Hyundai Sonata

Manufacturer: HYUNDAI, Model Year: , Model line: , Model:Pages: 340, PDF Size: 18.45 MB

Page 231 of 340

What to do in an emergency

4

6

EMERGENCY STARTING

F040100AUN

Jump starting

Jump starting can be dangerous if done

incorrectly. Therefore, to avoid harm to

yourself or damage to your vehicle or

battery, follow the jump starting proce-

dures. If in doubt, we strongly recom-

mend that you have a competent techni-

cian or towing service jump start your

vehicle. F040101AFD-EA

Jump starting procedure

1. Make sure the booster battery is 12-

volt and that its negative terminal is

grounded.

2. If the booster battery is in another vehicle, do not allow the vehicles totouch.

3. Turn off all unnecessary electrical loads.

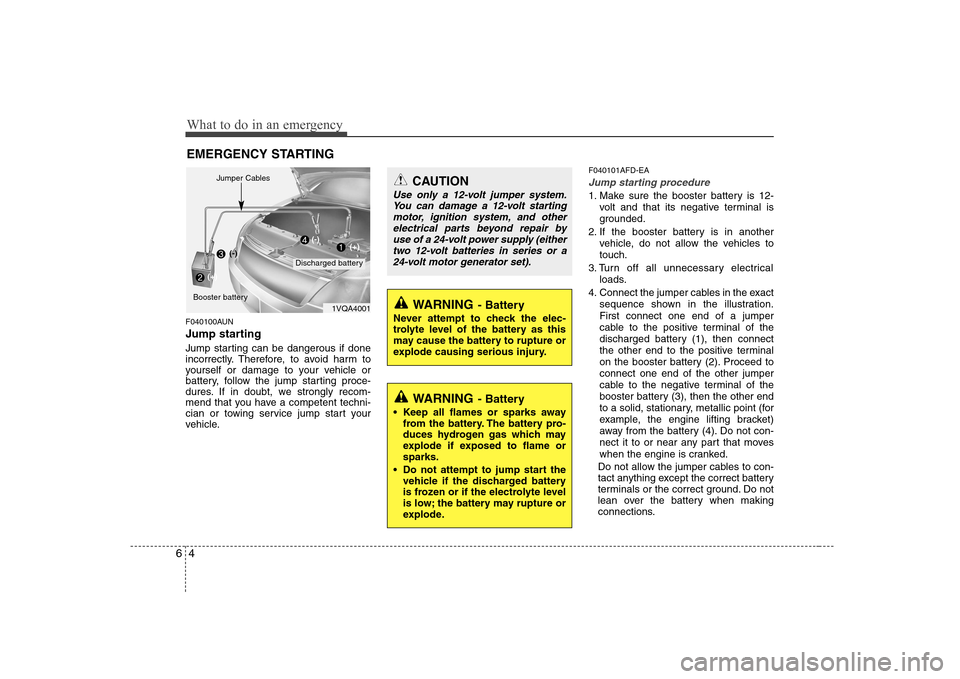

4. Connect the jumper cables in the exact sequence shown in the illustration.First connect one end of a jumper

cable to the positive terminal of the

discharged battery (1), then connect

the other end to the positive terminal

on the booster battery (2). Proceed toconnect one end of the other jumper

cable to the negative terminal of the

booster battery (3), then the other end

to a solid, stationary, metallic point (for

example, the engine lifting bracket)

away from the battery (4). Do not con-

nect it to or near any part that moves

when the engine is cranked.

Do not allow the jumper cables to con-

tact anything except the correct battery

terminals or the correct ground. Do not

lean over the battery when making

connections.

CAUTION

Use only a 12-volt jumper system. You can damage a 12-volt startingmotor, ignition system, and other electrical parts beyond repair by

use of a 24-volt power supply (eithertwo 12-volt batteries in series or a 24-volt motor generator set).

WARNING - Battery

• Keep all flames or sparks away from the battery. The battery pro-

duces hydrogen gas which may

explode if exposed to flame orsparks.

Do not attempt to jump start the vehicle if the discharged battery

is frozen or if the electrolyte level

is low; the battery may rupture or

explode.

WARNING - Battery

Never attempt to check the elec-

trolyte level of the battery as this

may cause the battery to rupture or

explode causing serious injury.1VQA4001

Discharged battery

Jumper Cables

Booster battery(-)

(+)

(+)(-)

Page 232 of 340

65

What to do in an emergency

5. Start the engine of the vehicle with thebooster battery and let it run at 2,000

rpm, then start the engine of the vehi-

cle with the discharged battery.

If the cause of your battery discharging is

not apparent, you should have your vehi-

cle checked by an authorised HYUNDAIdealer.

F040200AUN

Push-starting

Your manual transaxle-equipped vehicle

should not be push-started because itmight damage the emission control sys-tem.

Vehicles equipped with automatic

transaxle cannot be push-started.

Follow the directions in this section for

jump-starting.

WARNING

Never tow a vehicle to start it

because the sudden surge forward

when the engine starts could cause

a collision with the tow vehicle.

CAUTION - Battery cables

Do not connect the jumper cable

from the negative terminal of the booster battery to the negative ter-minal of the discharged battery.

This can cause the discharged bat-tery to overheat and crack, releas-ing battery acid.

Page 233 of 340

What to do in an emergency

6

6

IF THE ENGINE OVERHEATS

F050000AFD-EA

If your temperature gauge indicates over-

heating, you experience a loss of power,

or hear loud pinging or knocking, the

engine is probably too hot. If this hap-

pens, you should:

1. Pull off the road and stop as soon as it is safe to do so.

2. Place the gear selector lever in P (automatic transaxle) or neutral (manu-

al transaxle) and set the parking brake.

If the air conditioning is on, turn it off.

3. If engine coolant is running out under the car or steam is coming out from

the bonnet, stop the engine. Do notopen the bonnet until the coolant has

stopped running or the steaming has

stopped. If there is no visible loss of

engine coolant and no steam, leave

the engine running and check to be

sure the engine cooling fan is operat-

ing. If the fan is not running, turn the

engine off.

4. While engine is switched off, check to see if the water pump drive belt is

missing. If it is not missing, check to

see that it is tight. If the drive belt

seems to be satisfactory, check for

coolant leaking from the radiator,

hoses or under the car. (If the air con-

ditioning had been in use, it is normal

for cold water to be draining from it

when you stop). 5. If the water pump drive belt is broken

or engine coolant is leaking out, stop the engine immediately and call the

nearest authorised HYUNDAI dealer

for assistance. 6. If you cannot find the cause of the

overheating, wait until the engine tem-

perature has returned to normal. Then,if coolant has been lost, carefully add

coolant to the reservoir to bring the

fluid level in the reservoir up to the

halfway mark.

7. Proceed with caution, keeping alert for further signs of overheating. If over-heating happens again, call an autho-

rised HYUNDAI dealer for assistance.

CAUTION

Serious loss of coolant indicates

there is a leak in the cooling systemand this should be checked as soonas possible by an authorisedHYUNDAI dealer.

WARNING

While the engine is running, keep

hair, hands and clothing away from

moving parts such as the fan and

drive belts to prevent injury.

WARNING

Do not remove the radiator cap

when the engine is hot. This can

allow coolant to be blown out of the

opening and cause serious burns.

Page 234 of 340

67

What to do in an emergency

IF YOU HAVE A FLAT TYRE

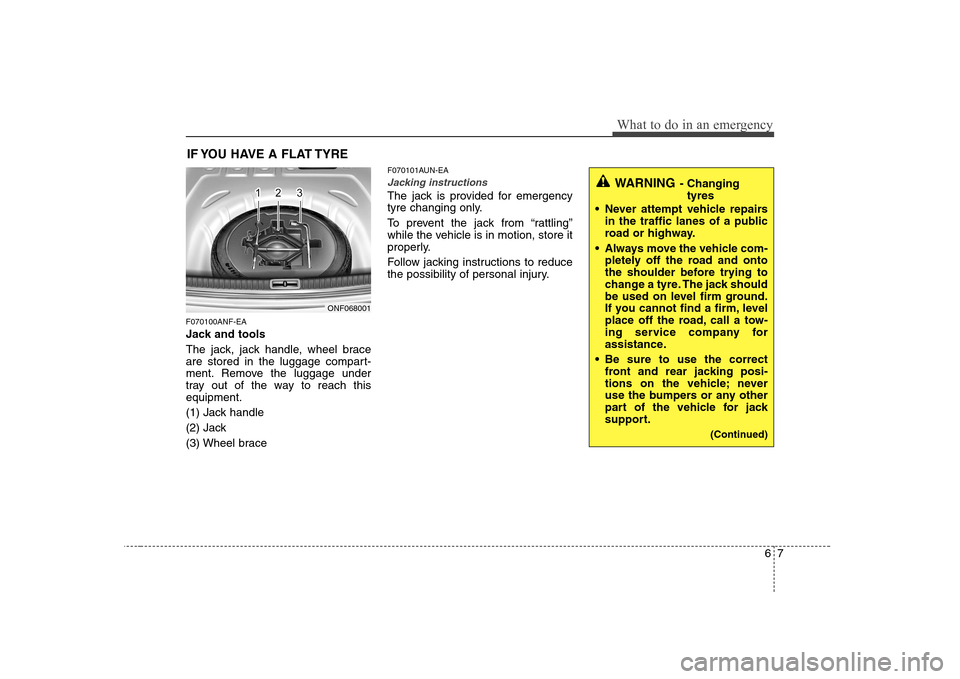

F070100ANF-EA

Jack and tools

The jack, jack handle, wheel brace

are stored in the luggage compart-

ment. Remove the luggage under

tray out of the way to reach thisequipment.

(1) Jack handle

(2) Jack

(3) Wheel brace F070101AUN-EA

Jacking instructions

The jack is provided for emergency

tyre changing only.

To prevent the jack from “rattling”

while the vehicle is in motion, store it

properly.

Follow jacking instructions to reduce

the possibility of personal injury.

ONF068001

WARNING

- Changing

tyres

Never attempt vehicle repairs in the traffic lanes of a public

road or highway.

Always move the vehicle com- pletely off the road and onto

the shoulder before trying to

change a tyre. The jack should

be used on level firm ground.

If you cannot find a firm, level

place off the road, call a tow-

ing service company for

assistance.

Be sure to use the correct front and rear jacking posi-

tions on the vehicle; never

use the bumpers or any other

part of the vehicle for jack

support.

(Continued)

Page 235 of 340

What to do in an emergency

8

6

F070200AFD-EA

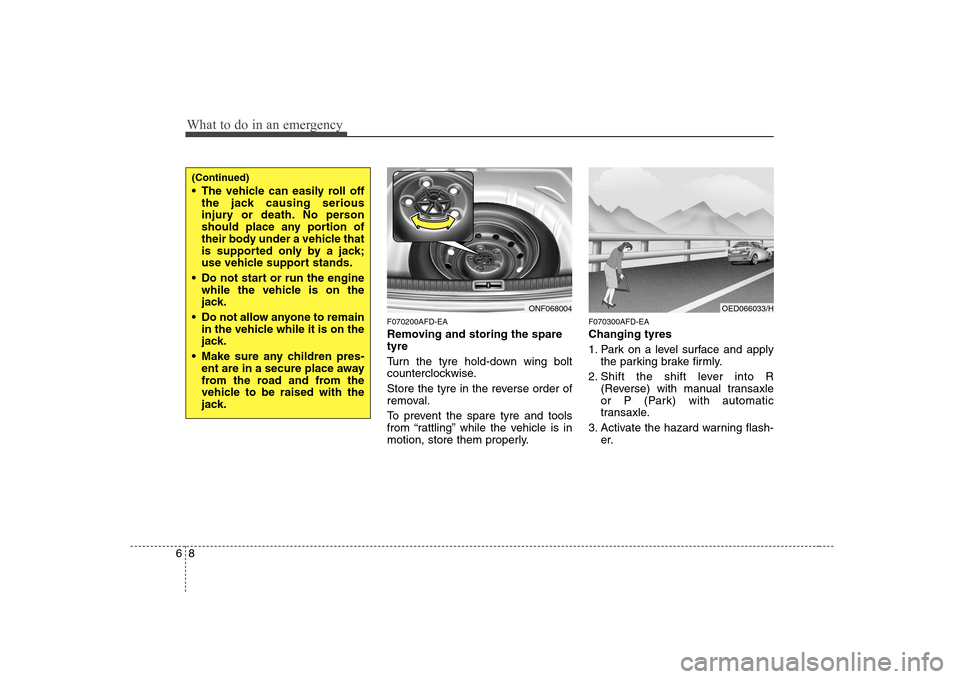

Removing and storing the spare tyre

Turn the tyre hold-down wing bolt

counterclockwise.

Store the tyre in the reverse order of

removal.

To prevent the spare tyre and tools

from “rattling” while the vehicle is in

motion, store them properly. F070300AFD-EA Changing tyres

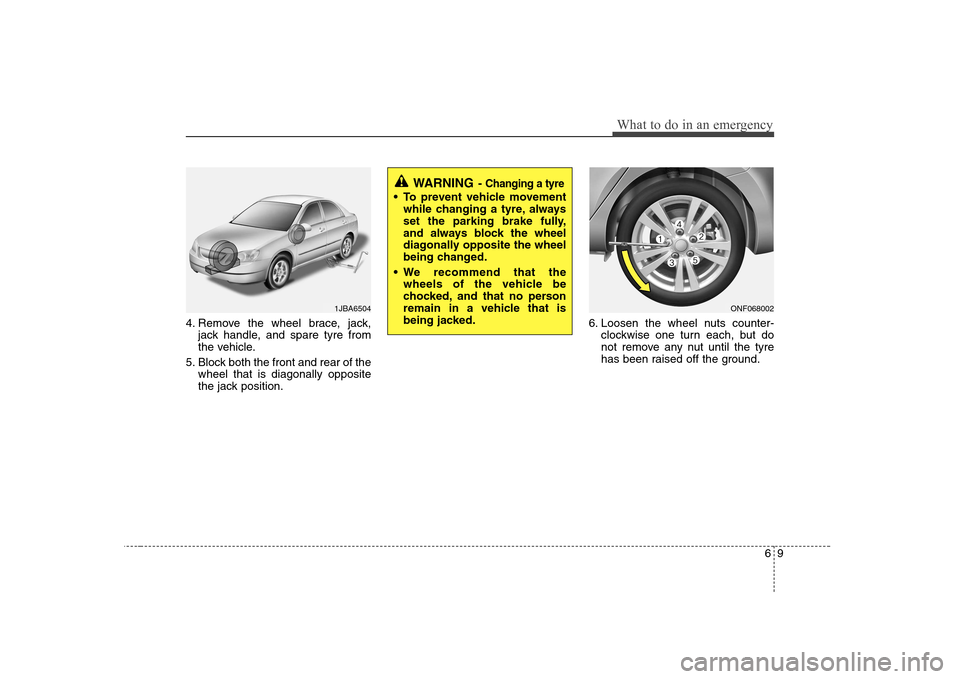

1. Park on a level surface and apply

the parking brake firmly.

2. Shift the shift lever into R (Reverse) with manual transaxle

or P (Park) with automatic

transaxle.

3. Activate the hazard warning flash- er.

ONF068004

(Continued)

The vehicle can easily roll offthe jack causing serious

injury or death. No person

should place any portion of

their body under a vehicle that

is supported only by a jack;

use vehicle support stands.

Do not start or run the engine while the vehicle is on the

jack.

Do not allow anyone to remain in the vehicle while it is on the

jack.

Make sure any children pres- ent are in a secure place away

from the road and from the

vehicle to be raised with the

jack.

OED066033/H

Page 236 of 340

69

What to do in an emergency

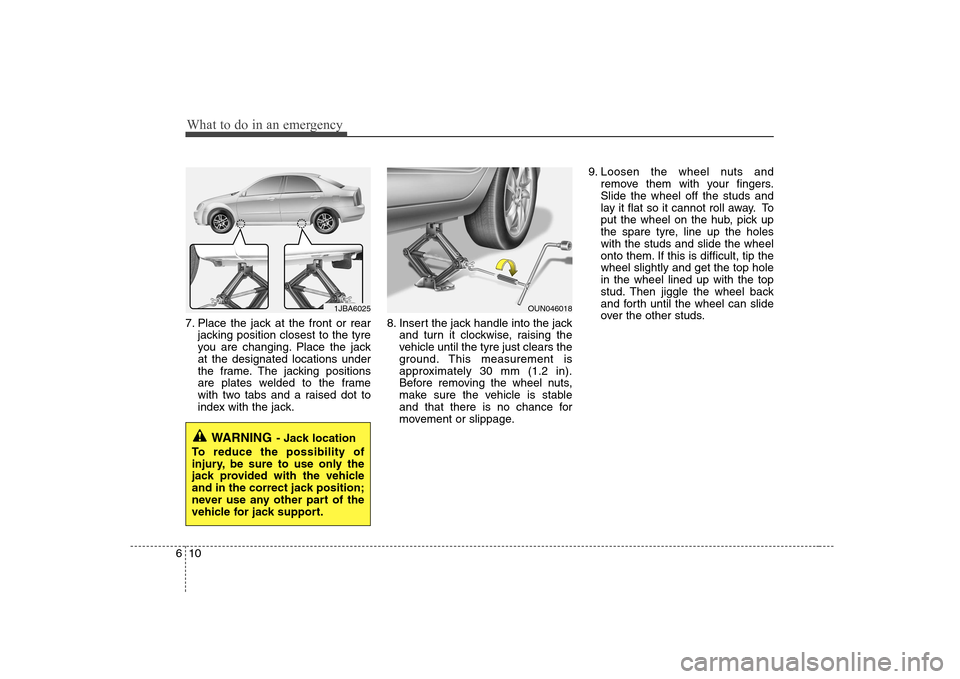

4. Remove the wheel brace, jack,jack handle, and spare tyre from

the vehicle.

5. Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6. Loosen the wheel nuts counter-

clockwise one turn each, but do

not remove any nut until the tyre

has been raised off the ground.

1JBA6504ONF068002

WARNING - Changing a tyre

To prevent vehicle movement

while changing a tyre, always

set the parking brake fully,

and always block the wheel

diagonally opposite the wheel

being changed.

We recommend that the wheels of the vehicle be

chocked, and that no person

remain in a vehicle that is

being jacked.

Page 237 of 340

What to do in an emergency

10

6

7. Place the jack at the front or rear

jacking position closest to the tyre

you are changing. Place the jackat the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack. 8. Insert the jack handle into the jack

and turn it clockwise, raising the

vehicle until the tyre just clears the

ground. This measurement is

approximately 30 mm (1.2 in).

Before removing the wheel nuts,

make sure the vehicle is stable

and that there is no chance for

movement or slippage. 9. Loosen the wheel nuts and

remove them with your fingers.Slide the wheel off the studs and

lay it flat so it cannot roll away. To

put the wheel on the hub, pick up

the spare tyre, line up the holeswith the studs and slide the wheel

onto them. If this is difficult, tip thewheel slightly and get the top holein the wheel lined up with the top

stud. Then jiggle the wheel back

and forth until the wheel can slide

over the other studs.

WARNING - Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

1JBA6025OUN046018

Page 238 of 340

611

What to do in an emergency

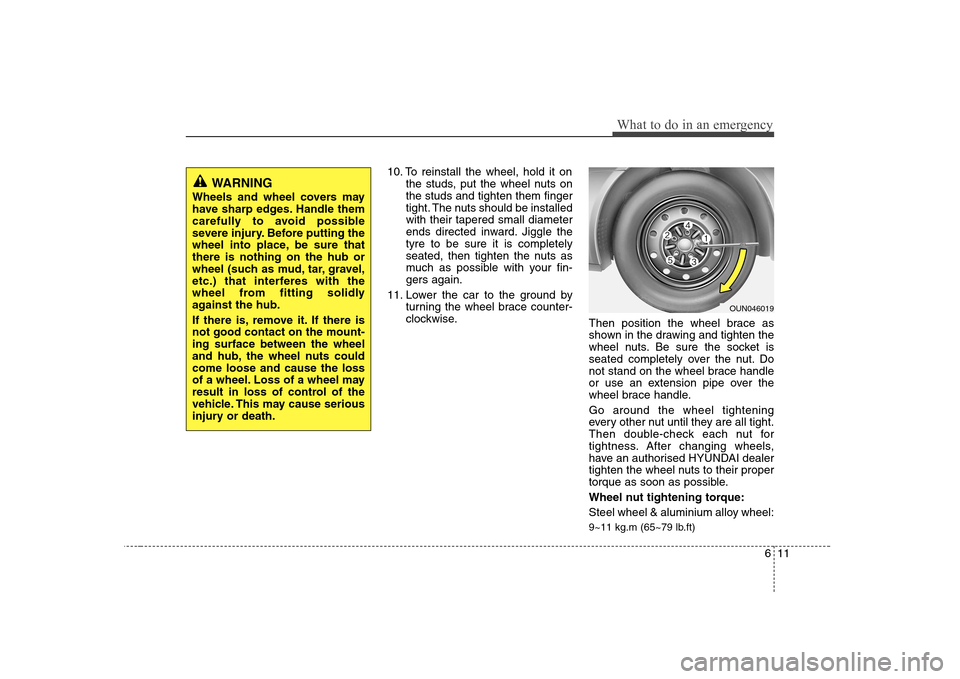

10. To reinstall the wheel, hold it onthe studs, put the wheel nuts on the studs and tighten them finger

tight. The nuts should be installedwith their tapered small diameter

ends directed inward. Jiggle thetyre to be sure it is completely

seated, then tighten the nuts as

much as possible with your fin-gers again.

11. Lower the car to the ground by turning the wheel brace counter-

clockwise. Then position the wheel brace as

shown in the drawing and tighten the

wheel nuts. Be sure the socket is

seated completely over the nut. Do

not stand on the wheel brace handle

or use an extension pipe over the

wheel brace handle. Go around the wheel tightening

every other nut until they are all tight.

Then double-check each nut for

tightness. After changing wheels,

have an authorised HYUNDAI dealer

tighten the wheel nuts to their proper

torque as soon as possible.

Wheel nut tightening torque:

Steel wheel & aluminium alloy wheel:

9~11 kg.m (65~79 lb.ft)

OUN046019

WARNING

Wheels and wheel covers may

have sharp edges. Handle them

carefully to avoid possible

severe injury. Before putting the

wheel into place, be sure thatthere is nothing on the hub or

wheel (such as mud, tar, gravel,

etc.) that interferes with the

wheel from fitting solidly

against the hub.

If there is, remove it. If there is not good contact on the mount-ing surface between the wheel

and hub, the wheel nuts couldcome loose and cause the loss

of a wheel. Loss of a wheel may

result in loss of control of the

vehicle. This may cause serious

injury or death.

Page 239 of 340

What to do in an emergency

12

6

If you have a tyre gauge, remove the

valve cap and check the air pressure.

If the pressure is lower than recom-

mended, drive slowly to the nearest

service station and inflate to the cor-

rect pressure. If it is too high, adjust

it until it is correct. Always reinstall

the valve cap after checking or

adjusting tyre pressure. If the cap is

not replaced, air may leak from the

tyre. If you lose a valve cap, buyanother and install it as soon as pos-

sible.

After you have changed wheels,

always secure the flat tyre in its place

and return the jack and tools to their

proper storage locations. To prevent the jack, jack handle,

wheel brace and spare tyre from rat-

tling while the vehicle is in motion,

store them properly.CAUTION

Your vehicle has metric threads

on the wheel studs and nuts.Make certain during wheelremoval that the same nuts that were removed are reinstalled -or, if replaced, that nuts withmetric threads and the same chamfer configuration are used.Installation of a non-metricthread nut on a metric stud or vice-versa will not secure thewheel to the hub properly andwill damage the stud so that itmust be replaced.

Note that most wheel nuts donot have metric threads. Be sureto use extreme care in checkingfor thread style before installing aftermarket wheel nuts orwheels. If in doubt, consult anauthorised HYUNDAI dealer.

WARNING - Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. This could lead to theloss of the wheel and a collisionresulting in serious injuries.

WARNING - Inadequate

spare tyre pressure

Check the inflation pressures as

soon as possible after installing

the spare tyre. Adjust it to the

specified pressure, if necessary.

Refer to “Tyres and wheels” insection 9.

Page 240 of 340

613

What to do in an emergency

TOWING

F080100AFD-EA

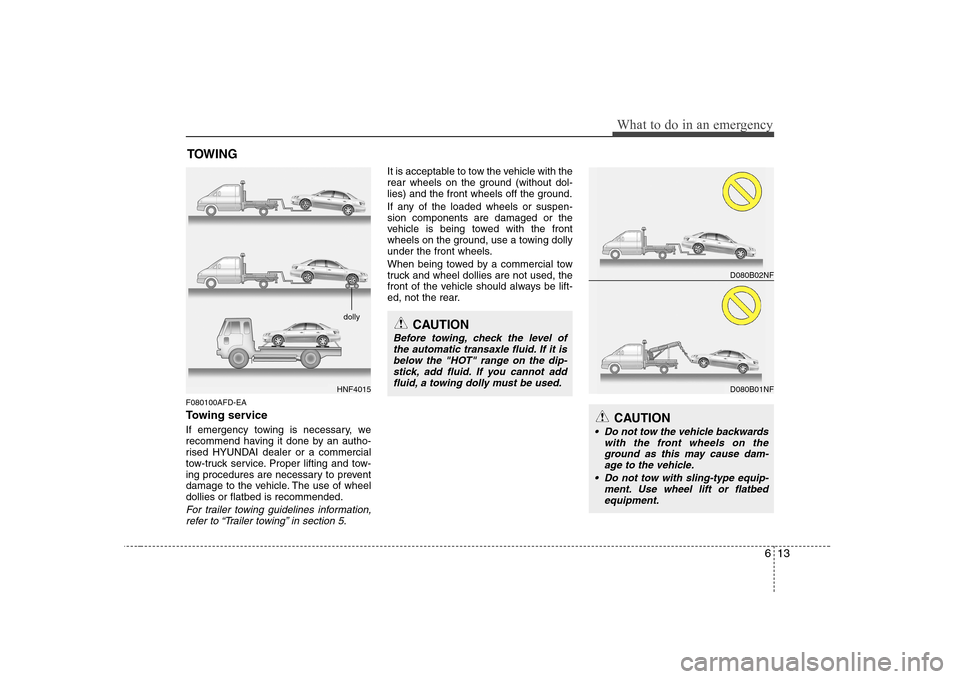

Towing service

If emergency towing is necessary, we

recommend having it done by an autho-

rised HYUNDAI dealer or a commercial

tow-truck service. Proper lifting and tow-

ing procedures are necessary to prevent

damage to the vehicle. The use of wheeldollies or flatbed is recommended.

For trailer towing guidelines information, refer to “Trailer towing” in section 5.

It is acceptable to tow the vehicle with the

rear wheels on the ground (without dol-

lies) and the front wheels off the ground.

If any of the loaded wheels or suspen- sion components are damaged or the

vehicle is being towed with the front

wheels on the ground, use a towing dolly

under the front wheels.

When being towed by a commercial tow

truck and wheel dollies are not used, the

front of the vehicle should always be lift-

ed, not the rear.

HNF4015

D080B02NF

D080B01NF

CAUTION

Do not tow the vehicle backwards

with the front wheels on theground as this may cause dam- age to the vehicle.

Do not tow with sling-type equip- ment. Use wheel lift or flatbed

equipment.

CAUTION

Before towing, check the level ofthe automatic transaxle fluid. If it isbelow the "HOT" range on the dip- stick, add fluid. If you cannot addfluid, a towing dolly must be used.

dolly