engine HYUNDAI IX35 2016 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2016, Model line: IX35, Model: HYUNDAI IX35 2016Pages: 550, PDF Size: 11.23 MB

Page 509 of 550

749

Maintenance

Engine compartment

OLM079026R/OLM079053R/OLM079027/OEL070306R/OLM079028

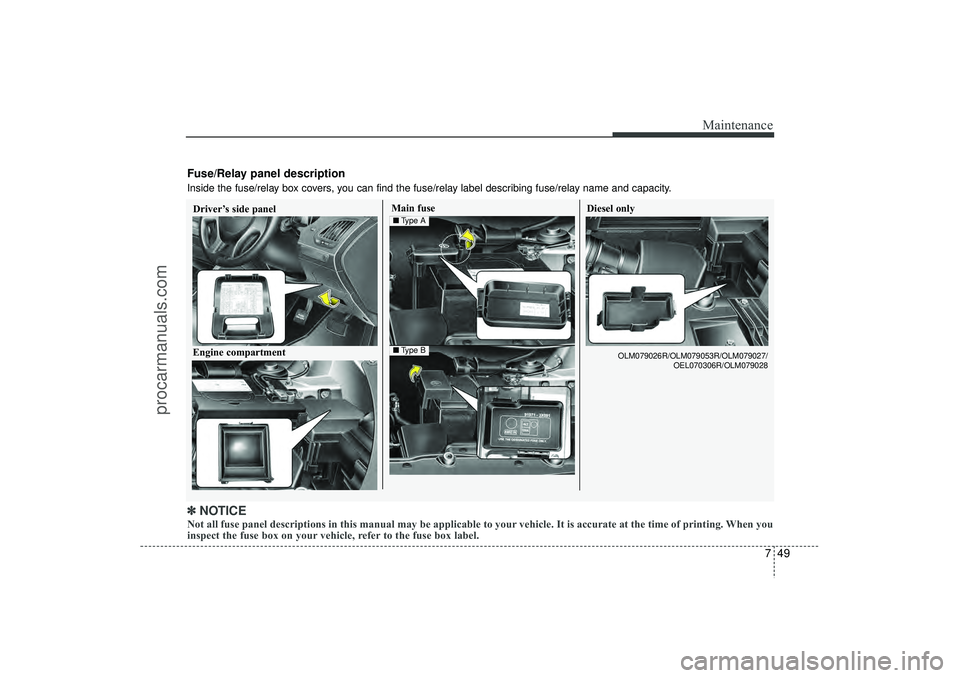

Fuse/Relay panel descriptionInside the fuse/relay box covers, you can find the fuse/relay label describing fuse/relay name and capacity.

Diesel only

Driver’s side panel Main fuse

■

Type A■Type B

✽

✽

NOTICENot all fuse panel descriptions in this manual may be applicable to your\

vehicle. It is accurate at the time of printing. When you

inspect the fuse box on your vehicle, refer to the fuse box label.

EL(FL) UK 7.QXP 3/4/2015 9:07 PM Page 49

procarmanuals.com

Page 513 of 550

753

Maintenance

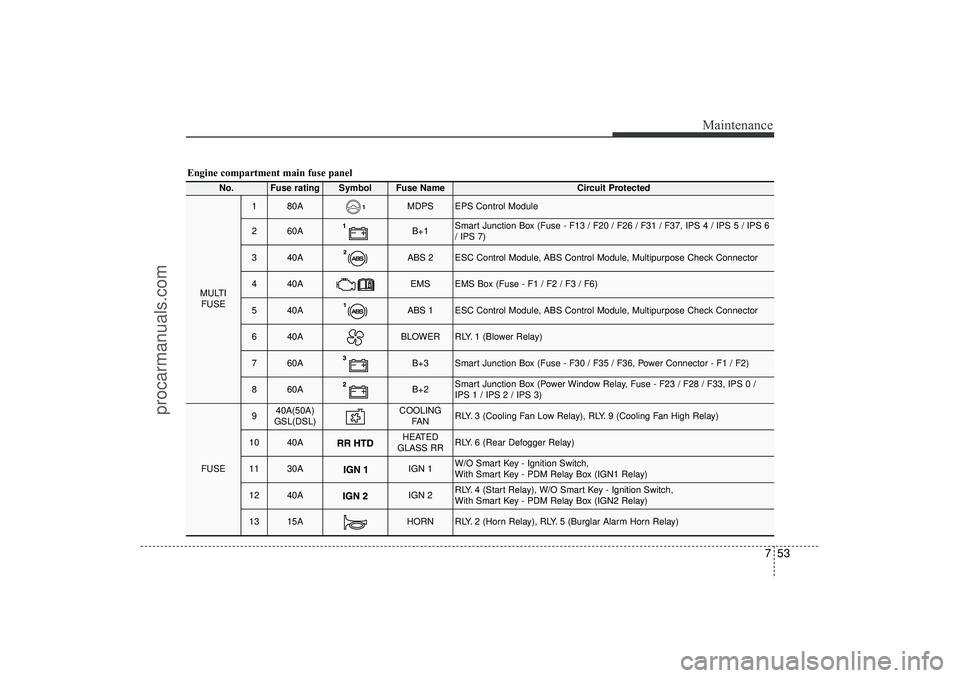

Engine compartment main fuse panel

No.

Fuse rating

Symbol

Fuse Name

Circuit Protected

MULTIFUSE

1

80A

MDPS

EPS Control Module

2

60A

B+1

Smart Junction Box (Fuse - F13 / F20 / F26 / F31 / F37, IPS 4 / IPS 5 / IPS 6

/ IPS 7)

3

40A

ABS 2

ESC Control Module, ABS Control Module, Multipurpose Check Connector

4

40A

EMS

EMS Box (Fuse - F1 / F2 / F3 / F6)

5

40A

ABS 1

ESC Control Module, ABS Control Module, Multipurpose Check Connector

6

40A

BLOWER

RLY. 1 (Blower Relay)

7

60A

B+3

Smart Junction Box (Fuse - F30 / F35 / F36, Power Connector - F1 / F2)

8

60A

B+2

Smart Junction Box (Power Window Relay, Fuse - F23 / F28 / F33, IPS 0 /

IPS 1 / IPS 2 / IPS 3)

FUSE

9

40A(50A)

GSL(DSL)

COOLING FA N

RLY. 3 (Cooling Fan Low Relay), RLY. 9 (Cooling Fan High Relay)

10

40A

HEATED

GLASS RR

RLY. 6 (Rear Defogger Relay)

11

30A

IGN 1

W/O Smart Key - Ignition Switch,

With Smart Key - PDM Relay Box (IGN1 Relay)

12

40A

IGN 2

RLY. 4 (Start Relay), W/O Smart Key - Ignition Switch,

With Smart Key - PDM Relay Box (IGN2 Relay)

13

15A

HORN

RLY. 2 (Horn Relay), RLY. 5 (Burglar Alarm Horn Relay)

EL(FL) UK 7.QXP 3/4/2015 9:07 PM Page 53

procarmanuals.com

Page 515 of 550

755

Maintenance

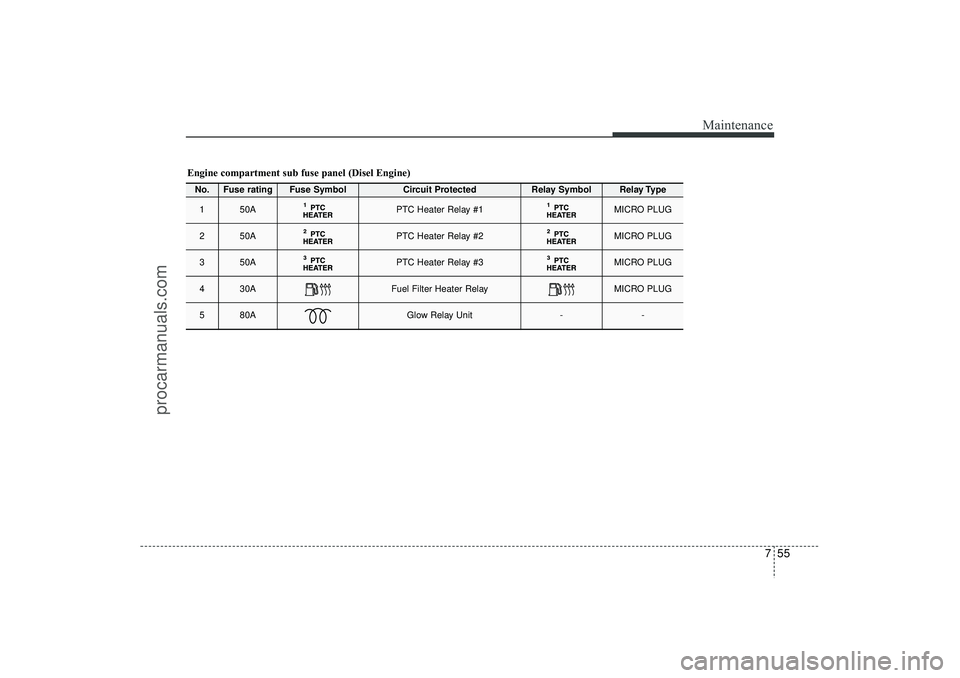

Engine compartment sub fuse panel (Disel Engine)No.

Fuse rating

Fuse Symbol

Circuit Protected

Relay Symbol

Relay Type

1

50A

PTC Heater Relay #1

MICRO PLUG

2

50A

PTC Heater Relay #2

MICRO PLUG

3

50A

PTC Heater Relay #3

MICRO PLUG

4

30A

Fuel Filter Heater Relay

MICRO PLUG

5

80A

Glow Relay Unit

-

-

EL(FL) UK 7.QXP 3/4/2015 9:07 PM Page 55

procarmanuals.com

Page 519 of 550

759

Maintenance

Turn signal light/Position lightTurn signal light

1. Turn off the engine and open the bon-net.

2. Remove the socket from the assembly by turning the socket counterclockwise

until the tabs on the socket align with

the slots on the assembly.

3. Remove the bulb from the socket by pressing it in and rotating it counter-

clockwise until the tabs on the bulb

align with the slots in the socket. Pull

the bulb out of the socket.

4. Insert a new bulb by inserting it into the socket and rotating it until it locks

into place.

5. Install the socket in the assembly by aligning the tabs on the socket with the

slots in the assembly. Push the socket

into the assembly and turn the socket

clockwise.

Position light

If the light bulb does not operate, we rec-

ommend that the system be checked by

a HYUNDAI authorised repairer.

(Continued)

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

Wear eye protection when chang- ing a bulb. Allow the bulb to cool

down before handling it.

WARNING

- Halogen bulbs

Halogen bulbs contain pressur-ized gas that will produce flying

pieces of glass if broken.

Always handle them carefully, and avoid scratches and abra-

sions. If the bulbs are lit, avoid

contact with liquids. Never touch

the glass with bare hands.

Residual oil may cause the bulb

to overheat and burst when lit. A

bulb should be operated only

when installed in a headlight.

(Continued)

OHD076046

EL(FL) UK 7.QXP 3/4/2015 9:07 PM Page 59

procarmanuals.com

Page 531 of 550

771

Maintenance

Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

Finish damage repair Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly rust

and may develop into a major repair

expense.✽ ✽NOTICEIf your vehicle is damaged and requires

any metal repair or replacement, be sure

the body shop applies anti-corrosion

materials to the parts repaired or

replaced.

CAUTION

Wiping dust or dirt off the body

with a dry cloth will scratch thefinish.

Do not use steel wool, abrasive cleaners, or strong detergentscontaining highly alkaline orcaustic agents on chrome-platedor anodized aluminium parts. This may result in damage to the pro-tective coating and cause discol- oration or paint deterioration.

CAUTION

Water washing in the engine com- partment including high pressurewater washing may cause the fail-ure of electrical circuits located inthe engine compartment.

Never allow water or other liquids to come in contact with electri-cal/electronic components insidethe vehicle as this may damage them.

OJB037800

EL(FL) UK 7.QXP 3/4/2015 9:08 PM Page 71

procarmanuals.com

Page 536 of 550

Maintenance76

7EMISSION CONTROL SYSTEMThe emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty infor-

mation contained in the Service Passport

in your vehicle.

Your vehicle is equipped with an emis-

sion control system to meet all emission

regulations.

There are three emission control sys-

tems which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of

the emission control systems, it is rec-

ommended that you have your car

inspected and maintained by a

HYUNDAI authorised repairer in accor-

dance with the maintenance schedule. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from misfir-

ing during dynamometer testing,

turn the Electronic Stability Control

(ESC) system off by pressing the

ESC switch.

After dynamometer testing is com- pleted, turn the ESC system back on

by pressing the ESC switch again.

1. Crankcase emission control systemThe positive crankcase ventilation sys-

tem is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission controlSystemThe Evaporative Emission Control

System is designed to prevent fuel

vapours from escaping into the atmos-

phere.CanisterFuel vapours generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapours absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant temper-

ature is low during idling, the PCSV clos-

es so that evaporated fuel is not taken

into the engine. After the engine warms-

up during ordinary driving, the PCSV

opens to introduce evaporated fuel to the

engine.

EL(FL) UK 7.QXP 3/4/2015 9:08 PM Page 76

procarmanuals.com

Page 537 of 550

777

Maintenance

3. Exhaust emission control systemThe Exhaust Emission Control System is

a highly effective system which controls

exhaust emissions whilst maintaining

good vehicle performance.Vehicle modifications This vehicle should not be modified.

Modification of your vehicle could

affect its performance, safety or dura-

bility and may even violate governmen-

tal safety and emissions regulations.

In addition, damage or performance

problems resulting from any modifica-

tion may not be covered under warran-

ty.

If you use unauthorised electronic devices, it may cause the vehicle to

operate abnormally, wire damage, bat-

tery discharge and fire. For your safety,

do not use unauthorised electronic

devices.

Engine exhaust gas precautions (carbon monoxide) Carbon monoxide can be present with other exhaust fumes. Therefore, if you

smell exhaust fumes of any kind inside

your vehicle, have it inspected and

repaired immediately. If you ever sus-

pect exhaust fumes are coming into

your vehicle, drive it only with all the

windows fully open. Have your vehicle

checked and repaired immediately. Do not operate the engine in confined

or closed areas (such as garages) any

more than what is necessary to move

the vehicle in or out of the area.

When the vehicle is stopped in an open area for more than a short time

with the engine running, adjust the

ventilation system (as needed) to draw

outside air into the vehicle.

Never sit in a parked or stopped vehi- cle for any extended time with the

engine running.

When the engine stalls or fails to start, excessive attempts to restart the

engine may cause damage to the

emission control system.

WARNING

- Exhaust

Engine exhaust gases contain car-

bon monoxide (CO). Though

colourless and odourless, it is dan-

gerous and could be lethal if

inhaled. Follow the instructions

following to avoid CO poisoning.

EL(FL) UK 7.QXP 3/4/2015 9:08 PM Page 77

procarmanuals.com

Page 538 of 550

Maintenance78

7Operating precautions for catalytic

converters (if equipped)

Your vehicle is equipped with a catalytic

converter emission control device.

Therefore, the following precautions

must be observed:

Use only UNLEADED FUEL for petrol engine.

Do not operate the vehicle when there are signs of engine malfunction, such

as misfire or a noticeable loss of per-

formance.

Do not misuse or abuse the engine. Examples of misuse are coasting with

the ignition off and descending steep

grades in gear with the ignition off.

Do not operate the engine at high idle speed for extended periods (5 minutes

or more).

Do not modify or tamper with any part of the engine or emission control sys-

tem. We recommend that the system

be inspected by a HYUNDAI autho-

rised repairer.

Avoid driving with a extremely low fuel level. Running out of fuel cause the

engine to misfire, damaging the cat-

alytic converter.

Failure to observe these precautions

could result in damage to the catalytic

converter and to your vehicle.

Additionally, such actions could void your

warranties.

Diesel Particulate Filter (if equipped)The Diesel Particulate Filter (DPF) sys-

tem removes the soot emitted from the

vehicle.

Unlike a disposable air filter, the DPF

system automatically burns (oxidizes)

and removes the accumulated soot

according to the driving condition. In

other words, the active burning by engine

control system and high exhaust gas

temperature caused by normal/high driv-

ing condition burns and removes the

accumulated soot.

However, if the vehicle continues to be

driven at low speed for long time, the

accumulated soot may not be automati-

cally removed because of low exhaust

gas temperature. In this particular case,

the amount of soot is out of detection

limit, the soot oxidation process by

engine control system may not happen

and the malfunction indicator light may

blink.

When the malfunction indicator light

blinks, it may stop blinking by driving the

vehicle at more than 37 mph (60km/h) or

at more than second gear with 1500 ~

2000 engine rpm for a certain time (for

about 25 minutes).

WARNING

- Fire

A hot exhaust system can ignite flammable items under your vehi-

cle. Do not park, idle, or drive the

vehicle over or near flammable

objects, such as dry grass, paper,

leaves, etc.

The exhaust system and catalytic system are very hot whilst the

engine is running or immediately

after the engine is turned off. Keep

away from the exhaust system

and catalytic, you may get burned.

Also, do not remove the heat sink

around the exhaust system, do

not seal the bottom of the vehicle

or do not coat the vehicle for cor-

rosion control. It may present a

fire risk under certain conditions.

EL(FL) UK 7.QXP 3/4/2015 9:08 PM Page 78

procarmanuals.com

Page 540 of 550

Specifications & Consumer informationDimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

8-2

Air conditioning system . . . . . . . . . . . . . . . . . . . . . . 8-2

Bulb wattage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Tyres and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Load and speed capacity tyres . . . . . . . . . . . . . . . . 8-4

Gross vehicle weight. . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Luggage volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Recommended lubricants and capacities . . . . . . . 8-6• Recommended engine oil . . . . . . . . . . . . . . . . . . . . . . . 8-7

• Recommended SAE viscosity number . . . . . . . . . . . 8-8Vehicle identification number (VIN) . . . . . . . . . . . 8-9

Vehicle certification label. . . . . . . . . . . . . . . . . . . . . 8-9

Tyre specification and pressure label . . . . . . . . . . 8-10

Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Air conditioner compressor label . . . . . . . . . . . . . 8-11

Declaration of conformity . . . . . . . . . . . . . . . . . . . 8-11

8

EL(FL) UK 8.QXP 3/13/2015 5:44 PM Page 1

procarmanuals.com

Page 541 of 550

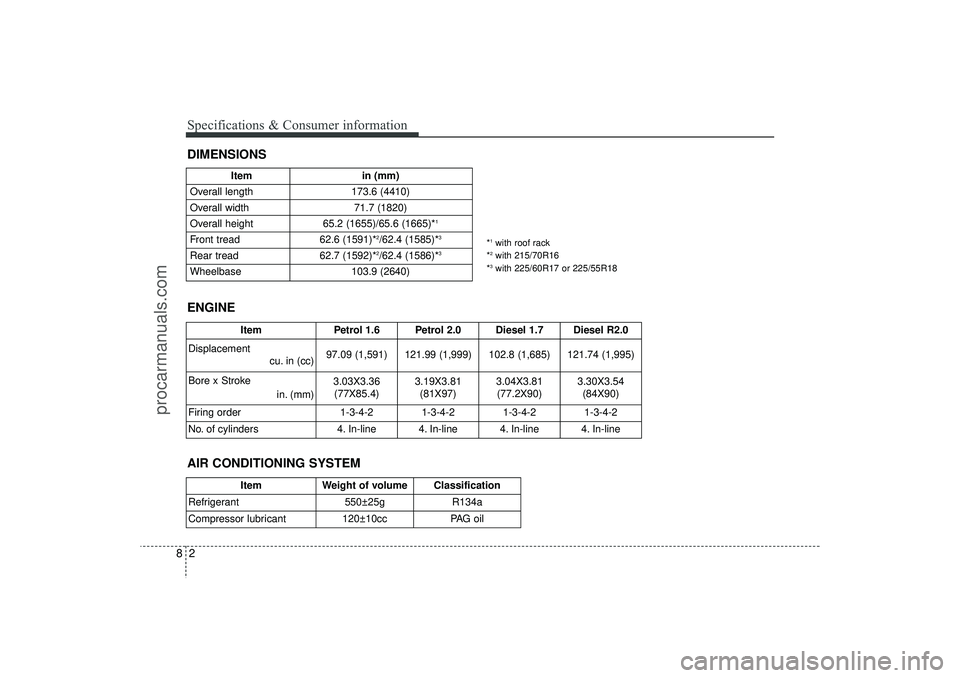

Specifications & Consumer information28DIMENSIONS

Itemin (mm)

Overall length 173.6 (4410)

Overall width 71.7 (1820)

Overall height 65.2 (1655)/65.6 (1665)*

1

Front tread62.6 (1591)*

2/62.4 (1585)*

3

Rear tread62.7 (1592)*

2/62.4 (1586)*

3

Wheelbase 103.9 (2640)

*1with roof rack

*2with 215/70R16

*3with 225/60R17 or 225/55R18

ENGINE

Item

Petrol 1.6 Petrol 2.0

Diesel 1.7

Diesel R2.0

Displacement cu. in (cc)

97.09 (1,591) 121.99 (1,999)

102.8 (1,685)

121.74 (1,995)

Bore x Stroke in. (mm)

3.03X3.36(77X85.4) 3.19X3.81

(81X97)

3.04X3.81(77.2X90)

3.30X3.54 (84X90)

Firing order

1-3-4-2 1-3-4-2

1-3-4-2

1-3-4-2

No. of cylinders

4. In-line 4. In-line

4. In-line

4. In-line

Item

Weight of volume Classification

Refrigerant

550±25g R134a

Compressor lubricant120±10cc PAG oil

AIR CONDITIONING SYSTEM

EL(FL) UK 8.QXP 3/13/2015 5:44 PM Page 2

procarmanuals.com