cooling Hyundai Sonata

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 340, PDF Size: 18.45 MB

Page 259 of 340

Maintenance

16

7

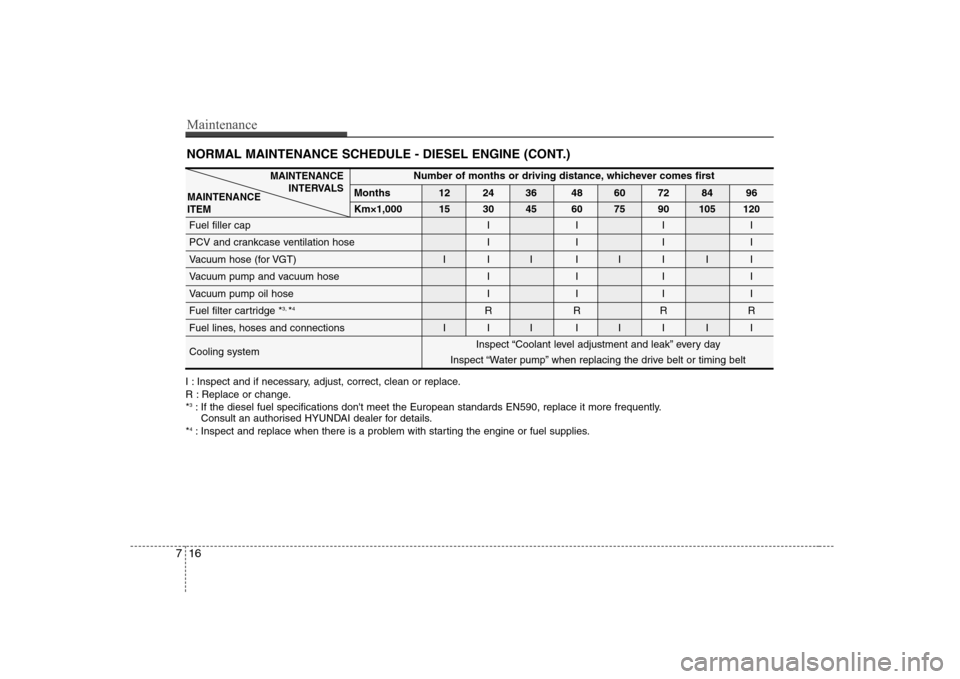

NORMAL MAINTENANCE SCHEDULE - DIESEL ENGINE (CONT.)

MAINTENANCE

INTERVALS

MAINTENANCE ITEMNumber of months or driving distance, whichever comes first

Months 12 24 36 48 60 72 84 96 Km×1,000

15 30 45 60 75 90 105 120

Fuel filler cap I I I I

PCV and crankcase ventilation hose I I I I

Vacuum hose (for VGT) I I I I I I I I

Vacuum pump and vacuum hose I I I I

Vacuum pump oil hose I I I I

Fuel filter cartridge * 3,

*4

RRRR

Fuel lines, hoses and connections I I I I I I I I Cooling system Inspect “Coolant level adjustment and leak” every day

Inspect “Water pump” when replacing the drive belt or timing belt

I : Inspect and if necessary, adjust, correct, clean or replace.

R : Replace or change.* 3

: If the diesel fuel specifications don't meet the European standards EN590, replace it more frequently.

Consult an authorised HYUNDAI dealer for details.

* 4

: Inspect and replace when there is a problem with starting the engine or fuel supplies.

Page 265 of 340

Maintenance

22

7

G050500AUN Timing belt (if equipped)

Inspect all parts related to the timing belt

for damage and deformation. Replace

any damaged parts immediately.

G050600AUN-EA

Vapour hose and fuel filler cap

The vapour hose and fuel filler cap

should be inspected at those intervals

specified in the maintenance schedule.

Make sure that a new vapour hose or fuelfiller cap is correctly replaced. G050700AUN

Vacuum crankcase ventilation hoses (if equipped)

Inspect the surface of hoses for evidence

of heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine those hose

surfaces nearest to high heat sources,

such as the exhaust manifold. Inspect the hose routing to assure that the hoses do not come in contact with

any heat source, sharp edges or movingcomponent which might cause heat dam-

age or mechanical wear. Inspect all hose

connections, such as clamps and cou-

plings, to make sure they are secure, and

that no leaks are present. Hoses should

be replaced immediately if there is any

evidence of deterioration or damage.G050800AFD

Air cleaner filter

A Genuine HYUNDAI air cleaner filter is recommended when the filter isreplaced.

G050900AUN-EA

Spark plugs (for petrol engine)

Make sure to install new spark plugs of

the correct heat range. G051000AFD-EA

Valve clearance (if equipped)

Inspect excessive valve noise and/or

engine vibration and adjust if necessary.

An authorised HYUNDAI dealer should

perform the operation.

G051100AUN Cooling system

Check the cooling system parts, such as

radiator, coolant reservoir, hoses and

connections for leakage and damage.

Replace any damaged parts.

G051200AUN Coolant The coolant should be changed at the

intervals specified in the maintenance

schedule.

Page 268 of 340

725

Maintenance

ENGINE COOLANT

G060200AFD-EA Changing the engine oil and filter

Have engine oil and filter changed by an

authorised HYUNDAI dealer according tothe Maintenance Schedule at the begin-ning of this section. G070000AFD-EA The high-pressure cooling system has a

reservoir filled with year-round antifreeze

coolant. The reservoir is filled at the fac-

tory.

Check the antifreeze protection and

coolant concentration level at least once

a year, at the beginning of the winter sea-

son, and before travelling to a colder cli-

mate. G070100AFD-EA

Checking the coolant level

WARNING

- Removing

radiator cap

Never attempt to remove the radi- ator cap while the engine is oper-

ating or hot. Doing so might leadto cooling system and engine

damage and could result in seri-

ous personal injury from escap-ing hot coolant or steam.

(Continued)

WARNING

Used engine oil may cause irrita- tion or cancer of the skin if left in

contact with the skin for prolonged

periods of time. Used engine oil

has been proven to contain car-

cinogens. Always protect your skin

by washing your hands thoroughlywith soap and warm water as soon

as possible after handling used oil.

(Continued)

Turn the engine off and wait until it cools down. Use extreme care

when removing the radiator cap.

Wrap a thick towel around it, and

turn it counterclockwise slowly to

the first stop. Step back while the

pressure is released from the

cooling system. When you aresure all the pressure has been

released, press down on the cap,

using a thick towel, and continue

turning counterclockwise to

remove it.

Even if the engine is not operat- ing, do not remove the radiatorcap or the drain plug while the

engine and radiator are hot. Hot

coolant and steam may still blow

out under pressure, causing seri-

ous injury.

Page 269 of 340

Maintenance

26

7

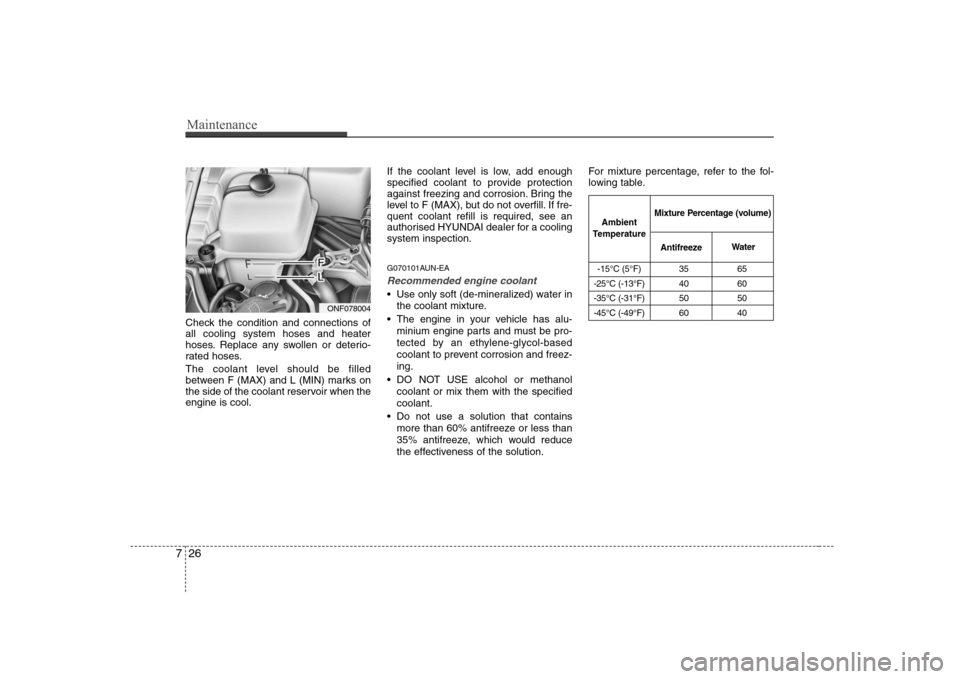

-15°C (5°F) 35 65

-25°C (-13°F) 40 60

-35°C (-31°F) 50 50

-45°C (-49°F) 60 40

Ambient

Temperature Mixture Percentage (volume)

Antifreeze Water

Check the condition and connections of all cooling system hoses and heater

hoses. Replace any swollen or deterio-

rated hoses.

The coolant level should be filled

between F (MAX) and L (MIN) marks on

the side of the coolant reservoir when theengine is cool. If the coolant level is low, add enough

specified coolant to provide protection

against freezing and corrosion. Bring the

level to F (MAX), but do not overfill. If fre-quent coolant refill is required, see an

authorised HYUNDAI dealer for a coolingsystem inspection.

G070101AUN-EA

Recommended engine coolant

Use only soft (de-mineralized) water in

the coolant mixture.

The engine in your vehicle has alu- minium engine parts and must be pro-

tected by an ethylene-glycol-based

coolant to prevent corrosion and freez-ing.

DO NOT USE alcohol or methanol coolant or mix them with the specifiedcoolant.

Do not use a solution that contains more than 60% antifreeze or less than

35% antifreeze, which would reduce

the effectiveness of the solution. For mixture percentage, refer to the fol-

lowing table.

ONF078004

Page 304 of 340

761

Maintenance

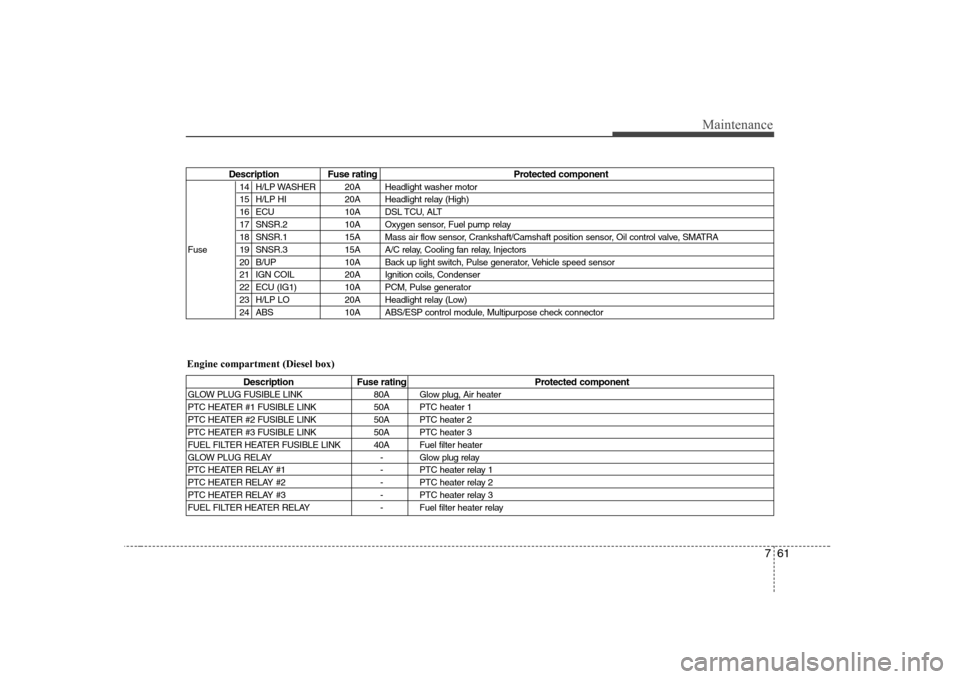

Description Fuse rating Protected component14 H/LP WASHER 20A Headlight washer motor

15 H/LP HI 20A Headlight relay (High)

16 ECU 10A DSL TCU, ALT

17 SNSR.2 10A Oxygen sensor, Fuel pump relay

18 SNSR.1 15A Mass air flow sensor, Crankshaft/Camshaft position sensor, Oil control valve, SMATRA

Fuse 19 SNSR.3 15A A/C relay, Cooling fan relay, Injectors 20 B/UP 10A Back up light switch, Pulse generator, Vehicle speed sensor

21 IGN COIL 20A Ignition coils, Condenser

22 ECU (IG1) 10A PCM, Pulse generator

23 H/LP LO 20A Headlight relay (Low)

24 ABS 10A ABS/ESP control module, Multipurpose check connector

Description Fuse rating Protected component

GLOW PLUG FUSIBLE LINK 80A Glow plug, Air heater

PTC HEATER #1 FUSIBLE LINK 50A PTC heater 1

PTC HEATER #2 FUSIBLE LINK 50A PTC heater 2

PTC HEATER #3 FUSIBLE LINK 50A PTC heater 3

FUEL FILTER HEATER FUSIBLE LINK 40A Fuel filter heater

GLOW PLUG RELAY - Glow plug relay

PTC HEATER RELAY #1 - PTC heater relay 1

PTC HEATER RELAY #2 - PTC heater relay 2

PTC HEATER RELAY #3 - PTC heater relay 3

FUEL FILTER HEATER RELAY - Fuel filter heater relay

Engine compartment (Diesel box)