wheel HYUNDAI IX35 2015 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2015, Model line: IX35, Model: HYUNDAI IX35 2015Pages: 550, PDF Size: 11.23 MB

Page 443 of 550

621

What to do in an emergency

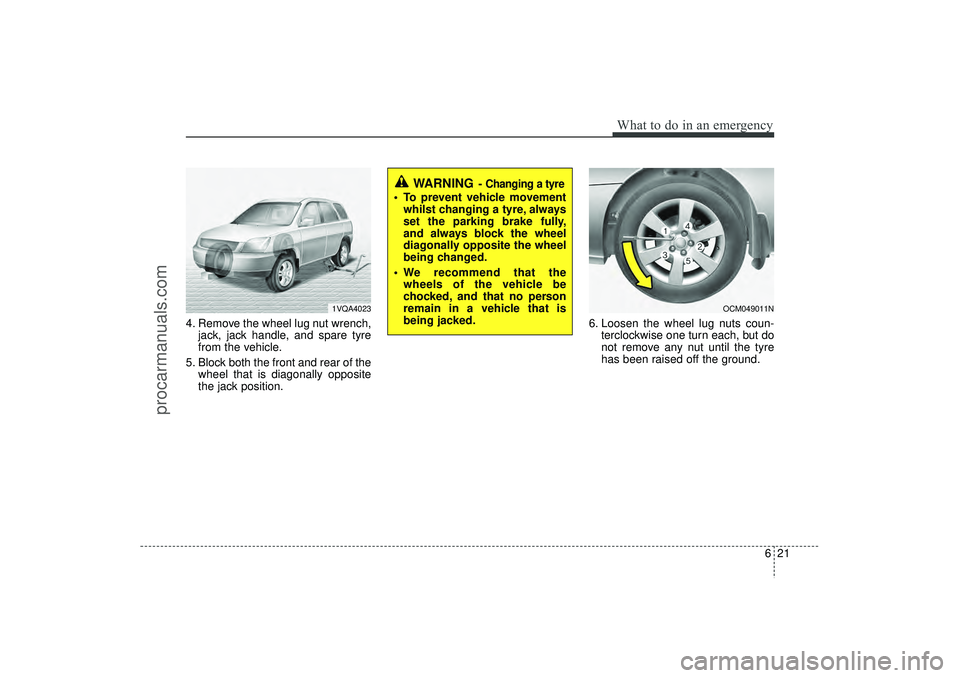

4. Remove the wheel lug nut wrench,jack, jack handle, and spare tyre

from the vehicle.

5. Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6. Loosen the wheel lug nuts coun-

terclockwise one turn each, but do

not remove any nut until the tyre

has been raised off the ground.

WARNING

- Changing a tyre

To prevent vehicle movementwhilst changing a tyre, always

set the parking brake fully,

and always block the wheel

diagonally opposite the wheel

being changed.

We recommend that the wheels of the vehicle be

chocked, and that no person

remain in a vehicle that is

being jacked.

1VQA4023

OCM049011N

EL(FL) UK 6.QXP 12/16/2014 8:12 PM Page 21

procarmanuals.com

Page 444 of 550

What to do in an emergency22

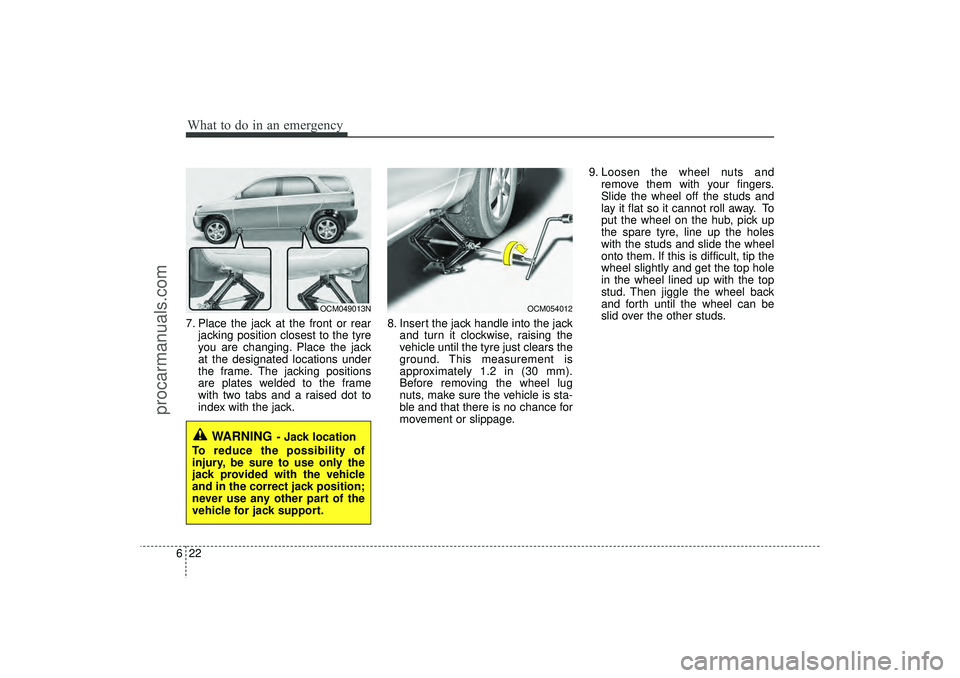

67. Place the jack at the front or rear

jacking position closest to the tyre

you are changing. Place the jack

at the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack. 8. Insert the jack handle into the jack

and turn it clockwise, raising the

vehicle until the tyre just clears the

ground. This measurement is

approximately 1.2 in (30 mm).

Before removing the wheel lug

nuts, make sure the vehicle is sta-

ble and that there is no chance for

movement or slippage. 9. Loosen the wheel nuts and

remove them with your fingers.

Slide the wheel off the studs and

lay it flat so it cannot roll away. To

put the wheel on the hub, pick up

the spare tyre, line up the holes

with the studs and slide the wheel

onto them. If this is difficult, tip the

wheel slightly and get the top hole

in the wheel lined up with the top

stud. Then jiggle the wheel back

and forth until the wheel can be

slid over the other studs.

WARNING

- Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

OCM049013N

OCM054012

EL(FL) UK 6.QXP 12/16/2014 8:12 PM Page 22

procarmanuals.com

Page 445 of 550

623

What to do in an emergency

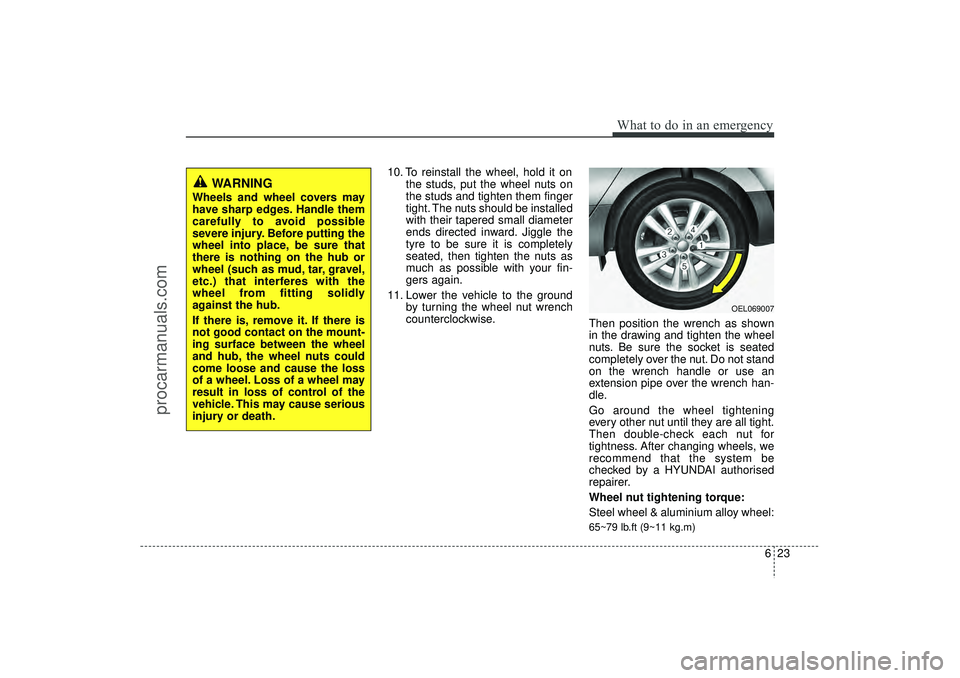

10. To reinstall the wheel, hold it onthe studs, put the wheel nuts on

the studs and tighten them finger

tight. The nuts should be installed

with their tapered small diameter

ends directed inward. Jiggle the

tyre to be sure it is completely

seated, then tighten the nuts as

much as possible with your fin-

gers again.

11. Lower the vehicle to the ground by turning the wheel nut wrench

counterclockwise. Then position the wrench as shown

in the drawing and tighten the wheel

nuts. Be sure the socket is seated

completely over the nut. Do not stand

on the wrench handle or use an

extension pipe over the wrench han-

dle.

Go around the wheel tightening

every other nut until they are all tight.

Then double-check each nut for

tightness. After changing wheels, we

recommend that the system be

checked by a HYUNDAI authorised

repairer.

Wheel nut tightening torque:

Steel wheel & aluminium alloy wheel:

65~79 lb.ft (9~11 kg.m)

WARNING

Wheels and wheel covers may

have sharp edges. Handle them

carefully to avoid possible

severe injury. Before putting the

wheel into place, be sure that

there is nothing on the hub or

wheel (such as mud, tar, gravel,

etc.) that interferes with the

wheel from fitting solidly

against the hub.

If there is, remove it. If there is

not good contact on the mount-

ing surface between the wheel

and hub, the wheel nuts could

come loose and cause the loss

of a wheel. Loss of a wheel may

result in loss of control of the

vehicle. This may cause serious

injury or death.

OEL069007

EL(FL) UK 6.QXP 12/16/2014 8:12 PM Page 23

procarmanuals.com

Page 446 of 550

What to do in an emergency24

6If you have a tyre gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust

it until it is correct. Always reinstall

the valve cap after checking or

adjusting tyre pressure. If the cap is

not replaced, air may leak from the

tyre. If you lose a valve cap, buy

another and install it as soon as pos-

sible.

After you have changed wheels,

always secure the flat tyre in its place

and return the jack and tools to their

proper storage locations. To prevent the jack, jack handle,

wheel lug nut wrench and spare tyre

from rattling whilst the vehicle is in

motion, store them properly.

CAUTION

Your vehicle has metric threads

on the wheel studs and nuts.Make certain during wheelremoval that the same nuts thatwere removed are reinstalled -or, if replaced, that nuts withmetric threads and the samechamfer configuration are used.Installation of a non-metricthread nut on a metric stud orvice-versa will not secure thewheel to the hub properly andwill damage the stud so that itmust be replaced.

Note that most lug nuts do nothave metric threads. Be sure touse extreme care in checkingfor thread style before installingaftermarket lug nuts or wheels.If in doubt, we recommend thatyou consult a HYUNDAI autho-rised repairer.

WARNING

- Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. This could lead to the

loss of the wheel and a collision

resulting in serious injuries.

WARNING -

Inadequate

spare tyre pressure

Check the inflation pressures as

soon as possible after installing

the spare tyre. Adjust it to the

specified pressure, if necessary.

Refer to “Tyres and wheels” in

section 8.

EL(FL) UK 6.QXP 12/16/2014 8:12 PM Page 24

procarmanuals.com

Page 450 of 550

What to do in an emergency28

6It is possible that some tyres, espe-

cially with larger punctures or dam-

age to the sidewall, cannot be sealed

completely.Air pressure loss in the tyre may

adversely affect tyre performance.

For this reason, you should avoid

abrupt steering or other driving

manoeuvres, especially if the vehicle

is heavily loaded or if a trailer is in

use.

The TyreMobilityKit is not designed

or intended as a permanent tyre

repair method and is to be used for

one tyre only. This instruction shows

you step by step how to temporarily

seal the puncture simply and reliably.

Read the section "Notes on the safe

use of the TyreMobilityKit". Notes on the safe use of the

TyreMobilityKit

Park your car at the side of the

road so that you can work with the

TyreMobilityKit away from moving

traffic.

To be sure your vehicle won't move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the TyreMobilityKit for sealing/inflation passenger car

tyres. Only punctured areas locat-

ed within the tread region of the

tyre can be sealed using the tyre

mobility kit.

Do not use on motorcycles, bicy- cles or any other type of tyres.

When the tyre and wheel are dam- aged, do not use Tyre Mobility Kit

for your safety.

Use of the Tyre Mobility Kit may not be effective for tyre damage larger

than approximately 0.24 in (6 mm).

If the tyre cannot be made road-

worthy with the Tyre Mobility Kit,

we recommend that you contact a

HYUNDAI authorised repairer. Do not use the Tyre Mobility Kit if a

tyre is severely damaged by driving

run flat or with insufficient air pres-

sure.

Do not remove any foreign objects- such as nails or screws that have

penetrated the tyre.

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery.

Never leave the TyreMobilityKit unattended whilst it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the TyreMobilityKit if the ambient temperature is below

-30°C (-22°F).

WARNING

Do not use the TMK if a tyre is

severely damaged by driving

run flat or with insufficient air

pressure.

Only punctured areas located

within the tread region of the

tyre can be sealed using the

TMK.

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 28

procarmanuals.com

Page 451 of 550

629

What to do in an emergency

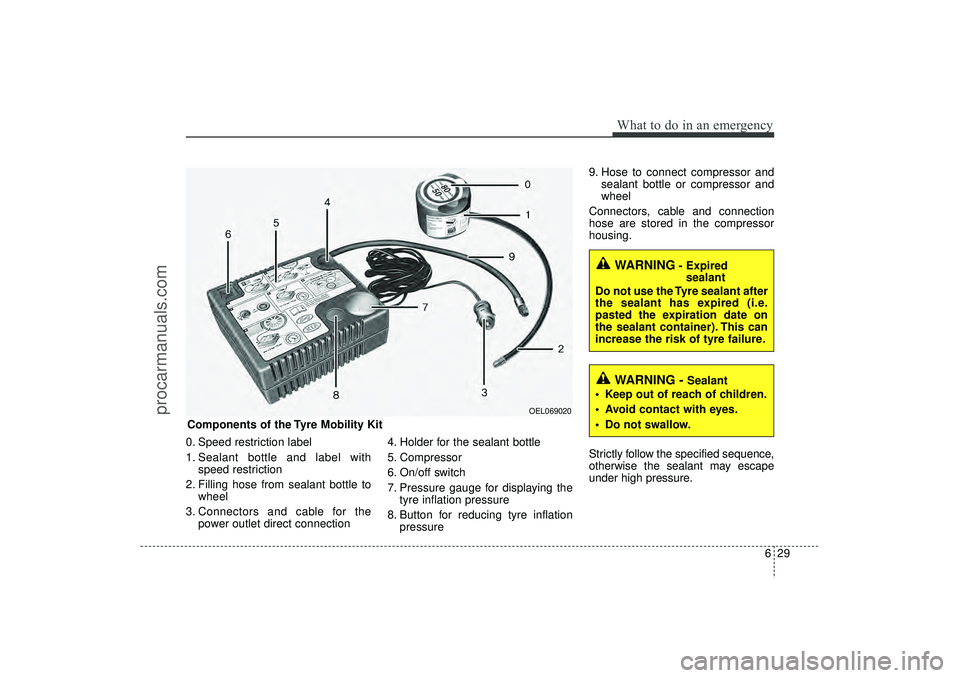

0. Speed restriction label

1. Sealant bottle and label withspeed restriction

2. Filling hose from sealant bottle to wheel

3. Connectors and cable for the power outlet direct connection 4. Holder for the sealant bottle

5. Compressor

6. On/off switch

7. Pressure gauge for displaying the

tyre inflation pressure

8. Button for reducing tyre inflation pressure 9. Hose to connect compressor and

sealant bottle or compressor and

wheel

Connectors, cable and connection

hose are stored in the compressor

housing.

Strictly follow the specified sequence,

otherwise the sealant may escape

under high pressure.

WARNING

- Expired sealant

Do not use the Tyre sealant after

the sealant has expired (i.e.

pasted the expiration date on

the sealant container). This can

increase the risk of tyre failure.

WARNING -

Sealant

Keep out of reach of children.

Avoid contact with eyes.

Do not swallow.

Components of the Tyre Mobility Kit

OEL069020

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 29

procarmanuals.com

Page 452 of 550

What to do in an emergency30

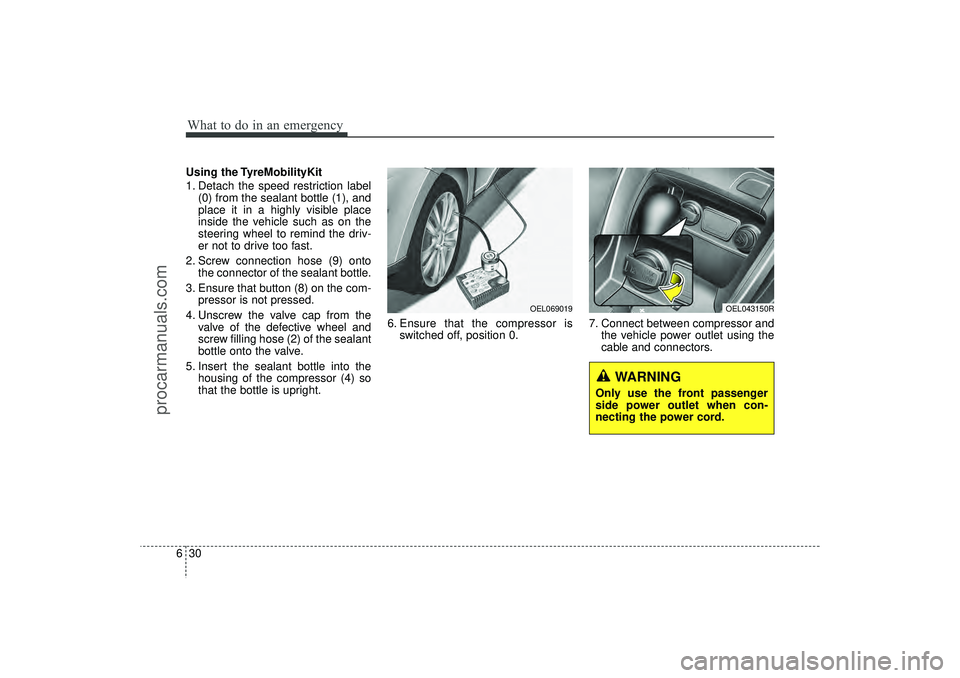

6Using the TyreMobilityKit

1. Detach the speed restriction label

(0) from the sealant bottle (1), and

place it in a highly visible place

inside the vehicle such as on the

steering wheel to remind the driv-

er not to drive too fast.

2. Screw connection hose (9) onto the connector of the sealant bottle.

3. Ensure that button (8) on the com- pressor is not pressed.

4. Unscrew the valve cap from the valve of the defective wheel and

screw filling hose (2) of the sealant

bottle onto the valve.

5. Insert the sealant bottle into the housing of the compressor (4) so

that the bottle is upright. 6. Ensure that the compressor is

switched off, position 0. 7. Connect between compressor and

the vehicle power outlet using the

cable and connectors.

OEL069019

OEL043150R

WARNING

Only use the front passenger

side power outlet when con-

necting the power cord.

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 30

procarmanuals.com

Page 453 of 550

631

What to do in an emergency

8. With the engine start/stop buttonposition on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tyre

and Wheels, chapter 8). The infla-

tion pressure of the tyre after filling

is unimportant and will be

checked/corrected later.

Be careful not to overinflate the

tyre and stay away from the tyre

when filling it. 9. Switch off the compressor.

10. Detach the hoses from the

sealant bottle connector and

from the tyre valve.

Return the TyreMobilityKit to its stor-

age location in the vehicle. Distributing the sealant

11. Immediately drive approximately

4~6 miles (7~10 km or, about

10min) to evenly distribute the

sealant in the tyre.

WARNING

- Carbonmonoxide

Do not leave your vehicle run-

ning in a poorly ventilated area

for extended periods of time.

Carbon monoxide poisoning

and suffocation can occur.

CAUTION

- Tyre pressure

Do not attempt to drive your vehicle if the tyre pressure isbelow 200kpa(29 PSI). Thiscould result in an accident dueto sudden tyre failure.

CAUTION

Do not exceed a speed of 80km/h (50 mph). If possible, donot fall below a speed of 20km/h (12 mph).

Whilst driving, if you experienceany unusual vibration, ride dis-turbance or noise, reduce yourspeed and drive with cautionuntil you can safely pull off ofthe side of the road.

Call for road side service or tow-ing. When you use the TyreMobility Kit, the tyre pressuresensors and wheel may be dam-aged by sealant, remove thesealant stained with tyre pres-sure sensors and wheel andinspect in authorized dealer.

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 31

procarmanuals.com

Page 454 of 550

What to do in an emergency32

6

CAUTION

- Tyre pressure

sensor

The sealant on the tyre pressuresensor and wheel should beremoved when you replace thetyre with a new one and inspectthe tyre pressure sensors inauthorised dealer.

Checking the tyre inflation pres-

sure

1. After driving approximately 4~6 miles (7~10 km or about 10 min),

stop at a safety location.

2. Connect connection hose (9) of the compressor directly to the tyre

valve.

3. Plug the compressor power cord into the vehicle power outlet.

4. Adjust the tyre inflation pressure to the recomended tyre inflation.

With the ignition switched on, pro-

ceed as follows.

- To increase the inflation pres- sure: Switch on the compressor,

position I. To check the current

inflation pressure setting, briefly

switch off the compressor.

✽ ✽ NOTICEThe pressure gauge may show high-

er than actual reading when the

compressor is running. To get an

accurate tyre reading, the compres-

sor needs to be turned off.- To reduce the inflation pres-

sure: Press the button 8 on the

compressor.

WARNING

Do not let the compressor run

for more than 10 minutes, other-

wise the device will overheat

and may be damaged.

CAUTION

If the inflation pressure is not maintained, drive the vehicle asecond time, refer toDistributing the sealant. Thenrepeat steps 1 to 4.

Use of the TMK may be ineffec-tual for tyre damage larger thanapproximately 4 mm (0.16 in).

We recommend that you contacta HYUNDAI authorised repairerif the tyre cannot be made road-worthy with the Tyre MobilityKit.

WARNING

The tyre inflation pressure must

be at least 220 kPa (32 psi). If it

is not, do not continue driving.

Call for road side service or

towing.

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 32

procarmanuals.com

Page 455 of 550

633

What to do in an emergency

Notes on the safe use of the

Tyre Mobility Kit Park your car at the side of theroad so that you can work with the

TMK away from moving traffic.

Place your warning triangle in a

prominent place to make passing

vehicles aware of your location.

To be sure your vehicle will not move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the TMK for sealing/infla- tion passenger car tyres. Do not

use on motorcycles, bicycles or

any other type of tyres.

Do not remove any foreign objects- such as nails or screws -that have

penetrated the tyre.

Before using the TMK, read the precautionary advice printed on

the sealant bottle!

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery. Never leave the TMK unattended

whilst it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the TMK if the ambient temperature is below -30°C (-

22°F).

When both the tyre and wheel are damaged, do not use Tyre Mobility

Kit for your safety. Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:

-30 ~ +70°C (-22 ~ +158°F)

Max. working pressure: 87 psi (6 bar)

Size

Compressor: 6.6 x 5.9 x 2.7 in. (168 x 150 x 68 mm)

Sealant bottle: 4.1 x ø 3.3 in. (104 x ø 85 mm)

Compressor weight: 2.31 lbs (1.05 kg)

Sealant volume: 18.3 cu. in. (300 ml)

❈ Sealant and spare parts can be

obtained and replaced at an

authorized vehicle or tyre dealer.

Empty sealant bottles may be dis-

posed of at home. Liquid residue

from the sealant should be dis-

posed of by your vehicle or tyre

dealer or in accordance with local

waste disposal regulations.

EL(FL) UK 6.QXP 12/16/2014 8:13 PM Page 33

procarmanuals.com