light Hyundai Matrix 2004 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2004, Model line: Matrix, Model: Hyundai Matrix 2004Pages: 317, PDF Size: 5.12 MB

Page 288 of 317

OWNER MAINTENANCE

6-10

SSA6062A

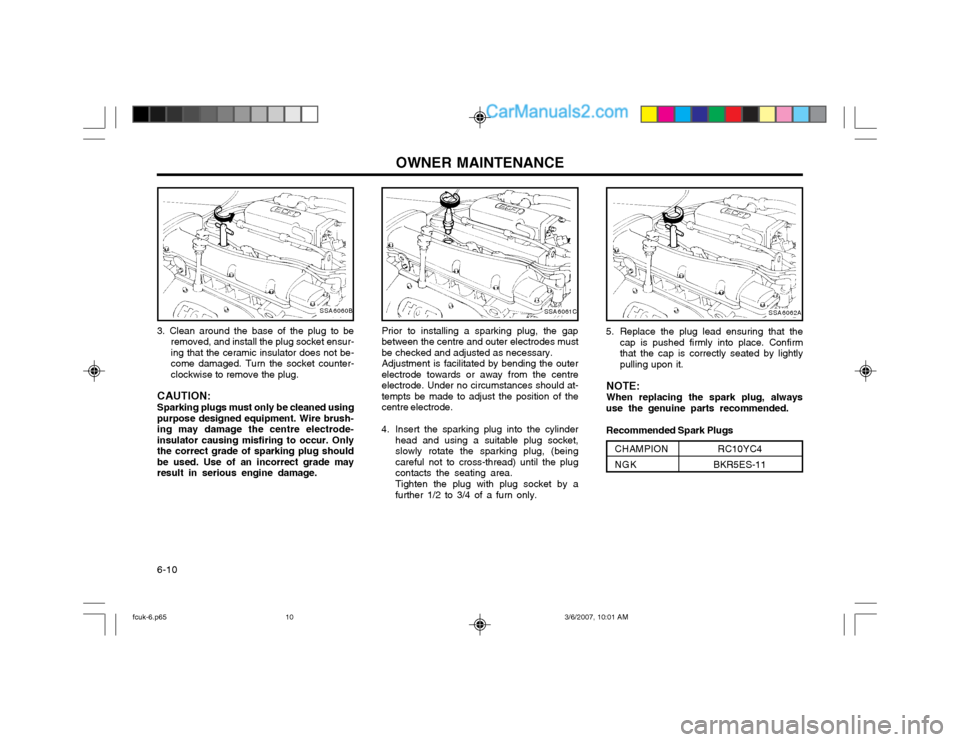

5. Replace the plug lead ensuring that the cap is pushed firmly into place. Confirm that the cap is correctly seated by lightlypulling upon it.

NOTE:When replacing the spark plug, always

use the genuine parts recommended.

Recommended Spark Plugs

RC10YC4

BKR5ES-11

NGK

CHAMPION

SSA6061CSSA6060B

Prior to installing a sparking plug, the gap between the centre and outer electrodes mustbe checked and adjusted as necessary.Adjustment is facilitated by bending the outerelectrode towards or away from the centreelectrode. Under no circumstances should at-tempts be made to adjust the position of thecentre electrode.

4. Insert the sparking plug into the cylinder head and using a suitable plug socket,slowly rotate the sparking plug, (beingcareful not to cross-thread) until the plugcontacts the seating area. Tighten the plug with plug socket by a further 1/2 to 3/4 of a furn only.

3. Clean around the base of the plug to be

removed, and install the plug socket ensur-ing that the ceramic insulator does not be-come damaged. Turn the socket counter-clockwise to remove the plug.

CAUTION: Sparking plugs must only be cleaned using

purpose designed equipment. Wire brush- ing may damage the centre electrode-insulator causing misfiring to occur. Onlythe correct grade of sparking plug shouldbe used. Use of an incorrect grade mayresult in serious engine damage.

fcuk-6.p65 3/6/2007, 10:01 AM

10

Page 292 of 317

OWNER MAINTENANCE

6-14 SG120D1-E

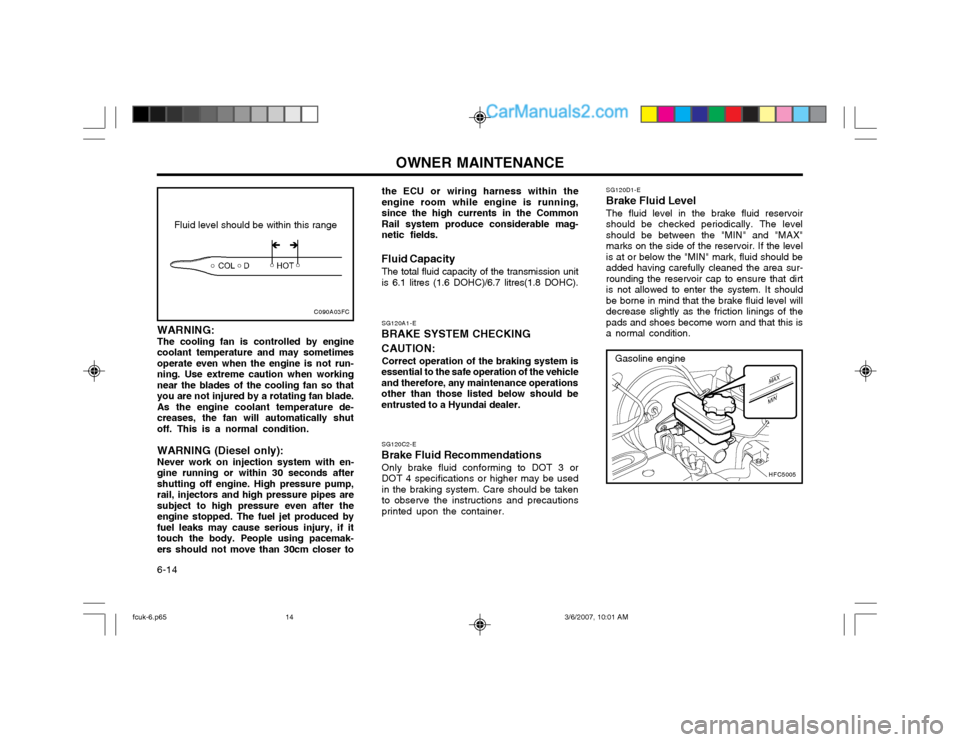

Brake Fluid Level

The fluid level in the brake fluid reservoir should be checked periodically. The levelshould be between the "MIN" and "MAX"marks on the side of the reservoir. If the levelis at or below the "MIN" mark, fluid should beadded having carefully cleaned the area sur-rounding the reservoir cap to ensure that dirtis not allowed to enter the system. It shouldbe borne in mind that the brake fluid level willdecrease slightly as the friction linings of thepads and shoes become worn and that this isa normal condition.

SG120A1-E

BRAKE SYSTEM CHECKING CAUTION: Correct operation of the braking system is

essential to the safe operation of the vehicle and therefore, any maintenance operationsother than those listed below should beentrusted to a Hyundai dealer.

SG120C2-E

Brake Fluid Recommendations Only brake fluid conforming to DOT 3 orDOT 4 specifications or higher may be usedin the braking system. Care should be takento observe the instructions and precautionsprinted upon the container.

HFC5005

Gasoline engine

the ECU or wiring harness within the engine room while engine is running,since the high currents in the CommonRail system produce considerable mag-netic fields.

Fluid Capacity The total fluid capacity of the transmission unitis 6.1 litres (1.6 DOHC)/6.7 litres(1.8 DOHC).

Fluid level should be within this range

C090A03FC

�Î�Î

WARNING: The cooling fan is controlled by engine

coolant temperature and may sometimes operate even when the engine is not run-ning. Use extreme caution when workingnear the blades of the cooling fan so thatyou are not injured by a rotating fan blade.As the engine coolant temperature de-creases, the fan will automatically shutoff. This is a normal condition.

WARNING (Diesel only): Never work on injection system with en-

gine running or within 30 seconds after shutting off engine. High pressure pump,rail, injectors and high pressure pipes aresubject to high pressure even after theengine stopped. The fuel jet produced byfuel leaks may cause serious injury, if ittouch the body. People using pacemak-ers should not move than 30cm closer to

fcuk-6.p65 3/6/2007, 10:01 AM

14

Page 296 of 317

OWNER MAINTENANCE

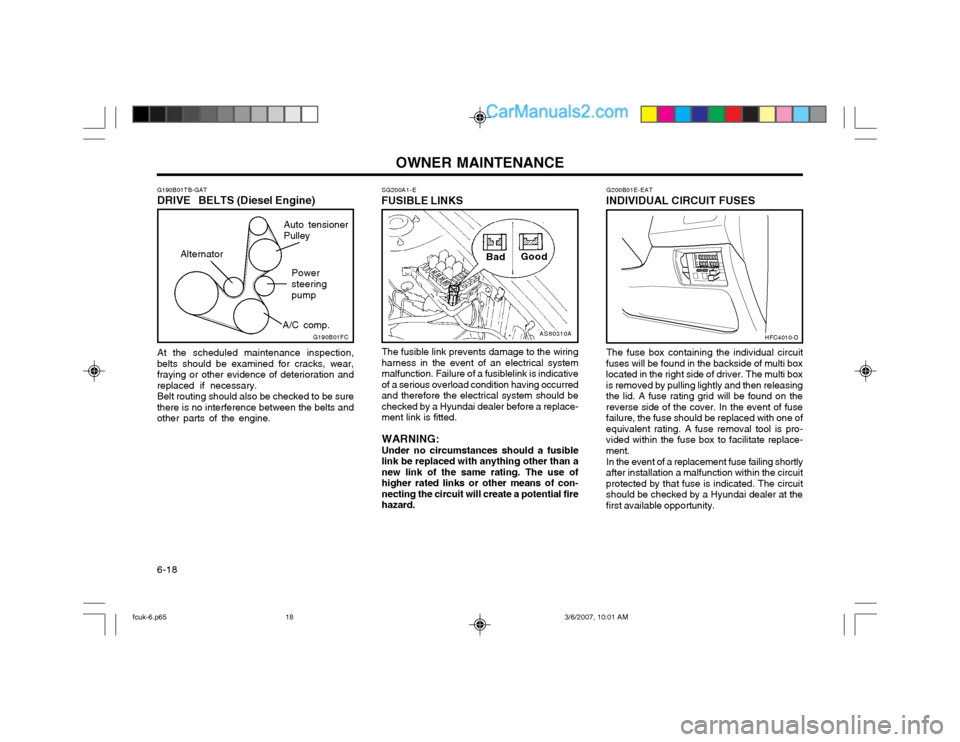

6-18 G200B01E-EAT

INDIVIDUAL CIRCUIT FUSES

The fuse box containing the individual circuit

fuses will be found in the backside of multi box located in the right side of driver. The multi boxis removed by pulling lightly and then releasingthe lid. A fuse rating grid will be found on thereverse side of the cover. In the event of fusefailure, the fuse should be replaced with one ofequivalent rating. A fuse removal tool is pro-vided within the fuse box to facilitate replace-ment.

In the event of a replacement fuse failing shortly

after installation a malfunction within the circuitprotected by that fuse is indicated. The circuitshould be checked by a Hyundai dealer at thefirst available opportunity.

HFC4010-D

SG200A1-E

FUSIBLE LINKSAS60310A

Bad

Good

The fusible link prevents damage to the wiring harness in the event of an electrical systemmalfunction. Failure of a fusiblelink is indicativeof a serious overload condition having occurredand therefore the electrical system should bechecked by a Hyundai dealer before a replace-ment link is fitted. WARNING: Under no circumstances should a fusible link be replaced with anything other than anew link of the same rating. The use ofhigher rated links or other means of con-necting the circuit will create a potential firehazard.

G190B01TB-GAT DRIVE BELTS (Diesel Engine)

At the scheduled maintenance inspection,

belts should be examined for cracks, wear, fraying or other evidence of deterioration andreplaced if necessary. Belt routing should also be checked to be sure

there is no interference between the belts andother parts of the engine.G190B01FC

Auto tensioner Pulley

Powersteeringpump

A/C comp.

Alternator

fcuk-6.p65

3/6/2007, 10:01 AM

18

Page 297 of 317

OWNER MAINTENANCE 6-19

AXA6201B

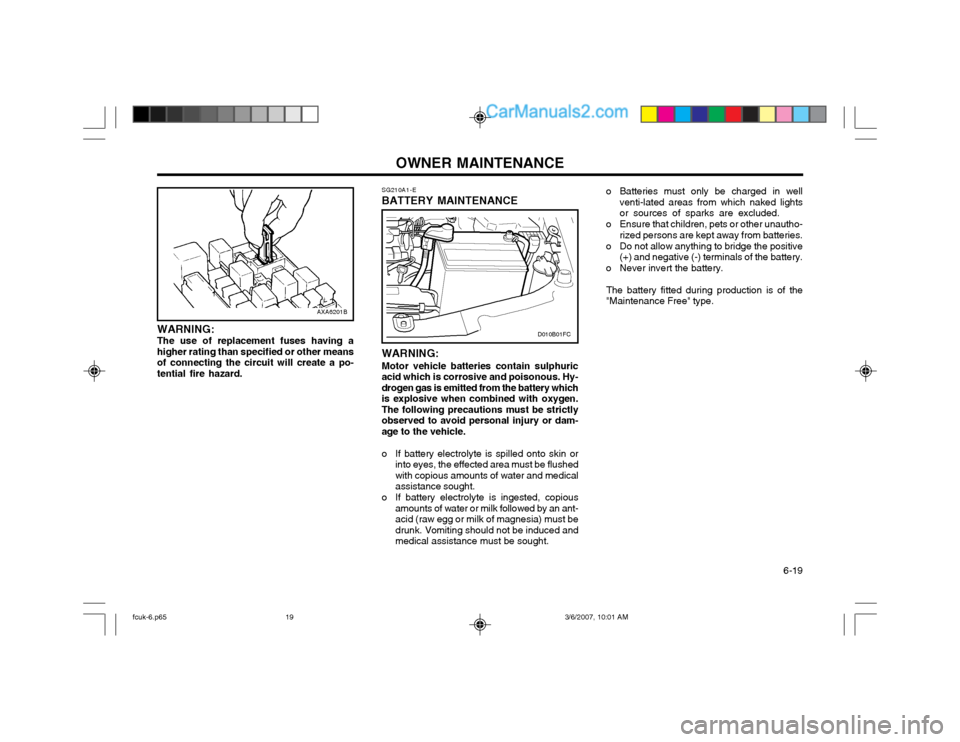

WARNING: The use of replacement fuses having a higher rating than specified or other meansof connecting the circuit will create a po-tential fire hazard. SG210A1-E

BATTERY MAINTENANCE

D010B01FC

WARNING:

Motor vehicle batteries contain sulphuric

acid which is corrosive and poisonous. Hy- drogen gas is emitted from the battery whichis explosive when combined with oxygen.The following precautions must be strictlyobserved to avoid personal injury or dam-age to the vehicle.

o If battery electrolyte is spilled onto skin or

into eyes, the effected area must be flushed with copious amounts of water and medicalassistance sought.

o If battery electrolyte is ingested, copious amounts of water or milk followed by an ant-acid (raw egg or milk of magnesia) must bedrunk. Vomiting should not be induced andmedical assistance must be sought. o Batteries must only be charged in well

venti-lated areas from which naked lightsor sources of sparks are excluded.

o Ensure that children, pets or other unautho- rized persons are kept away from batteries.

o Do not allow anything to bridge the positive (+) and negative (-) terminals of the battery.

o Never invert the battery.

The battery fitted during production is of the

"Maintenance Free" type.

fcuk-6.p65 3/6/2007, 10:01 AM

19

Page 299 of 317

OWNER MAINTENANCE 6-21

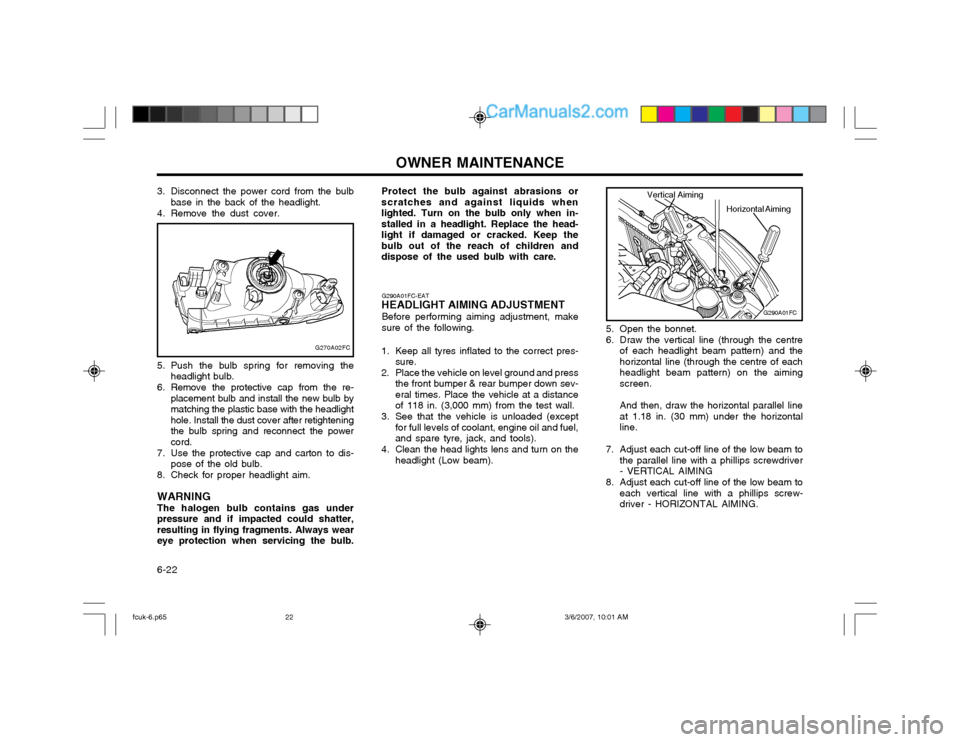

G270A02A-GAT

HEADLIGHT BULB Replacement instructions:

G270A01FC

1. Allow the bulb to cool. Wear eye protection.

2. Always grasp the bulb by its plastic base, avoid touching the glass.

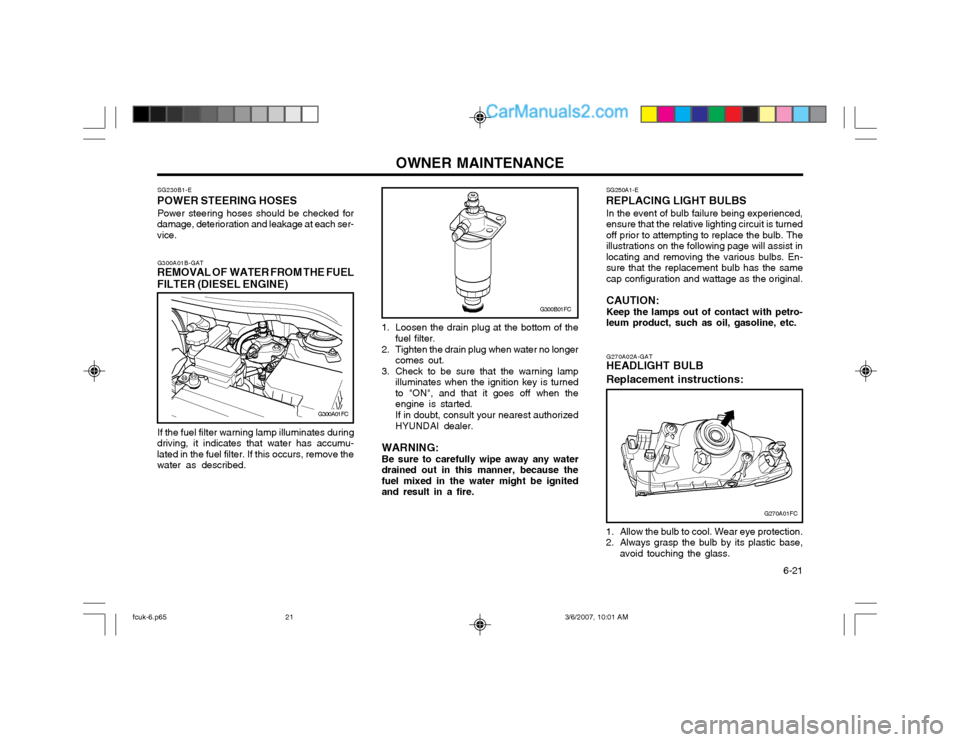

1. Loosen the drain plug at the bottom of thefuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when theengine is started. If in doubt, consult your nearest authorized HYUNDAI dealer.

WARNING: Be sure to carefully wipe away any water

drained out in this manner, because thefuel mixed in the water might be ignitedand result in a fire.

G300B01FC

SG250A1-E

REPLACING LIGHT BULBS

In the event of bulb failure being experienced, ensure that the relative lighting circuit is turnedoff prior to attempting to replace the bulb. Theillustrations on the following page will assist inlocating and removing the various bulbs. En-sure that the replacement bulb has the samecap configuration and wattage as the original. CAUTION: Keep the lamps out of contact with petro- leum product, such as oil, gasoline, etc.

G300A01B-GAT

REMOVAL OF WATER FROM THE FUEL FILTER (DIESEL ENGINE)

If the fuel filter warning lamp illuminates during

driving, it indicates that water has accumu- lated in the fuel filter. If this occurs, remove thewater as described.

G300A01FC

SG230B1-E

POWER STEERING HOSES

Power steering hoses should be checked for

damage, deterioration and leakage at each ser- vice.

fcuk-6.p65 3/6/2007, 10:01 AM

21

Page 300 of 317

OWNER MAINTENANCE

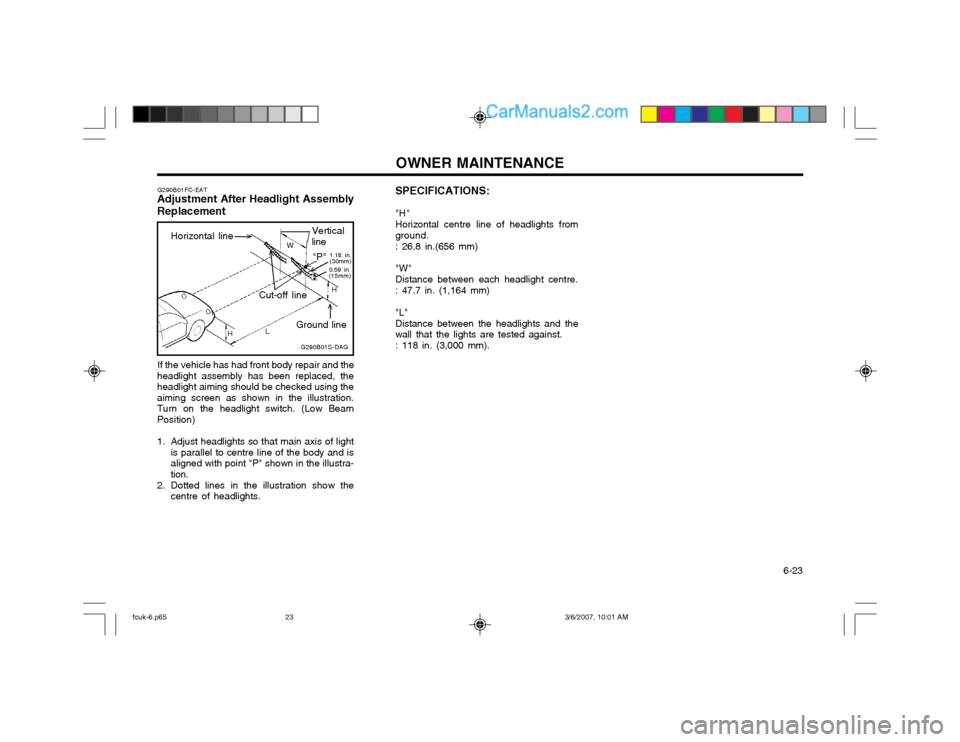

6-22 5. Open the bonnet.

6. Draw the vertical line (through the centre

of each headlight beam pattern) and the horizontal line (through the centre of eachheadlight beam pattern) on the aimingscreen. And then, draw the horizontal parallel line at 1.18 in. (30 mm) under the horizontalline.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips screwdriver- VERTICAL AIMING

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screw-driver - HORIZONTAL AIMING.

G290A01FC-EAT

HEADLIGHT AIMING ADJUSTMENT

Before performing aiming adjustment, makesure of the following.

1. Keep all tyres inflated to the correct pres- sure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down sev-eral times. Place the vehicle at a distanceof 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine oil and fuel,and spare tyre, jack, and tools).

4. Clean the head lights lens and turn on the headlight (Low beam).

G290A01FC

Horizontal Aiming

Vertical Aiming

Protect the bulb against abrasions or scratches and against liquids whenlighted. Turn on the bulb only when in-stalled in a headlight. Replace the head-light if damaged or cracked. Keep thebulb out of the reach of children anddispose of the used bulb with care.

5. Push the bulb spring for removing the headlight bulb.

6. Remove the protective cap from the re- placement bulb and install the new bulb bymatching the plastic base with the headlighthole. Install the dust cover after retighteningthe bulb spring and reconnect the powercord.

7. Use the protective cap and carton to dis- pose of the old bulb.

8. Check for proper headlight aim. WARNING The halogen bulb contains gas under pressure and if impacted could shatter,resulting in flying fragments. Always weareye protection when servicing the bulb.

G270A02FC

3. Disconnect the power cord from the bulb base in the back of the headlight.

4. Remove the dust cover.

fcuk-6.p65 3/6/2007, 10:01 AM

22

Page 301 of 317

OWNER MAINTENANCE 6-23

SPECIFICATIONS: "H" Horizontal centre line of headlights from ground. : 26.8 in.(656 mm) "W" Distance between each headlight centre.: 47.7 in. (1,164 mm) "L" Distance between the headlights and thewall that the lights are tested against. : 118 in. (3,000 mm).

G290B01FC-EAT

Adjustment After Headlight Assembly Replacement

Horizontal line

If the vehicle has had front body repair and the

headlight assembly has been replaced, the headlight aiming should be checked using theaiming screen as shown in the illustration.Turn on the headlight switch. (Low BeamPosition)

1. Adjust headlights so that main axis of light is parallel to centre line of the body and is aligned with point "P" shown in the illustra-tion.

2. Dotted lines in the illustration show the centre of headlights. G290B01S-DAGVertical line

W

0.59 in. (15mm)"P" 1.18 in. (30mm)

Cut-off line

Ground line H

H L

fcuk-6.p65

3/6/2007, 10:01 AM

23

Page 302 of 317

OWNER MAINTENANCE

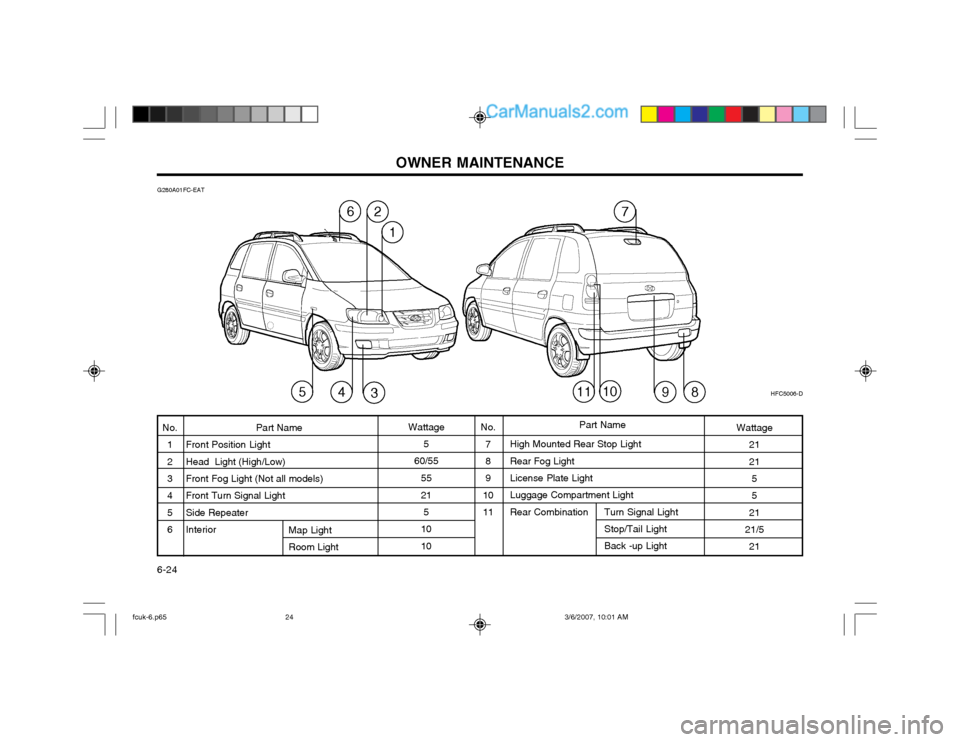

6-24 High Mounted Rear Stop Light Rear Fog Light License Plate Light Luggage Compartment Light

Rear Combination Turn Signal Light

Stop/Tail LightBack -up Light

Part Name

Front Position LightHead Light (High/Low)Front Fog Light (Not all models) Front Turn Signal Light Side RepeaterInterior No.

7 8 9

10 11

G280A01FC-EAT

Wattage5

60/55

55

21 5

10 10

No. 1 23 4 56Wattage 21 21

5 5

21

21/5 21

Map Light Room Light Part Name

HFC5006-D

67

45910118

2

1

3

fcuk-6.p65

3/6/2007, 10:01 AM

24

Page 305 of 317

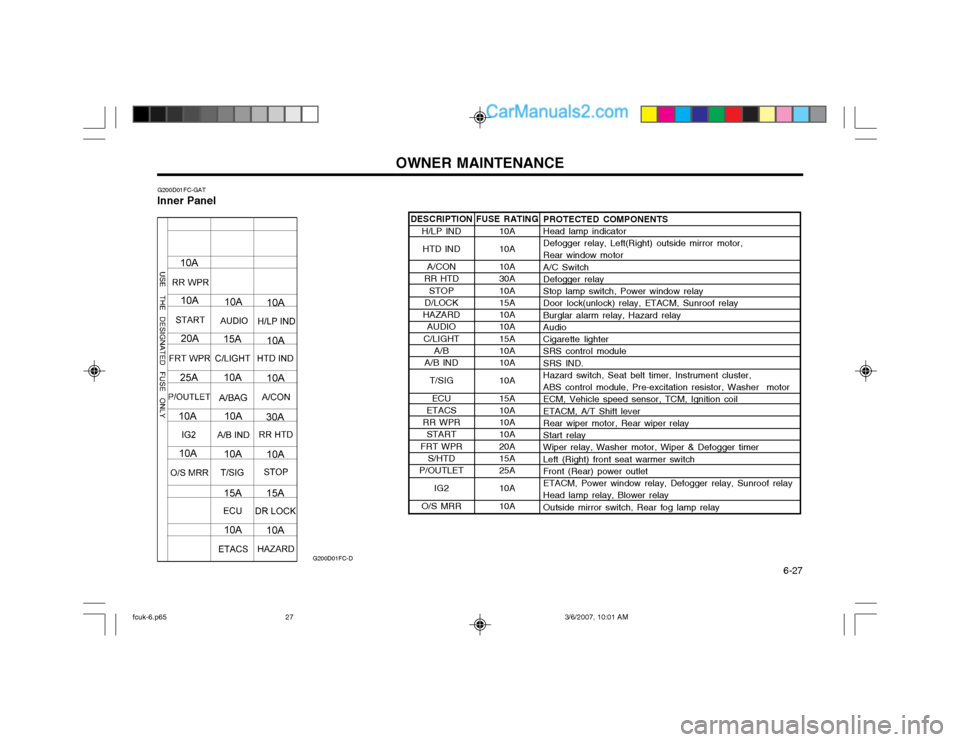

OWNER MAINTENANCE 6-27

DESCRIPTION

H/LP IND

HTD IND

A/CON

RR HTD

STOP

D/LOCK

HAZARD AUDIO

C/LIGHT A/B

A/B IND

T/SIG

ECU

ETACS

RR WPR START

FRT WPR S/HTD

P/OUTLET

IG2

O/S MRR

G200D01FC-GAT

Inner Panel

G200D01FC-D

PROTECTED COMPONENTS Head lamp indicator Defogger relay, Left(Right) outside mirror motor, Rear window motor A/C Switch Defogger relay Stop lamp switch, Power window relay Door lock(unlock) relay, ETACM, Sunroof relay Burglar alarm relay, Hazard relay Audio Cigarette lighter SRS control module SRS IND. Hazard switch, Seat belt timer, Instrument cluster, ABS control module, Pre-excitation resistor, Washer motor ECM, Vehicle speed sensor, TCM, Ignition coil ETACM, A/T Shift lever Rear wiper motor, Rear wiper relay Start relay Wiper relay, Washer motor, Wiper & Defogger timer Left (Right) front seat warmer switch Front (Rear) power outlet ETACM, Power window relay, Defogger relay, Sunroof relay Head lamp relay, Blower relay Outside mirror switch, Rear fog lamp relay

FUSE RATING

10A 10A 10A 30A 10A 15A 10A 10A 15A 10A 10A 10A 15A 10A 10A 10A 20A 15A 25A 10A 10A

fcuk-6.p65 3/6/2007, 10:01 AM

27

Page 314 of 317

INDEX10-1

A

ACCESSORY TRAY ..

...................................................................... 1-48

AIR CONDITIONING SWITCH ........................................................ 1-57

AIR CONDITIONING SYSTEM MAINTENANCE ........................... 6-16

AIR CLEANER ELEMENT REPLACEMENT .................................. 6-11

ANTENNA ......................................................................................... 1-62

ANTI-THEFT ALARM SYSTEM .............................................. 1-5 ~ 1-7

AUTO FUEL CUT SWITCH ............................................................. 1-51

AUTOMATIC TRANSAXLE ..................................................... 2-6 ~ 2-9

AUTOMATIC TRANSAXLE FLUID ..................................... 6-12 ~ 6-13

BBATTERY MAINTENANCE ............................................................. 6-19

BEFORE STARTING THE ENGINE ................................................. 2-2

BONNET RELEASE ......................................................................... 1-49

BRAKE PEDAL FREEPLAY ..................... ....................................... 6-17

BRAKE TRACTION CONTROL SYSTEM ...................................... 2-10

BRAKE SYSTEM CHECKING ........................................................ 6-14 CCARE OF SEAT

BELTS ................................................................. 1-14

CARGO AREA COVER ................................................................... 1-51

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............. 7-1

CENTRE VENTILATOR ................................................................... 1-53

CENTRAL DOOR LOCKS ................................................................. 1-5

CHANGING A FLAT TYRE . .............................................................. 3-4

CHECKING THE CLUTCH FLUID .................................................. 6-15

CHILD-PROOF REAR DOOR LOCK ................................................ 1-4

CHILD RESTRAINT SYSTEM ............................................. 1-16 ~ 1-20

CIGAR LIGHTER ............................................................................. 1-40

CLUTCH PEDAL FREEPLAY ......................................................... 6-17

COMBINATION IGNITION SWITCH AND STEERING LOCK ........ 2-2

COOLANT TEMPERATURE GAUG E ............................................. 1-33

DDAILY OPERATING CHECKS .......................................................... 6-4

DIGITAL CLOCK .............................................................................. 1-40

DOOR LOCKS ................................................................................... 1-3

DOOR WINDOWS ............................................................................. 1-7

DRINK HOLDER .............................................................................. 1-41

DRIVE BELTS .................................................................................. 6-17

DRIVING FOR ECONOMY ............................................................. 2-11

JK000A1-A 10. INDEX

10

fcuk-10.p65

3/6/2007, 10:03 AM

1