engine HYUNDAI IX20 2016 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: IX20, Model: HYUNDAI IX20 2016Pages: 385, PDF Size: 13.67 MB

Page 284 of 385

What to do in an emergency

4 6

IF THE ENGINE WILL NOT START

If engine doesn't turn over or

turns over slowly

1. If your vehicle has an automatic

transaxle, be sure the shift lever is in N

(Neutral) or P (Park) and the emer-

gency brake is set.

2. Check the battery connections to be

sure they are clean and tight.

3. Turn on the interior light. If the light

dims or goes out when you operate the

starter, the battery is discharged.

4. Check the starter connections to be

sure they are securely tightened.

5. Do not push or pull the vehicle to start

it. See instructions for "Jump starting".

If engine turns over normally but

does not start

1. Check the fuel level.

2. With the ignition switch in the LOCK/

OFF position, check all connectors at

the ignition coils and spark plugs.

Reconnect any that may be discon-

nected or loose.

3. Check the fuel line in the engine com-

partment.

4. If the engine still does not start, call a

HYUNDAI authorised repairer or seek

other qualified assistance.

WARNING

If the engine refuses to start, no

attempt should be made to push or

tow start the vehicle. Vehicles with

automatic transaxle or fuel injec-

tion will not be able to be started in

this manner since no drive is trans-

mitted through the automatic

transaxle whilst the engine is not

running, and in the case of fuel

injected derivatives, the fuel pump

will not operate under tow start

conditions. In addition, if the vehi-

cle is equipped with an exhaust cat-

alyst, damage to the catalyst may

result if the vehicle is tow started.

procarmanuals.com

Page 286 of 385

What to do in an emergency

6 6

Jump starting procedure 1. Make sure the booster battery is 12-

volt and that its negative terminal is

grounded.

2. If the booster battery is in another

vehicle, do not allow the vehicles come

in contact.

3. Turn off all unnecessary electrical

loads.

4. Connect the jumper cables in the exact

sequence shown in the illustration.

First connect one end of a jumper

cable to the positive terminal of the

discharged battery (1), then connect

the other end to the positive terminal

on the booster battery (2).

5. Proceed to connect one end of the

other jumper cable to the negative ter-

minal of the booster battery (3), then

the other end to a solid, stationary,

metallic point (for example, the engine

lifting bracket) away from the battery

(4). Do not connect it to or near any

part that moves when the engine is

cranked.

Do not allow the jumper cables to con-

tact anything except the correct bat-

tery terminals or the correct ground.

Do not lean over the battery when

making connections.6. Start the engine of the vehicle with the

booster battery and let it run at 2,000

rpm, then start the engine of the vehi-

cle with the discharged battery.

If the cause of your battery discharging is

not apparent, you should have your vehi-

cle checked by a HYUNDAI authorised

repairer.

CAUTION- Battery cables

Do not connect the jumper cable

from the negative terminal of the

booster battery to the negative ter-

minal of the discharged battery.

This can cause the discharged bat-

tery to overheat and crack, releas-

ing battery acid.CAUTION-AGM battery

(if equipped)

• Absorbent Glass Matt (AGM) bat-

teries are maintenance-free and

should only be serviced by a

HYUNDAI authorised repairer. For

charging your AGM battery, use

only fully automatic battery

chargers that are specially devel-

oped for AGM batteries.

• When replacing the AGM battery,

use only the HYUNDAI genuine

battery for the ISG system.

• Do not open or remove the cap on

top of the battery. This may cause

leaks of internal electrolyte that

could result in severe injury.

• If the AGM battery is reconnected

or replaced, ISG function will not

operate immediately.

If you want to use the ISG func-

tion, the battery sensor needs to

be calibrated for approximately 4

hours with the ignition off.

procarmanuals.com

Page 287 of 385

67

What to do in an emergency

Push-starting

Your manual transaxle-equipped vehicle

should not be push-started because it

might damage the emission control sys-

tem.

Vehicles equipped with automatic

transaxle cannot be push-started.

Follow the directions in this section for

jump-starting.

WARNING

Never tow a vehicle to start it

because the sudden surge forward

when the engine starts could cause

a collision with the tow vehicle.

procarmanuals.com

Page 288 of 385

What to do in an emergency

8 6

IF THE ENGINE OVERHEATS

If your temperature gauge indicates over-

heating, you will experience a loss of

power, or hear loud pinging or knocking,

the engine is probably too hot. If this hap-

pens, you should:

1. Pull off the road and stop as soon as it

is safe to do so.

2. Place the shift lever in P (automatic

transaxle) or Neutral (manual

transaxle) and set the parking brake. If

the air conditioning is on, turn it off.

3. If engine coolant is running out under

the vehicle or steam is coming out

from the bonnet, stop the engine. Do

not open the bonnet until the coolant

has stopped running or the steaming

has stopped. If there is no visible loss

of engine coolant and no steam, leave

the engine running and check to be

sure the engine cooling fan is operat-

ing. If the fan is not running, turn the

engine off.4. Check to see if the water pump drive

belt is missing. If it is not missing,

check to see that it is tight. If the drive

belt seems to be satisfactory, check for

coolant leaking from the radiator,

hoses or under the vehicle. (If the air

conditioning had been in use, it is nor-

mal for cold water to be draining from

it when you stop).

5. If the water pump drive belt is broken

or engine coolant is leaking out, stop

the engine immediately and call the

nearest a HYUNDAI authorised repair-

er for assistance.6. If the cause of the overheating cannot

be found, wait until the engine temper-

ature has returned to normal. Then, if

coolant has been lost, carefully add

coolant to the reservoir to bring the

fluid level in the reservoir up to the

base of the radiator fill opening. Fill the

coolant expansion tank to the halfway

mark. To ensure the correct water to

coolant mix is obtained after top up,

testing by a HYUNDAI authorised

repairer is required.

7. Proceed with caution, keeping alert for

further signs of overheating. If over-

heating happens again, call a

HYUNDAI authorised repairer for

assistance.

WARNING

Whilst the engine is running, keep

hair, hands and clothing away from

moving parts such as the fan and

drive belts to prevent injury.

WARNING

Do not remove the radiator cap

when the engine is hot. This can

allow coolant to be blown out of the

opening and cause serious burns.

CAUTION

Serious loss of coolant indicates

there is a leak in the cooling system

and this should be checked as soon

as possible by a HYUNDAI autho-

rised repairer.

procarmanuals.com

Page 290 of 385

What to do in an emergency

10 6

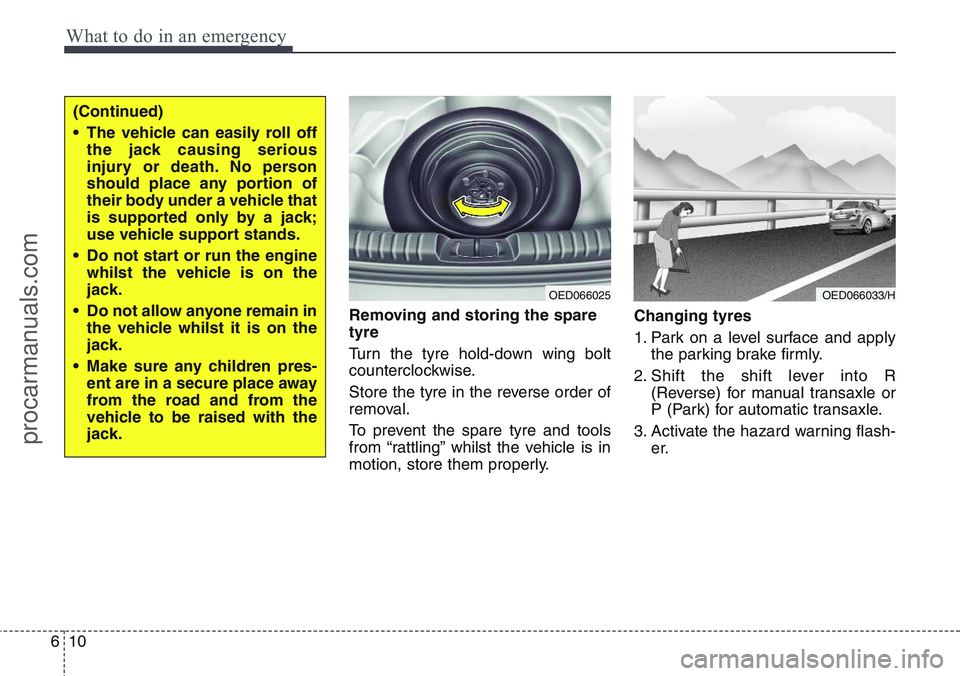

Removing and storing the spare

tyre

Turn the tyre hold-down wing bolt

counterclockwise.

Store the tyre in the reverse order of

removal.

To prevent the spare tyre and tools

from “rattling” whilst the vehicle is in

motion, store them properly.Changing tyres

1. Park on a level surface and apply

the parking brake firmly.

2. Shift the shift lever into R

(Reverse) for manual transaxle or

P (Park) for automatic transaxle.

3. Activate the hazard warning flash-

er.

(Continued)

• The vehicle can easily roll off

the jack causing serious

injury or death. No person

should place any portion of

their body under a vehicle that

is supported only by a jack;

use vehicle support stands.

• Do not start or run the engine

whilst the vehicle is on the

jack.

• Do not allow anyone remain in

the vehicle whilst it is on the

jack.

• Make sure any children pres-

ent are in a secure place away

from the road and from the

vehicle to be raised with the

jack.

OED066025OED066033/H

procarmanuals.com

Page 299 of 385

619

What to do in an emergency

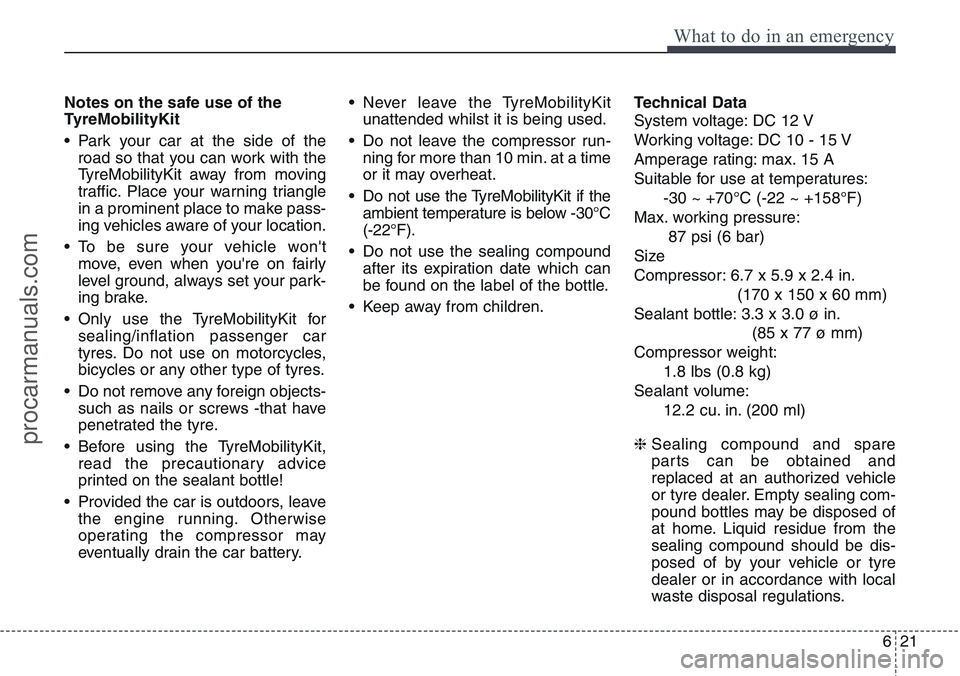

Using the TyreMobilityKit

1. Filling the sealant

Strictly follow the specified sequence,

otherwise the sealant may escape

under high pressure.

1) Shake the sealant bottle.

2) Screw connection hose 9 onto the

connector of the sealant bottle.

3) Ensure that button 8 on the com-

pressor is not pressed.

4) Unscrew the valve cap from the

valve of the defective wheel and

screw filling hose 2 of the sealant

bottle onto the valve.

5) Insert the sealant bottle into the

housing of the compressor so that

the bottle is upright.6) Ensure that the compressor is

switched off, position 0.

7) Connect between compressor

and the vehicle power outlet using

the cable and connectors.

8) With the ignition switched on:

Switch on the compressor and let it

run for approximately 3 minutes to fill

the sealant. The inflation pressure of

the tyre after filling is unimportant.9) Switch off the compressor.

10) Detach the hoses from the

sealant bottle connector and

from the tyre valve.

Return the TyreMobilityKit to its stor-

age location in the vehicle.

WARNING

Carbon monoxide poisoning

and suffocation is possible if the

engine is left running in a poorly

ventilated or unventilated loca-

tion (such as inside a building).

OYN069018

procarmanuals.com

Page 301 of 385

621

What to do in an emergency

Notes on the safe use of the

TyreMobilityKit

• Park your car at the side of the

road so that you can work with the

TyreMobilityKit away from moving

traffic. Place your warning triangle

in a prominent place to make pass-

ing vehicles aware of your location.

• To be sure your vehicle won't

move, even when you're on fairly

level ground, always set your park-

ing brake.

• Only use the TyreMobilityKit for

sealing/inflation passenger car

tyres. Do not use on motorcycles,

bicycles or any other type of tyres.

• Do not remove any foreign objects-

such as nails or screws -that have

penetrated the tyre.

• Before using the TyreMobilityKit,

read the precautionary advice

printed on the sealant bottle!

• Provided the car is outdoors, leave

the engine running. Otherwise

operating the compressor may

eventually drain the car battery.• Never leave the TyreMobilityKit

unattended whilst it is being used.

• Do not leave the compressor run-

ning for more than 10 min. at a time

or it may overheat.

• Do not use the TyreMobilityKit if the

ambient temperature is below -30°C

(-22°F).

• Do not use the sealing compound

after its expiration date which can

be found on the label of the bottle.

• Keep away from children.Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:

-30 ~ +70°C (-22 ~ +158°F)

Max. working pressure:

87 psi (6 bar)

Size

Compressor: 6.7 x 5.9 x 2.4 in.

(170 x 150 x 60 mm)

Sealant bottle: 3.3 x 3.0 ø in.

(85 x 77 ø mm)

Compressor weight:

1.8 lbs (0.8 kg)

Sealant volume:

12.2 cu. in. (200 ml)

❈Sealing compound and spare

parts can be obtained and

replaced at an authorized vehicle

or tyre dealer. Empty sealing com-

pound bottles may be disposed of

at home. Liquid residue from the

sealing compound should be dis-

posed of by your vehicle or tyre

dealer or in accordance with local

waste disposal regulations.

procarmanuals.com

Page 312 of 385

7

Engine compartment / 7-2

Maintenance services / 7-3

Owner maintenance / 7-5

Scheduled maintenance service / 7-7

Explanation of scheduled maintenance items / 7-8

Engine oil / 7-12

Engine coolant / 7-13

Brake/clutch fluid / 7-16

Automatic transaxle fluid / 7-17

Washer fluid / 7-19

Parking brake / 7-19

Fuel filter / 7-20

Air cleaner / 7-21

Wiper blades / 7-22

Battery / 7-25

Tyres and wheels / 7-28

Fuses / 7-38

Light bulbs / 7-49

Appearance care / 7-57

Emission control system / 7-63

Maintenance

procarmanuals.com

Page 313 of 385

Maintenance

2 7

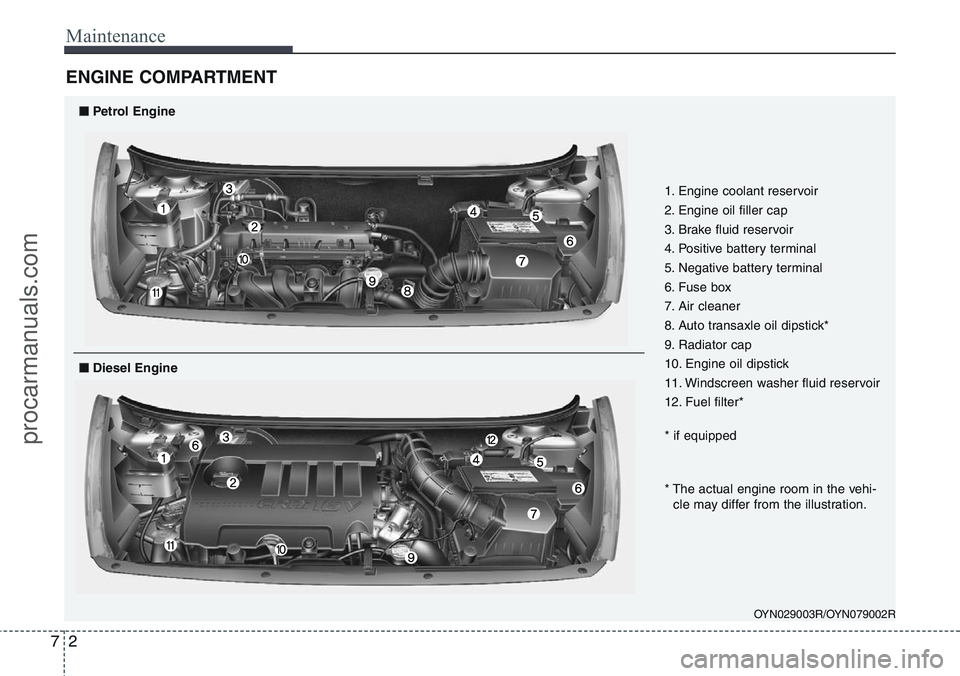

ENGINE COMPARTMENT

OYN029003R/OYN079002R

1. Engine coolant reservoir

2. Engine oil filler cap

3. Brake fluid reservoir

4. Positive battery terminal

5. Negative battery terminal

6. Fuse box

7. Air cleaner

8. Auto transaxle oil dipstick*

9. Radiator cap

10. Engine oil dipstick

11. Windscreen washer fluid reservoir

12. Fuel filter*

* if equipped

■Petrol Engine

* The actual engine room in the vehi-

cle may differ from the illustration.

■Diesel Engine

procarmanuals.com

Page 315 of 385

Maintenance

4 7

Owner maintenance precautions

Improper or incomplete service may

result in problems. This section gives

instructions only for the maintenance

items that are easy to perform.

As explained earlier in this section, sev-

eral procedures can be done only by a

HYUNDAI authorised repairer with spe-

cial tools.

✽NOTICE

Improper owner maintenance during

the warranty period may affect warran-

ty coverage. For details, read the sepa-

rate Service Passport provided with the

vehicle. If you're unsure about any serv-

icing or maintenance procedure, have it

done by a HYUNDAI authorised repair-

er.

WARNING- Maintenance

work

• Performing maintenance work on

a vehicle can be dangerous. You

can be seriously injured whilst

performing some maintenance

procedures. If you lack sufficient

knowledge and experience or the

proper tools and equipment to do

the work, have it done by a

HYUNDAI authorised repairer.

• Working under the bonnet with

the engine running is dangerous.

It becomes even more dangerous

when you wear jewelry or loose

clothing. These can become

entangled in moving parts and

result in injury. Therefore, if you

must run the engine whilst work-

ing under the bonnet, make cer-

tain that you remove all jewelry

(especially rings, bracelets,

watches, and necklaces) and all

neckties, scarves, and similar

loose clothing before getting

near the engine or cooling fans.

WARNING- Diesel Engine

Never work on injection system

with the engine running or within

30 seconds after shutting off the

engine. High-pressure pump, rail,

injectors and high-pressure pipes

are subject to high pressure even

after the engine stopped. The fuel

jet produced by fuel leaks may

cause serious injury, if it touches

the body. People using pacemakers

should not move than 30cm closer

to the ECU or wiring harness within

the engine room whilst engine is

running, since the high currents in

the electronic engine control sys-

tem produce considerable magnet-

ic fields.

procarmanuals.com