equipped) Always handle them carefully, and

avoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

OPDE076092

Handle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the bulb

to cool down before handling it.

WARNING

OLMB073042L

Page 600 of 659

7-87

7

Maintenance

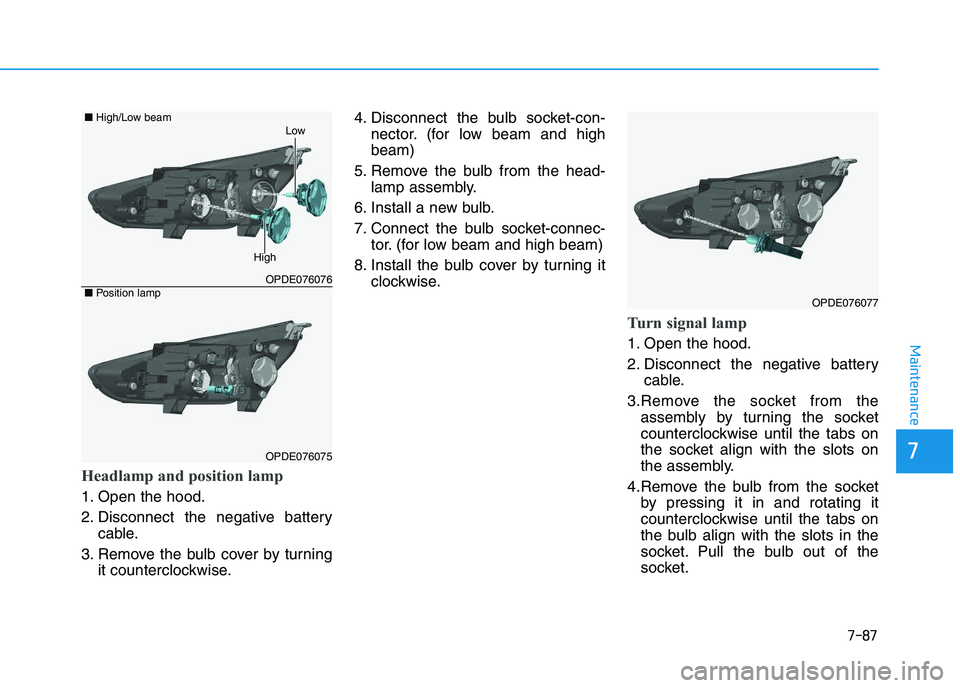

Headlamp and position lamp

1. Open the hood.

2. Disconnect the negative batterycable.

3. Remove the bulb cover by turning it counterclockwise. 4. Disconnect the bulb socket-con-

nector. (for low beam and high

beam)

5. Remove the bulb from the head- lamp assembly.

6. Install a new bulb.

7. Connect the bulb socket-connec- tor. (for low beam and high beam)

8. Install the bulb cover by turning it clockwise.

Turn signal lamp

1. Open the hood.

2. Disconnect the negative batterycable.

3.Remove the socket from the assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

4.Remove the bulb from the socket by pressing it in and rotating it

counterclockwise until the tabs on

the bulb align with the slots in the

socket. Pull the bulb out of the

socket.

OPDE076076

OPDE076075

■ Position lamp

■High/Low beam

High

Low

OPDE076077