fuel cap HYUNDAI TUCSON 2009 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2009, Model line: TUCSON, Model: HYUNDAI TUCSON 2009Pages: 273, PDF Size: 10.29 MB

Page 13 of 273

1FEATURES OF YOUR HYUNDAI2

!

B010A01JM

FUEL RECOMMENDATIONS

CAUTION:

Your Hyundai's New Vehicle Limited War-

ranty may not cover damage to the fuel

system and any performance problems

that are caused by the use of fuels con-

taining methanol or fuels containing

MTBE (Methyl Tertiary Butyl Ether) over

15.0% vol. (Oxygen Content 2.7% weight.)

B010B01A-AATWhat About Gasohol?Gasohol (a mixture of 90% unleaded gaso-

line and 10% ethanol or grain alcohol)

may be used in your Hyundai. However, if

your engine develops driveability prob-

lems, the use of 100% unleaded gasoline

is recommended. Fuels with unspecified

quantities of alcohol, or alcohols other

than ethanol, should not be used.

B010A05A-AATUse Unleaded GasolineUnleaded gasoline with a Pump Octane

Rating of 87 (Research Octane Number

91) or higher must be used in your

Hyundai.

B010C01A-AATUse of MTBEHyundai recommends that fuels contain-

ing MTBE (Methyl Tertiary Butyl Ether)

over 15.0% vol. (Oxygen Content 2.7%

weight) should not be used in your

Hyundai.

Fuel containing MTBE over 15.0% vol.

(Oxygen Content 2.7% weight) may re-

duce vehicle performance and produce

vapor lock or hard starting.

B010D01A-AATDo Not Use MethanolFuels containing methanol (wood alco-

hol) should not be used in your Hyundai.

This type of fuel can reduce vehicle perfor-

mance and damage components of the

fuel system.

!

UNLEADED

FUEL ONLY

WARNING:

o Do not "top off" after the nozzle auto-

matically shuts off when refueling.

o Tighten the cap until it clicks, other-

wise the "

" light will illuminate.

o Always check that the fuel cap is

installed securely to prevent fuel spill-

age in the event of an accident.

Page 66 of 273

1

FEATURES OF YOUR HYUNDAI

55

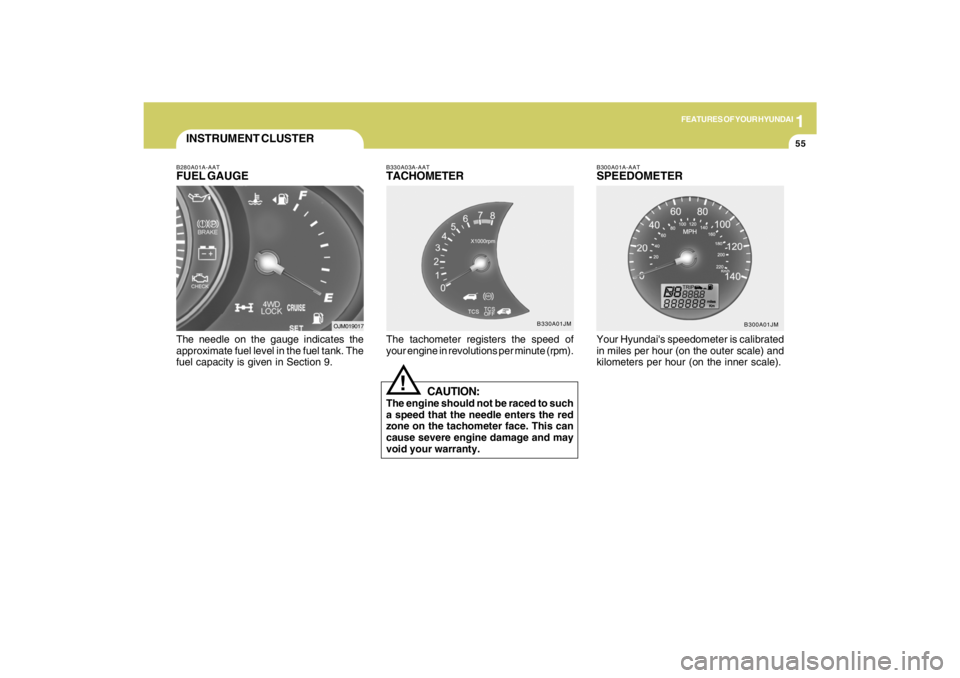

B280A01A-AATFUEL GAUGEThe needle on the gauge indicates the

approximate fuel level in the fuel tank. The

fuel capacity is given in Section 9.INSTRUMENT CLUSTER

OJM019017B330A03A-AAT

TACHOMETERThe tachometer registers the speed of

your engine in revolutions per minute (rpm).

CAUTION:

The engine should not be raced to such

a speed that the needle enters the red

zone on the tachometer face. This can

cause severe engine damage and may

void your warranty.

!

B300A01A-AATSPEEDOMETERYour Hyundai's speedometer is calibrated

in miles per hour (on the outer scale) and

kilometers per hour (on the inner scale).

B300A01JM B330A01JM

Page 95 of 273

1FEATURES OF YOUR HYUNDAI84

B560A01JM

!

o Tighten the cap until it clicks, other-

wise the "

" light will illuminate.

o If you open the fuel filler cap during

high ambient temperatures, a slight

"pressure sound" may be heard. This

is normal and not a cause for concern.

Whenever you open the fuel filler cap,

turn it slowly.

o Do not "top-off" after the nozzle auto-

matically shuts off when refueling.

o Automotive fuels are flammable/ex-

plosive materials. When refueling,

please note the following guidelines

carefully.

- Before touching the fuel nozzle or

fuel filler cap, have one's hands in

contact with metal parts away from

the filler neck to discharge static

electricity.

- Do not get back in the vehicle while

refueling. Do not operate anything

that can produce static electricity.

Static electricity discharge can ig-

nite fuel vapors resulting in explo-

sion.

!

WARNING:

o Gasoline vapors are dangerous. Be-

fore refueling, always stop the engine

and never smoke or allow sparks and

open flames near the filler area.

o Never operate your vehicle without a

filler cap properly installed, flammable

vapors and gasoline could leak out in

dangerous situations such as a colli-

sion or rollover. If the filler cap must

be replaced, only use genuine Hyundai

replacement parts.

o After refueling, make sure the fuel

cap is installed securely to prevent

fuel spillage in the event of an acci-

dent.

- When using a portable fuel con-

tainer be sure to place the con-

tainer on the ground while refueling.

Static electricity discharge from the

container can ignite fuel vapors

causing a fire. While starting refuel-

ing contact should be maintained

until the filling is complete.

- Do not use cellular phones around

a gas station. The electric current

or electronic interference from cel-

lular phones can ignite fuel vapors

causing a fire.

- When refueling always shut the en-

gine off. Sparks by electrical equip-

ment of the engine can ignite fuel

vapors causing a fire. After refuel-

ing, check to make sure the fuel

filler cap is securely closed, and

then start the engine.

- Do not smoke or try to light ciga-

rettes around a gas station. Auto-

motive fuels are flammable.

WARNING:

Page 167 of 273

2

DRIVING YOUR HYUNDAI

32

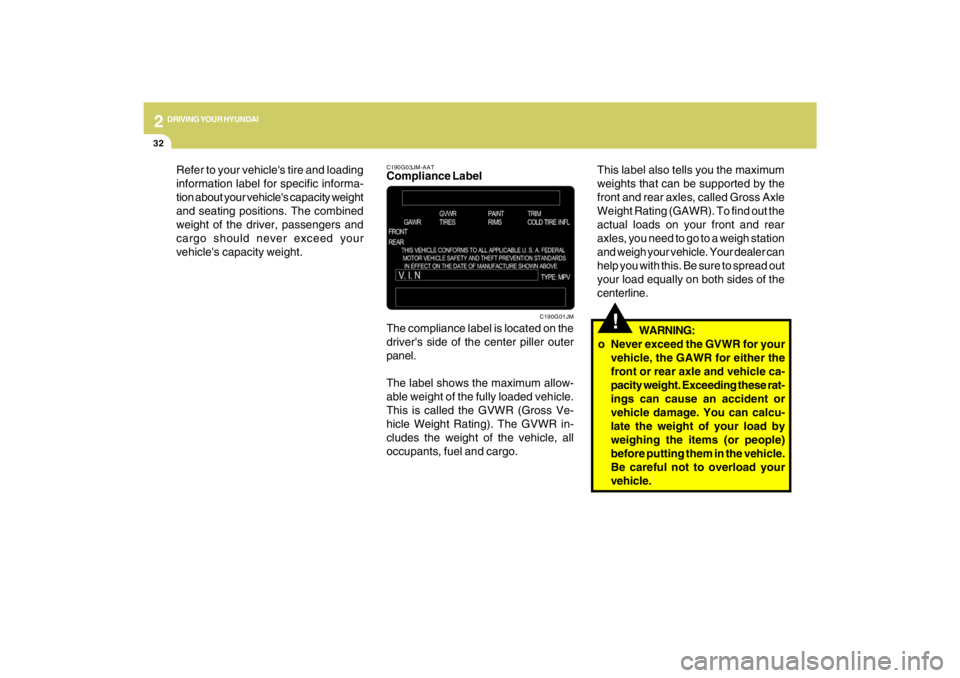

C190G03JM-AATCompliance Label

The compliance label is located on the

driver's side of the center piller outer

panel.

The label shows the maximum allow-

able weight of the fully loaded vehicle.

This is called the GVWR (Gross Ve-

hicle Weight Rating). The GVWR in-

cludes the weight of the vehicle, all

occupants, fuel and cargo.

C190G01JM

!

This label also tells you the maximum

weights that can be supported by the

front and rear axles, called Gross Axle

Weight Rating (GAWR). To find out the

actual loads on your front and rear

axles, you need to go to a weigh station

and weigh your vehicle. Your dealer can

help you with this. Be sure to spread out

your load equally on both sides of the

centerline.

WARNING:

o Never exceed the GVWR for your

vehicle, the GAWR for either the

front or rear axle and vehicle ca-

pacity weight. Exceeding these rat-

ings can cause an accident or

vehicle damage. You can calcu-

late the weight of your load by

weighing the items (or people)

before putting them in the vehicle.

Be careful not to overload your

vehicle. Refer to your vehicle's tire and loading

information label for specific informa-

tion about your vehicle's capacity weight

and seating positions. The combined

weight of the driver, passengers and

cargo should never exceed your

vehicle's capacity weight.

Page 198 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS4

R: 100.000 miles / 120 months

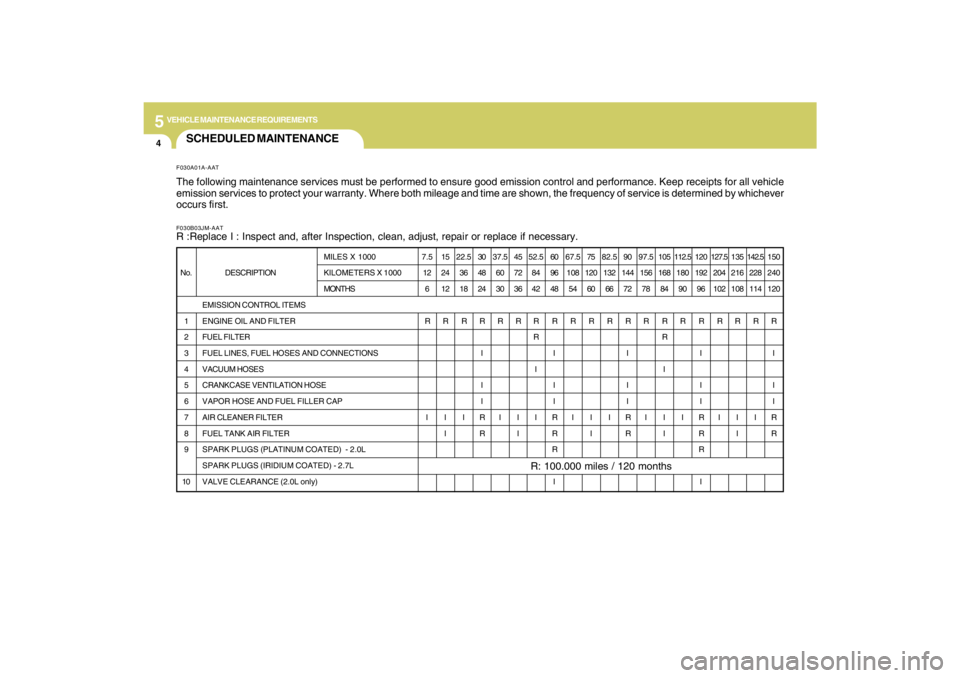

SCHEDULED MAINTENANCEF030B03JM-AATR :Replace I : Inspect and, after Inspection, clean, adjust, repair or replace if necessary.

DESCRIPTION

EMISSION CONTROL ITEMS

ENGINE OIL AND FILTER

FUEL FILTER

FUEL LINES, FUEL HOSES AND CONNECTIONS

VACUUM HOSES

CRANKCASE VENTILATION HOSE

VAPOR HOSE AND FUEL FILLER CAP

AIR CLEANER FILTER

FUEL TANK AIR FILTER

SPARK PLUGS (PLATINUM COATED) - 2.0L

SPARK PLUGS (IRIDIUM COATED) - 2.7L

VALVE CLEARANCE (2.0L only) No.

1

2

3

4

5

6

7

8

9

10MILES X 1000

KILOMETERS X 1000

MONTHS7.5

12

6

R

I15

24

12

R

I

I22.5

36

18

R

I30

48

24

R

I

I

I

R

R37.5

60

30

R

I45

72

36

R

I

I52.5

84

42

R

R

I

I60

96

48

R

I

I

I

R

R

R

I67.5

108

54

R

I75

120

60

R

I

I82.5

132

66

R

I90

144

72

R

I

I

I

R

R97.5

156

78

R

I105

168

84

R

R

I

I

I112.5

180

90

R

I120

192

96

R

I

I

I

R

R

R

I127.5

204

102

R

I135

216

108

R

I

I142.5

228

114

R

I150

240

120

R

I

I

I

R

R

F030A01A-AATThe following maintenance services must be performed to ensure good emission control and performance. Keep receipts for all vehicle

emission services to protect your warranty. Where both mileage and time are shown, the frequency of service is determined by whichever

occurs first.

Page 202 of 273

5

VEHICLE MAINTENANCE REQUIREMENTS8

F070D01A-AATo Manual Transaxle OilInspect the manual transaxle oil according

to the maintenance schedule.NOTE:If the oil level is low, check for possible

leaks before adding oil. Do not overfill.

F070C01A-AATo CoolantThe coolant should be changed at the

intervals specified in the maintenance

schedule.F060E01A-AATo Timing BeltInspect all parts related to the timing belt for

damage and deformation. Replace any

damaged parts immediately.F060J01A-AATo Spark PlugsMake sure to install new spark plugs of the

correct heat range.F060H01A-AATo Air Cleaner FilterA Genuine Hyundai air cleaner filter is

recommended when the filter is replaced.

F060G01A-AATo Vapor Hose and Fuel Filler CapThe vapor hose and fuel filler cap should

be inspected at those intervals specified in

the maintenance schedule. Make sure that

a new vapor hose or fuel filler cap is cor-

rectly replaced.F065F01O-AATo Crankcase Ventilation HoseInspect the surface of hose for evidence of

heat and/or mechanical damage. Hard

and brittle rubber, cracking, tears, cuts,

abrasions, and excessive swelling indi-

cate deterioration. Particular attention

should be paid to examine that hose sur-

face nearest to high heat sources, such as

the exhaust manifold.

Inspect the hose routing to assure that the

hose does not come in contact with any

heat source, sharp edges or moving com-

ponent which might cause heat damage or

mechanical wear. Inspect all hose con-

nections, such as clamps and couplings,

to make sure they are secure, and that no

leaks are present. Hose should be re-

placed immediately if there is any evi-

dence of deterioration or damage.

F070E06A-AATo Automatic Transaxle FluidThe fluid level should be in the “HOT”

range of the dipstick, after the engine and

transaxle are at normal operating tem-

perature. Check the automatic transaxle

fluid level with the engine running and the

transaxle in neutral, with the parking brake

properly applied. Use HYUNDAI GENU-

INE ATF SP III, DIAMOND ATF SP III, SK

ATF SP III or other brands meeting the SP

III specification approved by Hyundai Motor

Co. when adding or changing fluid. Using

the wrong ATF may result in damage to the

ATM.

Page 244 of 273

7

EMISSION CONTROL SYSTEMS2

EMISSION CONTROL SYSTEM

H010D01A-AAT3. Exhaust Emission Control

SystemThe Exhaust Emission Control System is a

highly effective system which controls ex-

haust emissions while maintaining good

vehicle performace.

H010B01A-AAT1. Crankcase Emission Control

SystemThe positive crankcase ventilation system

is employed to prevent air pollution caused

by blow-by gases being emitted from the

crankcase. This system supplies filtered

air to the crankcase through the air intake

hose. Inside the crankcase, the fresh air

mixes with blow-by gases, which then pass

through the PCV valve and into the induc-

tion system.

H010A02O-AATYour Hyundai is equipped with an emis-

sion control system to meet all require-

ments of the U.S. Environmental Protec-

tion Agency or California Air Resources

Board.

There are three emission control systems

which are as follows.

(1) Crankcase emission control system

(2) Evaporative emission control system

(3) Exhaust emission control system

In order to assure the proper function of the

emission control systems, it is recom-

mended that you have your car inspected

and maintained by an authorized Hyundai

dealer in accordance with the maintenance

schedule in this manual.

Caution for the Inspection and Mainte-

nance Test (V6 Vehicle with Traction

Control System)

o To prevent the vehicle from misfiring

during dynamometer testing, discon-

nect the ABS connector in the engine

compartment. (2.7 V6 only)

o For more information, see shop manual

(Wheel Speed Sensor).

o After dynamometer testing is com-

pleted, erase the ABS/TCS DTC

(Diagnotic Trouble Code) with a GST

(Generic Scan Tool) or Hi-Scan Pro.

CanisterFuel vapors generated inside the fuel tank

are absorbed and stored in the canister.

When the engine is running, the fuel va-

pors absorbed in the canister are drawn

into the induction system through the purge

control solenoid valve.Purge Control Solenoid Valve (PCSV)The purge control solenoid valve is con-

trolled by the Engine Control Module

(ECM); when the engine coolant tempera-

ture is low during idling, the PCSV closes

so that evaporated fuel is not taken into the

engine. After the engine warms-up during

ordinary driving, the PCSV opens to intro-

duce evaporated fuel to the engine.

H010C01S-AAT2. Evaporative Emission Control (In-

cluding ORVR: Onboard Refuel-

ing Vapor Recovery) SystemThe Evaporative Emission Control Sys-

tem is designed to prevent fuel vapors from

escaping into the atmosphere.

(The ORVR system is designed to allow

the vapors from the fuel tank to be loaded

into a canister while refueling at the gas

station, preventing the escape of fuel va-

pors into the atmosphere.)

Page 253 of 273

8

CONSUMER INFORMATION, REPORTING SAFETY DEFECTS & BINDING ARBITRATION OF WARRANTY CLAIMS8

Intended Outboard Sidewall: The side

of an asymmetrical tire, that must al-

ways face outward when mounted on a

vehicle.

Kilopascal (kPa): The metric unit for

air pressure.

Load Index: An assigned number rang-

ing from 1 to 279 that corresponds to

the load carrying capacity of a tire.

Maximum Inflation Pressure: The

maximum air pressure to which a cold

tire may be inflated. The maximum air

pressure is molded onto the sidewall.

Maximum Load Rating: The load rat-

ing for a tire at the maximum permis-

sible inflation pressure for that tire.

Maximum Loaded Vehicle Weight:

The sum of curb weight; accessory

weight; vehicle capacity weight; and

production options weight.

Normal Occupant Weight: The num-

ber of occupants a vehicle is designed

to seat multiplied by 150 pounds (68

kg).Occupant Distribution: Designated

seating positions.

Outward Facing Sidewall: The side of

a asymmetrical tire that has a particular

side that faces outward when mounted

on a vehicle. The side of the tire that

contains a whitewall, bears white letter-

ing or bears manufacturer, brand and or

model name molding that is higher or

deeper than the same moldings on the

other sidewall of the tire.

Passenger (P-Metric) Tire: A tire used

on passenger cars and some light duty

trucks and multipurpose vehicles.

Recommended Inflation Pressure:

Vehicle manufacturer's recommended

tire inflation pressure and shown on the

tire placard.

Radial Ply tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and upon

which the tire beads are seated. Cold Tire Pressure: The amount of air

pressure in a tire, measured in pounds

per square inch (psi) or kilopascals

(kPa) before a tire has built up heat from

driving.

Curb Weight: This means the weight of

a motor vehicle with standard and op-

tional equipment including the maxi-

mum capacity of fuel, oil and coolant,

but without passengers and cargo.

DOT Markings: A code molded into the

sidewall of a tire signifying that the tire

is in compliance with the U.S. Depart-

ment of Transportation motor vehicle

safety standards. The DOT code in-

cludes the Tire Identification Number

(TIN), an alphanumeric designator which

can also identify the tire manufacturer,

production plant, brand and date of

production.

GVWR: Gross Vehicle Weight Rating

GAWR FRT: Gross Axle Weight Rating

for the front Axle.

GAWR RR: Gross Axle Weight Rating

for the rear axle.

Page 265 of 273

9

VEHICLE SPECIFICATIONS2

J010A02JM-AATMEASUREMENT

170 (4,325)

70 (1,795) / 72 (1,830)*

1

66 (1,680) / 68 (1,730)*

2

103 (2,630)

60 (1,540) / 61 (1,550)*

3

60 (1,540) / 61 (1,550)*

3

Overall Length

Overall Width

Overall Height (Unladen)

Wheel base

Wheel tread

Front

Rear

J060A01JM-AATFUEL SYSTEMJ020A01JM-AATPOWER STEERING

in. (mm)

Engine

2.7L

2.0L

Fuel tank capacity

17 us.gal (65L)

15 us.gal (58L)

Type

Wheel free play

Rack stroke

Oil pump typeRack and pinion

0 ~ 1.18 in. (0 ~ 30 mm)

5.5 in. (142 mm)

Vane type

J030A01JM-AATTIREStandard

Option

Spare

P 215/65R16

P 235/60R16

T155/90R16 (Temporary)

T155/90D16 (Temporary)

2WD

4WD

J050A01JM-AATBRAKE

Dual hydraulic with brake booster

Ventilated disc

Cable operated on rear wheel Type

Front brake type

Rear brake type

Parking brake

CBS (With ABS)

ABS

CBS, ABSDrum type

Disc type

Disc type

Type A

Type B, C

*1 : with side garnish

*2 : with roof rack

*3 : with 235/60R16 tire

Page 270 of 273

10

INDEX

3

Drive Belts.........................................................................................6-20

Driving

Driving for economy .....................................................................2-22

Smooth cornering.........................................................................2-23

Winter driving...............................................................................2-23

E

Emission Control System ................................................................... 7-2

Engine

Before starting the engine .............................................................. 2-4

Compartment................................................................................. 6-2

Coolant........................................................................................... 6-8

If the engine overheats .................................................................. 3-4

Number........................................................................................... 8-2

Oil ................................................................................................... 6-5

Starting........................................................................................... 2-6

Engine Exhaust Can Be Dangerous .................................................. 2-2

F

4WD Lock System ............................................................................2-19

Fan Speed Control............................................................................1-94

Floor Mat Anchor ..............................................................................1-86

Fog Light

Front.............................................................................................1-64

Front Seats

Adjustable front seats ..................................................................1-13

Adjustable headrests...................................................................1-14

Adjusting seat forward and rearward..........................................1-13

Adjusting seatback angle .............................................................1-13

Fuel

Capacity......................................................................................... 9-2

Gauge...........................................................................................1-55

Recommendations......................................................................... 1-2Fuel Filler Lid

Remote release............................................................................1-83

Full-time 4WD Operation..................................................................2-16

Fuses ................................................................................................6-21

Fuse panel description......................................................................6-35

G

General Checks.................................................................................. 6-4

Glove Box..........................................................................................1-72

H

Hazard Warning System ..................................................................1-64

Heating and Cooling Control.............................................................1-93

Heating and Ventilation

Air flow control..............................................................................1-95

Air intake control switch ............................................................1-105

Bi-level heating.............................................................................1-99

Defrosting / Defogging ..............................................................1-101

Fan speed control (Blower control).............................................1-94

Temperature control....................................................................1-98

High-Mounted Rear Stop Light .........................................................1-83

Hood Release....................................................................................1-85

Horn.................................................................................................1-88

How to Use Luggage Room.............................................................1-80

I

Ignition Switch ...................................................................................... 2-5

Instrument Cluster and Indicator Lights...........................................1-48

Instrument Panel Light Control (Rheostat).......................................1-66

Interior Light.......................................................................................1-71

J

Jump Starting...................................................................................... 3-3