maintenance HYUNDAI IX35 2014 Owner's Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2014, Model line: IX35, Model: HYUNDAI IX35 2014Pages: 1534, PDF Size: 39.76 MB

Page 306 of 1534

Maintenance

12

7

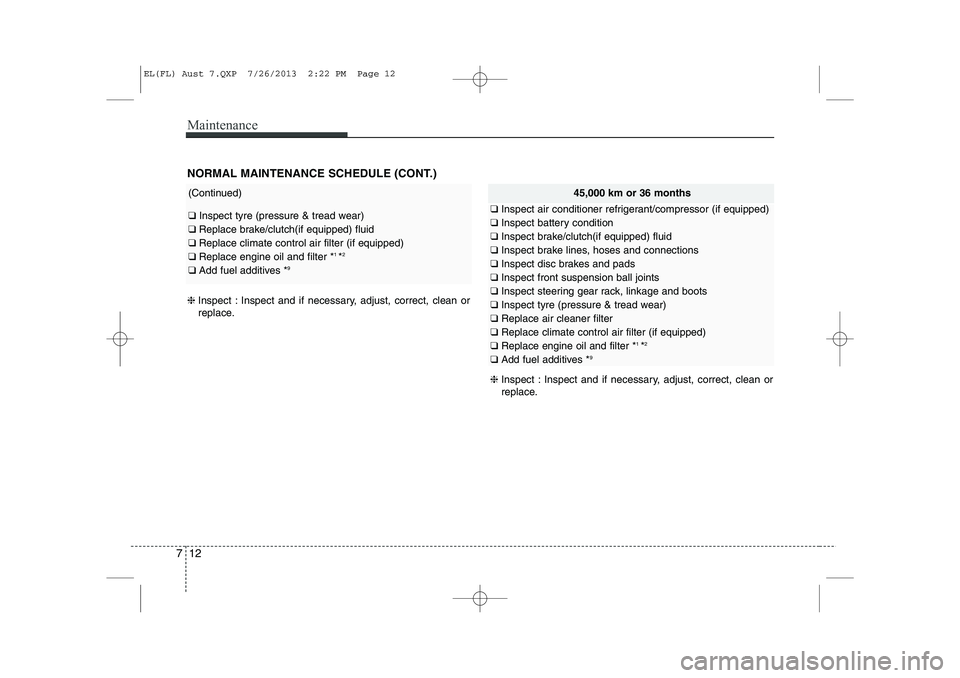

NORMAL MAINTENANCE SCHEDULE (CONT.)

(Continued)

❑ Inspect tyre (pressure & tread wear)

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

45,000 km or 36 months

❑

Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect brake lines, hoses and connections

❑ Inspect disc brakes and pads

❑ Inspect front suspension ball joints

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace air cleaner filter

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

❈

Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 12

Page 307 of 1534

713

Maintenance

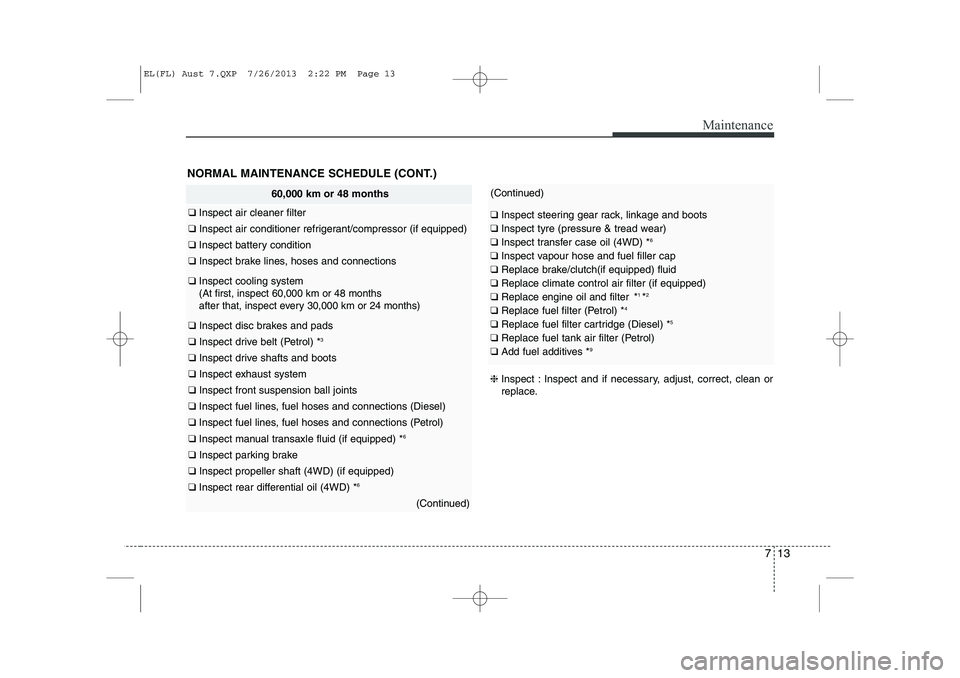

NORMAL MAINTENANCE SCHEDULE (CONT.)

60,000 km or 48 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑

Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel lines, fuel hoses and connections (Petrol)

❑ Inspect manual transaxle fluid (if equipped) * 6

❑

Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect rear differential oil (4WD) * 6

(Continued)

(Continued)

❑

Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect transfer case oil (4WD) * 6

❑ Inspect vapour hose and fuel filler cap

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Replace fuel filter (Petrol) * 4

❑ Replace fuel filter cartridge (Diesel) * 5

❑ Replace fuel tank air filter (Petrol)

❑ Add fuel additives * 9

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 13

Page 308 of 1534

Maintenance

14

7

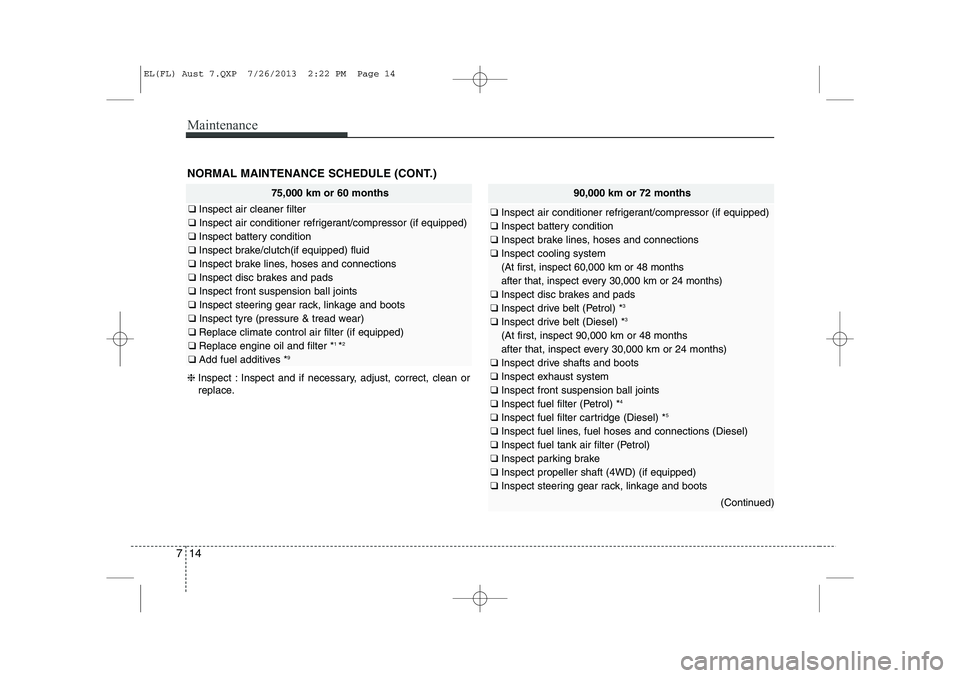

NORMAL MAINTENANCE SCHEDULE (CONT.)

75,000 km or 60 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake/clutch(if equipped) fluid

❑ Inspect brake lines, hoses and connections

❑ Inspect disc brakes and pads

❑ Inspect front suspension ball joints

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

❈

Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

90,000 km or 72 months

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑ Inspect drive belt (Diesel) * 3

(At first, inspect 90,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel filter (Petrol) * 4

❑ Inspect fuel filter cartridge (Diesel) * 5

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel tank air filter (Petrol)

❑ Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect steering gear rack, linkage and boots

(Continued)

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 14

Page 309 of 1534

715

Maintenance

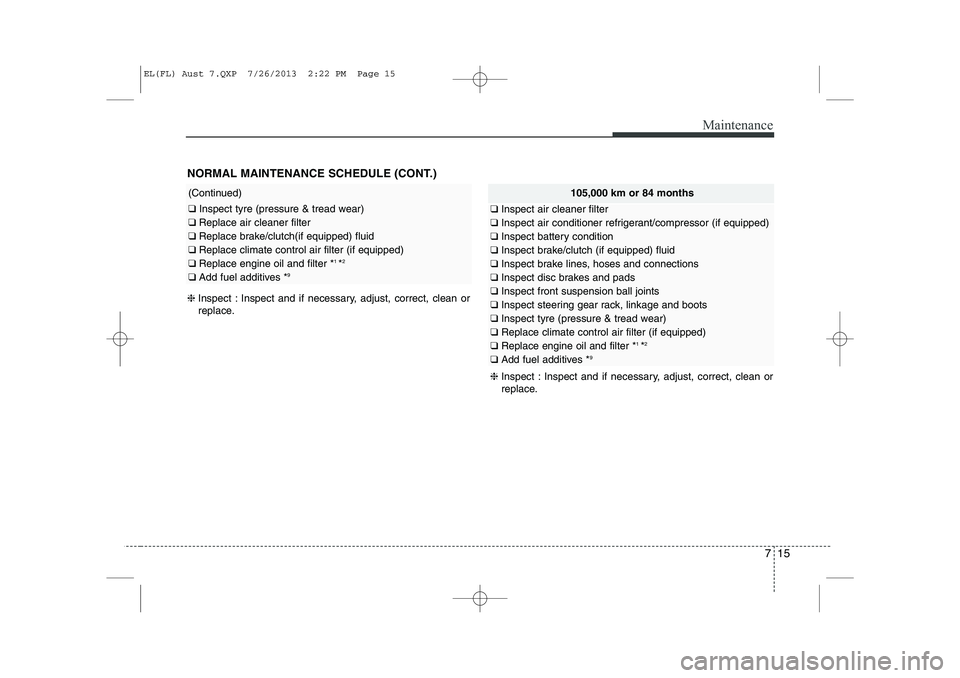

NORMAL MAINTENANCE SCHEDULE (CONT.)

105,000 km or 84 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake/clutch (if equipped) fluid

❑ Inspect brake lines, hoses and connections

❑ Inspect disc brakes and pads

❑ Inspect front suspension ball joints

❑ Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

❈

Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

(Continued)

❑ Inspect tyre (pressure & tread wear)

❑ Replace air cleaner filter

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace engine oil and filter * 1

*2

❑ Add fuel additives * 9

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 15

Page 310 of 1534

Maintenance

16

7

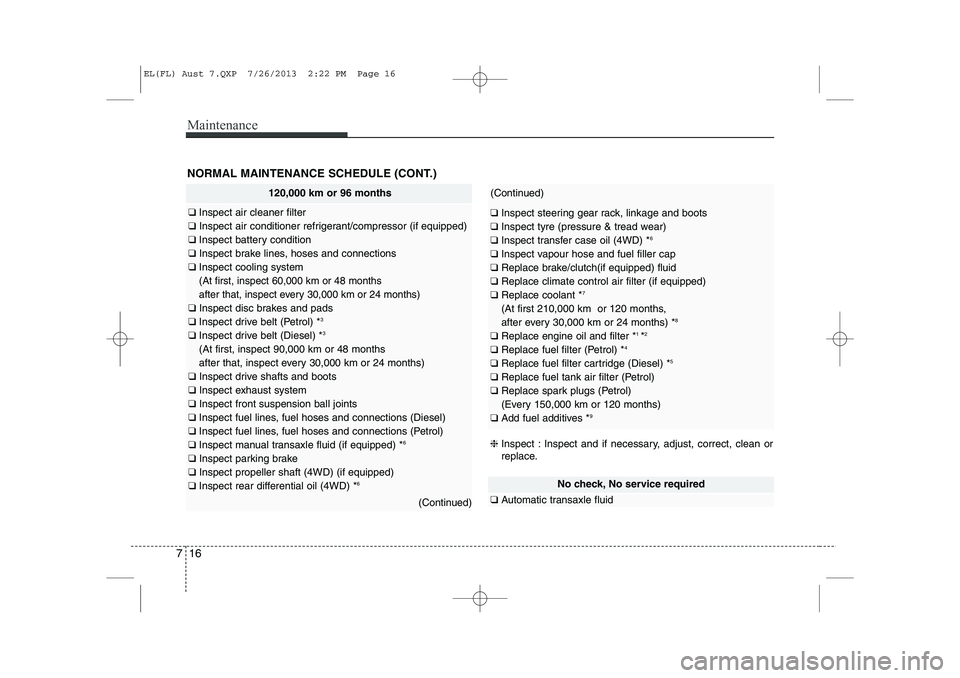

NORMAL MAINTENANCE SCHEDULE (CONT.)

120,000 km or 96 months

❑ Inspect air cleaner filter

❑ Inspect air conditioner refrigerant/compressor (if equipped)

❑ Inspect battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect cooling system

(At first, inspect 60,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect disc brakes and pads

❑ Inspect drive belt (Petrol) * 3

❑ Inspect drive belt (Diesel) * 3

(At first, inspect 90,000 km or 48 months

after that, inspect every 30,000 km or 24 months)

❑ Inspect drive shafts and boots

❑ Inspect exhaust system

❑ Inspect front suspension ball joints

❑ Inspect fuel lines, fuel hoses and connections (Diesel)

❑ Inspect fuel lines, fuel hoses and connections (Petrol)

❑ Inspect manual transaxle fluid (if equipped) * 6

❑ Inspect parking brake

❑ Inspect propeller shaft (4WD) (if equipped)

❑ Inspect rear differential oil (4WD) * 6

(Continued)

(Continued)

❑

Inspect steering gear rack, linkage and boots

❑ Inspect tyre (pressure & tread wear)

❑ Inspect transfer case oil (4WD) * 6

❑ Inspect vapour hose and fuel filler cap

❑ Replace brake/clutch(if equipped) fluid

❑ Replace climate control air filter (if equipped)

❑ Replace coolant * 7

(At first 210,000 km or 120 months,

after every 30,000 km or 24 months) * 8

❑ Replace engine oil and filter * 1

*2

❑ Replace fuel filter (Petrol) * 4

❑ Replace fuel filter cartridge (Diesel) * 5

❑ Replace fuel tank air filter (Petrol)

❑ Replace spark plugs (Petrol)

(Every 150,000 km or 120 months)

❑ Add fuel additives * 9

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

No check, No service required

❑Automatic transaxle fluid

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 16

Page 311 of 1534

717

Maintenance

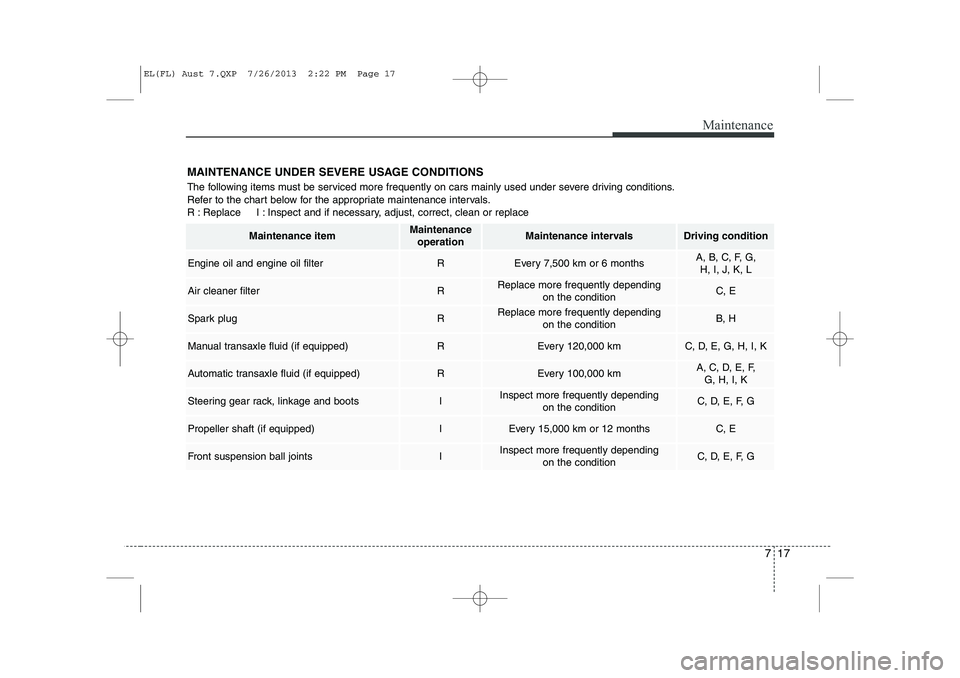

MAINTENANCE UNDER SEVERE USAGE CONDITIONS

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenanceoperationMaintenance intervalsDriving condition

Engine oil and engine oil filterREvery 7,500 km or 6 monthsA, B, C, F, G, H, I, J, K, L

Air cleaner filterRReplace more frequently depending on the conditionC, E

Spark plugRReplace more frequently depending on the conditionB, H

Manual transaxle fluid (if equipped)REvery 120,000 kmC, D, E, G, H, I, K

Automatic transaxle fluid (if equipped)REvery 100,000 kmA, C, D, E, F, G, H, I, K

Steering gear rack, linkage and bootsIInspect more frequently depending

on the conditionC, D, E, F, G

Propeller shaft (if equipped) IEvery 15,000 km or 12 monthsC, E

Front suspension ball jointsIInspect more frequently depending on the conditionC, D, E, F, G

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 17

Page 312 of 1534

Maintenance

18

7

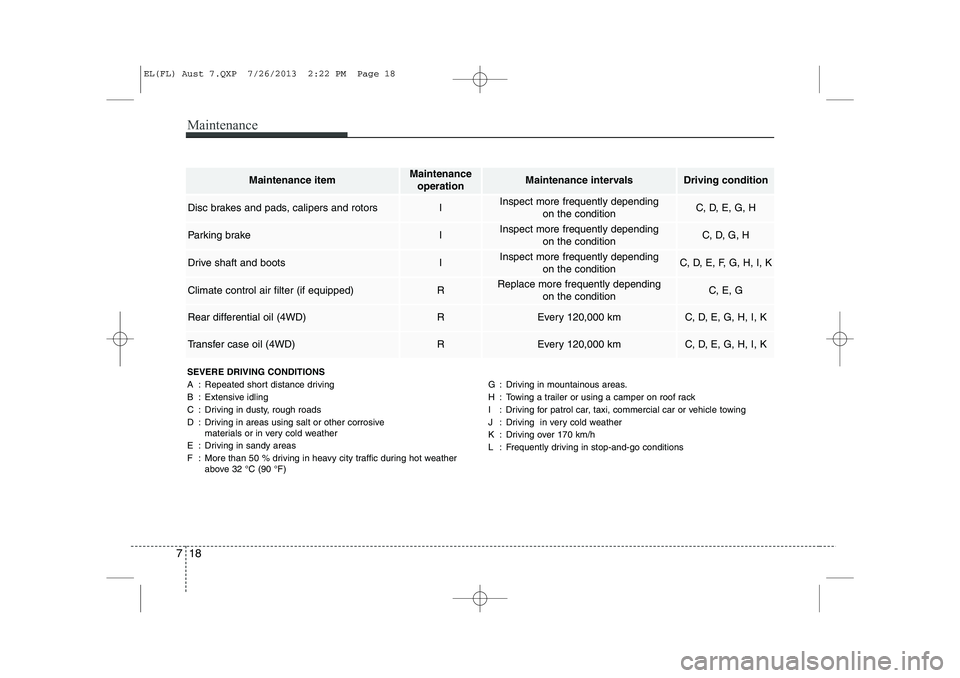

SEVERE DRIVING CONDITIONS

A : Repeated short distance driving

B : Extensive idling

C : Driving in dusty, rough roads

D : Driving in areas using salt or other corrosive

materials or in very cold weather

E : Driving in sandy areas

F : More than 50 % driving in heavy city traffic during hot weather above 32 °C (90 °F) G : Driving in mountainous areas.

H : Towing a trailer or using a camper on roof rack

I : Driving for patrol car, taxi, commercial car or vehicle towing

J : Driving in very cold weather

K : Driving over 170 km/h

L : Frequently driving in stop-and-go conditions

Maintenance itemMaintenance

operationMaintenance intervalsDriving condition

Disc brakes and pads, calipers and rotorsIInspect more frequently depending on the conditionC, D, E, G, H

Parking brakeIInspect more frequently depending on the conditionC, D, G, H

Drive shaft and bootsIInspect more frequently depending on the conditionC, D, E, F, G, H, I, K

Climate control air filter (if equipped) RReplace more frequently depending on the conditionC, E, G

Rear differential oil (4WD)REvery 120,000 kmC, D, E, G, H, I, K

Transfer case oil (4WD)REvery 120,000 kmC, D, E, G, H, I, K

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 18

Page 313 of 1534

719

Maintenance

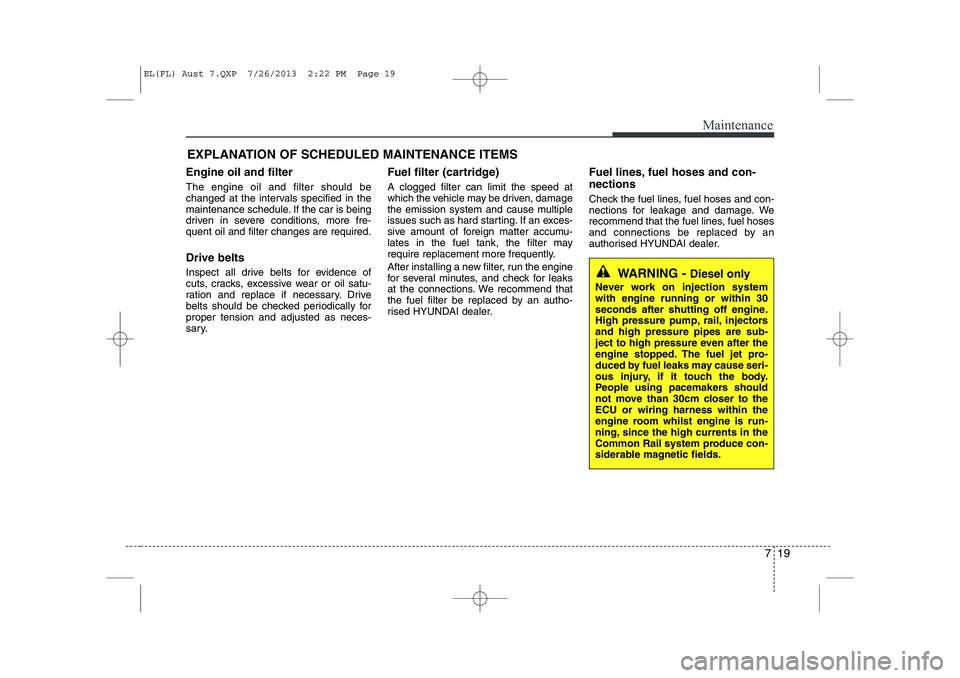

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Engine oil and filter The engine oil and filter should be

changed at the intervals specified in the

maintenance schedule. If the car is being

driven in severe conditions, more fre-quent oil and filter changes are required. Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil satu-

ration and replace if necessary. Drive

belts should be checked periodically forproper tension and adjusted as neces-

sary. Fuel filter (cartridge) A clogged filter can limit the speed at

which the vehicle may be driven, damage

the emission system and cause multiple

issues such as hard starting. If an exces-

sive amount of foreign matter accumu-

lates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks

at the connections. We recommend that

the fuel filter be replaced by an autho-

rised HYUNDAI dealer.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and con-

nections for leakage and damage. We

recommend that the fuel lines, fuel hoses

and connections be replaced by an

authorised HYUNDAI dealer.

WARNING -

Diesel only

Never work on injection system with engine running or within 30

seconds after shutting off engine.

High pressure pump, rail, injectorsand high pressure pipes are sub-

ject to high pressure even after the

engine stopped. The fuel jet pro-

duced by fuel leaks may cause seri-

ous injury, if it touch the body.

People using pacemakers should

not move than 30cm closer to theECU or wiring harness within the

engine room whilst engine is run-

ning, since the high currents in the

Common Rail system produce con-

siderable magnetic fields.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 19

Page 314 of 1534

Maintenance

20

7

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage. Air cleaner filter

We recommend that you use air cleaner

filter for replacement from an authorised

HYUNDAI dealer.

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range. Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts. Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Manual transaxle fluid (if equipped)

Inspect the manual transaxle fluid

according to the maintenance schedule.

Automatic transaxle fluid (if equipped)

Automatic transaxle fluid should not be

checked under normal usage conditions.

But in severe conditions, we recommend

that the fluid be changed by an autho-

rised HYUNDAI dealer in accordance tothe scheduled maintenance at the begin-

ning of this chapter.

✽✽

NOTICE

Automatic transaxle fluid colour is basi-

cally red. As the vehicle is driven, the automatic

transaxle fluid will begin to look darker.It is normal condition and you should

not judge the need to replace the fluid

based upon the changed colour.

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 20

Page 315 of 1534

721

Maintenance

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately. Brake fluid

Check brake fluid level in the brake fluid

reservoir. The level should be between

“MIN” and “MAX” marks on the side of

the reservoir. Use only hydraulic brake

fluid conforming to DOT 3 or DOT 4specification.Parking brake

Inspect the parking brake system includ-

ing the parking brake lever and cables.

Brake pads, calipers and rotors

Check the pads for excessive wear, discs

for run out and wear, and calipers for fluid

leakage.

For more information on checking the

pads or lining wear limit, refer to the

Hyundai web site. (

http://brakeman

ual.hmc.co.kr)

Suspension mounting bolts

Check the suspension connections for

looseness or damage. Retighten to the

specified torque. Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or damage.

Check the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts. Drive shafts and boots

Check the drive shafts, boots and clamps

for cracks, deterioration, or damage.

Replace any damaged parts and, if nec-

essary, repack the grease.

Air conditioning refrigerant/ compressor (if equipped)

Check the air conditioning lines and con-

nections for leakage and damage.

CAUTION

The use of a non-specified fluid

could result in transaxle malfunc-

tion and failure.

Use only specified automatictransaxle fluid. (Refer to“Recommended lubricants and

capacities” in section 8.)

EL(FL) Aust 7.QXP 7/26/2013 2:22 PM Page 21