Gas Hyundai Kona 2018 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2018, Model line: Kona, Model: Hyundai Kona 2018Pages: 523, PDF Size: 33.6 MB

Page 429 of 523

7-17

7

Maintenance

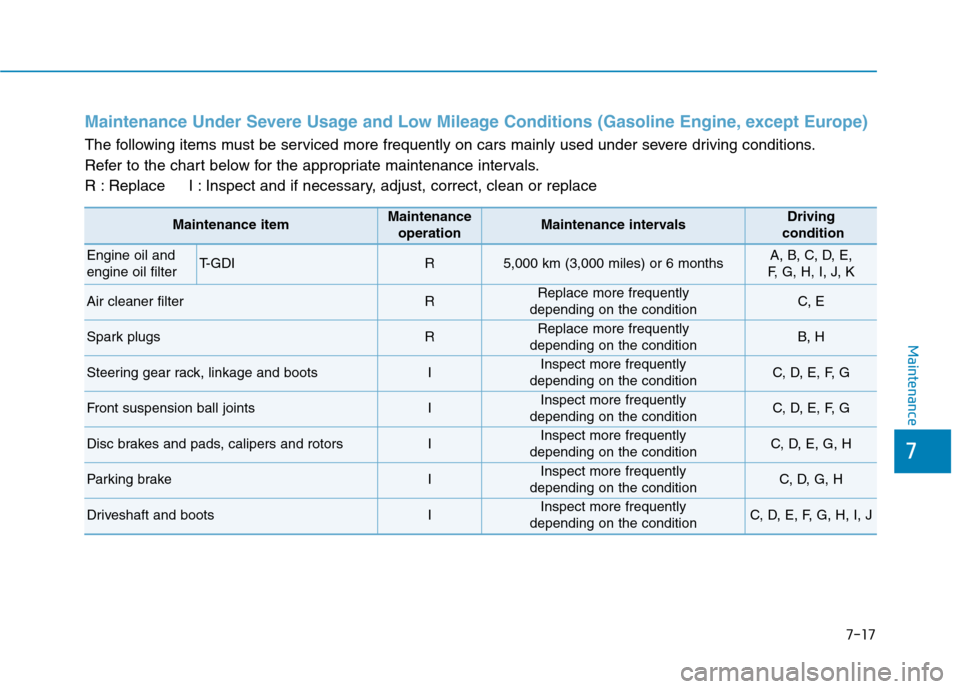

Maintenance Under Severe Usage and Low Mileage Conditions (Gasoline Engine, except Europe)

The following items must be serviced more frequently on cars mainly used under severe driving conditions.

Refer to the chart below for the appropriate maintenance intervals.

R : Replace I : Inspect and if necessary, adjust, correct, clean or replace

Maintenance itemMaintenance operationMaintenance intervalsDriving

condition

Engine oil and engine oil filterT-GDI R5,000 km (3,000 miles) or 6 monthsA, B, C, D, E,

F, G, H, I, J, K

Air cleaner filterRReplace more frequently

depending on the conditionC, E

Spark plugsRReplace more frequently

depending on the conditionB, H

Steering gear rack, linkage and bootsIInspect more frequently

depending on the conditionC, D, E, F, G

Front suspension ball jointsIInspect more frequently

depending on the conditionC, D, E, F, G

Disc brakes and pads, calipers and rotorsIInspect more frequently

depending on the conditionC, D, E, G, H

Parking brakeIInspect more frequently

depending on the conditionC, D, G, H

Driveshaft and bootsIInspect more frequently

depending on the conditionC, D, E, F, G, H, I, J

Page 431 of 523

7-19

7

Maintenance

EEXX PPLLAA NN AATTIIOO NN OO FF SS CC HH EEDD UU LLEE DD MM AAIINN TTEENN AANN CCEE IITT EEMM SS

Engine oil and filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filterchanges are required.

Drive belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel lines, fuel hoses and con- nections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. We recommend that the fuel

lines, fuel hoses and connections be

replaced by an authorized HYUNDAI

dealer.

Fuel filter (for gasoline)

HYUNDAI gasoline vehicle is

equipped a lifetime fuel filter that

integrated with the fuel tank. Regularmaintenance or replacement is not

needed but depends on fuel quality. If

there are some important safety mat-

ters like fuel flow restriction, surging,

loss of power, hard starting problem

etc, fuel filter inspection or replace is

needed. We recommend that the fuel

filter be Inspected or replaced by an

authorized HYUNDAI dealer.

Vapor hose and fuel filler cap

The vapor hose and fuel filler cap should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure that a new

vapor hose or fuel filler cap is cor-rectly replaced.

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evi- dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.Inspect the hose routing to ensurethat the hoses do not come in con-

tact with any heat source, sharp

edges or moving component whichmight cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

When you are inspecting the belt,

place the ignition switch to the

LOCK/OFF or ACC position.

CAUTION

Page 432 of 523

7-20

Maintenance

Air cleaner filter

We recommend that the air cleaner

filter be replaced by an authorized

HYUNDAI dealer.

Spark plugs

(for Gasoline Engine)

Make sure to install new spark plugs

of the correct heat range.

Valve clearance

(for Gasoline Engine)

Inspect excessive valve noise and/or

engine vibration and adjust if neces-

sary. We recommend that the system

be serviced by an authorized HYUNDAI

dealer.

Cooling system

Check the cooling system parts,

such as radiator, coolant reservoir,

hoses and connections for leakage

and damage. Replace any damaged

parts.

Engine coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Manual transmission fluid (if equipped)

Inspect the manual transmission fluid according to the maintenance

schedule.

Dual clutch transmission fluid (if equipped)

Inspect the dual clutch transmission fluid according to the maintenance

schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake/Clutch fluid (if equipped)

Check the brake/clutch fluid level in

the brake fluid reservoir. The level

should be between “MIN” and “MAX”

marks on the side of the reservoir.

Use only hydraulic brake fluid con-

forming to DOT 3 or DOT 4 specifi-cation.

Parking brake

Inspect the parking brake system

including the parking brake lever and

cables.

Do not disconnect and inspectspark plugs when the engine is

hot. You may burn yourself.

WARNING

Page 433 of 523

7-21

7

Maintenance

Brake pads, calipers and

rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

For more information on checking

the pads or lining wear limit, refer to

the HYUNDAI web site. (http://ser

vice.hyundai-motor.com)

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and engine

off, check for excessive free-play in

the steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or

damage. Replace any damaged

parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant/ compressor

Check the air conditioning lines and

connections for leakage and dam-

age.

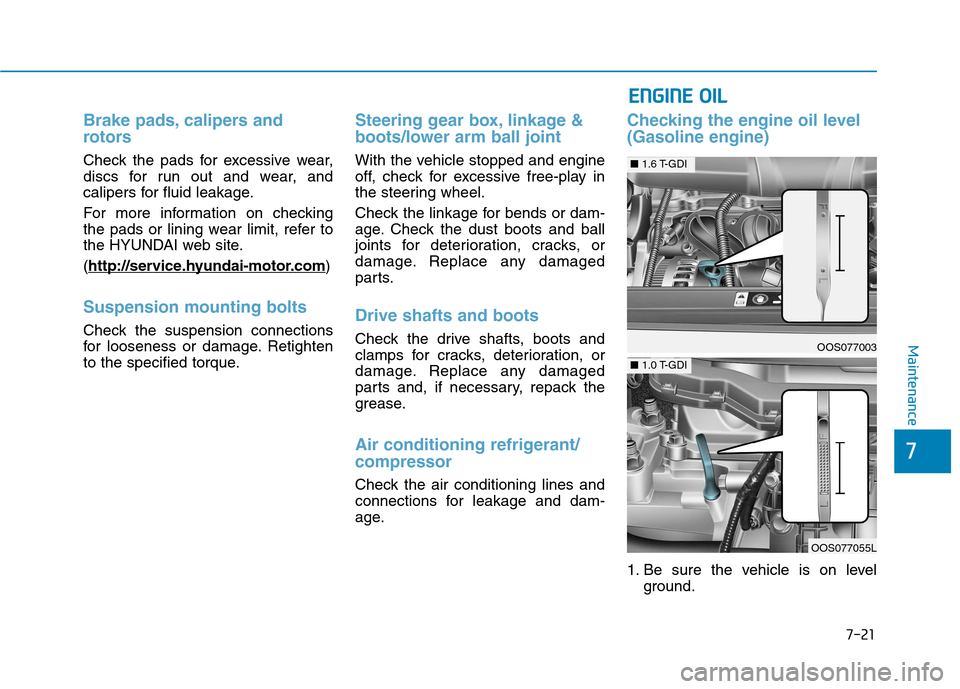

Checking the engine oil level (Gasoline engine)

1. Be sure the vehicle is on level

ground.

EENN GGIINN EE OO IILL

OOS077003

OOS077055L

■ 1.0 T-GDI

■1.6 T-GDI

Page 435 of 523

7-23

7

Maintenance

Checking the engine oil and filter

We recommend that the engine oil

and filter be replaced by an author-

ized HYUNDAI dealer.The high-pressure cooling system

has a reservoir filled with year-round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant concentration level at least

once a year, at the beginning of the

winter season, and before traveling

to a colder climate.

When the engine overheats from

low engine coolant, suddenly

adding engine coolant may cause

cracks in the engine. To prevent

damage, add engine coolant

slowly in small quantities.

Do not drive with no engine coolant. It may cause water pump

failure and engine seizure, etc.

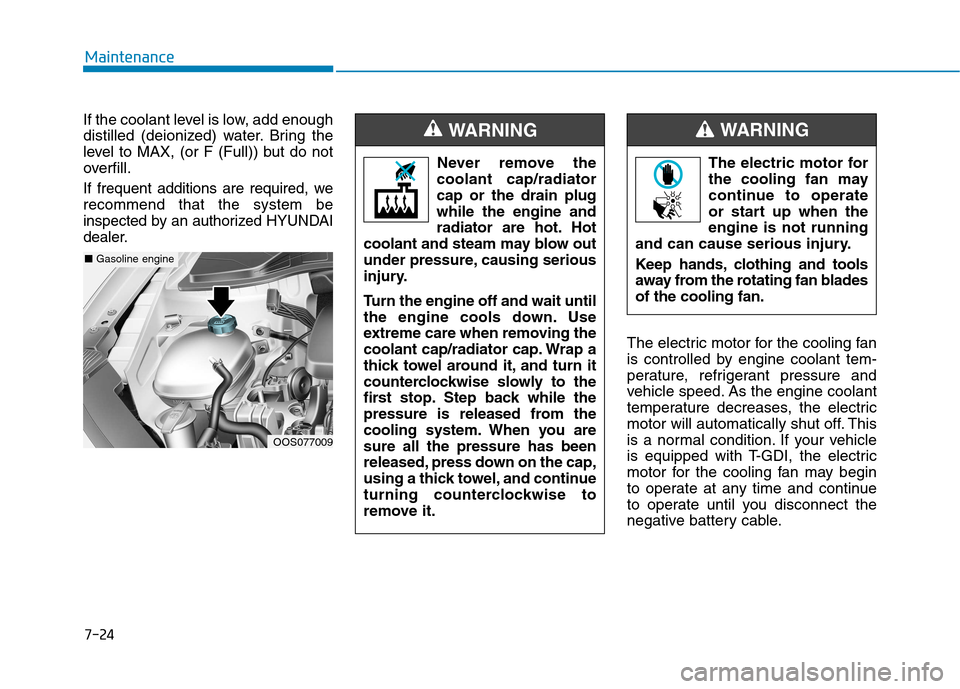

Checking the engine coolant

level

Check the condition and connections of all cooling system hoses and

heater hoses. Replace any swollen

or deteriorated hoses.

The coolant level should be filled

between MAX and MIN (or F (Full)

and L (Low)) marks on the side of the

coolant reservoir when the engine iscool.

NOTICE

Used engine oil may cause irri- tation or cancer of the skin if

left in contact with the skin for

prolonged periods of time. Used

engine oil contains chemicals

that have caused cancer in lab-

oratory animals. Always protect

your skin by washing your

hands thoroughly with soapand warm water as soon as pos-

sible after handling used oil.

WARNING

EENN GGIINN EE CC OO OOLLAA NN TT

OOS077007

■Gasoline engine

Page 436 of 523

7-24

Maintenance

If the coolant level is low, add enough

distilled (deionized) water. Bring the

level to MAX, (or F (Full)) but do not

overfill.

If frequent additions are required, werecommend that the system be

inspected by an authorized HYUNDAI

dealer.

The electric motor for the cooling fan

is controlled by engine coolant tem-

perature, refrigerant pressure and

vehicle speed. As the engine coolant

temperature decreases, the electric

motor will automatically shut off. This

is a normal condition. If your vehicle

is equipped with T-GDI, the electric

motor for the cooling fan may begin

to operate at any time and continue

to operate until you disconnect the

negative battery cable.

OOS077009

■Gasoline engine The electric motor for

the cooling fan may

continue to operate

or start up when theengine is not running

and can cause serious injury.

Keep hands, clothing and tools

away from the rotating fan bladesof the cooling fan.

WARNING

Never remove the

coolant cap/radiator cap or the drain plugwhile the engine and

radiator are hot. Hot

coolant and steam may blow out

under pressure, causing serious

injury.

Turn the engine off and wait until

the engine cools down. Use

extreme care when removing the

coolant cap/radiator cap. Wrap a

thick towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

WARNING

Page 442 of 523

7-30

MaintenanceW

W IIPP EERR BB LLAA DDEESS

Blade inspection

Contamination of either the wind-

shield or the wiper blades with for-

eign matter can reduce the effective-

ness of the windshield wipers. Common sources of contamination

are insects, tree sap, and hot wax

treatments used by some commer-

cial car washes. If the blades are not

wiping properly, clean both the win-

dow and the blades with a good

cleaner or mild detergent, and rinse

thoroughly with clean water.

To prevent damage to the wiper

blades, arms or other compo-

nents, do not:

Use gasoline, kerosene, paint

thinner, or other solvents on or near them.

Attempt to move the wipers manually.

Use non-specified wiper blades.

Information

Commercial hot waxes applied by auto-

matic car washes have been known to

make the windshield difficult to clean. Information

Wiper blades are consumable item and

normal wear of the wipers may not be

covered by your vehicle warranty.

Blade replacement

When the wipers no longer clean

adequately, the blades may be worn

or cracked, and require replacement.

To prevent damage to the wiper arms

or other components, do not attempt

to move the wipers manually.

The use of a non-specified wiper

blade could result in wiper mal-

function and failure.

In order to prevent damage to the hood and the wiper arms, the

wiper arms should only be liftedwhen in the top wiping position.

Always return the wiper arms to the windshield before driving.

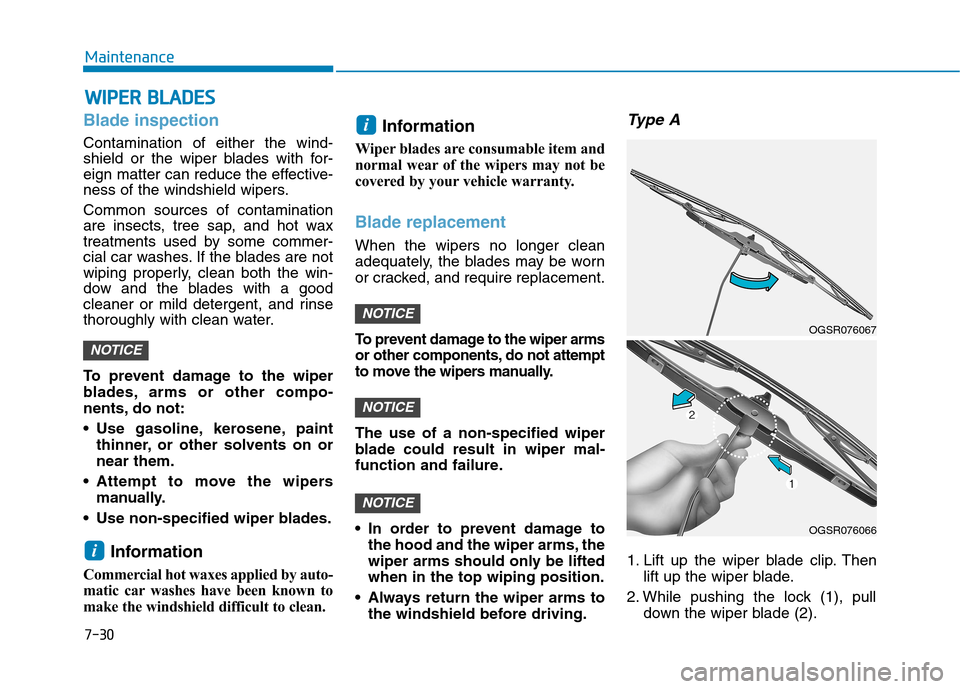

Type A

1. Lift up the wiper blade clip. Then lift up the wiper blade.

2. While pushing the lock (1), pull down the wiper blade (2).

NOTICE

NOTICE

NOTICE

i

i

NOTICE

OGSR076067

OGSR076066

Page 476 of 523

7-64

Maintenance

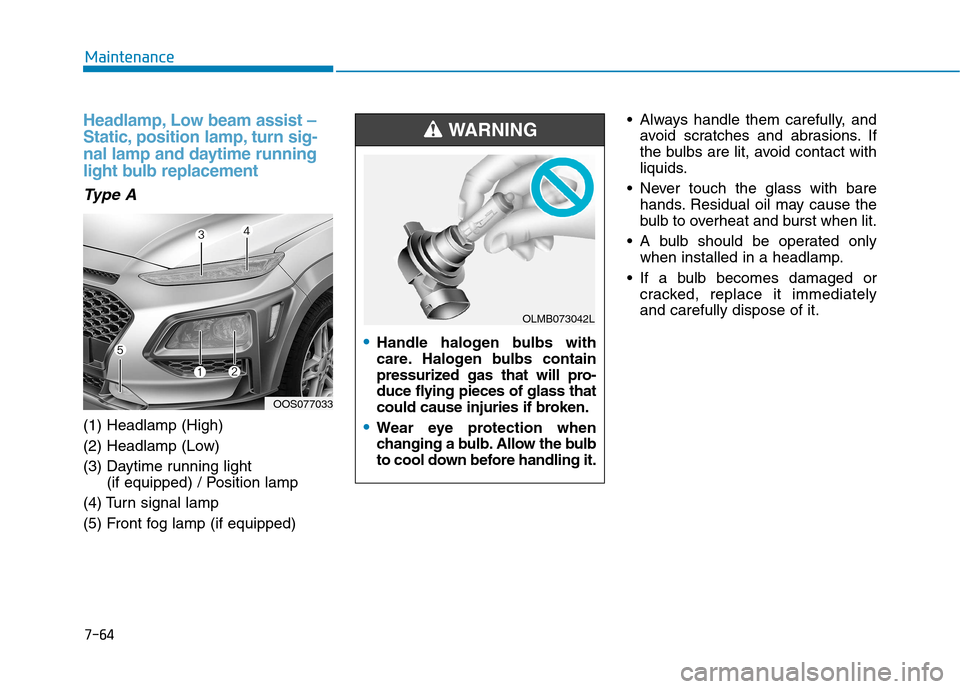

Headlamp, Low beam assist –

Static, position lamp, turn sig-

nal lamp and daytime running

light bulb replacement

Type A

(1) Headlamp (High)

(2) Headlamp (Low)

(3) Daytime running light (if equipped) / Position lamp

(4) Turn signal lamp

(5) Front fog lamp (if equipped) Always handle them carefully, and

avoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediatelyand carefully dispose of it.

OOS077033

Handle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the bulb

to cool down before handling it.

WARNING

OLMB073042L

Page 478 of 523

7-66

Maintenance

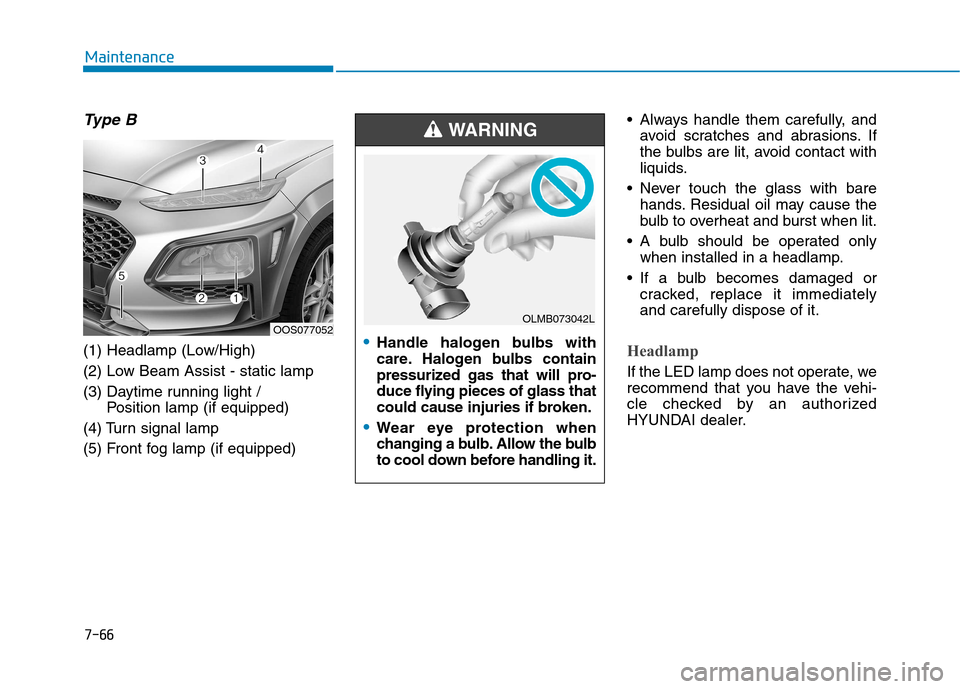

Type B

(1) Headlamp (Low/High)

(2) Low Beam Assist - static lamp

(3) Daytime running light / Position lamp (if equipped)

(4) Turn signal lamp

(5) Front fog lamp (if equipped) Always handle them carefully, and

avoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids.

Never touch the glass with bare hands. Residual oil may cause the

bulb to overheat and burst when lit.

A bulb should be operated only when installed in a headlamp.

If a bulb becomes damaged or cracked, replace it immediatelyand carefully dispose of it.Headlamp

If the LED lamp does not operate, we

recommend that you have the vehi-

cle checked by an authorized

HYUNDAI dealer.

OOS077052Handle halogen bulbs with

care. Halogen bulbs contain

pressurized gas that will pro-

duce flying pieces of glass that

could cause injuries if broken.

Wear eye protection when

changing a bulb. Allow the bulb

to cool down before handling it.

WARNING

OLMB073042L

Page 497 of 523

7-85

7

Maintenance

EEMM IISS SSIIOO NN CC OO NNTTRR OO LL SS YY SSTT EEMM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an emission control system to meet all

emission regulations. There are three emission control

systems which are as follows.

(1) Crankcase emission control sys-

tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control systemIn order to ensure the proper function

of the emission control systems, it is

recommended that you have your car

inspected and maintained by an

authorized HYUNDAI dealer in accor-dance with the maintenance schedule

in this manual.

1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

Canister

Fuel vapors generated inside the fueltank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in

the canister are drawn into the surgetank through the purge control sole-

noid valve.

Purge Control Solenoid Valve

(PCSV)

The purge control solenoid valve is

controlled by the Engine Control

Module (ECM); when the engine

coolant temperature is low during

idling, the PCSV closes so that evap-

orated fuel is not taken into the

engine. After the engine warms-up

during ordinary driving, the PCSV

opens to introduce evaporated fuel to

the engine.

For the Inspection and Maintenance

Test (with Electronic Stability Control(ESC) system)

To prevent the vehicle from

misfiring during dynamome-

ter testing, turn the Electronic

Stability Control (ESC) sys-

tem off by pressing the ESC

switch.

After dynamometer testing is

completed, turn the ESC sys-

tem back on by pressing the

ESC switch again.

CAUTION