fuel HYUNDAI I40 2014 Repair Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: I40, Model: HYUNDAI I40 2014Pages: 534, PDF Size: 11.05 MB

Page 443 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

38

7

NORMAL MAINTENANCE SCHEDULE - FOR DIESEL ENGINE (EXCEPT EUROPE) (CONT.)

120,000 km (80,000 miles) or 96months

❑ Inspect air cleaner filter - Except Middle East

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect disc brakes and pads

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filler cap

❑ Inspect fuel lines, hoses and connections

❑ Inspect parking brake

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tire (pressure & tread wear)

❑ Inspect manual transaxle fluid *6(if equipped)

(Continued)

(Continued)

❑ Replace air cleaner filter - For Middle East

❑ Replace climate control air filter (if equipped)

❑ Replace fuel filter cartridge *3

❑ Replace fuel tank air filter

❑ Replace coolant *8

(At first, 210,000 km (120,000 miles) or 120months

after that, every 30,000 km (20,000 miles) or 24months *10)

❑ Replace engine oil and filter *1 *2 *3 *4

(Every 10,000 km (6,500 miles) or 12months)

❑ Inspect cooling system

(At first, 60,000 km (40,000 miles) or 48months

after that, every 30,000 km (20,000 miles) or 24months)

❑ Inspect drive belt *9

(At first, 80,000 km (50,000 miles) or 48months

after that, every 20,000 km (12,500 miles) or 24months)

No check, No service required

❑ Automatic transaxle fluid

Page 446 of 534

Downloaded from www.Manualslib.com manuals search engine 741

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-

quent oil and filter changes are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically for

proper tension and adjusted as neces-

sary.

Fuel filter (cartridge)

A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

Fuel lines, fuel hoses and con-

nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. Have

an authorized HYUNDAI dealer replace

any damaged or leaking parts immedi-

ately.

WARNING - Diesel only

Never work on injection system

with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectors

and high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move than 30cm closer to the

ECU or wiring harness within the

engine room while engine is run-

ning, since the high currents in the

Common Rail system produce con-

siderable magnetic fields.

Page 447 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

42

7

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should

be inspected at those intervals specified

in the maintenance schedule. Make sure

that a new vapor hose or fuel filler cap is

correctly replaced.

Vacuum crankcase ventilation

hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that

the hoses do not come in contact with

any heat source, sharp edges or moving

component which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is

recommended when the filter is replaced.

Spark plugs (for gasoline engine)

Make sure to install new spark plugs of

the correct heat range.

Valve clearance

(for gasoline engine 1.6L)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorized HYUNDAI dealer should

perform the operation.

Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

Coolant

The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid

(if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid

(if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, the fluid should

be changed at an authorized HYUNDAI

dealer in accordance to the scheduled

maintenance at the beginning of this

chapter.

✽ ✽

NOTICE

Automatic transaxle fluid color is basi-

cally red.

As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.

It is normal condition and you should

not judge the need to replace the fluid

based upon the changed color.

Page 455 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

50

7

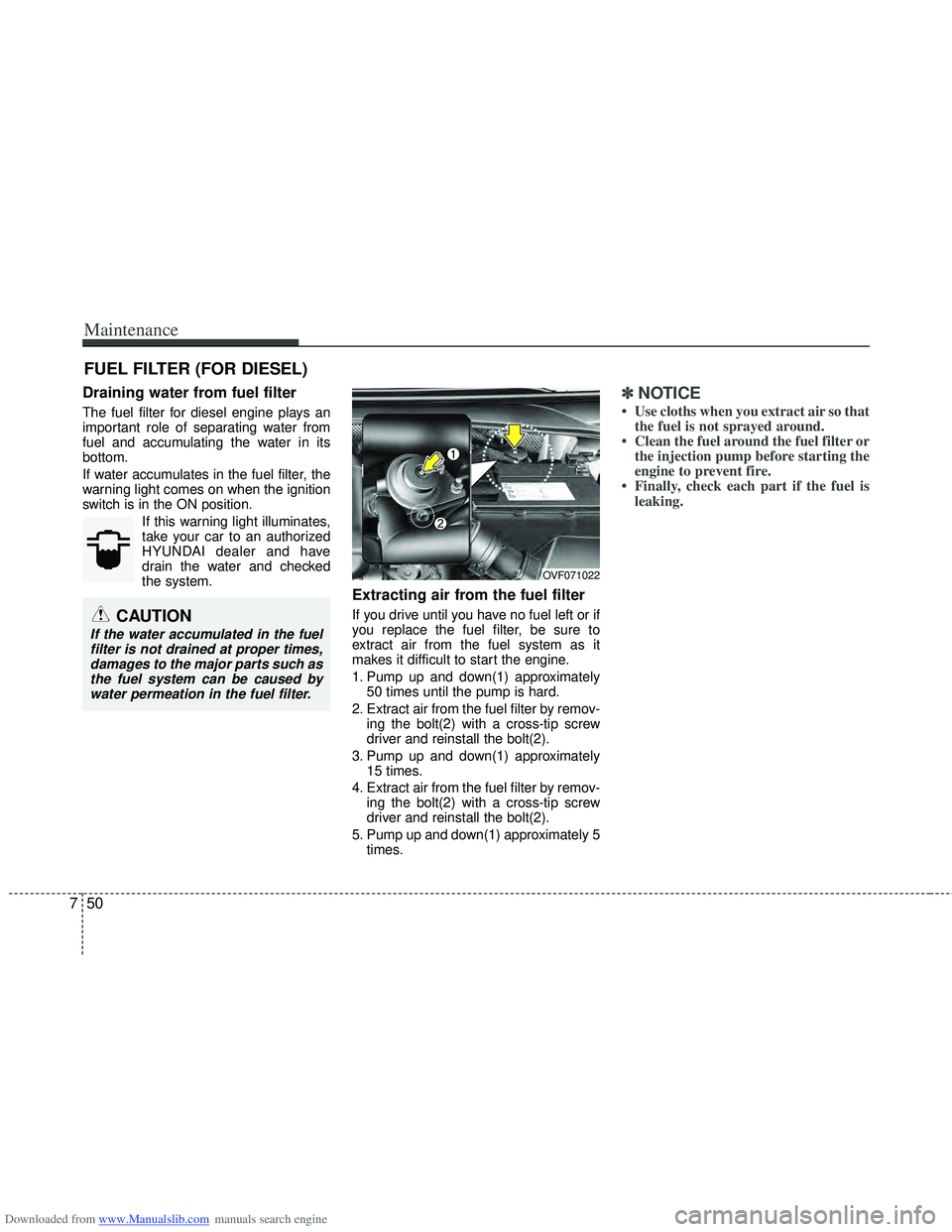

FUEL FILTER (FOR DIESEL)

Draining water from fuel filter

The fuel filter for diesel engine plays an

important role of separating water from

fuel and accumulating the water in its

bottom.

If water accumulates in the fuel filter, the

warning light comes on when the ignition

switch is in the ON position.

If this warning light illuminates,

take your car to an authorized

HYUNDAI dealer and have

drain the water and checked

the system.

Extracting air from the fuel filter

If you drive until you have no fuel left or if

you replace the fuel filter, be sure to

extract air from the fuel system as it

makes it difficult to start the engine.

1. Pump up and down(1) approximately50 times until the pump is hard.

2. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

3. Pump up and down(1) approximately 15 times.

4. Extract air from the fuel filter by remov- ing the bolt(2) with a cross-tip screw

driver and reinstall the bolt(2).

5. Pump up and down(1) approximately 5 times.

✽ ✽NOTICE

• Use cloths when you extract air so that

the fuel is not sprayed around.

• Clean the fuel around the fuel filter or the injection pump before starting the

engine to prevent fire.

• Finally, check each part if the fuel is leaking.

CAUTION

If the water accumulated in the fuel

filter is not drained at proper times, damages to the major parts such asthe fuel system can be caused bywater permeation in the fuel filter.

OVF071022

Page 466 of 534

Downloaded from www.Manualslib.com manuals search engine 761

Maintenance

TIRES AND WHEELS

Tire care

For proper maintenance, safety, and

maximum fuel economy, you must

always maintain recommended tire

inflation pressures and stay within

the load limits and weight distribution

recommended for your vehicle.

Recommended cold tire inflation

pressures

All tire pressures (including the

spare) should be checked when the

tires are cold. “Cold Tires” means the

vehicle has not been driven for at

least three hours or driven less than

1.6 km (1 mile).

Recommended pressures must be

maintained for the best ride, top vehi-

cle handling, and minimum tire wear.

For recommended inflation pressure

refer to “Tire and wheels” in section 8.All specifications (sizes and pres-

sures) can be found on a label

attached to the vehicle.

WARNING - Tire underin-

flation

Severe underinflation (70 kPa

(10 psi) or more) can lead to

severe heat build-up, causing

blowouts, tread separation and

other tire failures that can result

in the loss of vehicle control

leading to severe injury or

death. This risk is much higher

on hot days and when driving

for long periods at high speeds.

OVF081002

Page 467 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

62

7

WARNING - Tire inflation

Overinflation or underinflation

can reduce tire life, adversely

affect vehicle handling, and

lead to sudden tire failure. This

could result in loss of vehicle

control and potential injury.

CAUTION - Tire pressure

Always observe the following:

Check tire pressure when the tires are cold. (After vehiclehas been parked for at leastthree hours or hasn't beendriven more than 1.6 km (1mile) since startup.)

Check the pressure of your spare tire each time you checkthe pressure of other tires.

Never overload your vehicle. Be careful not to overload avehicle luggage rack if yourvehicle is equipped with one.

Worn, old tires can cause acci- dents. If your tread is badlyworn, or if your tires havebeen damaged, replace them.

CAUTION

Underinflation also results in excessive wear, poor handlingand reduced fuel economy.Wheel deformation also ispossible. Keep your tire pres-sures at the proper levels. If atire frequently needs refilling,have it checked by an author-ized HYUNDAI dealer.

Overinflation produces a harsh ride, excessive wear atthe center of the tire tread, anda greater possibility of dam-age from road hazards.

CAUTION

Warm tires normally exceed recommended cold tire pres-sures by 28 to 41 kPa (4 to 6psi). Do not release air fromwarm tires to adjust the pres-sure or the tires will be under-inflated.

Be sure to reinstall the tire inflation valve caps. Withoutthe valve cap, dirt or moisturecould get into the valve coreand cause air leakage. If avalve cap is missing, install anew one as soon as possible.

Page 481 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

76

7

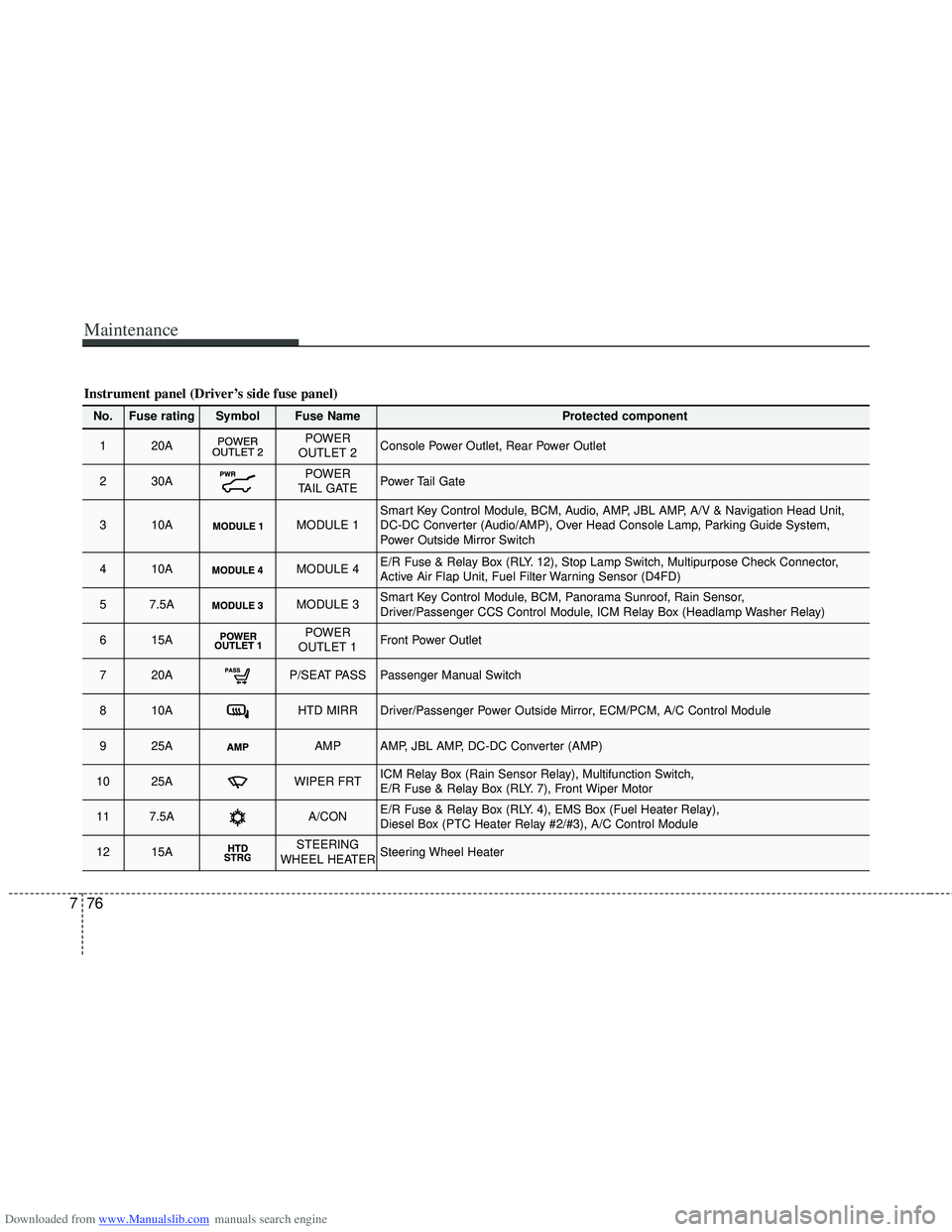

Instrument panel (Driver’s side fuse panel)

No.Fuse ratingSymbol Fuse NameProtected component

120APOWER

OUTLET 2Console Power Outlet, Rear Power Outlet

230APOWER

TAIL GATEPower Tail Gate

310AMODULE 1Smart Key Control Module, BCM, Audio, AMP, JBL AMP, A/V & Navigation Head Unit,

DC-DC Converter (Audio/AMP), Over Head Console Lamp, Parking Guide System,

Power Outside Mirror Switch

410AMODULE 4E/R Fuse & Relay Box (RLY. 12), Stop Lamp Switch, Multipurpose Check Connector,

Active Air Flap Unit, Fuel Filter Warning Sensor (D4FD)

57.5AMODULE 3Smart Key Control Module, BCM, Panorama Sunroof, Rain Sensor,

Driver/Passenger CCS Control Module, ICM Relay Box (Headlamp Washer Relay)

615APOWER

OUTLET 1Front Power Outlet

720AP/SEAT PASSPassenger Manual Switch

810AHTD MIRRDriver/Passenger Power Outside Mirror, ECM/PCM, A/C Control Module

925AAMPAMP, JBL AMP, DC-DC Converter (AMP)

1025AWIPER FRTICM Relay Box (Rain Sensor Relay), Multifunction Switch,

E/R Fuse & Relay Box (RLY. 7), Front Wiper Motor

117.5AA/CONE/R Fuse & Relay Box (RLY. 4), EMS Box (Fuel Heater Relay),

Diesel Box (PTC Heater Relay #2/#3), A/C Control Module

1215ASTEERING

WHEEL HEATERSteering Wheel Heater

Page 482 of 534

Downloaded from www.Manualslib.com manuals search engine 777

Maintenance

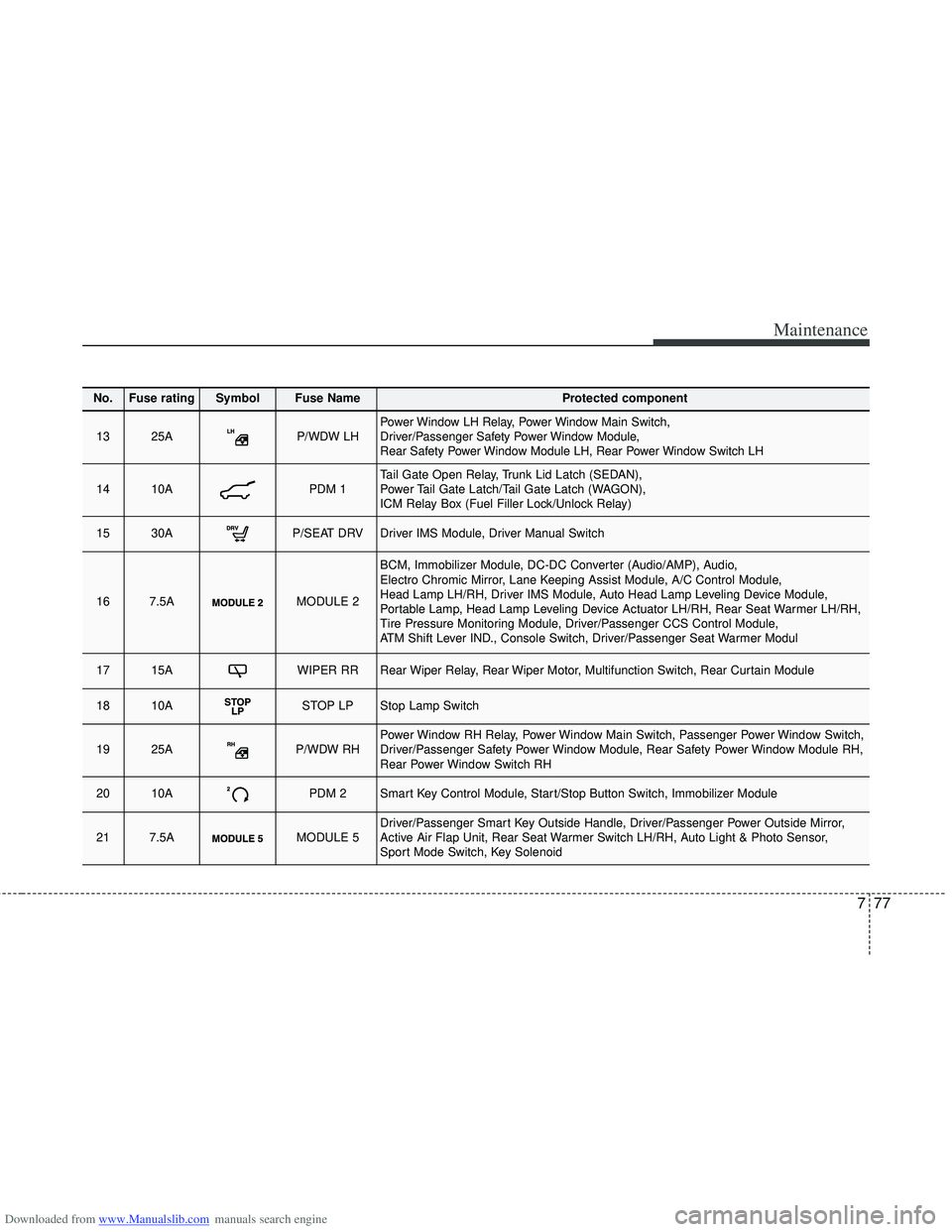

No.Fuse ratingSymbol Fuse NameProtected component

1325AP/WDW LHPower Window LH Relay, Power Window Main Switch,

Driver/Passenger Safety Power Window Module,

Rear Safety Power Window Module LH, Rear Power Window Switch LH

1410APDM 1Tail Gate Open Relay, Trunk Lid Latch (SEDAN),

Power Tail Gate Latch/Tail Gate Latch (WAGON),

ICM Relay Box (Fuel Filler Lock/Unlock Relay)

1530AP/SEAT DRVDriver IMS Module, Driver Manual Switch

167.5AMODULE 2

BCM, Immobilizer Module, DC-DC Converter (Audio/AMP), Audio,

Electro Chromic Mirror, Lane Keeping Assist Module, A/C Control Module,

Head Lamp LH/RH, Driver IMS Module, Auto Head Lamp Leveling Device Module,

Portable Lamp, Head Lamp Leveling Device Actuator LH/RH, Rear Seat Warmer LH/RH,

Tire Pressure Monitoring Module, Driver/Passenger CCS Control Module,

ATM Shift Lever IND., Console Switch, Driver/Passenger Seat Warmer Modul

1715AWIPER RRRear Wiper Relay, Rear Wiper Motor, Multifunction Switch, Rear Curtain Module

1810ASTOP LPStop Lamp Switch

1925AP/WDW RHPower Window RH Relay, Power Window Main Switch, Passenger Power Window Switch,

Driver/Passenger Safety Power Window Module, Rear Safety Power Window Module RH,

Rear Power Window Switch RH

2010APDM 2Smart Key Control Module, Start/Stop Button Switch, Immobilizer Module

217.5AMODULE 5Driver/Passenger Smart Key Outside Handle, Driver/Passenger Power Outside Mirror,

Active Air Flap Unit, Rear Seat Warmer Switch LH/RH, Auto Light & Photo Sensor,

Sport Mode Switch, Key Solenoid

Page 487 of 534

Downloaded from www.Manualslib.com manuals search engine Maintenance

82

7

No.Fuse ratingSymbol Protected component

FUSE

2715AG4FD/G4NC - Ignition Coil #1/ #2/ #3/ #4, Condenser

2815AFuel Pump Relay

2915AG4FD : ECM

G4NA/G4NC : PCM (A/T), ECM (M/T)

3010ASPARE

3110AG4NA - Injector #1/#2/#3/#4

3210A

G4FD : ECM

G4NA : Fuel Pump Relay

G4NC : Fuel Pump Relay, PCM (A/T), ECM (M/T)

D4FD : Oil Level Sensor, Fuel Pressure Regulating Valve

3320AG4NA : Ignition Coil #1/#2/#3/#4, Condenser

3420AG4FD/D4FD : ECM

G4NA/G4NC : PCM (A/T), ECM (M/T)

3510A

G4FD : Oil Control Valve #1/ #2, Oil Level Sensor, E/R Fuse & Relay Box (RLY. 1)

G4NA/G4NC : Oil Control Valve #1/ #2, Camshaft Position Sensor (Intake/Exhaust),

E/R Fuse & Relay Box (RLY. 1)

D4FD : E/R Fuse & Relay Box (RLY. 1), Diesel Box (PTC Heater Relay#1), Lambda Sensor, VGT Control Solenoid Valve

3610A

G4FD : Oxygen Sensor (UP/DOWN), Variable Intake Solenoid Valve, Purge Control Solenoid Valve

G4NA/G4NC : Oxygen Sensor (UP/DOWN), Variable Intake Solenoid Valve, Purge Control Solenoid Valve

D4FD : Camshaft Position Sensor, EGR Cooling Bypass Solenoid Valve, Diesel Box (Glow Relay)

Page 506 of 534

Downloaded from www.Manualslib.com manuals search engine 7101

Maintenance

Bright-metal maintenance

To remove road tar and insects, use atar remover, not a scraper or other

sharp object.

To protect the surfaces of bright-metal parts from corrosion, apply a coating of

wax or chrome preservative and rub to

a high luster.

During winter weather or in coastal areas, cover the bright metal parts with

a heavier coating of wax or preserva-

tive. If necessary, coat the parts with

non-corrosive petroleum jelly or other

protective compound.

Underbody maintenance

Corrosive materials used for ice and

snow removal and dust control may col-

lect on the underbody. If these materials

are not removed, accelerated rusting can

occur on underbody parts such as the

fuel lines, frame, floor pan and exhaust

system, even though they have been

treated with rust protection.

Thoroughly flush the vehicle underbody

and wheel openings with lukewarm or

cold water once a month, after off-road

driving and at the end of each winter. Pay

special attention to these areas because

it is difficult to see all the mud and dirt. It

will do more harm than good to wet down

the road grime without removing it. The

lower edges of doors, rocker panels, and

frame members have drain holes that

should not be allowed to clog with dirt;

trapped water in these areas can cause

rusting.WARNING

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired,

dry the brakes by applying them

lightly while maintaining a slow for-

ward speed.