Mount Hyundai Kona 2020 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2020, Model line: Kona, Model: Hyundai Kona 2020Pages: 505, PDF Size: 13.47 MB

Page 409 of 505

7-18

Maintenance

E

EX

X P

PL

LA

A N

N A

AT

TI

IO

O N

N

O

O F

F

S

S C

C H

H E

ED

D U

U L

LE

E D

D

M

M A

AI

IN

N T

TE

EN

N A

AN

N C

CE

E

I

IT

T E

EM

M S

S

Engine Oil and Filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the

vehicle is being driven in severe con-

ditions, more frequent oil and filter

changes are required.

Drive Belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel Filter

A clogged-up fuel filter may limit the

vehicle driving speed, damage the

emission system, and cause the

hard starting. When a considerable

amount of foreign substances are

accumulated in the fuel tank, the fuel

filter should be replaced.

Upon installing a new fuel filter, oper-

ate the engine for several minutes,

and check the connections for any

leakages. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized HYUNDAI

dealer replace any damaged or leak-

ing parts immediately.

Vapor Hose and Fuel Filler

Cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure a new vapor

hose or fuel filler cap is correctly

replaced.

Vacuum Crankcase Ventilation

Hoses (if equipped)

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to ensure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Page 411 of 505

7-20

Maintenance

Brake Hoses and Lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake Fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between the MIN and the MAX

marks on the side of the reservoir.

Use only hydraulic brake fluid con-

forming to DOT 3 or DOT 4 specifi-

cation.

Parking Brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the engine

and listen carefully for any exhaust

gas leakage. Tighten connections or

replace parts as necessary.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

engine off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 427 of 505

7-36

Maintenance

When you do not use the vehicle for a long time in a low tempera-

ture area, disconnect the battery

and keep it indoors.

Always charge the battery fully to prevent battery case damage

in low temperature areas.

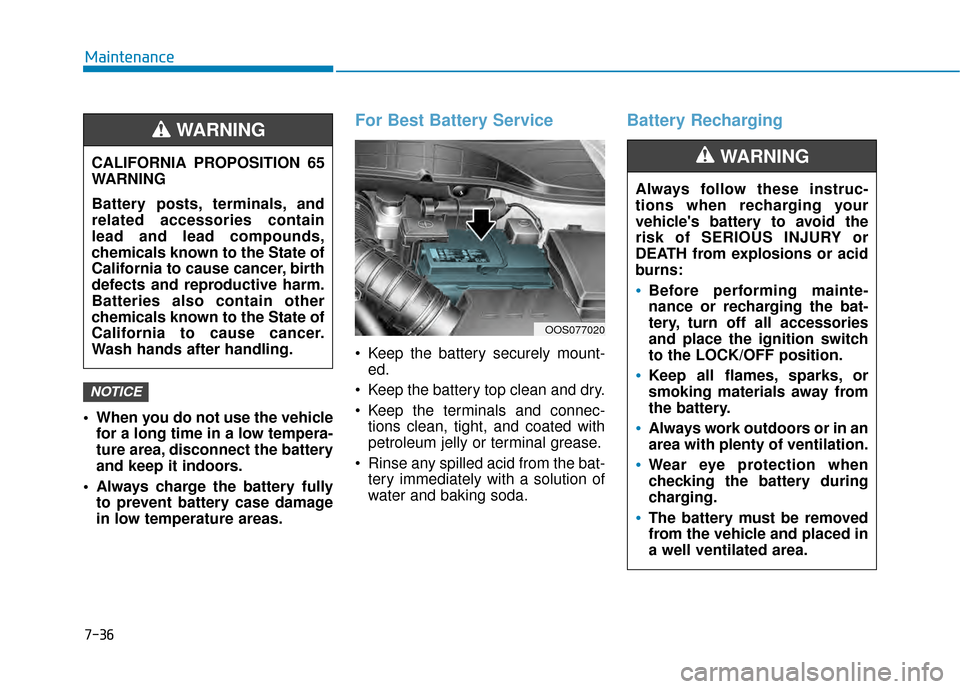

For Best Battery Service

Keep the battery securely mount-ed.

Keep the battery top clean and dry.

Keep the terminals and connec- tions clean, tight, and coated with

petroleum jelly or terminal grease.

Rinse any spilled acid from the bat- tery immediately with a solution of

water and baking soda.

Battery Recharging

NOTICE

CALIFORNIA PROPOSITION 65

WARNING

Battery posts, terminals, and

related accessories contain

lead and lead compounds,

chemicals known to the State of

California to cause cancer, birth

defects and reproductive harm.

Batteries also contain other

chemicals known to the State of

California to cause cancer.

Wash hands after handling.

WARNING

Always follow these instruc-

tions when recharging your

vehicle's battery to avoid the

risk of SERIOUS INJURY or

DEATH from explosions or acid

burns:

Before performing mainte-

nance or recharging the bat-

tery, turn off all accessories

and place the ignition switch

to the LOCK/OFF position.

Keep all flames, sparks, or

smoking materials away from

the battery.

Always work outdoors or in an

area with plenty of ventilation.

Wear eye protection when

checking the battery during

charging.

The battery must be removed

from the vehicle and placed in

a well ventilated area.

WARNING

OOS077020

Page 434 of 505

7-43

7

Maintenance

Compact spare tire replacement

A compact spare tire has a shorter

tread life than a regular size tire.

Replace it when you can see the

tread wear indicator bars on the tire.

The replacement compact spare tire

should be the same size and design

tire as the one provided with your

new vehicle and should be mounted

on the same compact spare tire

wheel. The compact spare tire is not

designed to be mounted on a regular

size wheel, and the compact spare

tire wheel is not designed for mount-

ing a regular size tire.

Wheel Replacement

When replacing the metal wheels for

any reason, make sure the new

wheels are equivalent to the original

factory units in diameter, rim width

and offset.

Tire Traction

Tire traction can be reduced if you

drive on worn tires, tires that are

improperly inflated or on slippery

road surfaces. Tires should be

replaced when the tread depth is at

least 2/32 inch (1.6 mm). To reduce

the possibility of losing control, slow

down whenever there is rain, snow or

ice on the road.

Tire Maintenance

In addition to proper inflation, correct

wheel alignment helps to decrease

tire wear. If you find a tire is worn

unevenly, have your dealer check the

wheel alignment.

When you have new tires installed,

make sure they are balanced. This

will increase vehicle ride comfort and

tire life. Additionally, a tire should

always be rebalanced if it is removed

from the wheel.

Tire Sidewall Labeling

This information identifies and

describes the fundamental charac-

teristics of the tire and also provides

the tire identification number (TIN)

for safety standard certification. The

TIN can be used to identify the tire in

case of a recall.

The original tire should be

repaired or replaced as soon as

possible to avoid failure of the

spare and loss of vehicle con-

trol resulting in an accident. The

compact spare tire is for emer-

gency use only. Do not operate

your vehicle over 50 mph (80

km/h) when using the compact

spare tire.WARNING

Page 436 of 505

7-45

7

Maintenance

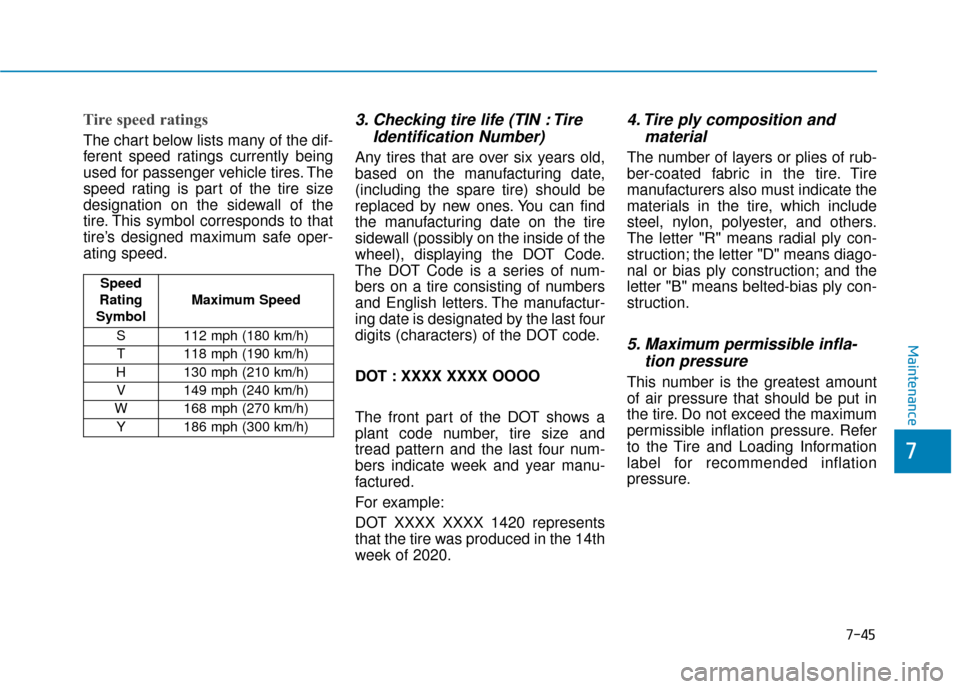

Tire speed ratings

The chart below lists many of the dif-

ferent speed ratings currently being

used for passenger vehicle tires. The

speed rating is part of the tire size

designation on the sidewall of the

tire. This symbol corresponds to that

tire’s designed maximum safe oper-

ating speed.

3. Checking tire life (TIN : TireIdentification Number)

Any tires that are over six years old,

based on the manufacturing date,

(including the spare tire) should be

replaced by new ones. You can find

the manufacturing date on the tire

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tire consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT shows a

plant code number, tire size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1420 represents

that the tire was produced in the 14th

week of 2020.

4. Tire ply composition andmaterial

The number of layers or plies of rub-

ber-coated fabric in the tire. Tire

manufacturers also must indicate the

materials in the tire, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and the

letter "B" means belted-bias ply con-

struction.

5. Maximum permissible infla-tion pressure

This number is the greatest amount

of air pressure that should be put in

the tire. Do not exceed the maximum

permissible inflation pressure. Refer

to the Tire and Loading Information

label for recommended inflation

pressure.

Speed

Rating

Symbol Maximum Speed

S 112 mph (180 km/h) T 118 mph (190 km/h)

H 130 mph (210 km/h) V 149 mph (240 km/h)

W 168 mph (270 km/h)

Y186 mph (300 km/h)

Page 438 of 505

7-47

7

Maintenance

Temperature - A, B & C

The temperature grades are A (the

highest), B and C representing the

tire’s resistance to the generation of

heat and its ability to dissipate heat

when tested under controlled condi-

tions on a specified indoor laboratory

test wheel.

Sustained high temperature can

cause the material of the tire to

degenerate and reduce tire life, and

excessive temperature can lead to

sudden tire failure. Grade C

responds to a level of performance

which all passenger car tires must

meet under the Federal Motor

Vehicle Safety Standard No. 109.

Grades B and A represent higher

levels of performance on the labora-

tory test wheel than the minimum

required by law.

Tire Terminology and

Definitions

Air Pressure

The amount of air inside the tire

pressing outward on the tire. Air

pressure is expressed in pounds per

square inch (psi) or kilopascal (kPa).

Accessory Weight

This means the combined weight of

optional accessories. Some exam-

ples of optional accessories are

automatic transmission, power

seats, and air conditioning.

Aspect Ratio

The relationship of a tire's height to

its width.

Belt

A rubber coated layer of cords that is

located between the plies and the

tread. Cords may be made from steel

or other reinforcing materials.

The temperature grade for this

tire is established for a tire that

is properly inflated and not

overloaded. Excessive speed,

under-inflation, over-inflation,

or excessive loading, either

separately or in combination,

can cause heat build-up and

possible sudden tire failure.

This may cause loss of vehicle

control resulting in an accident.

WARNING

Page 439 of 505

7-48

Maintenance

Bead

The tire bead contains steel wires

wrapped by steel cords that hold the

tire onto the rim.

Bias Ply Tire

A pneumatic tire in which the plies

are laid at alternate angles less than

90 degrees to the centerline of the

tread.

Cold Tire Pressure

The amount of air pressure in a tire,

measured in pounds per square inch

(psi) or kilopascals (kPa) before a tire

has built up heat from driving.

Curb Weight

This means the weight of a motor

vehicle with standard and optional

equipment including the maximum

capacity of fuel, oil and coolant, but

without passengers and cargo.

DOT Markings

A code molded into the sidewall of a

tire signifying that the tire is in com-

pliance with the U.S. Department of

Transportation motor vehicle safety

standards. The DOT code includes

the Tire Identification Number (TIN),

an alphanumeric designator which

can also identify the tire manufactur-

er, production plant, brand and date

of production.

GVWR

Gross Vehicle Weight Rating

GAWR FRT

Gross Axle Weight Rating for the

Front Axle.

GAWR RR

Gross Axle Weight Rating for the

Rear axle.

Intended Outboard Sidewall

The side of an asymmetrical tire, that

must always face outward when

mounted on a vehicle.

Kilopascal (kPa)

The metric unit for air pressure.

Light truck(LT) tire

A tire designated by its manufacturer

as primarily intended for use on light-

weight trucks or multipurpose pas-

senger vehicles.

Load ratings

The maximum load that a tire is rated

to carry for a given inflation pressure.

Load Index

An assigned number ranging from 1

to 279 that corresponds to the load

carrying capacity of a tire.

Maximum Inflation Pressure

The maximum air pressure to which

a cold tire may be inflated. The max-

imum air pressure is molded onto the

sidewall.

Page 440 of 505

7-49

7

Maintenance

Maximum Load Rating

The load rating for a tire at the maxi-

mum permissible inflation pressure

for that tire.

Maximum Loaded VehicleWeight

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight

The number of occupants a vehicle

is designed to seat multiplied by 150

pounds (68 kg).

Occupant Distribution

Designated seating positions.

Outward Facing Sidewall

An asymmetrical tire has a particular

side that faces outward when mount-

ed on a vehicle. The outward facing

sidewall bears white lettering or

bears manufacturer, brand, and/or

model name molding that is higher or

deeper than the same moldings on

the inner facing sidewall.

Passenger (P-Metric) tire

A tire used on passenger cars and

some light duty trucks and multipur-

pose vehicles.

Ply

A layer of rubber-coated parallel

cords.

Pneumatic tire

A mechanical device made of rubber,

chemicals, fabric and steel or other

materials, that, when mounted on an

automotive wheel provides the trac-

tion and contains the gas or fluid that

sustains the load.

Pneumatic options weight

The combined weight of installed

regular production options weighing

over 5 lb. (2.3 kg) in excess of the

standard items which they replace,

not previously considered in curb

weight or accessory weight, includ-

ing heavy duty breaks, ride levelers,

roof rack, heavy duty battery, and

special trim.

Recommended InflationPressure

Vehicle manufacturer's recommend-

ed tire inflation pressure as shown

on the tire placard.

Radial Ply Tire

A pneumatic tire in which the ply

cords that extend to the beads are

laid at 90 degrees to the centerline of

the tread.

Rim

A metal support for a tire and upon

which the tire beads are seated.

Sidewall

The portion of a tire between the

tread and the bead.

Speed Rating

An alphanumeric code assigned to a

tire indicating the maximum speed at

which a tire can operate.

Page 441 of 505

7-50

Maintenance

Traction

The friction between the tire and the

road surface. The amount of grip pro-

vided.

Tread

The portion of a tire that comes into

contact with the road.

Treadwear Indicators

Narrow bands, sometimes called

"wear bars", that show across the

tread of a tire when only 1/16 inch of

tread remains.

UTQGS

Uniform Tire Quality Grading

Standards is a tire information sys-

tem that provides consumers with

ratings for a tire's traction, tempera-

ture and treadwear. Ratings are

determined by tire manufacturers

using government testing proce-

dures. The ratings are molded into

the sidewall of the tire.

Vehicle Capacity Weight

The number of designated seating

positions multiplied by 150 lbs. (68

kg) plus the rated cargo and luggage

load.

Vehicle Maximum Load on theTire

Load on an individual tire due to curb

and accessory weight plus maximum

occupant and cargo weight.

Vehicle Normal Load on the Tire

Load on an individual tire that is

determined by distributing to each

axle its share of the curb weight,

accessory weight, and normal occu-

pant weight and dividing by 2.

Vehicle Placard

A label permanently attached to a

vehicle showing the original equip-

ment tire size and recommended

inflation pressure.

All Season Tires

HYUNDAI specifies all season tires

on some models to provide good

performance for use all year round,

including snowy and icy road condi-

tions. All season tires are identified

by ALL SEASON and/or M+S (Mud

and Snow) on the tire sidewall. Snow

tires have better snow traction than

all season tires and may be more

appropriate in some areas.

Summer Tires

HYUNDAI specifies summer tires on

some models to provide superior

performance on dry roads. Summer

tire performance is substantially

reduced in snow and ice. Summer

tires do not have the tire traction rat-

ing M+S (Mud and Snow) on the tire

side wall. If you plan to operate your

vehicle in snowy or icy conditions,

HYUNDAI recommends the use of

snow tires or all season tires on all

four wheels.

Page 468 of 505

7-77

7

Maintenance

Tail / Stop lamp (Type B)

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAi

dealer.

Turn signal lamp / Back up lamp

If the light bulb does not operate,

have the vehicle checked by an

authorized HYUNDAI dealer.

Side marker

Your vehicle is equipped with LED

lamps. LED lamps do not have

replaceable bulbs. If the LED lamp

does not operate, have the vehicle

checked by an authorized HYUNDAI

dealer.

High Mounted Stop Lamp

Replacement

1. Open the liftgate.

2. Gently remove the cover of the lift-gate trim.

3. Remove the spoiler plug hole.

4. Disconnect the connector and remove the washer hose and the

plug holes.

5. Remove the mounting nuts.

6. Remove the rear spoiler assembly. 7. Remove the high mounted stop

lamp after removing the mounting

nuts.

8. Install a new lamp

9. Reinstall the rear spoiler and the liftgate upper trim in the reverse

order.

OOS077042