air filter Hyundai Matrix 2007 Owner's Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2007, Model line: Matrix, Model: Hyundai Matrix 2007Pages: 490, PDF Size: 12.81 MB

Page 430 of 490

6 OWNER MAINTENANCE

2

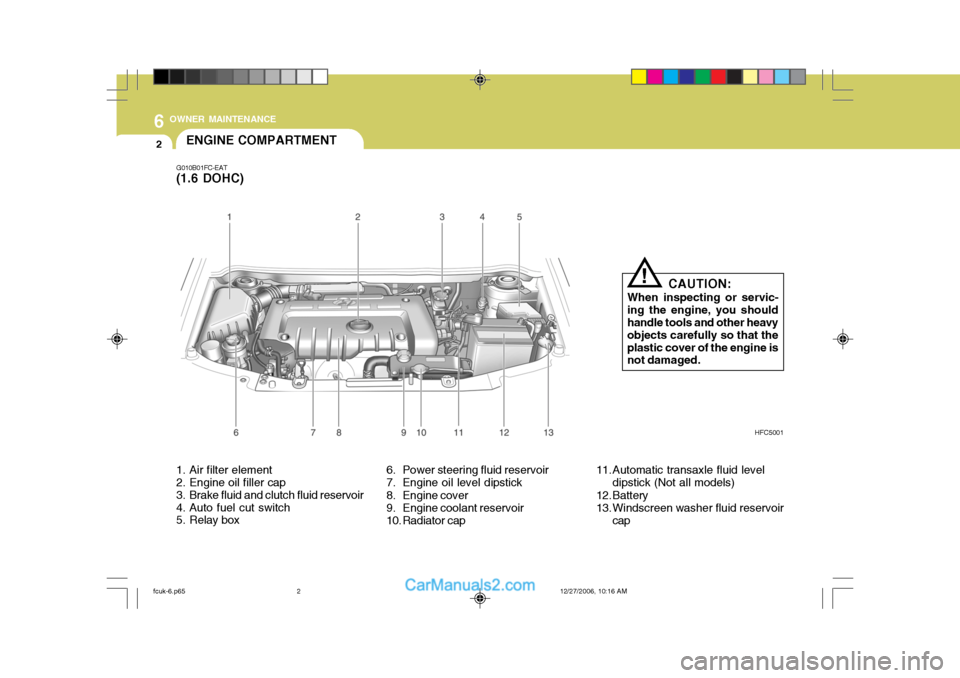

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap HFC5001

G010B01FC-EAT (1.6 DOHC)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavy objects carefully so that theplastic cover of the engine is not damaged.

!

ENGINE COMPARTMENT

fcuk-6.p65

12/27/2006, 10:16 AM

2

Page 431 of 490

6

OWNER MAINTENANCE

3

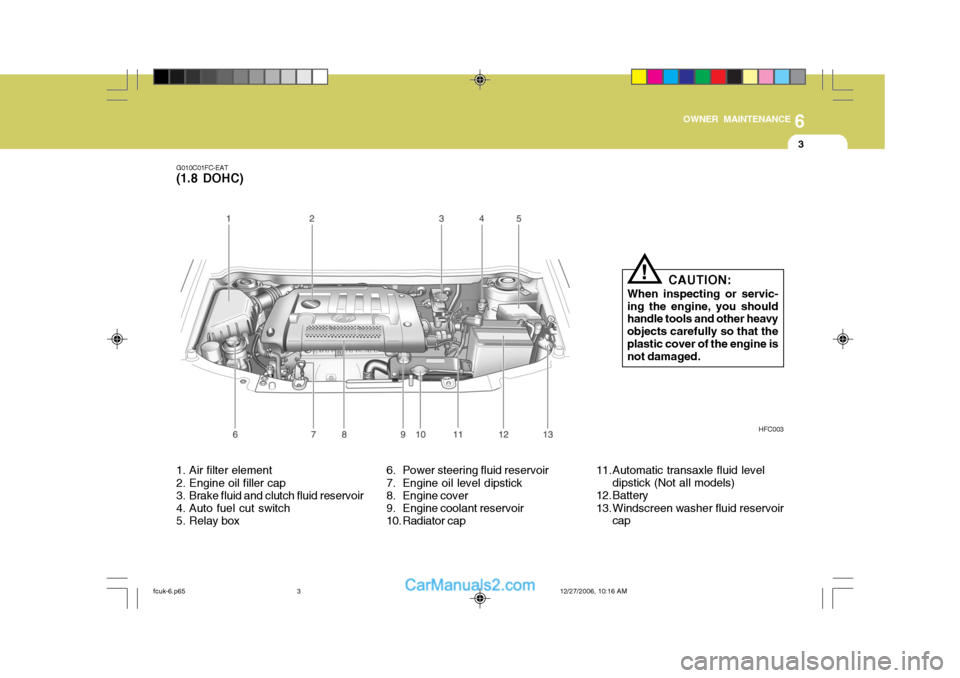

G010C01FC-EAT

(1.8 DOHC)

HFC003

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Auto fuel cut switch

5. Relay box 6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine cover

9. Engine coolant reservoir

10. Radiator cap11. Automatic transaxle fluid level

dipstick (Not all models)

12. Battery

13. Windscreen washer fluid reservoir cap CAUTION:

When inspecting or servic- ing the engine, you should handle tools and other heavy objects carefully so that the plastic cover of the engine is not damaged.

!

fcuk-6.p65 12/27/2006, 10:16 AM

3

Page 432 of 490

6 OWNER MAINTENANCE

4

1. Air filter element

2. Engine oil filler cap

3. Brake fluid and clutch fluid reservoir

4. Fuel filter 5. Relay box

6. Power steering fluid reservoir

7. Engine oil level dipstick

8. Engine coolant reservoir G010E02FC

G010E02FC-EAT

Diesel (1.5 CRDi)

CAUTION:

When inspecting or servic-

ing the engine, you should handle tools and other heavyobjects carefully so that the plastic cover of the engine is not damaged.

!

9. Radiator cap

10. Battery

11. Windscreen washer fluid reservoir

cap

fcuk-6.p65 12/27/2006, 10:16 AM

4

Page 439 of 490

6

OWNER MAINTENANCE

11

!

!

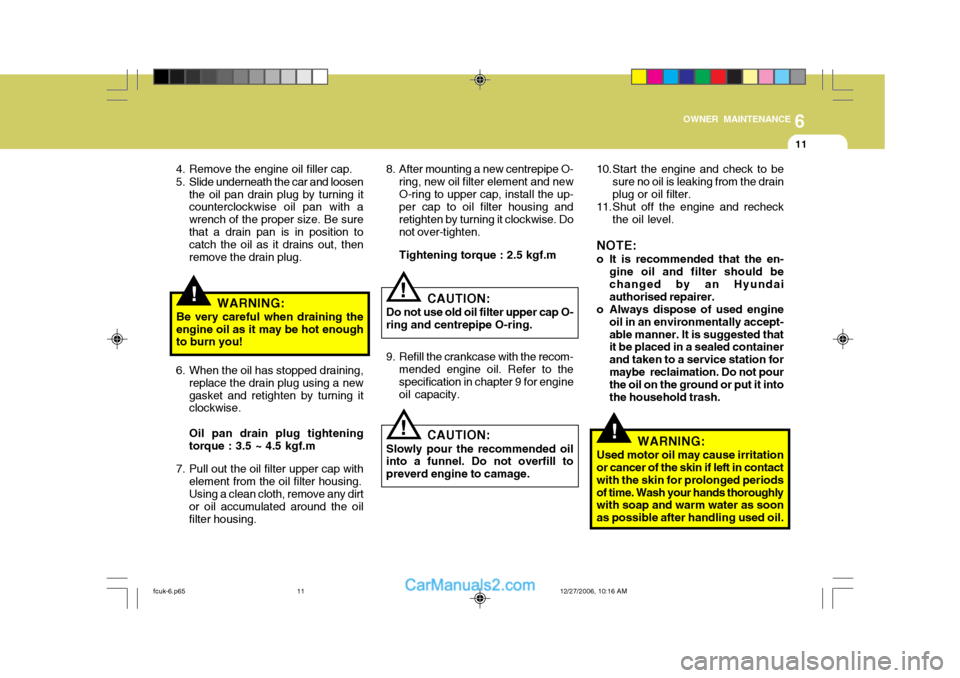

4. Remove the engine oil filler cap.

5. Slide underneath the car and loosen

the oil pan drain plug by turning it counterclockwise oil pan with a wrench of the proper size. Be surethat a drain pan is in position to catch the oil as it drains out, then remove the drain plug.

WARNING:

Be very careful when draining theengine oil as it may be hot enough to burn you!

6. When the oil has stopped draining, replace the drain plug using a new gasket and retighten by turning it clockwise. Oil pan drain plug tightening torque : 3.5 ~ 4.5 kgf.m

7. Pull out the oil filter upper cap with element from the oil filter housing.Using a clean cloth, remove any dirtor oil accumulated around the oilfilter housing. 8. After mounting a new centrepipe O-

ring, new oil filter element and newO-ring to upper cap, install the up- per cap to oil filter housing and retighten by turning it clockwise. Donot over-tighten. Tightening torque : 2.5 kgf.m

CAUTION:

Do not use old oil filter upper cap O- ring and centrepipe O-ring.

!

9. Refill the crankcase with the recom- mended engine oil. Refer to the specification in chapter 9 for engine oil capacity.

CAUTION:

Slowly pour the recommended oilinto a funnel. Do not overfill to preverd engine to camage.

! 10. Start the engine and check to be

sure no oil is leaking from the drain plug or oil filter.

11. Shut off the engine and recheck

the oil level.

NOTE:

o It is recommended that the en- gine oil and filter should be changed by an Hyundai authorised repairer.

o Always dispose of used engine oil in an environmentally accept-able manner. It is suggested that it be placed in a sealed container and taken to a service station formaybe reclaimation. Do not pour the oil on the ground or put it into the household trash.

WARNING:

Used motor oil may cause irritation or cancer of the skin if left in contact with the skin for prolonged periodsof time. Wash your hands thoroughly with soap and warm water as soon as possible after handling used oil.

fcuk-6.p65 12/27/2006, 10:16 AM

11

Page 453 of 490

6

OWNER MAINTENANCE

25

SG140B1-E

Compressor Drive Belt The air conditioning compressor drive belt should be checked to ensure free- dom from damage or excessive wearand correct tension. The belt tension is correct when the belt deflects by about 0.3 inches (8 mm) when a forceof 98 N is applied to the belt halfway between the compressor and crank- shaft pulleys. Adjustment of the belt should be en- trusted to a Hyundai authorised re- pairer. CRANK PULLEY

G140D01A

A/C

TENSION PULLEY 0.315 in. (8mm)

CHANGING THE POLLEN FILTER

B140E02FC-EAT

(In Front of Blower Unit)

The pollen filter is located in front of

the blower unit behind the glove box. It helps to decrease pollutants from

entering the car.

1. Open the glove box and remove the adjusting pins on both sides of the glove box. 2. Remove the filter cover by pulling

upward the hooks of the filter cover.

HLC2096 KQNA020A

fcuk-6.p65

12/27/2006, 10:16 AM

25

Page 454 of 490

6 OWNER MAINTENANCE

26CHECKING THE FREEPLAY

SG160A1-E

Clutch Pedal

G160A01E

0.24 ~ 0.51 in. (6 ~ 13 mm)

The clutch pedal freeplay should bechecked against the specified value. If the freeplay is not correct, the clutchshould be adjusted by a Hyundai authorised repairer.

SG150A1-E

Steering Wheel

G150A01FC

Steering wheel freeplay should be

checked to ensure that the specified value is not exceeded. 1.18 in. (30 mm)

3. Replace the pollen filter with a new

one.

4. Installation is the reverse order of disassembly.

CAUTION:

Be sure to install the pollen filter in the direction of the arrow sign.

! KQNA020B

fcuk-6.p65

12/27/2006, 10:16 AM

26

Page 460 of 490

6 OWNER MAINTENANCE

32

2. Pump the hand pump until there are

no more bubbles in the fuel coming out of the air pipe. When doing this, place a cloth around the air pipe to prevent the escaping fuel from spew-ing about.

3. Replace the air cap when there are no more bubbles in the fuel.

4. Continue pumping until the hand pump becomes stiff.

5. Finally, check to be sure that there

is no leakage of fuel. If in doubt, consult your nearest Hyundai authorised repairer. G350B01FC

Air pipeG350B01FC-EAT

(Diesel engine)

The fuel system should be bled to

remove air as described in the illustra- tion if the fuel supply is exhaustedduring travel, when the fuel filter is replaced, or if the vehicle is not used for a long time.

1. Remove the air cap with pushing

the button.

G350A01FC

BLEEDING THE FUEL SYSTEM

SG230B1-E POWER STEERING HOSES Power steering hoses should be checked for damage, deterioration and leakage at each service.

fcuk-6.p65 12/27/2006, 10:16 AM

32

Page 461 of 490

6

OWNER MAINTENANCE

33

!WARNING:

o Do not smoke or have any other open flame near the vehicle whilst bleeding the fuel system.

o Be sure to carefully wipe away

any water drained out in thismanner, because the fuel mixed in the water might be ignited and result in a fire.

G300A02FC

G300A02B-EAT

(Diesel engine)

If the fuel filter warning lamp illumi- nates during driving, it indicates thatwater has accumulated in the fuel filter. If this occurs, remove the water as described. REMOVAL OF WATER FROM THE FUEL FILTER1. Loosen the drain plug at the bottom

of the fuel filter.

2. Tighten the drain plug when water no longer comes out.

3. Check to be sure that the warning lamp illuminates when the ignition key is turned to "ON", and that it goes off when the engine is started. If in doubt, consult your nearest Hyundai authorised repairer.

NOTE: It is recommended that water accu-

mulated in the fuel filter should be removed by an authorised Hyundaiauthorised repairer. G300B02FC

fcuk-6.p65

12/27/2006, 10:16 AM

33

Page 462 of 490

6 OWNER MAINTENANCE

34

G290A01FC

5. Open the bonnet.

6. Draw the vertical line (through the centre of each headlight beam pat- tern) and the horizontal line (through the centre of each headlight beampattern) on the aiming screen.And then, draw the horizontal paral-lel line at 1.18 in. (30 mm) under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillipsscrewdriver - VERTICAL AIMING

8. Adjust each cut-off line of the low beam to each vertical line with a phillips screwdriver - HORIZONTALAIMING.

Horizontal Aiming

Vertical Aiming

HEADLIGHT AIMING ADJUSTMENT

G290A01FC-EAT Before performing aiming adjustment,

make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper down several times. Place the vehicle at a distance of 118 in. (3,000 mm) from the test wall.

3. See that the vehicle is unloaded (except for full levels of coolant,engine oil and fuel, and spare tyre,jack, and tools).

4. Clean the head lights lens and turn on the headlight (Low beam).

!WARNING:

o Do not smoke or have any other open flame near the vehicle whilst bleeding the fuel system.

o Be sure to carefully wipe away any water drained out in thismanner, because the fuel mixed in the water might be ignited and result in a fire.

Extracting air in the fuel filter If you drove until you have no fuel left

or if you replaced the fuel filter, be sureto extract air in the fuel system as it makes you difficult to start the engine.

1) Remove the air extract nozzle cap

on the fuel filter.

2) Pump up and down until the fuel flows out of the plug opening.

NOTE: Use cloths when you extract air so

that the fuel is not sprayed around. Clean the fuel around the fuel filteror the injection pump before start- ing the engine to prevent fire. Fi- nally, check each part if the fuel isleaking.

fcuk-6.p65 12/27/2006, 10:16 AM

34

Page 485 of 490

10INDEX

2

A ACCESSORY TRAY ................................................. 1-67

AIR CONDITIONING SWITCH.................................. 1-82

AIR CONDITIONING SYSTEM MAINTENANCE ....... 6-24

AIR CLEANER ELEMENT REPLACEMENT .............6-14

ANTENNA ................................................................. 1-95

ANTI-LOCK BRAKE SYSTEM (ABS) .......................2-14

ANTI-THEFT ALARM SYSTEM .................................. 1-8

ASHTRAY ................................................................. 1-61

AUTO FUEL CUT SWITCH ....................................... 1-75

AUTOMATIC TRANSAXLE .......................................2-10

AUTOMATIC TRANSAXLE FLUID ........................... 6-19

B BATTERY MAINTENANCE .......................................6-30

BEFORE STARTING THE ENGINE ............................ 2-3

BLEEDING THE FUEL SYSTEM .............................. 6-32

BONNET RELEASE .................................................. 1-70

BRAKE PEDAL FREEPLAY .....................................6-27

BRAKE TRACTION CONTROL SYSTEM (BTCS) .... 2-14

BRAKE SYSTEM CHECKING.................................. 6-22

C

CARE OF SEAT BELTS .... .......................................1-20

CARGO AREA COVER ............................................. 1-74

CATALYTIC CONVERTOR OPERATING PRECAUTIONS ............................................................................. 7-3

CENTRE VENTILATOR ............................................. 1-76

CENTRAL DOOR LOCKS ......... .................................. 1-7

CHANGING A FLAT TYRE ......................................... 3-7

CHECKING THE CLUTCH FLU ID .............................6-23CHILD-PROOF REAR DOOR LOCK

........................... 1-7

CHILD RESTRAINT SYSTEM ................................... 1-24

CIGAR LIGHTER ....................................................... 1-60

CLUTCH PEDAL FREEPLAY ....................................6-26

COMBINATION IGNITION SWITCH ANDSTEERING LOCK ....................................................... 2-3

COOLANT TEMPERATURE GAUGE ........................1-49

DDAILY OPERATING CHECKS .................................... 6-5

DIGITAL CLOCK ....................................................... 1-59

DOOR LOCKS ............................................................. 1-5

DOOR WINDOWS ..................................................... 1-11

DRINK HOLDER ........................................................ 1-61

DRIVE BELTS ........................................................... 6-27

DRIVING FOR ECONOMY ....... .................................2-18

E EFFECTIVE BRAKING ............................................. 2-17

ELECTRIC COOLING FANS ..................................... 6-31

ELECTRONIC STABILITY PROGRAM (ESP) ...........2-16

EMERGENCY TOWING ............................................ 3-14

EMISSION CONTROL SYSTEM ................................. 7-2

ENGINE COMPARTMENT ....... ................................... 6-2

ENGINE COOLANT CHECKING AND REPLACING . 6-12

ENGINE OIL AND FILTER REPLACEMENT .............. 6-8

ENGINE OIL CONSUMPTION .................................... 6-8

ENGINE OIL REPLENISHMENT ................................. 6-7

ENGINE OIL ................................................................ 6-5 EXTERIOR REAR VIEW MIRROR ........................... 1-67

fcuk-10.p65 12/27/2006, 10:14 AM

2