761

Maintenance

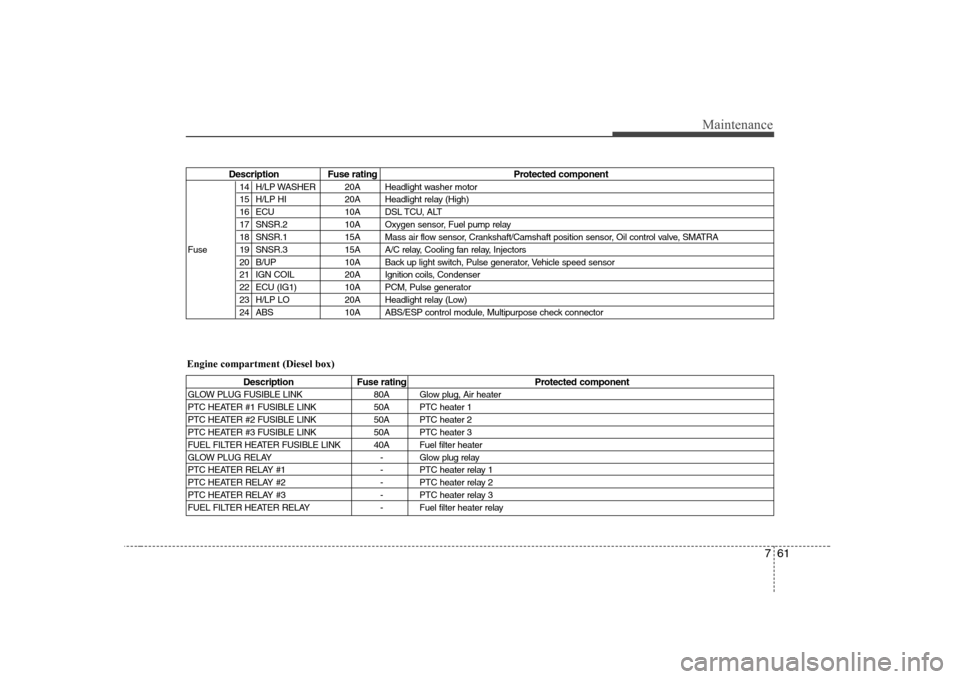

Description Fuse rating Protected component14 H/LP WASHER 20A Headlight washer motor

15 H/LP HI 20A Headlight relay (High)

16 ECU 10A DSL TCU, ALT

17 SNSR.2 10A Oxygen sensor, Fuel pump relay

18 SNSR.1 15A Mass air flow sensor, Crankshaft/Camshaft position sensor, Oil control valve, SMATRA

Fuse 19 SNSR.3 15A A/C relay, Cooling fan relay, Injectors 20 B/UP 10A Back up light switch, Pulse generator, Vehicle speed sensor

21 IGN COIL 20A Ignition coils, Condenser

22 ECU (IG1) 10A PCM, Pulse generator

23 H/LP LO 20A Headlight relay (Low)

24 ABS 10A ABS/ESP control module, Multipurpose check connector

Description Fuse rating Protected component

GLOW PLUG FUSIBLE LINK 80A Glow plug, Air heater

PTC HEATER #1 FUSIBLE LINK 50A PTC heater 1

PTC HEATER #2 FUSIBLE LINK 50A PTC heater 2

PTC HEATER #3 FUSIBLE LINK 50A PTC heater 3

FUEL FILTER HEATER FUSIBLE LINK 40A Fuel filter heater

GLOW PLUG RELAY - Glow plug relay

PTC HEATER RELAY #1 - PTC heater relay 1

PTC HEATER RELAY #2 - PTC heater relay 2

PTC HEATER RELAY #3 - PTC heater relay 3

FUEL FILTER HEATER RELAY - Fuel filter heater relay

Engine compartment (Diesel box)

Maintenance

68

7

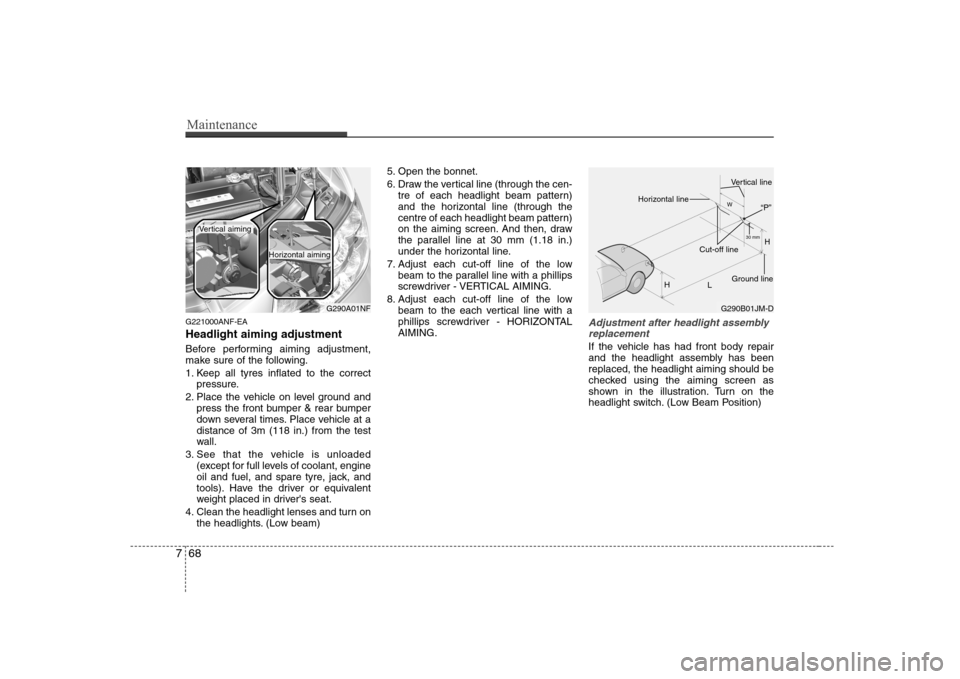

G221000ANF-EA Headlight aiming adjustment

Before performing aiming adjustment,

make sure of the following.

1. Keep all tyres inflated to the correct

pressure.

2. Place the vehicle on level ground and press the front bumper & rear bumper

down several times. Place vehicle at adistance of 3m (118 in.) from the test

wall.

3. See that the vehicle is unloaded (except for full levels of coolant, engine

oil and fuel, and spare tyre, jack, and

tools). Have the driver or equivalent

weight placed in driver's seat.

4. Clean the headlight lenses and turn on the headlights. (Low beam) 5. Open the bonnet.

6. Draw the vertical line (through the cen-

tre of each headlight beam pattern)

and the horizontal line (through the

centre of each headlight beam pattern)

on the aiming screen. And then, draw

the parallel line at 30 mm (1.18 in.)

under the horizontal line.

7. Adjust each cut-off line of the low beam to the parallel line with a phillips

screwdriver - VERTICAL AIMING.

8. Adjust each cut-off line of the low beam to the each vertical line with a

phillips screwdriver - HORIZONTALAIMING.Adjustment after headlight assembly

replacement

If the vehicle has had front body repair

and the headlight assembly has beenreplaced, the headlight aiming should be

checked using the aiming screen as

shown in the illustration. Turn on the

headlight switch. (Low Beam Position)

G290A01NF

Vertical aiming

Horizontal aiming

G290B01JM-D H

H L30 mm

W

Horizontal line

Vertical line

“P”

Ground line

Cut-off line