TO START Hyundai Tucson 2019 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2019, Model line: Tucson, Model: Hyundai Tucson 2019Pages: 546, PDF Size: 61.38 MB

Page 424 of 546

6-15

What to do in an emergency

6

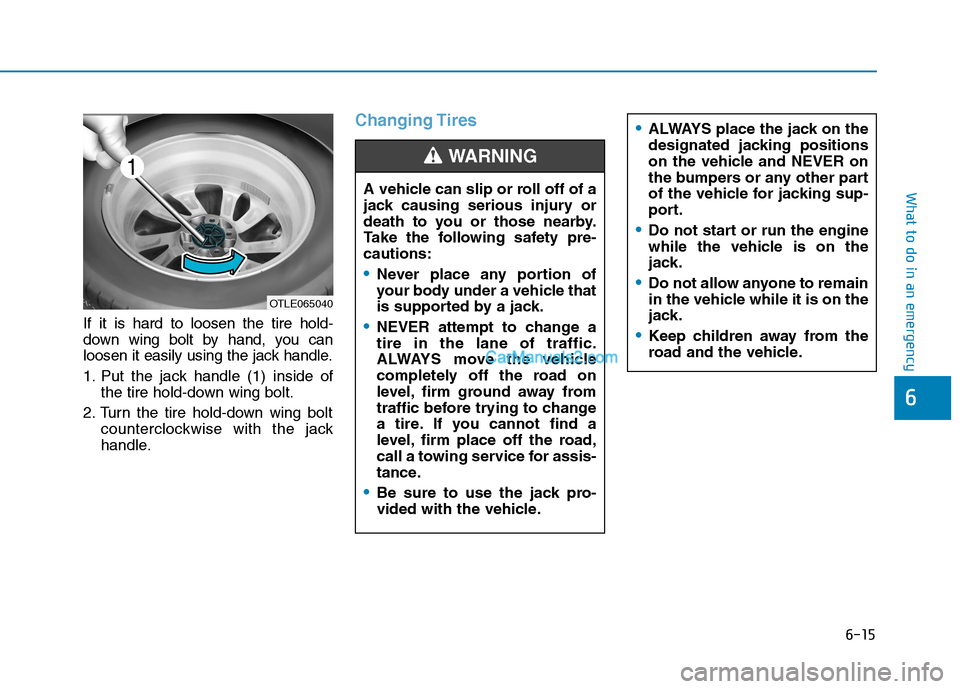

If it is hard to loosen the tire hold-

down wing bolt by hand, you can

loosen it easily using the jack handle.

1. Put the jack handle (1) inside of

the tire hold-down wing bolt.

2. Turn the tire hold-down wing bolt

counterclockwise with the jack

handle.

Changing Tires

A vehicle can slip or roll off of a

jack causing serious injury or

death to you or those nearby.

Take the following safety pre-

cautions:

Never place any portion of

your body under a vehicle that

is supported by a jack.

NEVER attempt to change a

tire in the lane of traffic.

ALWAYS move the vehicle

completely off the road on

level, firm ground away from

traffic before trying to change

a tire. If you cannot find a

level, firm place off the road,

call a towing service for assis-

tance.

Be sure to use the jack pro-

vided with the vehicle.

ALWAYS place the jack on the

designated jacking positions

on the vehicle and NEVER on

the bumpers or any other part

of the vehicle for jacking sup-

port.

Do not start or run the engine

while the vehicle is on the

jack.

Do not allow anyone to remain

in the vehicle while it is on the

jack.

Keep children away from the

road and the vehicle.

WARNING

OTLE065040

Page 445 of 546

7-11

7

Maintenance

I : Inspect and if necessary, adjust, correct, clean or replace. R : Replace or change.

*4: Transfer case oil and rear differential oil should be changed anytime they have been submerged in water.

*5: Fuel filter & Fuel tank air filter are considered to be maintenance free but periodic inspection is recommended for this mainte-

nance schedule depends on fuel quality. If there are some important safety matters like fuel flow restriction, surging, loss of

power, hard starting problem, etc. replace the fuel filter immediately regardless of maintenance schedule and consult an

authorized HYUNDAI dealer for details.

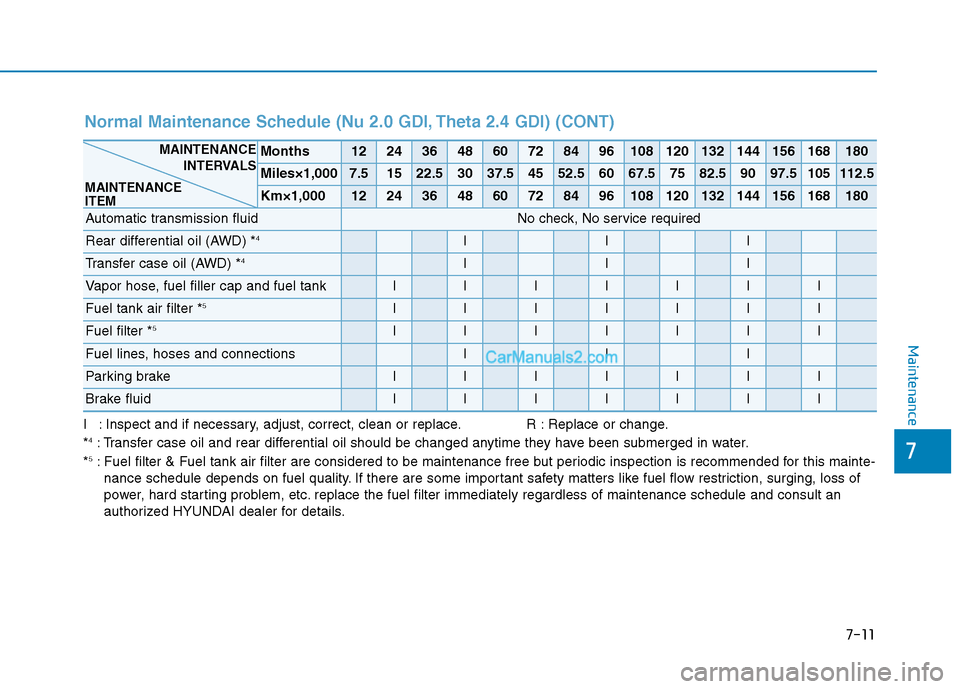

Months1224364860728496108120132144156168180

Miles×1,0007.51522.53037.54552.56067.57582.59097.5105112.5

Km×1,0001224364860728496108120132144156168180

Automatic transmission fluidNo check, No service required

Rear differential oil (AWD) *4III

Transfer case oil (AWD) *4III

Vapor hose, fuel filler cap and fuel tankIIIIIII

Fuel tank air filter *5IIIIIII

Fuel filter *5IIIIIII

Fuel lines, hoses and connectionsIII

Parking brakeIIIIIII

Brake fluidIIIIIII

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Normal Maintenance Schedule (Nu 2.0 GDI, Theta 2.4 GDI) (CONT)

Page 448 of 546

7-14

Maintenance

E EX

XP

PL

LA

AN

NA

AT

TI

IO

ON

N

O

OF

F

S

SC

CH

HE

ED

DU

UL

LE

ED

D

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

I

IT

TE

EM

MS

S

Engine Oil and Filter

The engine oil and filter should be

changed at the intervals specified in

the maintenance schedule. If the car

is being driven in severe conditions,

more frequent oil and filter changes

are required.

Drive Belts

Inspect all drive belts for evidence of

cuts, cracks, excessive wear or oil

saturation and replace if necessary.

Drive belts should be checked peri-

odically for proper tension and

adjusted as necessary.

Fuel Filter

A clogged-up fuel filter may limit the

vehicle driving speed, damage the

emission system, and cause the

hard starting. When a considerable

amount of foreign substances are

accumulated in the fuel tank, the fuel

filter should be replaced.Upon installing a new fuel filter, oper-

ate the diesel engine for several min-

utes, and check the connections for

any leakages. Fuel filters should be

installed by an authorized HYUNDAI

dealer.

Fuel Lines, Fuel Hoses and

Connections

Check the fuel lines, fuel hoses and

connections for leakage and dam-

age. Have an authorized HYUNDAI

dealer replace any damaged or leak-

ing parts immediately.

Vapor Hose and Fuel Filler

Cap

The vapor hose and fuel filler cap

should be inspected at those inter-

vals specified in the maintenance

schedule. Make sure a new vapor

hose or fuel filler cap is correctly

replaced.

Vacuum Crankcase Ventilation

Hoses (if equipped)

Inspect the surface of hoses for evi-

dence of heat and/or mechanical

damage. Hard and brittle rubber,

cracking, tears, cuts, abrasions, and

excessive swelling indicate deterio-

ration. Particular attention should be

paid to examine those hose surfaces

nearest to high heat sources, such

as the exhaust manifold.

Inspect the hose routing to assure

that the hoses do not come in con-

tact with any heat source, sharp

edges or moving component which

might cause heat damage or

mechanical wear. Inspect all hose

connections, such as clamps and

couplings, to make sure they are

secure, and that no leaks are pres-

ent. Hoses should be replaced

immediately if there is any evidence

of deterioration or damage.

Page 450 of 546

7-16

Maintenance

Parking Brake

Inspect the parking brake system

including the parking brake pedal

and cables.

Brake Discs, Pads, Calipers

and Rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

Exhaust Pipe and Muffler

Visually inspect the exhaust pipes,

muffler and hangers for cracks, dete-

rioration, or damage. Start the

engine and listen carefully for any

exhaust gas leakage. Tighten con-

nections or replace parts as neces-

sary.

Suspension Mounting Bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering Gear Box, Linkage &

Boots/Lower Arm Ball Joint

With the vehicle stopped and the

engine off, check for excessive free-

play in the steering wheel. Check the

linkage for bends or damage. Check

the dust boots and ball joints for

deterioration, cracks, or damage.

Replace any damaged parts.

Drive Shafts and Boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air Conditioning Refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 454 of 546

7-20

Maintenance

The electric motor for the cooling fan

is controlled by engine coolant tem-

perature, refrigerant pressure and

vehicle speed. As the engine coolant

temperature decreases, the electric

motor will automatically shut off. This

is a normal condition. If your vehicle

is equipped with GDI, the electric

motor for the cooling fan may begin

to operate at any time and continue

to operate until you disconnect the

negative battery cable. Never remove the

engine coolant reser-

voir tank/radiator cap

or the drain plug

while the engine and

radiator are hot. Hot coolant

and steam may blow out under

pressure, causing serious

injury.

Turn the engine off and wait

until the engine cools down.

Use extreme care when remov-

ing the engine coolant reservoir

tank/radiator cap. Wrap a thick

towel around it, and turn it

counterclockwise slowly to the

first stop. Step back while the

pressure is released from the

cooling system. When you are

sure all the pressure has been

released, press down on the

cap, using a thick towel, and

continue turning counterclock-

wise to remove it.

WARNING

The electric motor for

the cooling fan may

continue to operate

or start up when the

engine is not running

and can cause serious injury.

Keep hands, clothing and tools

away from the rotating fan

blades of the cooling fan.

WARNING

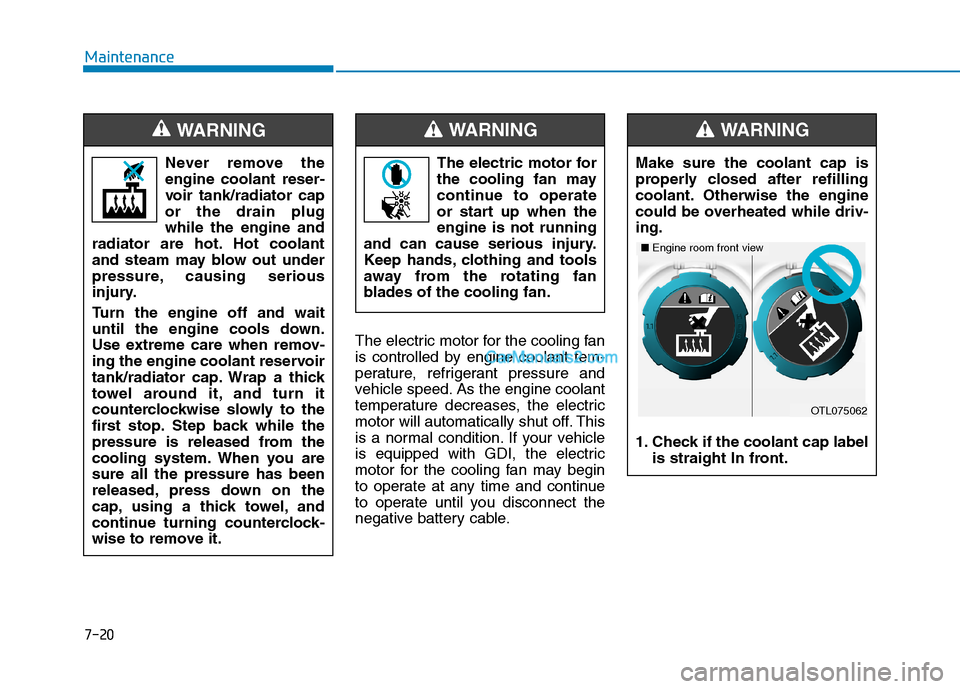

Make sure the coolant cap is

properly closed after refilling

coolant. Otherwise the engine

could be overheated while driv-

ing.

1. Check if the coolant cap label

is straight In front.

WARNING

OTL075062

■Engine room front view

Page 467 of 546

7-33

7

Maintenance

B BA

AT

TT

TE

ER

RY

Y

To prevent SERIOUS INJURY or

DEATH to you or bystanders,

always follow these precautions

when working near or handling

the battery:

Always read and follow

instructions carefully

when handling a battery.

Wear eye protection

designed to protect the

eyes from acid splashes.

Keep all flames, sparks,

or smoking materials

away from the battery.

Hydrogen is always pres-

ent in battery cells, is

highly combustible, and

may explode if ignited.

Keep batteries out of

reach of children.

WARNING Batteries contain sulfu-

ric acid which is highly

corrosive. Do not allow

acid to contact your

eyes, skin or clothing.

If acid gets into your eyes, flush

your eyes with clean water for at

least 15 minutes and get imme-

diate medical attention. If acid

gets on your skin, thoroughly

wash the area. If you feel pain or

a burning sensation, get med-

ical attention immediately.

When lifting a plastic-cased

battery, excessive pressure

on the case may cause battery

acid to leak. Lift with a battery

carrier or with your hands on

opposite corners.

Do not attempt to jump start

your vehicle if your battery is

frozen.

NEVER attempt to recharge

the battery when the vehicle’s

battery cables are connected

to the battery.

The electrical ignition system

works with high voltage.

NEVER touch these compo-

nents with the engine running

or when the ignition switch is

in the ON position.

Page 469 of 546

7-35

7

Maintenance

By jump starting

After a jump start from a good bat-

tery, drive the vehicle for 20-30 min-

utes before it is shutoff. The vehicle

may not restart if you shut it off

before the battery had a chance to

adequately recharge. See "Jump

Starting" in chapter 6 for more infor-

mation on jump starting procedures.

Information

An inappropriately disposed

battery can be harmful to

the environment and human

health. Dispose of the bat-

tery according to your local

law(s) or regulations.

Reset Features

The following items may need to be

reset after the battery has been dis-

charged or the battery has been dis-

connected. See chapter 3 or 4 for:

Power Windows

Trip Computer

Climate Control System

Clock

Audio System

Sunroof

i

Watch the battery during

charging, and stop or reduce

the charging rate if the battery

cells begin boiling violently.

The negative battery cable

must be removed first and

installed last when the battery

is disconnected. Disconnect

the battery charger in the fol-

lowing order:

(1) Turn off the battery charg-

er main switch.

(2) Unhook the negative

clamp from the negative

battery terminal.

(3) Unhook the positive clamp

from the positive battery

terminal.

Always use a genuine

HYUNDAI approved battery

when you replace the battery.

Page 491 of 546

7

Maintenance

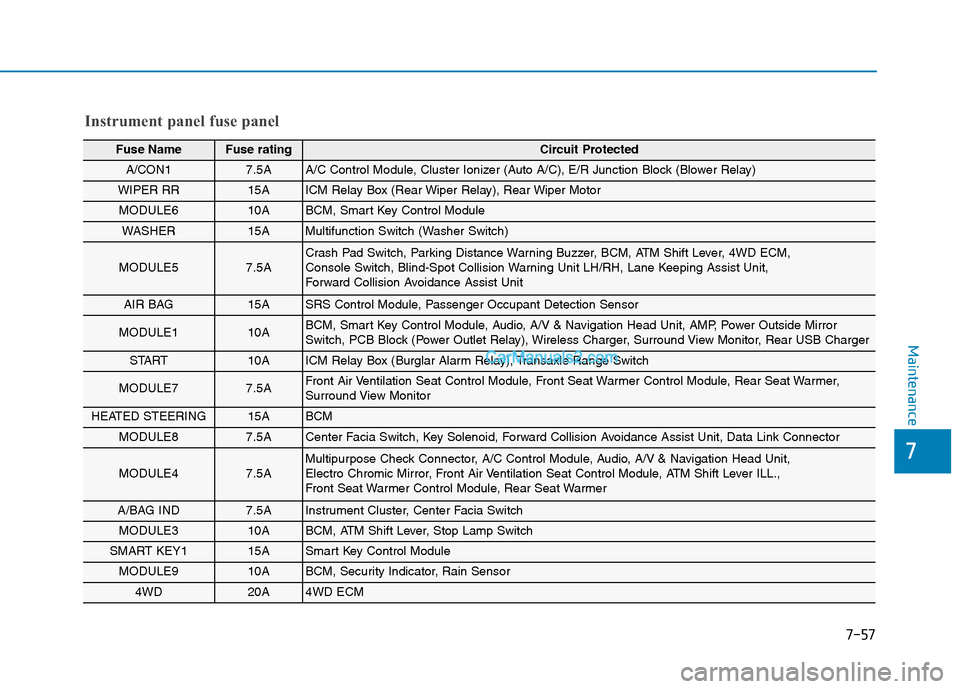

Instrument panel fuse panel

Fuse Name Fuse ratingCircuit Protected

A/CON1 7.5AA/C Control Module, Cluster Ionizer (Auto A/C), E/R Junction Block (Blower Relay)

WIPER RR 15AICM Relay Box (Rear Wiper Relay), Rear Wiper Motor

MODULE6 10ABCM, Smart Key Control Module

WASHER 15AMultifunction Switch (Washer Switch)

MODULE5 7.5ACrash Pad Switch, Parking Distance Warning Buzzer, BCM, ATM Shift Lever, 4WD ECM,

Console Switch, Blind-Spot Collision Warning Unit LH/RH, Lane Keeping Assist Unit,

Forward Collision Avoidance Assist Unit

AIR BAG 15ASRS Control Module, Passenger Occupant Detection Sensor

MODULE1 10ABCM, Smart Key Control Module, Audio, A/V & Navigation Head Unit, AMP, Power Outside Mirror

Switch, PCB Block (Power Outlet Relay), Wireless Charger, Surround View Monitor, Rear USB Charger

START 10AICM Relay Box (Burglar Alarm Relay), Transaxle Range Switch

MODULE7 7.5AFront Air Ventilation Seat Control Module, Front Seat Warmer Control Module, Rear Seat Warmer,

Surround View Monitor

HEATED STEERING 15ABCM

MODULE8 7.5ACenter Facia Switch, Key Solenoid, Forward Collision Avoidance Assist Unit, Data Link Connector

MODULE4 7.5AMultipurpose Check Connector, A/C Control Module, Audio, A/V & Navigation Head Unit,

Electro Chromic Mirror, Front Air Ventilation Seat Control Module, ATM Shift Lever ILL.,

Front Seat Warmer Control Module, Rear Seat Warmer

A/BAG IND 7.5AInstrument Cluster, Center Facia Switch

MODULE310ABCM, ATM Shift Lever, Stop Lamp Switch

SMART KEY115ASmart Key Control Module

MODULE910ABCM, Security Indicator, Rain Sensor

4WD20A4WD ECM

7-57

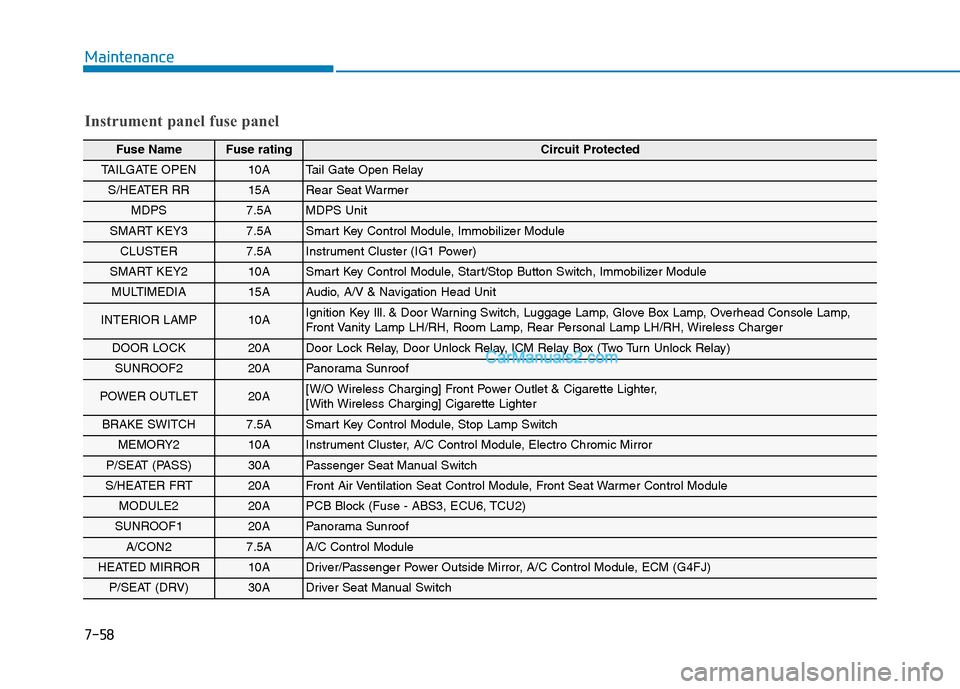

Page 492 of 546

7-58

Maintenance

Instrument panel fuse panel

Fuse Name Fuse ratingCircuit Protected

TAILGATE OPEN10ATail Gate Open Relay

S/HEATER RR15ARear Seat Warmer

MDPS7.5AMDPS Unit

SMART KEY37.5A Smart Key Control Module, Immobilizer Module

CLUSTER7.5A Instrument Cluster (IG1 Power)

SMART KEY210A Smart Key Control Module, Start/Stop Button Switch, Immobilizer Module

MULTIMEDIA15A Audio, A/V & Navigation Head Unit

INTERIOR LAMP10A Ignition Key Ill. & Door Warning Switch, Luggage Lamp, Glove Box Lamp, Overhead Console Lamp,

Front Vanity Lamp LH/RH, Room Lamp, Rear Personal Lamp LH/RH, Wireless Charger

DOOR LOCK20A Door Lock Relay, Door Unlock Relay, ICM Relay Box (Two Turn Unlock Relay)

SUNROOF220A Panorama Sunroof

POWER OUTLET20A [W/O Wireless Charging] Front Power Outlet & Cigarette Lighter,

[With Wireless Charging] Cigarette Lighter

BRAKE SWITCH7.5A Smart Key Control Module, Stop Lamp Switch

MEMORY210A Instrument Cluster, A/C Control Module, Electro Chromic Mirror

P/SEAT (PASS)30A Passenger Seat Manual Switch

S/HEATER FRT20A Front Air Ventilation Seat Control Module, Front Seat Warmer Control Module

MODULE220A PCB Block (Fuse - ABS3, ECU6, TCU2)

SUNROOF120A Panorama Sunroof

A/CON27.5A A/C Control Module

HEATED MIRROR10ADriver/Passenger Power Outside Mirror, A/C Control Module, ECM (G4FJ)

P/SEAT (DRV)30ADriver Seat Manual Switch

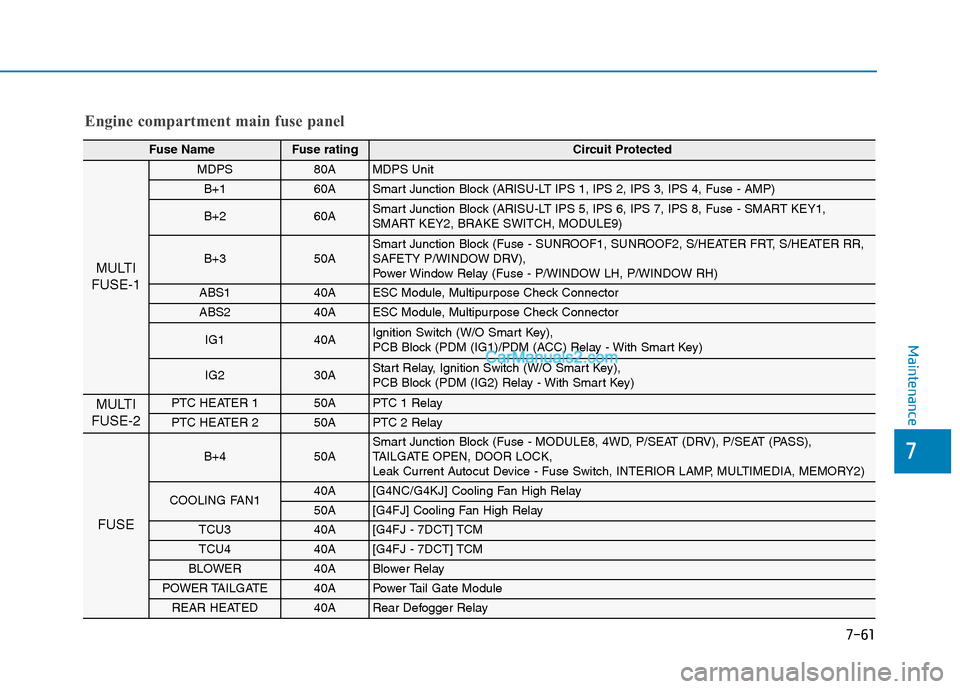

Page 495 of 546

7

Maintenance

Engine compartment main fuse panel

Fuse NameFuse rating Circuit Protected

MULTI

FUSE-1

MDPS 80AMDPS Unit

B+1 60ASmart Junction Block (ARISU-LT IPS 1, IPS 2, IPS 3, IPS 4, Fuse - AMP)

B+2 60ASmart Junction Block (ARISU-LT IPS 5, IPS 6, IPS 7, IPS 8, Fuse - SMART KEY1,

SMART KEY2, BRAKE SWITCH, MODULE9)

B+3 50ASmart Junction Block (Fuse - SUNROOF1, SUNROOF2, S/HEATER FRT, S/HEATER RR,

SAFETY P/WINDOW DRV),

Power Window Relay (Fuse - P/WINDOW LH, P/WINDOW RH)

ABS1 40AESC Module, Multipurpose Check Connector

ABS2 40AESC Module, Multipurpose Check Connector

IG1 40AIgnition Switch (W/O Smart Key),

PCB Block (PDM (IG1)/PDM (ACC) Relay - With Smart Key)

IG2 30AStart Relay, Ignition Switch (W/O Smart Key),

PCB Block (PDM (IG2) Relay - With Smart Key)

MULTI

FUSE-2PTC HEATER 150APTC 1 Relay

PTC HEATER 250APTC 2 Relay

FUSE

B+450A Smart Junction Block (Fuse - MODULE8, 4WD, P/SEAT (DRV), P/SEAT (PASS),

TAILGATE OPEN, DOOR LOCK,

Leak Current Autocut Device - Fuse Switch, INTERIOR LAMP, MULTIMEDIA, MEMORY2)

COOLING FAN140A [G4NC/G4KJ] Cooling Fan High Relay

50A [G4FJ] Cooling Fan High Relay

TCU340A [G4FJ - 7DCT] TCM

TCU440A [G4FJ - 7DCT] TCM

BLOWER40A Blower Relay

POWER TAILGATE40A Power Tail Gate Module

REAR HEATED40A Rear Defogger Relay

7-61