fuel cap Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 286, PDF Size: 9.58 MB

Page 15 of 286

1FEATURES OF YOUR HYUNDAI2

!

B010A01NF-A

FUEL RECOMMENDATIONS

CAUTION:

Your Hyundai's New Vehicle Limited War-

ranty may not cover damage to the fuel

system and any performance problems

that are caused by the use of fuels con-

taining methanol or fuels containing

MTBE (Methyl Tertiary Butyl Ether) over

15.0% vol. (Oxygen Content 2.7% weight.)

B010B01A-AATWhat About Gasohol?Gasohol (a mixture of 90% unleaded

gasoline and 10% ethanol or grain alcohol)

may be used in your Hyundai. However, if

your engine develops driveability

problems, the use of 100% unleaded

gasoline is recommended. Fuels with

unspecified quantities of alcohol, or

alcohols other than ethanol, should not be

used.

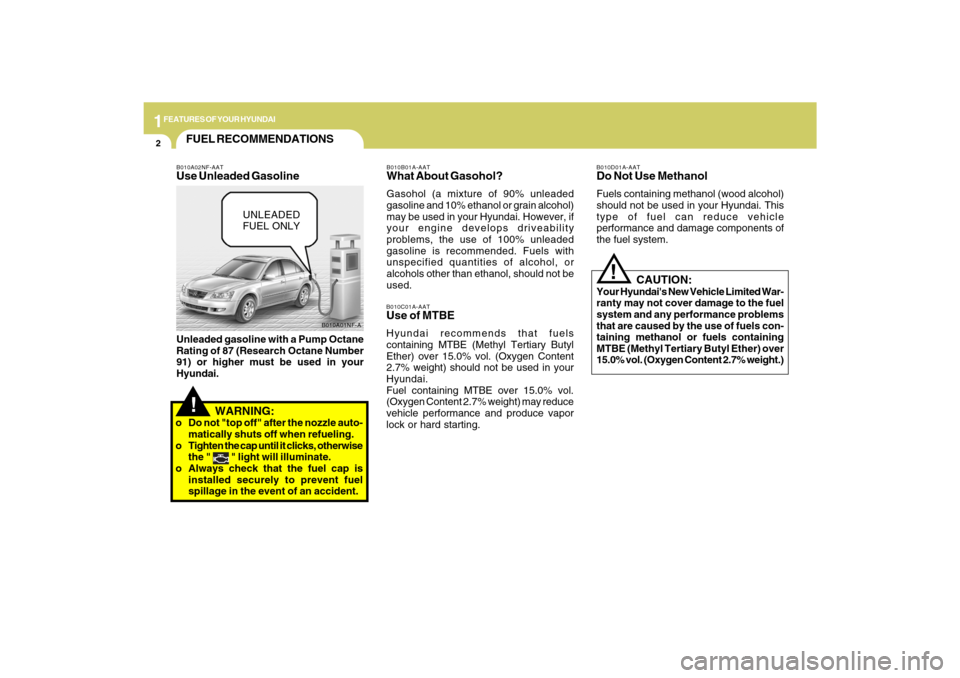

B010A02NF-AATUse Unleaded GasolineUnleaded gasoline with a Pump Octane

Rating of 87 (Research Octane Number

91) or higher must be used in your

Hyundai.

B010C01A-AATUse of MTBEHyundai recommends that fuels

containing MTBE (Methyl Tertiary Butyl

Ether) over 15.0% vol. (Oxygen Content

2.7% weight) should not be used in your

Hyundai.

Fuel containing MTBE over 15.0% vol.

(Oxygen Content 2.7% weight) may reduce

vehicle performance and produce vapor

lock or hard starting.

B010D01A-AATDo Not Use MethanolFuels containing methanol (wood alcohol)

should not be used in your Hyundai. This

type of fuel can reduce vehicle

performance and damage components of

the fuel system.

!

UNLEADED

FUEL ONLY

WARNING:

o Do not "top off" after the nozzle auto-

matically shuts off when refueling.

o Tighten the cap until it clicks, otherwise

the "

" light will illuminate.

o Always check that the fuel cap is

installed securely to prevent fuel

spillage in the event of an accident.

Page 68 of 286

1

FEATURES OF YOUR HYUNDAI

55

!

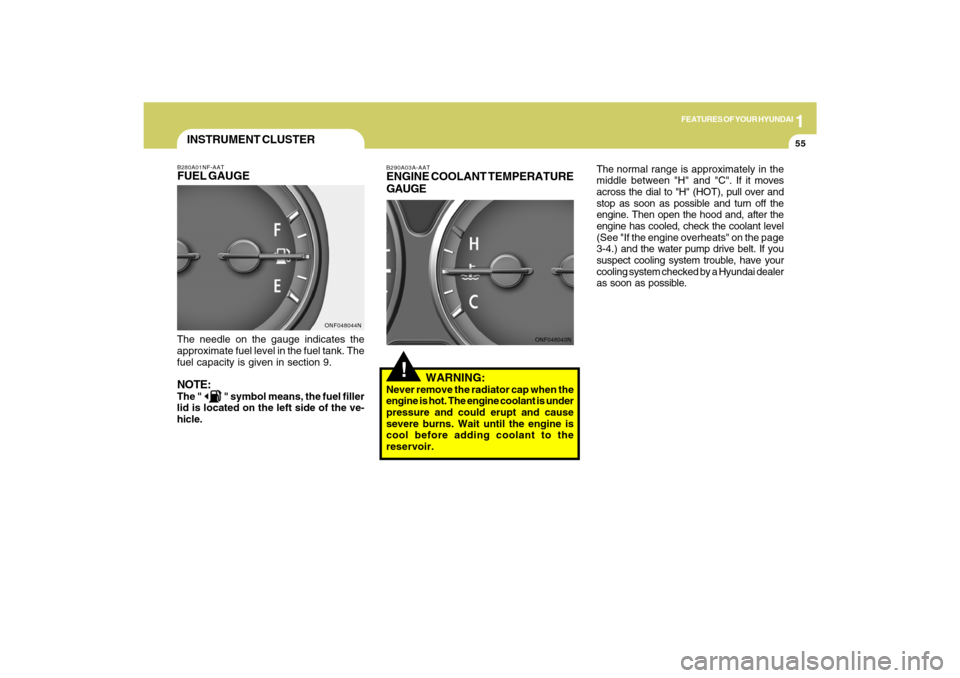

B290A03A-AATENGINE COOLANT TEMPERATURE

GAUGE

WARNING:Never remove the radiator cap when the

engine is hot. The engine coolant is under

pressure and could erupt and cause

severe burns. Wait until the engine is

cool before adding coolant to the

reservoir.The normal range is approximately in the

middle between "H" and "C". If it moves

across the dial to "H" (HOT), pull over and

stop as soon as possible and turn off the

engine. Then open the hood and, after the

engine has cooled, check the coolant level

(See "If the engine overheats" on the page

3-4.) and the water pump drive belt. If you

suspect cooling system trouble, have your

cooling system checked by a Hyundai dealer

as soon as possible.

ONF048043N

INSTRUMENT CLUSTERB280A01NF-AATFUEL GAUGEThe needle on the gauge indicates the

approximate fuel level in the fuel tank. The

fuel capacity is given in section 9.NOTE:The "

" symbol means, the fuel filler

lid is located on the left side of the ve-

hicle.

ONF048044N

Page 99 of 286

1FEATURES OF YOUR HYUNDAI86

!

WARNING:

- When using a portable fuel container,

be sure to place the container on the

ground while refueling. Static elec-

tricity discharge from the container

can ignite fuel vapors causing a fire.

While starting refueling, contact

should be maintained until the filling

is complete.

- Do not use cellular phones around a

gas station. The electric current or

electronic interference from cellular

phones can ignite fuel vapors caus-

ing a fire.

- When refueling, always turn the en-

gine off. Sparks by engine compart-

ment electrical equipment can ignite

fuel vapors causing a fire. After re-

fueling, check to make sure the fuel

filler cap is securely closed, and

then start the engine.

- Do not smoke or try to light cigarettes

around a gas station. Automotive

fuels are flammable.

o After refueling, make sure the fuel

cap is installed securely to prevent

fuel spillage in the event of an accident

o Tighten the cap until it clicks, otherwise

the "

" light will illuminate

o If you open the fuel filler cap during

high ambient temperatures, a slight

"pressure sound" may be heard. This

is normal and not a cause for concern.

Whenever you open the fuel filler cap,

turn it slowly.

o Do not "top off" after the nozzle auto-

matically shuts off when refueling.

o Automotive fuels are flammable/ex-

plosive materials. When refueling,

please note the following guidelines

carefully.

- Before touching the fuel nozzle or

fuel filler cap, have one's hands in

contact with metal parts away from

the filler neck to discharge static

electricity.

- Do not get back in the vehicle while

refueling. Do not operate anything

that can produce static electricity.

Static electricity discharge can ignite

fuel vapors resulting in an explosion.

!

!

WARNING:

o Gasoline vapors are dangerous.

Before refueling, always stop the

engine and never smoke or allow

sparks and open flames near the filler

area.

o Never operate your vehicle without a

filler cap properly installed, flammable

vapors and gasoline could leak out in

dangerous situations such as a

collision or rollover. If the filler cap

must be replaced, only use genuine

Hyundai replacement parts.

HNF2021

WARNING:

Page 179 of 286

2

DRIVING YOUR HYUNDAI

26

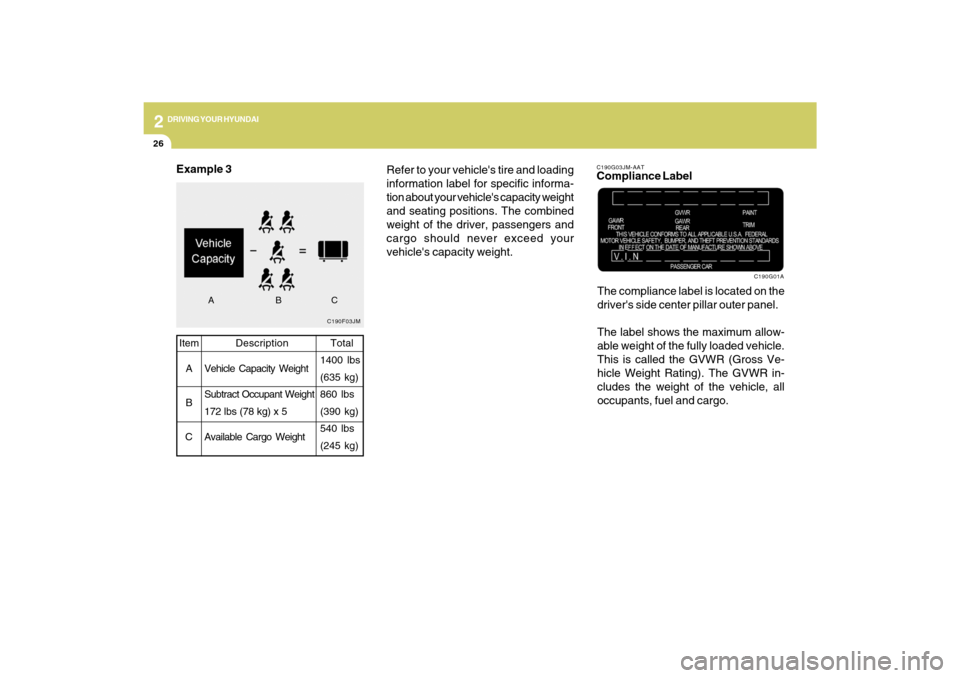

C190F03JMTotal

1400 lbs

(635 kg)

860 lbs

(390 kg)

540 lbs

(245 kg) Item

A

B

CDescription

Vehicle Capacity Weight

Subtract Occupant Weight

172 lbs (78 kg) x 5

Available Cargo Weight

Example 3

ABC

Refer to your vehicle's tire and loading

information label for specific informa-

tion about your vehicle's capacity weight

and seating positions. The combined

weight of the driver, passengers and

cargo should never exceed your

vehicle's capacity weight.

C190G03JM-AATCompliance Label

The compliance label is located on the

driver's side center pillar outer panel.

The label shows the maximum allow-

able weight of the fully loaded vehicle.

This is called the GVWR (Gross Ve-

hicle Weight Rating). The GVWR in-

cludes the weight of the vehicle, all

occupants, fuel and cargo.

C190G01A

Page 209 of 286

5

VEHICLE MAINTENANCE REQUIREMENTS4

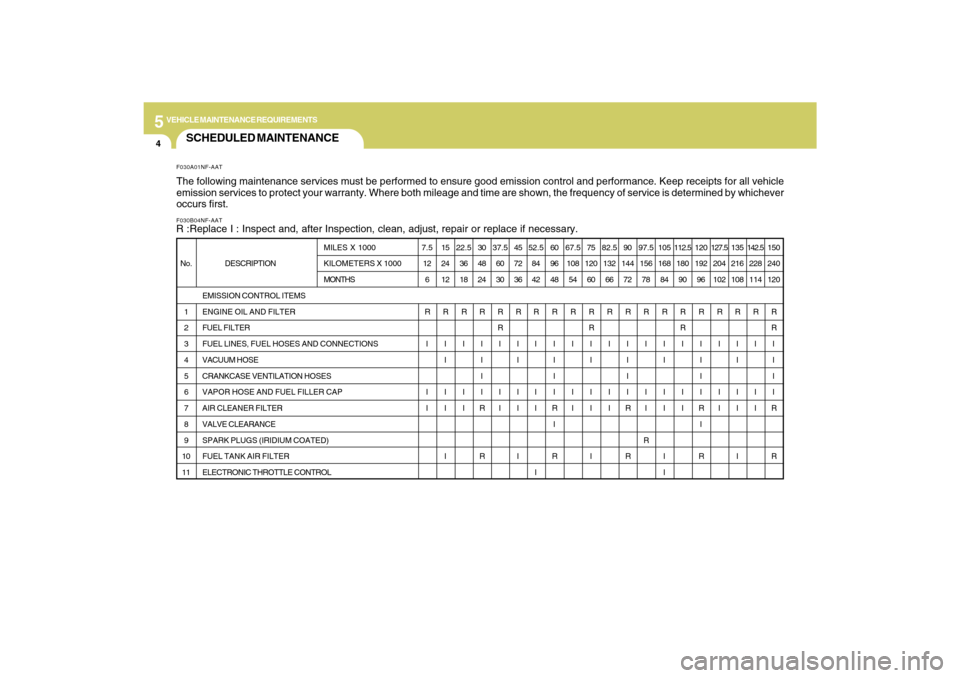

SCHEDULED MAINTENANCEF030B04NF-AATR :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.F030A01NF-AATThe following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all vehicle

emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever

occurs first.

DESCRIPTION

EMISSION CONTROL ITEMS

ENGINE OIL AND FILTER

FUEL FILTER

FUEL LINES, FUEL HOSES AND CONNECTIONS

VACUUM HOSE

CRANKCASE VENTILATION HOSES

VAPOR HOSE AND FUEL FILLER CAP

AIR CLEANER FILTER

VALVE CLEARANCE

SPARK PLUGS (IRIDIUM COATED)

FUEL TANK AIR FILTER

ELECTRONIC THROTTLE CONTROL No.

1

2

3

4

5

6

7

8

9

10

11MILES X 1000

KILOMETERS X 1000

MONTHS7.5

12

6

R

I

I

I15

24

12

R

I

I

I

I

I22.5

36

18

R

I

I

I30

48

24

R

I

I

I

I

R

R37.5

60

30

R

R

I

I

I45

72

36

R

I

I

I

I

I52.5

84

42

R

I

I

I

I60

96

48

R

I

I

I

I

R

I

R67.5

108

54

R

I

I

I75

120

60

R

R

I

I

I

I

I82.5

132

66

R

I

I

I90

144

72

R

I

I

I

I

R

R97.5

156

78

R

I

I

I

R105

168

84

R

I

I

I

I

I

I112.5

180

90

R

R

I

I

I120

192

96

R

I

I

I

I

R

I

R127.5

204

102

R

I

I

I135

216

108

R

I

I

I

I

I142.5

228

114

R

I

I

I150

240

120

R

R

I

I

I

I

R

R

Page 213 of 286

5

VEHICLE MAINTENANCE REQUIREMENTS8

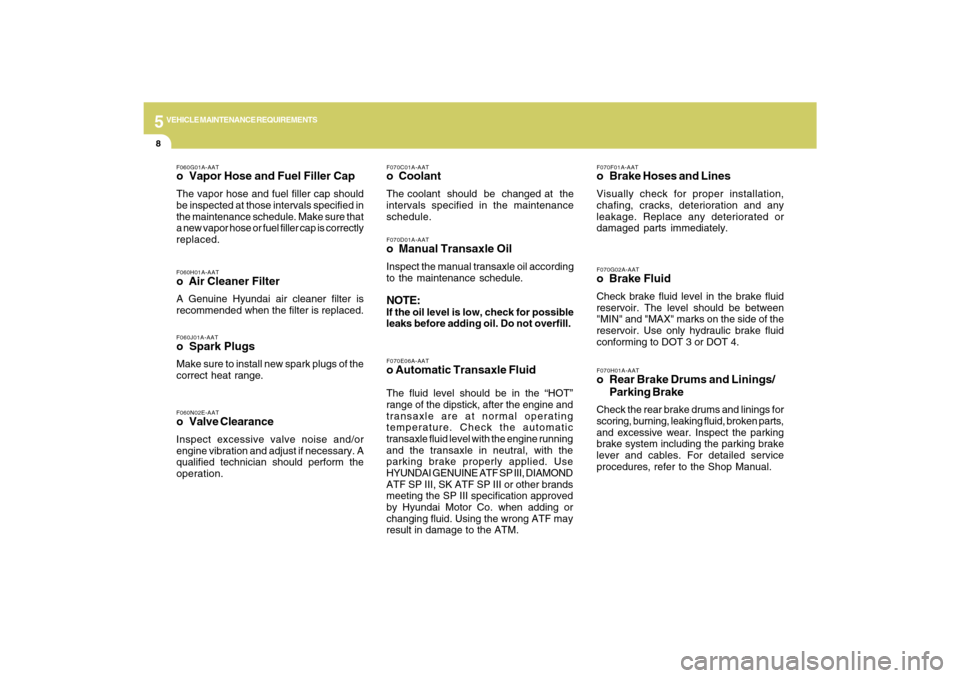

F070G02A-AATo Brake FluidCheck brake fluid level in the brake fluid

reservoir. The level should be between

"MIN" and "MAX" marks on the side of the

reservoir. Use only hydraulic brake fluid

conforming to DOT 3 or DOT 4.F070F01A-AATo Brake Hoses and LinesVisually check for proper installation,

chafing, cracks, deterioration and any

leakage. Replace any deteriorated or

damaged parts immediately.

F070E06A-AATo Automatic Transaxle FluidThe fluid level should be in the “HOT”

range of the dipstick, after the engine and

transaxle are at normal operating

temperature. Check the automatic

transaxle fluid level with the engine running

and the transaxle in neutral, with the

parking brake properly applied. Use

HYUNDAI GENUINE ATF SP III, DIAMOND

ATF SP III, SK ATF SP III or other brands

meeting the SP III specification approved

by Hyundai Motor Co. when adding or

changing fluid. Using the wrong ATF may

result in damage to the ATM.

F070H01A-AATo Rear Brake Drums and Linings/

Parking BrakeCheck the rear brake drums and linings for

scoring, burning, leaking fluid, broken parts,

and excessive wear. Inspect the parking

brake system including the parking brake

lever and cables. For detailed service

procedures, refer to the Shop Manual.

F070C01A-AATo CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.

F060J01A-AATo Spark PlugsMake sure to install new spark plugs of the

correct heat range.F060H01A-AATo Air Cleaner FilterA Genuine Hyundai air cleaner filter is

recommended when the filter is replaced.F060G01A-AATo Vapor Hose and Fuel Filler CapThe vapor hose and fuel filler cap should

be inspected at those intervals specified in

the maintenance schedule. Make sure that

a new vapor hose or fuel filler cap is correctly

replaced.

F070D01A-AATo Manual Transaxle OilInspect the manual transaxle oil according

to the maintenance schedule.NOTE:If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

F060N02E-AATo Valve ClearanceInspect excessive valve noise and/or

engine vibration and adjust if necessary. A

qualified technician should perform the

operation.

Page 257 of 286

7

EMISSION CONTROL SYSTEMS2

EMISSION CONTROL

SYSTEMS

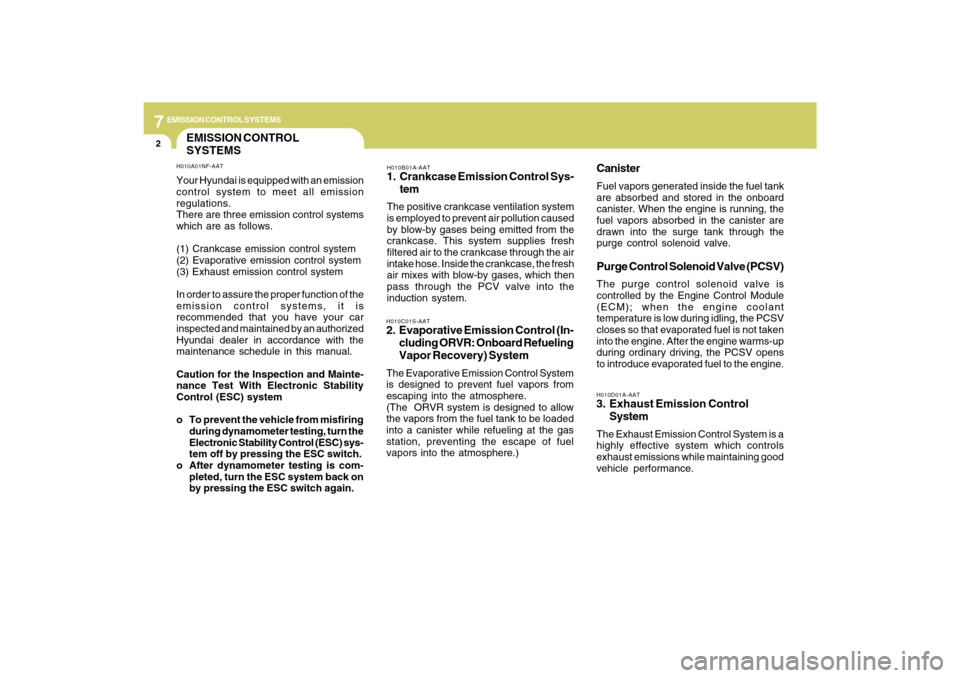

H010B01A-AAT1. Crankcase Emission Control Sys-

temThe positive crankcase ventilation system

is employed to prevent air pollution caused

by blow-by gases being emitted from the

crankcase. This system supplies fresh

filtered air to the crankcase through the air

intake hose. Inside the crankcase, the fresh

air mixes with blow-by gases, which then

pass through the PCV valve into the

induction system.

CanisterFuel vapors generated inside the fuel tank

are absorbed and stored in the onboard

canister. When the engine is running, the

fuel vapors absorbed in the canister are

drawn into the surge tank through the

purge control solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is

controlled by the Engine Control Module

(ECM); when the engine coolant

temperature is low during idling, the PCSV

closes so that evaporated fuel is not taken

into the engine. After the engine warms-up

during ordinary driving, the PCSV opens

to introduce evaporated fuel to the engine.H010D01A-AAT3. Exhaust Emission Control

SystemThe Exhaust Emission Control System is a

highly effective system which controls

exhaust emissions while maintaining good

vehicle performance.

H010A01NF-AATYour Hyundai is equipped with an emission

control system to meet all emission

regulations.

There are three emission control systems

which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of the

emission control systems, it is

recommended that you have your car

inspected and maintained by an authorized

Hyundai dealer in accordance with the

maintenance schedule in this manual.

Caution for the Inspection and Mainte-

nance Test With Electronic Stability

Control (ESC) system

o To prevent the vehicle from misfiring

during dynamometer testing, turn the

Electronic Stability Control (ESC) sys-

tem off by pressing the ESC switch.

o After dynamometer testing is com-

pleted, turn the ESC system back on

by pressing the ESC switch again.

H010C01S-AAT2. Evaporative Emission Control (In-

cluding ORVR: Onboard Refueling

Vapor Recovery) SystemThe Evaporative Emission Control System

is designed to prevent fuel vapors from

escaping into the atmosphere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be loaded

into a canister while refueling at the gas

station, preventing the escape of fuel

vapors into the atmosphere.)

Page 265 of 286

8

CONSUMER INFORMATION, REPORTING SAFETY DEFECTS & BINDING ARBITRATION OF WARRANTY CLAIMS

7

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that

can be carried by the tire. When

replacing the tires on the vehicle,

always use a tire that has the same

load rating as the factory installed

tire.

7. Uniform Tire Quality Grading

(UTQG):

Tire manufacturers are required to

grade tires based on three perfor-

mance factors: treadwear, traction

and temperature resistance. For more

information, see Uniform Tire Qual-

ity Grading on page 8-14.

I030D01JM-AATTIRE TERMINOLOGY AND DEFINI-

TIONS

Air Pressure: The amount of air inside

the tire pressing outward on the tire. Air

pressure is expressed in pounds per

square inch (psi) or kilopascal (kPa).

Accessory Weight: This means the

combined weight of optional accesso-

ries. Some examples of optional ac-

cessories are, automatic transmission,

power seats, and air conditioning.

Aspect Ratio: The relationship of a

tire's height to its width.

Belt: A rubber coated layer of cords that

is located between the plies and the

tread. Cords may be made from steel or

other reinforcing materials.

Bead: The tire bead contains steel

wires wrapped by steel cords that hold

the tire onto the rim.

Bias Ply Tire: A pneumatic tire in which

the plies are laid at alternate angles

less than 90 degrees to the centerline of

the tread.Cold Tire Pressure: The amount of air

pressure in a tire, measured in pounds

per square inch (psi) or kilopascals

(kPa) before a tire has built up heat from

driving.

Curb Weight: This means the weight of

a motor vehicle with standard and op-

tional equipment including the maxi-

mum capacity of fuel, oil and coolant,

but without passengers and cargo.

DOT Markings: A code molded into the

sidewall of a tire signifying that the tire

is in compliance with the U.S. Depart-

ment of Transportation motor vehicle

safety standards. The DOT code in-

cludes the Tire Identification Number

(TIN), an alphanumeric designator which

can also identify the tire manufacturer,

production plant, brand and date of

production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight Rating

for the front Axle.

GAWR RR: Gross Axle Weight Rating

for the rear axle.

Page 277 of 286

9

VEHICLE SPECIFICATIONS2

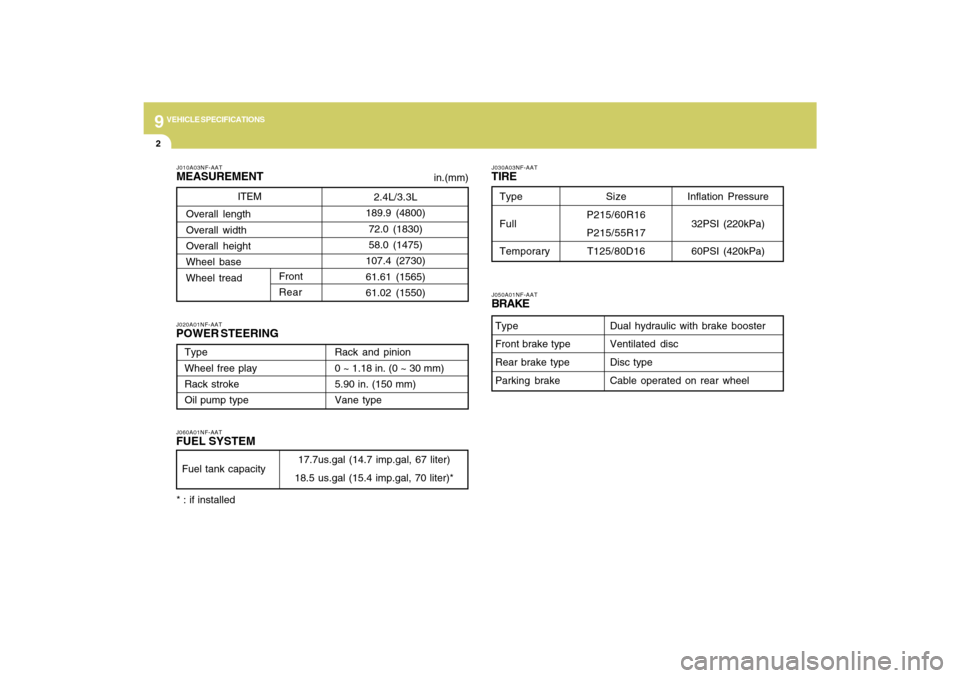

J010A03NF-AATMEASUREMENTJ060A01NF-AATFUEL SYSTEMJ020A01NF-AATPOWER STEERING

J030A03NF-AATTIRE

in.(mm)

Fuel tank capacity

17.7us.gal (14.7 imp.gal, 67 liter)

18.5 us.gal (15.4 imp.gal, 70 liter)* ITEM

J050A01NF-AATBRAKE

Dual hydraulic with brake booster

Ventilated disc

Disc type

Cable operated on rear wheel Type

Front brake type

Rear brake type

Parking brake

Type

Wheel free play

Rack stroke

Oil pump typeRack and pinion

0 ~ 1.18 in. (0 ~ 30 mm)

5.90 in. (150 mm)

Vane type

2.4L/3.3L

189.9 (4800)

72.0 (1830)

58.0 (1475)

107.4 (2730)

61.61 (1565)

61.02 (1550) Overall length

Overall width

Overall height

Wheel base

Wheel tread

Front

Rear

Inflation Pressure

32PSI (220kPa)

60PSI (420kPa)

Type

Full

TemporarySize

P215/60R16

P215/55R17

T125/80D16

* : if installed

Page 283 of 286

10

INDEX

4

Fuel

Capacity............................................................................ 9-2

Gauge..............................................................................1-55

Recommendations............................................................ 1-2

Fuel Filler Lid

Remote release ..............................................................1-85

Fuse Panel Description .....................................................6-37

Fuses..................................................................................6-22

G

General Checks ................................................................... 6-4

Glove Box ...........................................................................1-73

H

Hazard Warning System ....................................................1-65

Headlight

Aiming adjustment ..........................................................6-27

Replacement...................................................................6-28

Switch..............................................................................1-61

Heating and Cooling Control ............................................1-96

Heating and Ventilation

Air flow control ................................................... 1-98, 1-108

Air intake control switch ..................................... 1-99, 1-107

Bi-level heating .............................................................1-100

Defrosting/Defogging....................................................1-103

Fan speed control (Blower Control) .................. 1-97, 1-107

Temperature control .......................................................1-97

High-Mounted Rear Stop Light .........................................1-85

Hood Release ....................................................................1-87

Horn....................................................................................1-90I

Ignition Switch ...................................................................... 2-3

Instrument Cluster and Indicator Lights ............................1-48

Instrument Panel Light Control (Rheostat) .......................1-66

Interior Light .......................................................................1-72

Intermittent Wiper ...............................................................1-64

J

Jump Starting ....................................................................... 3-3

K

Key ........................................................................................ 1-3

If you lose your keys ......................................................3-18

Positions............................................................................ 2-3

L

Light Bulb Watages ............................................................6-36

Light Bulbs Replacement ..................................................6-28

Lubrication Chart .................................................................. 9-4

M

Maintenance Intervals

Explanation of scheduled maintenance items ................ 5-7

Maintenance under severe usage conditions ................. 5-6

Scheduled maintenance .................................................. 5-4

Service requirements ........................................................ 5-2

Mirrors

Day/night inside rearview ...............................................1-76

Homelink mirror ..............................................................1-77

Outside rearview .............................................................1-75

Outside rearview mirror heater ......................................1-76