maintenance Hyundai Santa Fe 2008 User Guide

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2008, Model line: Santa Fe, Model: Hyundai Santa Fe 2008Pages: 355, PDF Size: 12.36 MB

Page 239 of 355

2

DRIVING YOUR HYUNDAI

28

C190C02Y-AATTrailer BrakesIf your trailer is equipped with a braking

system, make sure it conforms to federal

and/or local regulations and that it is prop-

erly installed and operating correctly.NOTE:If you tow a trailer or vehicle, your car will

require more frequent maintenance due

to the additional load. See Maintenance

Under Severe Usage Conditions" on

page 5-6.

CAUTION:

o Never connect a trailer brake system

directly to the vehicle brake system.

o When towing a trailer on steep grades

(in excess of 6%) pay close attention

to the engine coolant temperature

gauge to ensure the engine does not

overheat. If the needle of the coolant

temperature gauge moves across the

dial towards "H" (HOT), pull over and

stop as soon as it is safe to do so, and

allow the engine to idle until it cools

down. You may proceed once the

engine has cooled sufficiently.

!

C190D01S-AATSafety ChainsShould the hitch connection between your

vehicle and the trailer or vehicle you are

towing fail, the trailer or vehicle could

wander dangerously across other lanes of

traffic and ultimately leave the roadway. To

eliminate this potentially dangerous situa-

tion, safety chains, attached between your

car and the trailer or towed vehicle, are

required in most states.

C190B01S-AATTrailer HitchesSelect the proper hitch and ball combina-

tion, making sure that its location is com-

patible with that of the trailer or vehicle

being towed.

Use a quality non-equalizing hitch which

distributes the tongue load uniformly

throughout the chassis.

The hitch should be bolted securely to the

car and installed by a qualified technician.

DO NOT USE A HITCH DESIGNED FOR

TEMPORARY INSTALLATION AND

NEVER USE ONE THAT ATTACHES

ONLY TO THE BUMPER.

Page 253 of 355

3

WHAT TO DO IN AN EMERGENCY

5

TIRE PRESSURE MONITORING SYSTEM (TPMS)

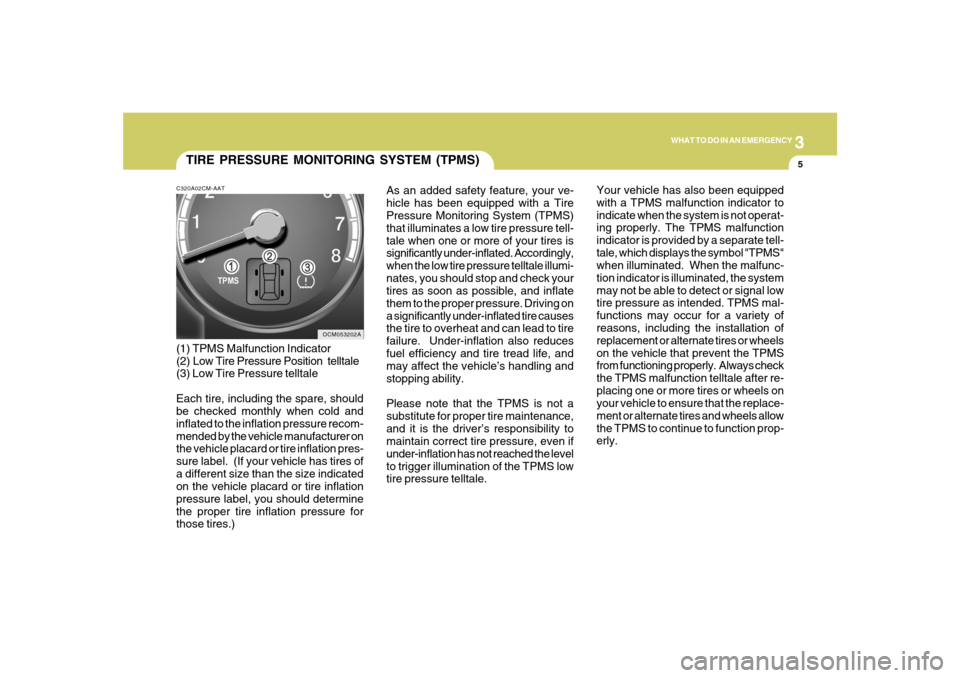

OCM053202A C320A02CM-AAT

(1) TPMS Malfunction Indicator

(2) Low Tire Pressure Position telltale

(3) Low Tire Pressure telltale

Each tire, including the spare, should

be checked monthly when cold and

inflated to the inflation pressure recom-

mended by the vehicle manufacturer on

the vehicle placard or tire inflation pres-

sure label. (If your vehicle has tires of

a different size than the size indicated

on the vehicle placard or tire inflation

pressure label, you should determine

the proper tire inflation pressure for

those tires.)As an added safety feature, your ve-

hicle has been equipped with a Tire

Pressure Monitoring System (TPMS)

that illuminates a low tire pressure tell-

tale when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale illumi-

nates, you should stop and check your

tires as soon as possible, and inflate

them to the proper pressure. Driving on

a significantly under-inflated tire causes

the tire to overheat and can lead to tire

failure. Under-inflation also reduces

fuel efficiency and tire tread life, and

may affect the vehicle’s handling and

stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance,

and it is the driver’s responsibility to

maintain correct tire pressure, even if

under-inflation has not reached the level

to trigger illumination of the TPMS low

tire pressure telltale.Your vehicle has also been equipped

with a TPMS malfunction indicator to

indicate when the system is not operat-

ing properly. The TPMS malfunction

indicator is provided by a separate tell-

tale, which displays the symbol "TPMS"

when illuminated. When the malfunc-

tion indicator is illuminated, the system

may not be able to detect or signal low

tire pressure as intended. TPMS mal-

functions may occur for a variety of

reasons, including the installation of

replacement or alternate tires or wheels

on the vehicle that prevent the TPMS

from functioning properly. Always check

the TPMS malfunction telltale after re-

placing one or more tires or wheels on

your vehicle to ensure that the replace-

ment or alternate tires and wheels allow

the TPMS to continue to function prop-

erly.

Page 277 of 355

5

Maintenance Intervals ................................................... 5-2

Scheduled Maintenance ................................................ 5-4

Maintenance under Severe Usage Conditions ............. 5-6

Explanation of Scheduled Maintenance Items .............. 5-7

California Perchlorate Notice......................................5-10VEHICLE MAINTENANCE REQUIREMENTS

5

Page 278 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS2

F010C01A-AATSpecified Scheduled ProceduresThese are the procedures such as inspec-

tions, adjustments and replacements that

are listed in the maintenance charts start-

ing on page 5-4. These procedures must

be performed at the intervals shown in the

maintenance schedule to assure that your

warranty remains in effect. Although it is

strongly recommended that they be per-

formed by the trained technicians at your

Hyundai dealer, these procedures may be

performed at any qualified service facility.

It is suggested that genuine Hyundai ser-

vice parts be used for any required repairs

or replacements. Other parts of equivalent

quality such as engine oil, engine coolant,

manual or auto transaxle oil, brake fluid

and so on which are not supplied by

Hyundai Motor Company or its distributor

may be used without affecting your war-

ranty coverage but you should always be

sure these are equivalent to the quality of

the original Hyundai parts. Your Owner's

Handbook provides further information

about your warranty coverage.

F010A01A-AATService RequirementsTo ensure that you receive the greatest

number of miles of satisfying operation

from your Hyundai, certain maintenance

procedures must be performed. Although

careful design and engineering have re-

duced these to a minimum, those that are

required are of the utmost importance.

It is your responsibility to have these main-

tenance procedures performed to comply

with the terms of the warranties covering

your new Hyundai. The Owner's Hand-

book supplied with your new vehicle pro-

vides further information about these war-

ranties.

F010B01A-AATMaintenance RequirementsThe maintenance required for your

Hyundai can be divided into three main

areas:

o Specified scheduled procedures

o General checks

o Do-it-yourself maintenance

MAINTENANCE INTERVALS

Page 279 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS

3

SCHEDULED MAINTE-

NANCE REQUIREMENTSF020A02Y-AATo Inspection should be performed any

time a malfunction is experienced or

suspected.

o Receipts for all emission control system

services should be retained to demon-

strate compliance with conditions of the

emissions system warranty.

o After 120 months or 150,000 miles

(240,000 km), continue to follow the

prescribed maintenance intervals.

o For severe usage maintenance require-

ments, see page 5-6 of this section.

F010D02A-AATGeneral ChecksThese are the regular checks you should

perform when you drive your Hyundai or

you fill the fuel tank. A list of these items will

be found on page 6-5.F010E01A-AATDo-It-Yourself MaintenanceIf you are mechanically inclined, own a few

tools that are required and want to take the

time to do so, you can inspect and service

a number of items. For more information

about doing it yourself, see Section 6.

F010F01A-AATA Few Tipso Whenever you have your Hyundai ser-

viced, keep copies of the service records

in your glovebox. This will help ensure

that you can document that the required

procedures have been performed to

keep your warranties in effect. This is

especially important when service is

not performed by an authorized

Hyundai dealer.

o If you choose to do your own mainte-

nance and repairs, you may find it

helpful to have an official Hyundai Shop

Manual. A copy of this publication may

be purchased at your Hyundai dealer's

parts department.

Page 280 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS4

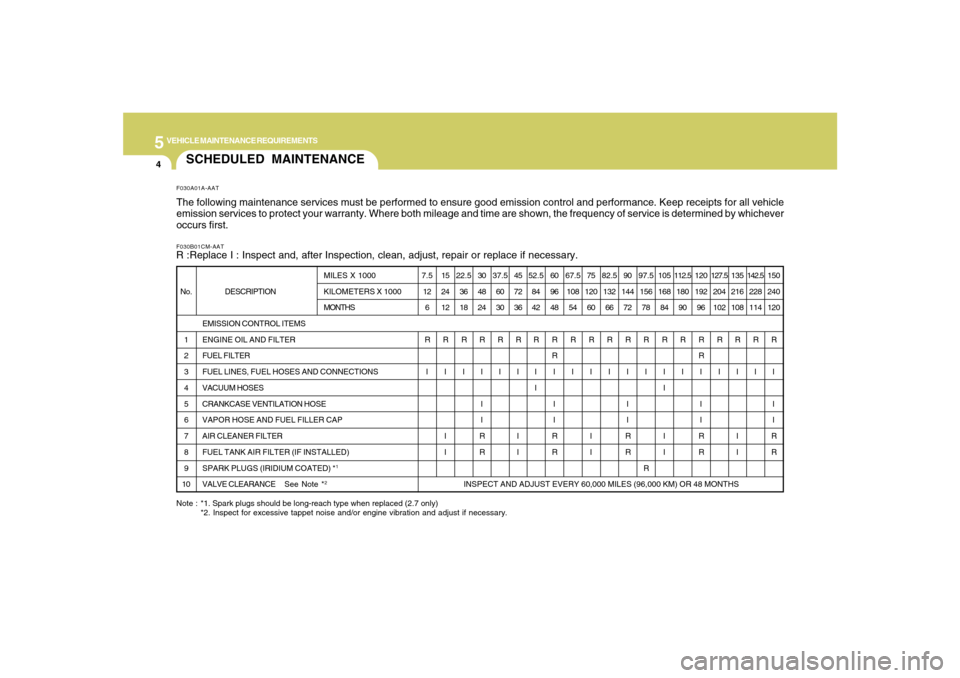

SCHEDULED MAINTENANCEF030B01CM-AATR :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

DESCRIPTION

EMISSION CONTROL ITEMS

ENGINE OIL AND FILTER

FUEL FILTER

FUEL LINES, FUEL HOSES AND CONNECTIONS

VACUUM HOSES

CRANKCASE VENTILATION HOSE

VAPOR HOSE AND FUEL FILLER CAP

AIR CLEANER FILTER

FUEL TANK AIR FILTER (IF INSTALLED)

SPARK PLUGS (IRIDIUM COATED) *

1

VALVE CLEARANCESee Note *

2

No.

1

2

3

4

5

6

7

8

9

10MILES X 1000

KILOMETERS X 1000

MONTHS7.5

12

6

R

I15

24

12

R

I

I

I22.5

36

18

R

I30

48

24

R

I

I

I

R

R37.5

60

30

R

I45

72

36

R

I

I

I52.5

84

42

R

I

I60

96

48

R

R

I

I

I

R

R67.5

108

54

R

I75

120

60

R

I

I

I82.5

132

66

R

I90

144

72

R

I

I

I

R

R97.5

156

78

R

I

R105

168

84

R

I

I

I

I112.5

180

90

R

I120

192

96

R

R

I

I

I

R

R127.5

204

102

R

I135

216

108

R

I

I

I142.5

228

114

R

I150

240

120

R

I

I

I

R

R

F030A01A-AATThe following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all vehicle

emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever

occurs first.

INSPECT AND ADJUST EVERY 60,000 MILES (96,000 KM) OR 48 MONTHS

Note : *1. Spark plugs should be long-reach type when replaced (2.7 only)

*2. Inspect for excessive tappet noise and/or engine vibration and adjust if necessary.

Page 281 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS

5

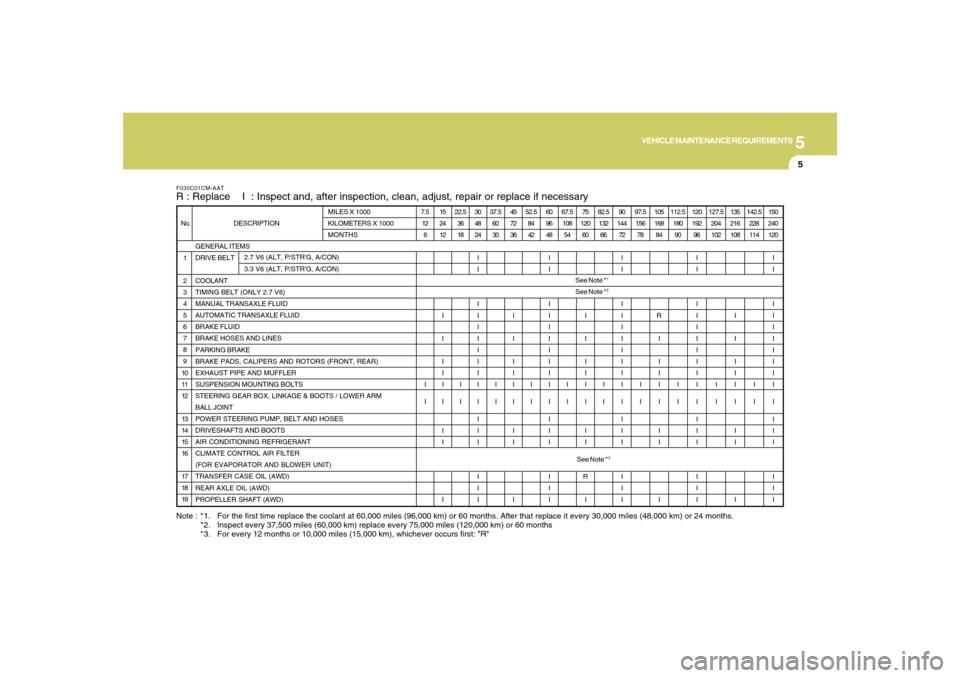

Note : *1. For the first time replace the coolant at 60,000 miles (96,000 km) or 60 months. After that replace it every 30,000 miles (48,000 km) or 24 months.

*2. Inspect every 37,500 miles (60,000 km) replace every 75,000 miles (120,000 km) or 60 months

*3. For every 12 months or 10,000 miles (15,000 km), whichever occurs first: "R"F030C01CM-AATR : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

GENERAL ITEMS

DRIVE BELT

COOLANT

TIMING BELT (ONLY 2.7 V6)

MANUAL TRANSAXLE FLUID

AUTOMATIC TRANSAXLE FLUID

BRAKE FLUID

BRAKE HOSES AND LINES

PARKING BRAKE

BRAKE PADS, CALIPERS AND ROTORS (FRONT, REAR)

EXHAUST PIPE AND MUFFLER

SUSPENSION MOUNTING BOLTS

STEERING GEAR BOX, LINKAGE & BOOTS / LOWER ARM

BALL JOINT

POWER STEERING PUMP, BELT AND HOSES

DRIVESHAFTS AND BOOTS

AIR CONDITIONING REFRIGERANT

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)

TRANSFER CASE OIL (AWD)

REAR AXLE OIL (AWD)

PROPELLER SHAFT (AWD) 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 No. DESCRIPTIONMILES X 1000

KILOMETERS X 1000

MONTHS

2.7 V6 (ALT, P/STR'G, A/CON)

3.3 V6 (ALT, P/STR'G, A/CON)7.5

12

6

I

I15

24

12

I

I

I

I

I

I

I

I

I22.5

36

18

I

I30

48

24

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I37.5

60

30

I

I45

72

36

I

I

I

I

I

I

I

I

I52.5

84

42

I

I60

96

48

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I67.5

108

54

I

I75

120

60

I

I

I

I

I

I

I

I

R

I82.5

132

66

I

I90

144

72

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I97.5

156

78

I

I105

168

84

R

I

I

I

I

I

I

I

I112.5

180

90

I

I120

192

96

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I127.5

204

102

I

I135

216

108

I

I

I

I

I

I

I

I

I142.5

228

114

I

I150

240

120

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

ISee Note *

1

See Note *

2

See Note *

3

Page 282 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS6

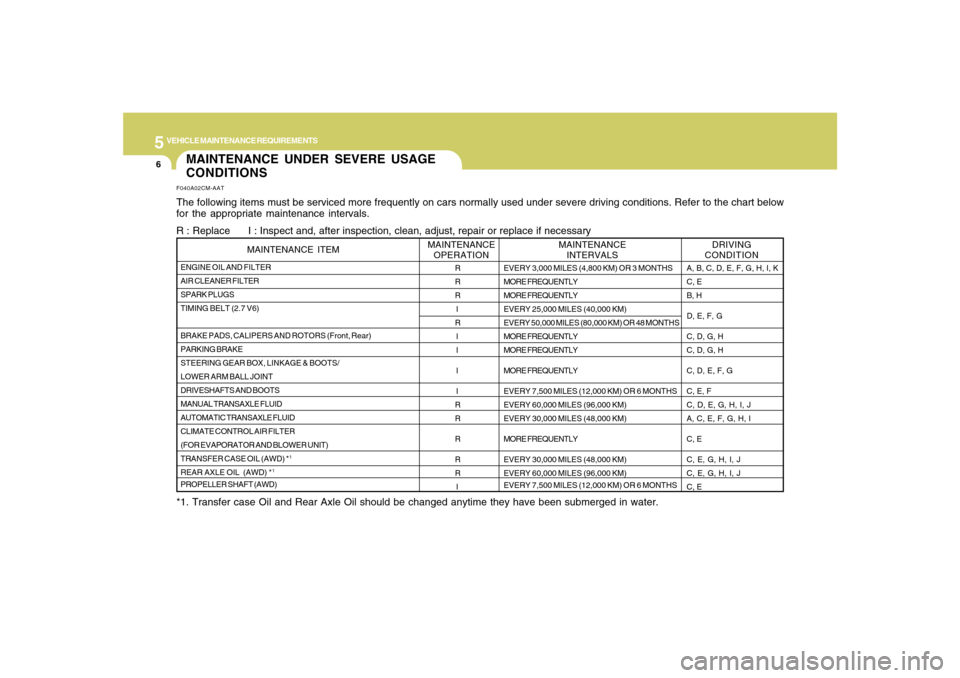

MAINTENANCE UNDER SEVERE USAGE

CONDITIONSF040A02CM-AATThe following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below

for the appropriate maintenance intervals.

R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary

*1. Transfer case Oil and Rear Axle Oil should be changed anytime they have been submerged in water.ENGINE OIL AND FILTER

AIR CLEANER FILTER

SPARK PLUGS

TIMING BELT (2.7 V6)

BRAKE PADS, CALIPERS AND ROTORS (Front, Rear)

PARKING BRAKE

STEERING GEAR BOX, LINKAGE & BOOTS/

LOWER ARM BALL JOINT

DRIVESHAFTS AND BOOTS

MANUAL TRANSAXLE FLUID

AUTOMATIC TRANSAXLE FLUID

CLIMATE CONTROL AIR FILTER

(FOR EVAPORATOR AND BLOWER UNIT)

TRANSFER CASE OIL (AWD) *

1

REAR AXLE OIL (AWD) *

1

PROPELLER SHAFT (AWD)

MAINTENANCE ITEM

R

R

R

I

R

I

I

I

I

R

R

R

R

R

I

EVERY 3,000 MILES (4,800 KM) OR 3 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 25,000 MILES (40,000 KM)

EVERY 50,000 MILES (80,000 KM) OR 48 MONTHS

MORE FREQUENTLY

MORE FREQUENTLY

MORE FREQUENTLY

EVERY 7,500 MILES (12,000 KM) OR 6 MONTHS

EVERY 60,000 MILES (96,000 KM)

EVERY 30,000 MILES (48,000 KM)

MORE FREQUENTLY

EVERY 30,000 MILES (48,000 KM)

EVERY 60,000 MILES (96,000 KM)

EVERY 7,500 MILES (12,000 KM) OR 6 MONTHS

DRIVING

CONDITION MAINTENANCE

INTERVALS MAINTENANCE

OPERATION

A, B, C, D, E, F, G, H, I, K

C, E

B, H

D, E, F, G

C, D, G, H

C, D, G, H

C, D, E, F, G

C, E, F

C, D, E, G, H, I, J

A, C, E, F, G, H, I

C, E

C, E, G, H, I, J

C, E, G, H, I, J

C, E

Page 283 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS

7

SEVERE DRIVING CONDITIONSA - Repeatedly driving short distance of

less than 5miles(8km) in normal tem-

perature or less than 10miles(16km) in

freezing temperature

B - Extensive engine idling or low speed

driving for long distances

C - Driving on rough, dusty, muddy, un-

paved, graveled or salt-spread roads

D - Driving in areas using salt or other

corrosive materials or in very cold

weather

E - Driving in sandy areas

F - More than 50% driving in heavy city

traffic during hot weather above 32°C

(90°F)

G - Driving in mountainous areas

H - Towing a Trailer, or using a camper, or

roof rack

I - Driving as a patrol car, taxi, other com-

mercial use or vehicle towing

J - Driving over 100 MPH(170 Km/h)

K - Frequently driving in stop-and-go con-

ditions

F060D01A-AATo Fuel Lines, Fuel Hoses and Con-

nectionsCheck the fuel lines, fuel hoses and con-

nections for leakage and damage. Have a

trained technician replace any damaged

or leaking parts immediately.F060B01A-AATo Drive BeltsInspect all drive belts for evidence of cuts,

cracks, excessive wear or oil saturation

and replace if necessary. Drive belts should

be checked periodically for proper tension

and adjusted as necessary.

F060M01A-AATo Engine Oil and FilterThe engine oil and filter should be changed

at the intervals specified in the mainte-

nance schedule. If the car is being driven

in severe conditions, more frequent oil and

filter changes are required.F060C01A-AATo Fuel FilterA clogged filter can limit the speed at which

the vehicle may be driven, damage the

emission system and cause hard starting.

If an excessive amount of foreign matter

accumulates in the fuel tank, the filter may

require replacement more frequently.

After installing a new filter, run the engine

for several minutes, and check for leaks at

the connections. Fuel filters should be

installed by trained technicians.EXPLANATION OF SCHEDULED

MAINTENANCE ITEMS

Page 284 of 355

5

VEHICLE MAINTENANCE REQUIREMENTS8

F070C01A-AATo CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.F060E01A-AATo Timing Belt (2.7L V6 only)Inspect all parts related to the timing belt for

damage and deformation. Replace any

damaged parts immediately.F060J01A-AATo Spark PlugsMake sure to install new spark plugs of the

correct heat range.F060H01A-AATo Air Cleaner FilterA Genuine Hyundai air cleaner filter is

recommended when the filter is replaced.

F060G01A-AATo Vapor Hose and Fuel Filler CapThe vapor hose and fuel filler cap should

be inspected at those intervals specified in

the maintenance schedule. Make sure that

a new vapor hose or fuel filler cap is cor-

rectly replaced.F065F01O-AATo Crankcase Ventilation HoseInspect the surface of hose for evidence of

heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine that hose sur-

face nearest to high heat sources, such as

the exhaust manifold.

Inspect the hose routing to assure that the

hose does not come in contact with any

heat source, sharp edges or moving com-

ponent which might cause heat damage or

mechanical wear. Inspect all hose con-

nections, such as clamps and couplings,

to make sure they are secure, and that no

leaks are present. Hose should be re-

placed immediately if there is any evi-

dence of deterioration or damage.

F060F01O-AATo Vacuum HosesInspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold.

Inspect the hose routing to assure that the

hoses do not come in contact with any heat

source, sharp edges or moving compo-

nent which might cause heat damage or

mechanical wear. Inspect all hose con-

nections, such as clamps and couplings,

to make sure they are secure, and that no

leaks are present. Hoses should be re-

placed immediately if there is any evi-

dence of deterioration or damage.