engine HYUNDAI TUCSON HYBRID 2021 Owners Manual

[x] Cancel search | Manufacturer: HYUNDAI, Model Year: 2021, Model line: TUCSON HYBRID, Model: HYUNDAI TUCSON HYBRID 2021Pages: 630, PDF Size: 77.98 MB

Page 588 of 630

09

9-41

WARNING

NEVER replace a fuse with anything but

another fuse of the same rating.

• A higher capacity fuse could cause

damage and possibly cause a fire.

• Do not install a wire or aluminum

foil instead of the proper fuse -

even as a temporary repair. It may

cause extensive wiring damage and

possibly a fire.

NOTICE

Do not use a screwdriver or any other

metal object to remove fuses because

it may cause a short circuit and damage

the system.

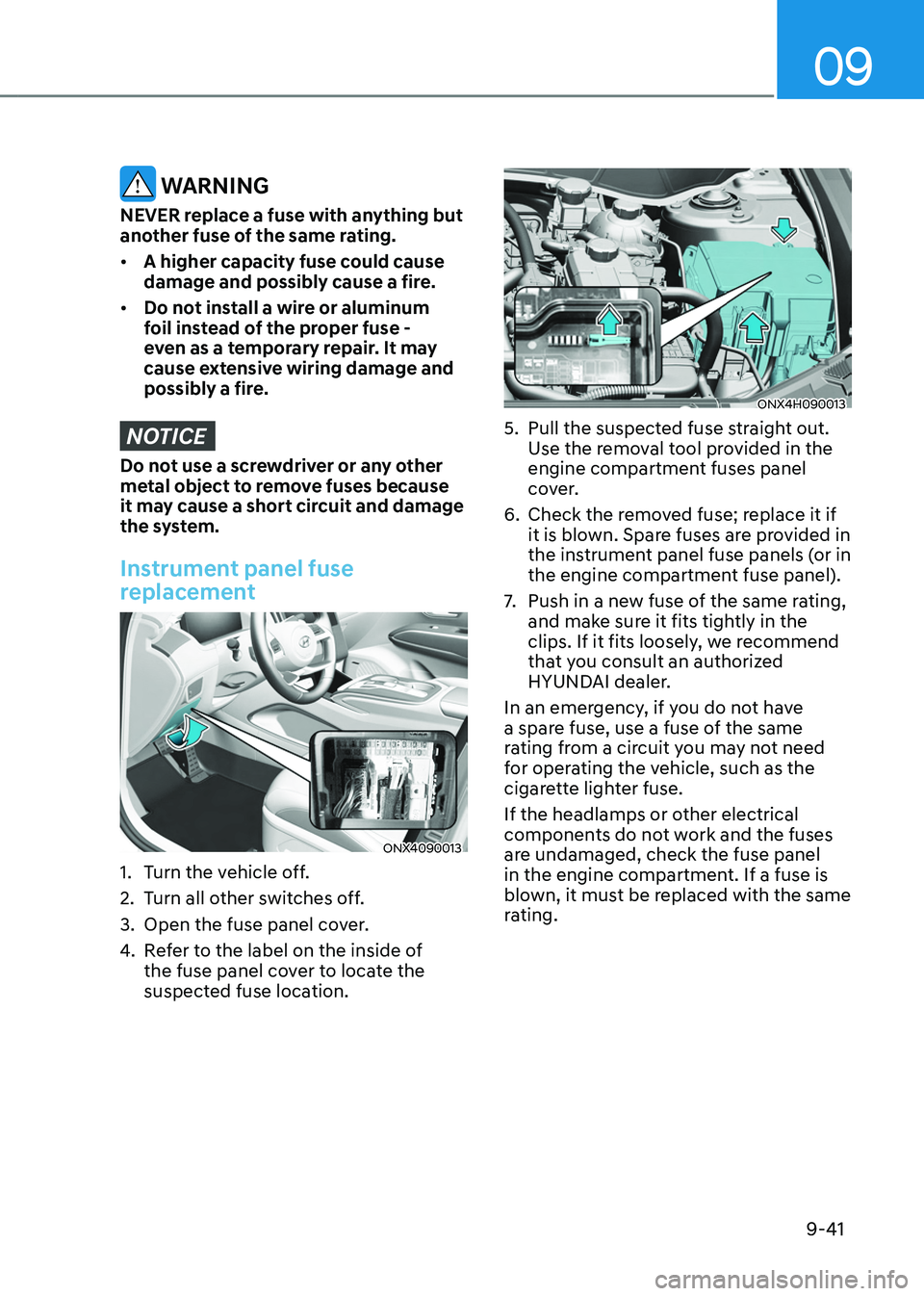

Instrument panel fuse

replacement

ONX4090013

1. Turn the vehicle off.

2.

Turn all o

ther switches off.

3.

Open the fuse panel cov

er.

4.

Re

fer to the label on the inside of

the fuse panel cover to locate the

suspected fuse location.

ONX4H090013

5. Pull the suspected fuse s traight out.

Use the removal tool provided in the

engine compartment fuses panel

cover.

6.

Check the remo

ved fuse; replace it if

it is blown. Spare fuses are provided in

the instrument panel fuse panels (or in

the engine compartment fuse panel).

7.

Push in a new fuse o

f the same rating,

and make sure it fits tightly in the

clips. If it fits loosely, we recommend

that you consult an authorized

HYUNDAI dealer.

In an emergency, if you do not have

a spare fuse, use a fuse of the same

rating from a circuit you may not need

for operating the vehicle, such as the

cigarette lighter fuse.

If the headlamps or other electrical

components do not work and the fuses

are undamaged, check the fuse panel

in the engine compartment. If a fuse is

blown, it must be replaced with the same

rating.

Page 589 of 630

Maintenance

9-42

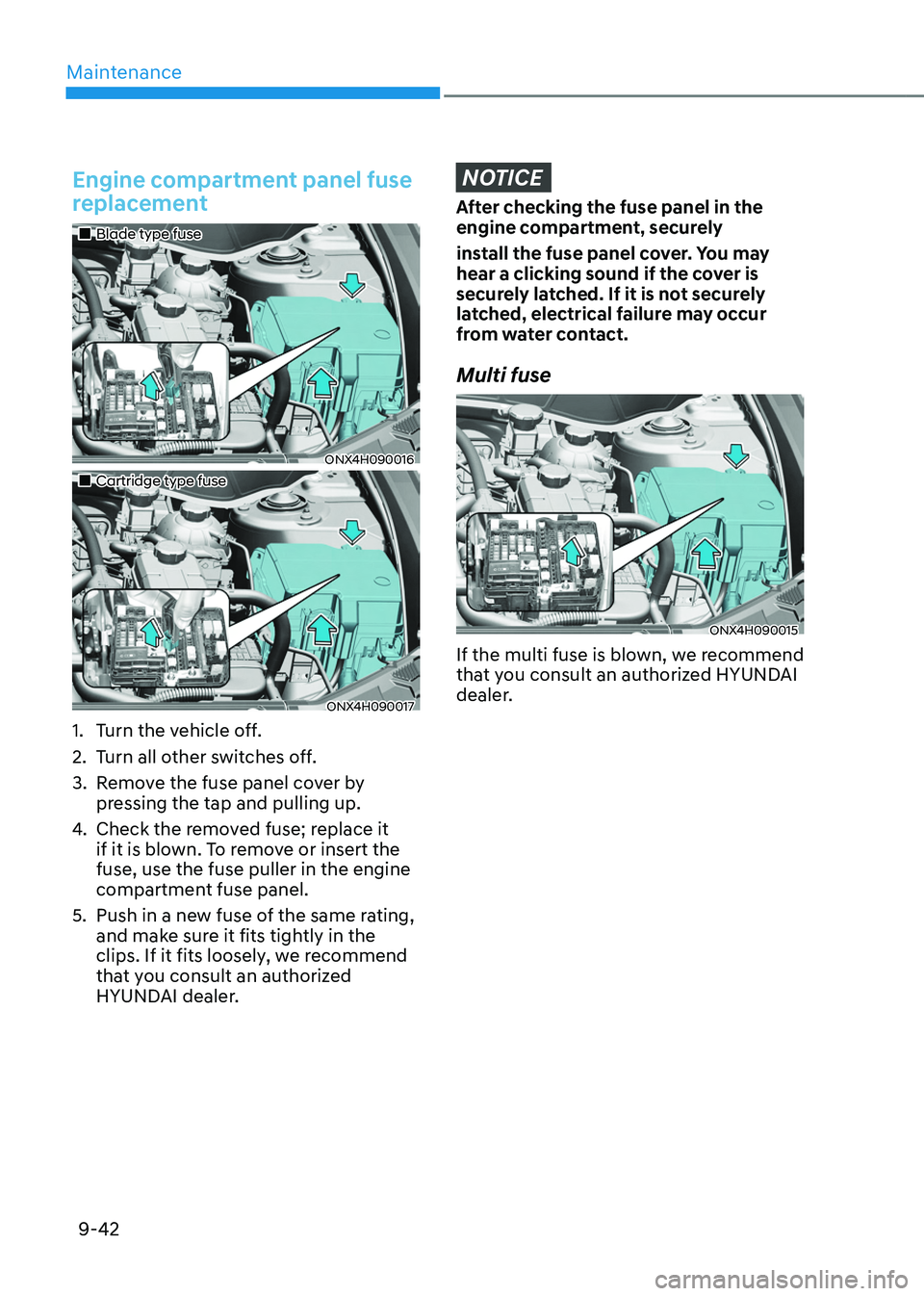

Engine compartment panel fuse

replacement

„„Blade type fuse

ONX4H090016

„„Cartridge type fuse

ONX4H090017

1. Turn the vehicle off.

2.

Turn all o

ther switches off.

3.

Remo

ve the fuse panel cover by

pressing the tap and pulling up.

4.

Check the remo

ved fuse; replace it

if it is blown. To remove or insert the

fuse, use the fuse puller in the engine

compartment fuse panel.

5.

Push in a new fuse o

f the same rating,

and make sure it fits tightly in the

clips. If it fits loosely, we recommend

that you consult an authorized

HYUNDAI dealer.

NOTICE

After checking the fuse panel in the

engine compartment, securely

install the fuse panel cover. You may

hear a clicking sound if the cover is

securely latched. If it is not securely

latched, electrical failure may occur

from water contact.

Multi fuse

ONX4H090015

If the multi fuse is blown, we recommend

that you consult an authorized HYUNDAI

dealer.

Page 594 of 630

09

9-47

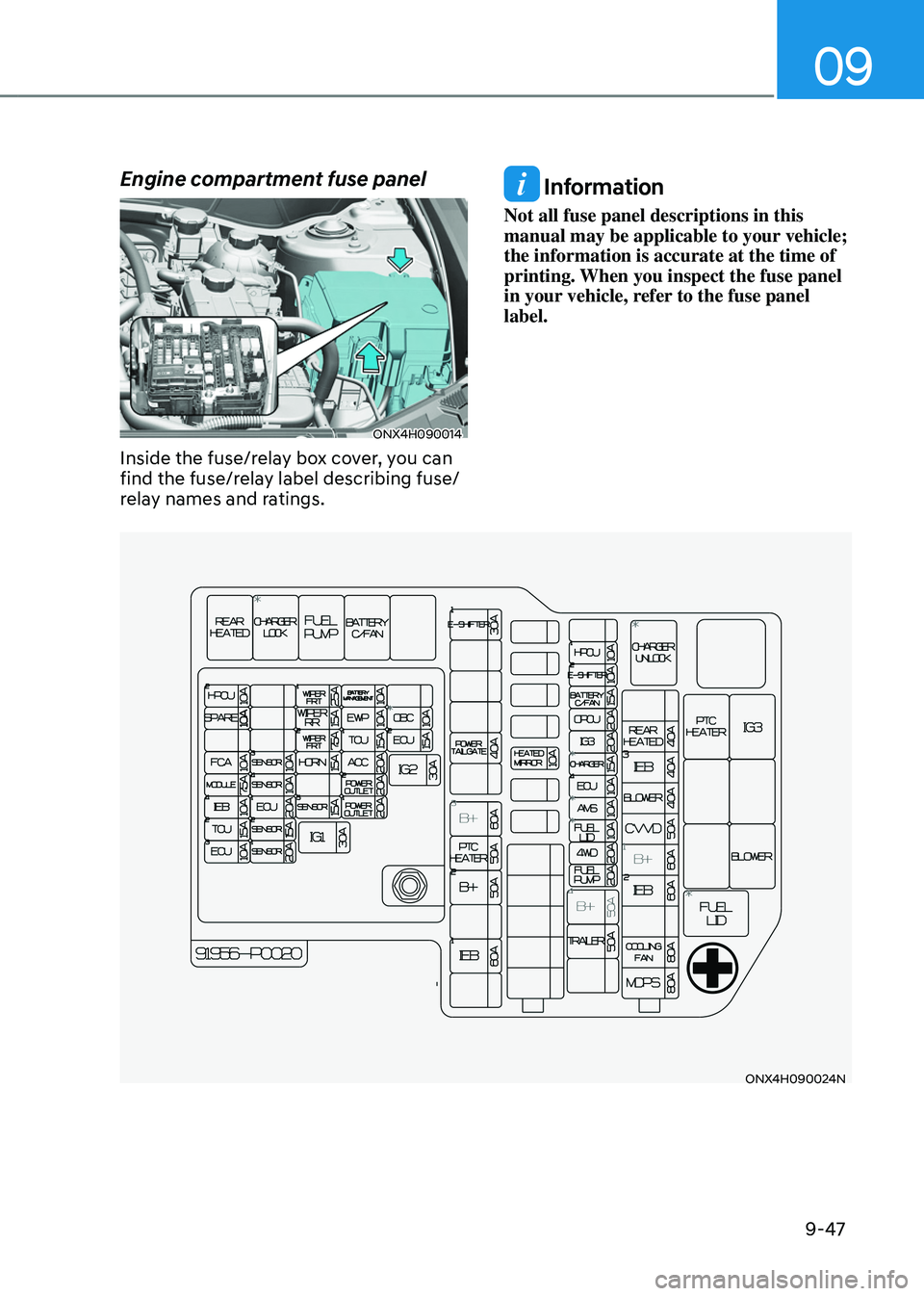

Engine compartment fuse panel

ONX4H090014

Inside the fuse/relay box cover, you can

find the fuse/relay label describing fuse/

relay names and ratings.

Information

Not all fuse panel descriptions in this

manual may be applicable to your vehicle;

the information is accurate at the time of

printing. When you inspect the fuse panel

in your vehicle, refer to the fuse panel

label.

ONX4H090024N

Page 595 of 630

Maintenance

9-48

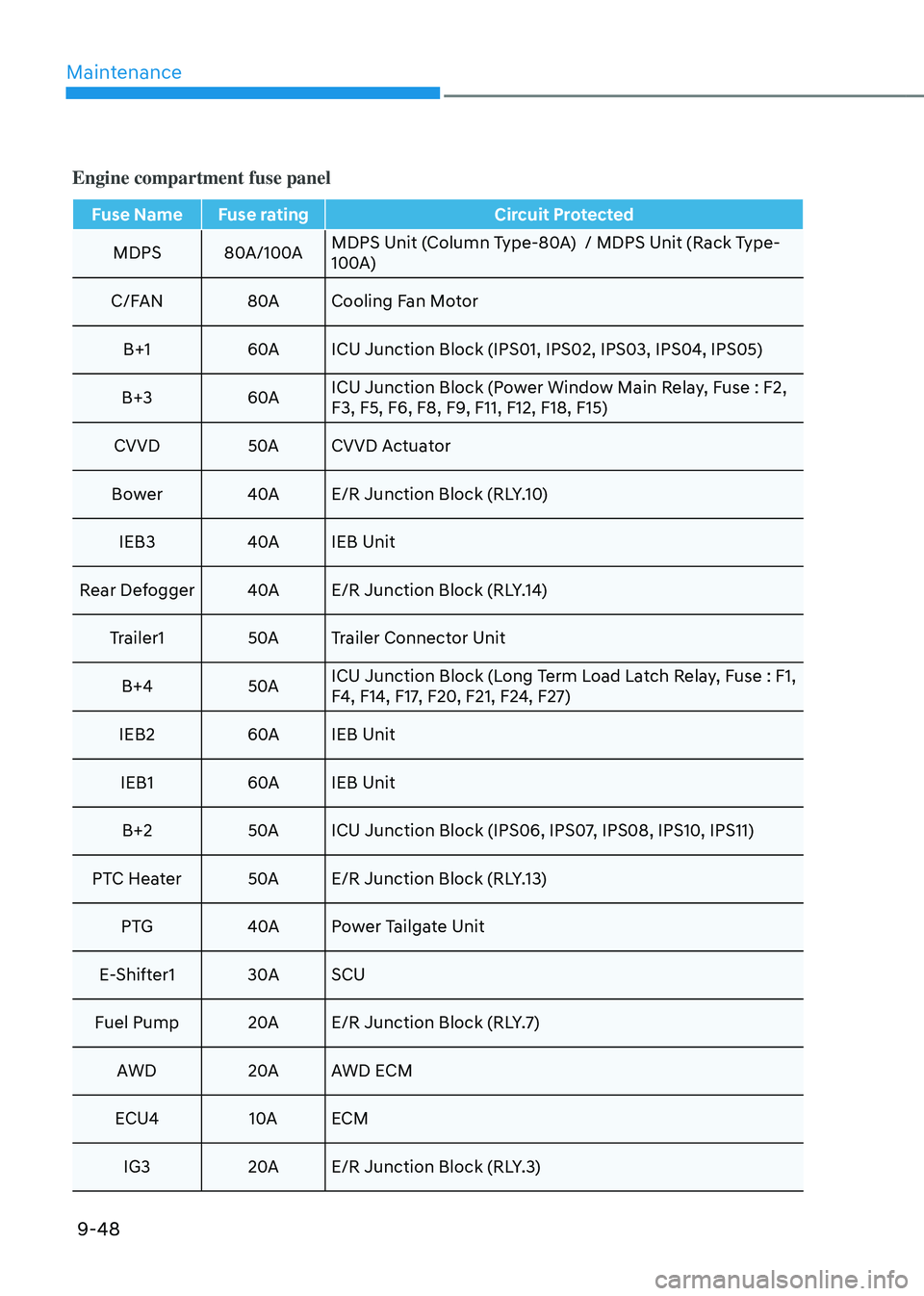

Engine compartment fuse panel

Fuse Name Fuse ratingCircuit Protected

MDPS 80A/100A MDPS Unit (Column Type-80A) / MDPS Unit (Rack Type-

100A)

C/FAN 80ACooling Fan Motor

B+1 60AICU Junction Block (IPS01, IPS02, IPS03, IPS04, IPS05)

B+3 60AICU Junction Block (Power Window Main Relay, Fuse : F2,

F3, F5, F6, F8, F9, F11, F12, F18, F15)

CVVD 50ACVVD Actuator

Bower 40AE/R Junction Block (RLY.10)

IEB3 40AIEB Unit

Rear Defogger 40AE/R Junction Block (RLY.14)

Trailer1 50ATrailer Connector Unit

B+4 50AICU Junction Block (Long Term Load Latch Relay, Fuse : F1,

F4, F14, F17, F20, F21, F24, F27)

IEB2 60AIEB Unit

IEB1 60AIEB Unit

B+2 50AICU Junction Block (IPS06, IPS07, IPS08, IPS10, IPS11)

PTC Heater 50AE/R Junction Block (RLY.13)

PTG 40APower Tailgate Unit

E-Shifter1 30ASCU

Fuel Pump 20AE/R Junction Block (RLY.7)

AWD 20AAWD ECM

ECU4 10AECM

IG3 20AE/R Junction Block (RLY.3)

Page 596 of 630

09

9-49

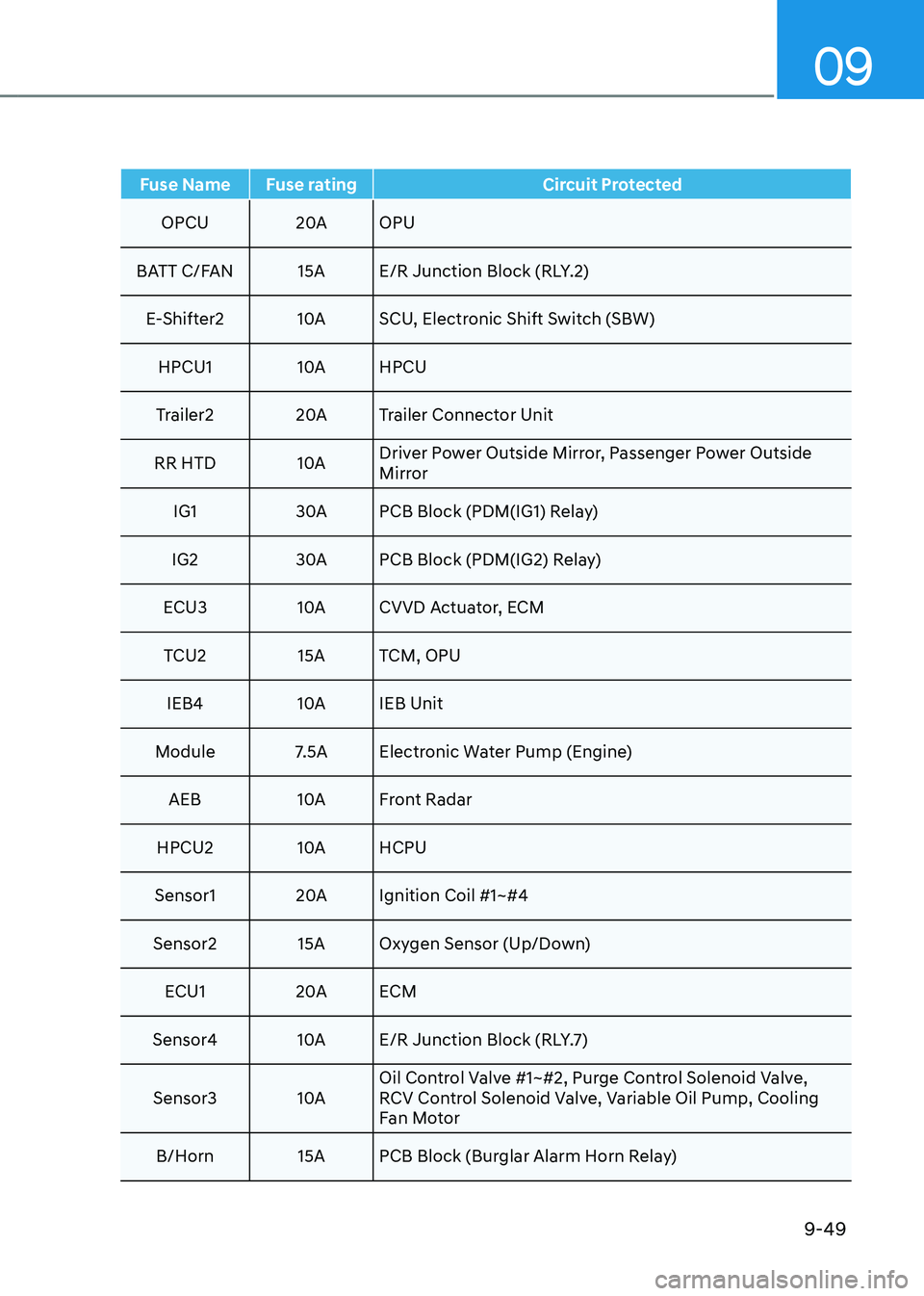

Fuse Name Fuse ratingCircuit Protected

OPCU 20AOPU

BATT C/FAN 15A E/R Junction Block (RLY.2) E-Shifter2 10ASCU, Electronic Shift Switch (SBW)

HPCU1 10AHPCU

Trailer2 20ATrailer Connector Unit

RR HTD 10ADriver Power Outside Mirror, Passenger Power Outside

Mirror

IG1 30APCB Block (PDM(IG1) Relay)

IG2 30APCB Block (PDM(IG2) Relay)

ECU3 10ACVVD Actuator, ECM

TCU2 15A TCM, OPU

IEB4 10AIEB Unit

Module 7.5A Electronic Water Pump (Engine) AEB 10AFront Radar

HPCU2 10AHCPU

Sensor1 20AIgnition Coil #1~#4

Sensor2 15A Oxygen Sensor (Up/Down) ECU1 20AECM

Sensor4 10AE/R Junction Block (RLY.7)

Sensor3 10AOil Control Valve #1~#2, Purge Control Solenoid Valve,

RCV Control Solenoid Valve, Variable Oil Pump, Cooling

Fan Motor

B/Horn 15A PCB Block (Burglar Alarm Horn Relay)

Page 597 of 630

Maintenance

9-50

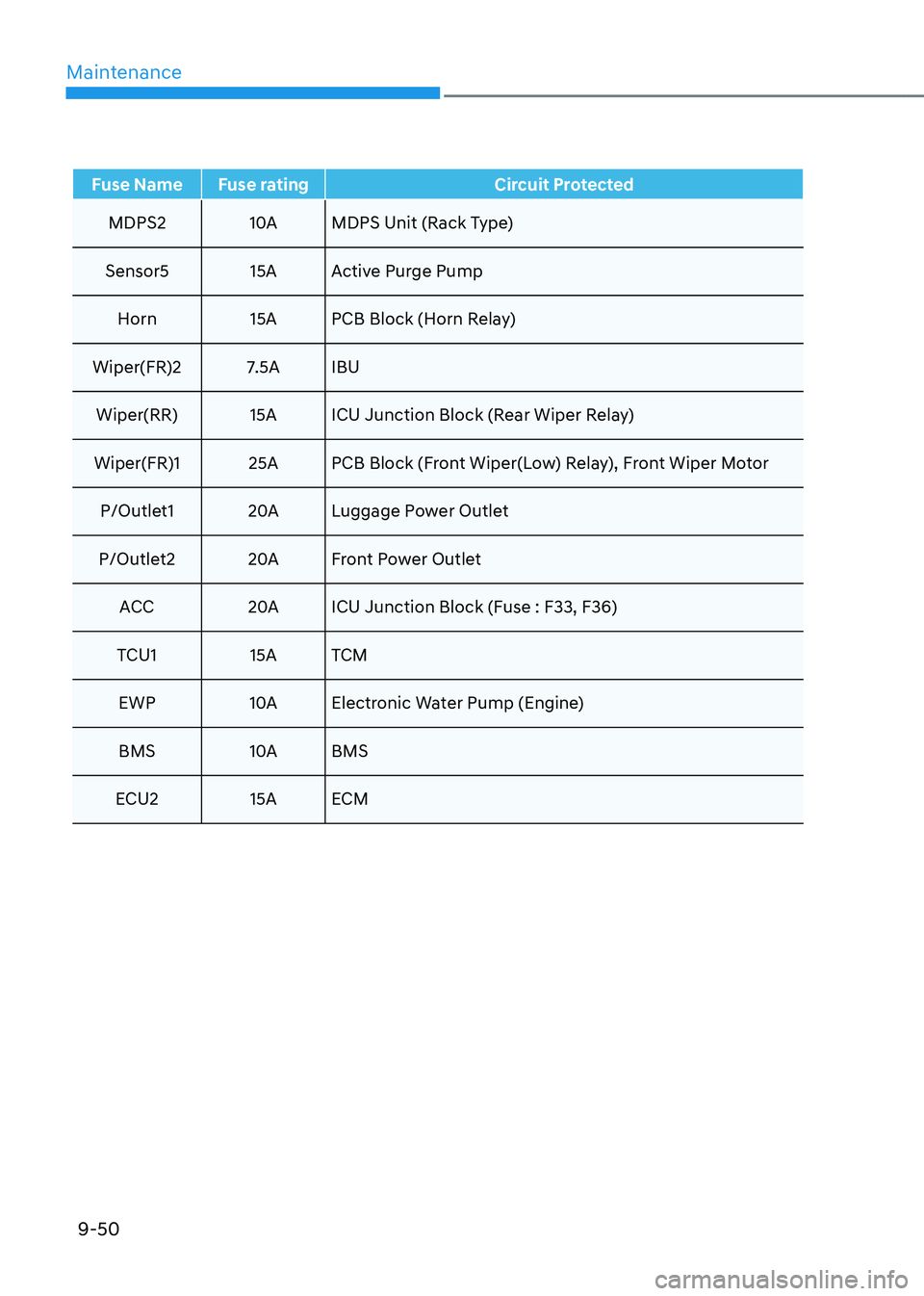

Fuse Name Fuse ratingCircuit Protected

MDPS2 10AMDPS Unit (Rack Type)

Sensor5 15A Active Purge Pump Horn 15A PCB Block (Horn Relay)

Wiper(FR)2 7.5A IBU Wiper(RR) 15A ICU Junction Block (Rear Wiper Relay)

Wiper(FR)1 25A PCB Block (Front Wiper(Low) Relay), Front Wiper Motor P/Outlet1 20ALuggage Power Outlet

P/Outlet2 20AFront Power Outlet

ACC 20AICU Junction Block (Fuse : F33, F36)

TCU1 15ATCM

EWP 10AElectronic Water Pump (Engine)

BMS 10ABMS

ECU2 15AECM

Page 600 of 630

09

9-53

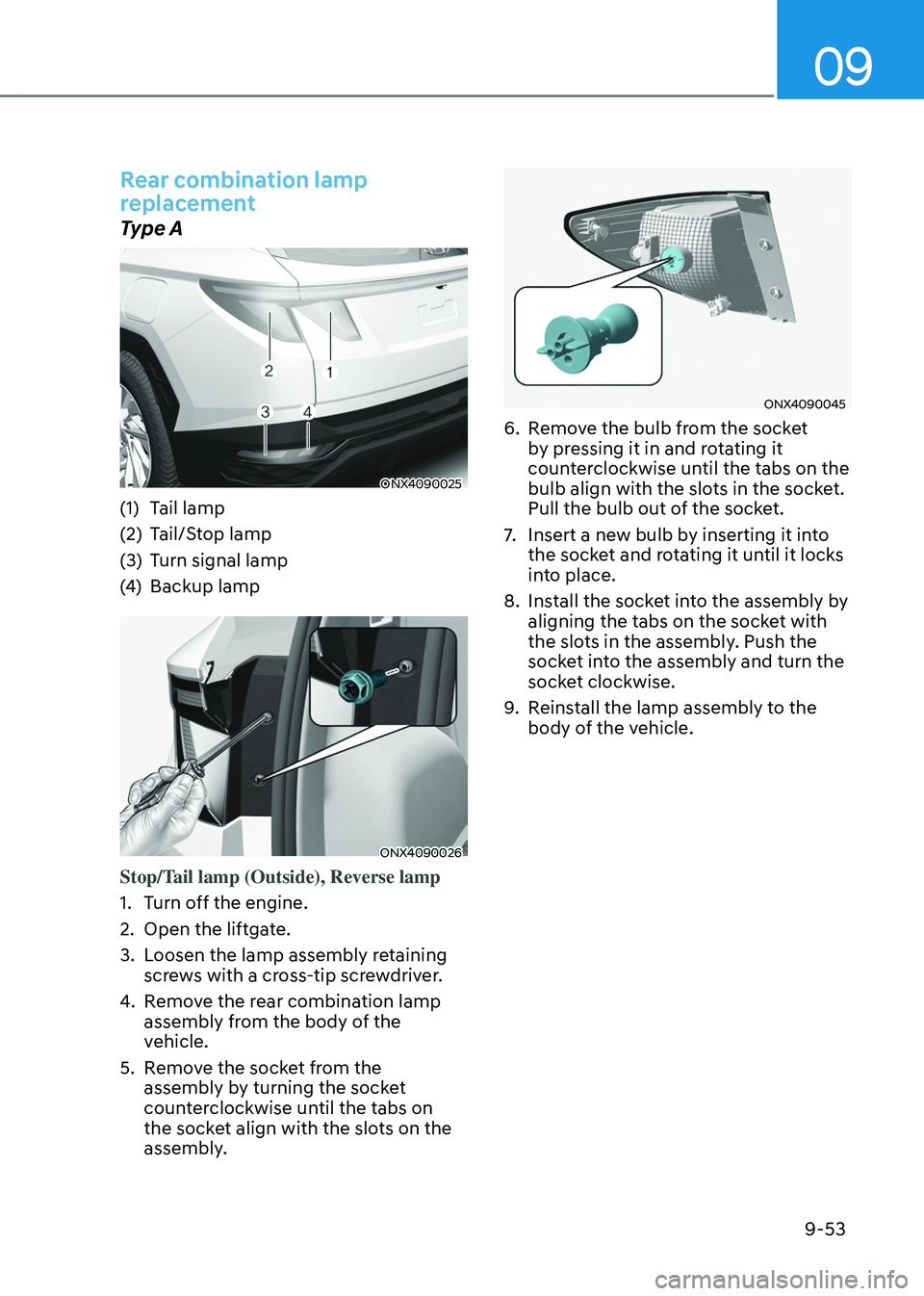

Rear combination lamp

replacement

Type A

ONX4090025

(1) Tail lamp

(2)

Tail/S

top lamp

(3)

Turn signal lamp

(4

)

Backup lamp

ONX4090026

Stop/Tail lamp (Outside), Reverse lamp

1.

Turn o

ff the engine.

2.

Open the liftga

te.

3.

Loosen the lamp assembly r

etaining

screws with a cross-tip screwdriver.

4.

Remo

ve the rear combination lamp

assembly from the body of the

vehicle.

5.

Remo

ve the socket from the

assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on the

assembly.

ONX4090045

6. Remove the bulb from the socket

b y pressing it in and rotating it

counterclockwise until the tabs on the

bulb align with the slots in the socket.

Pull the bulb out of the socket.

7.

Insert a new bulb b

y inserting it into

the socket and rotating it until it locks

into place.

8.

Install the sock

et into the assembly by

aligning the tabs on the socket with

the slots in the assembly. Push the

socket into the assembly and turn the

socket clockwise.

9.

Reins

tall the lamp assembly to the

body of the vehicle.

Page 601 of 630

Maintenance

9-54

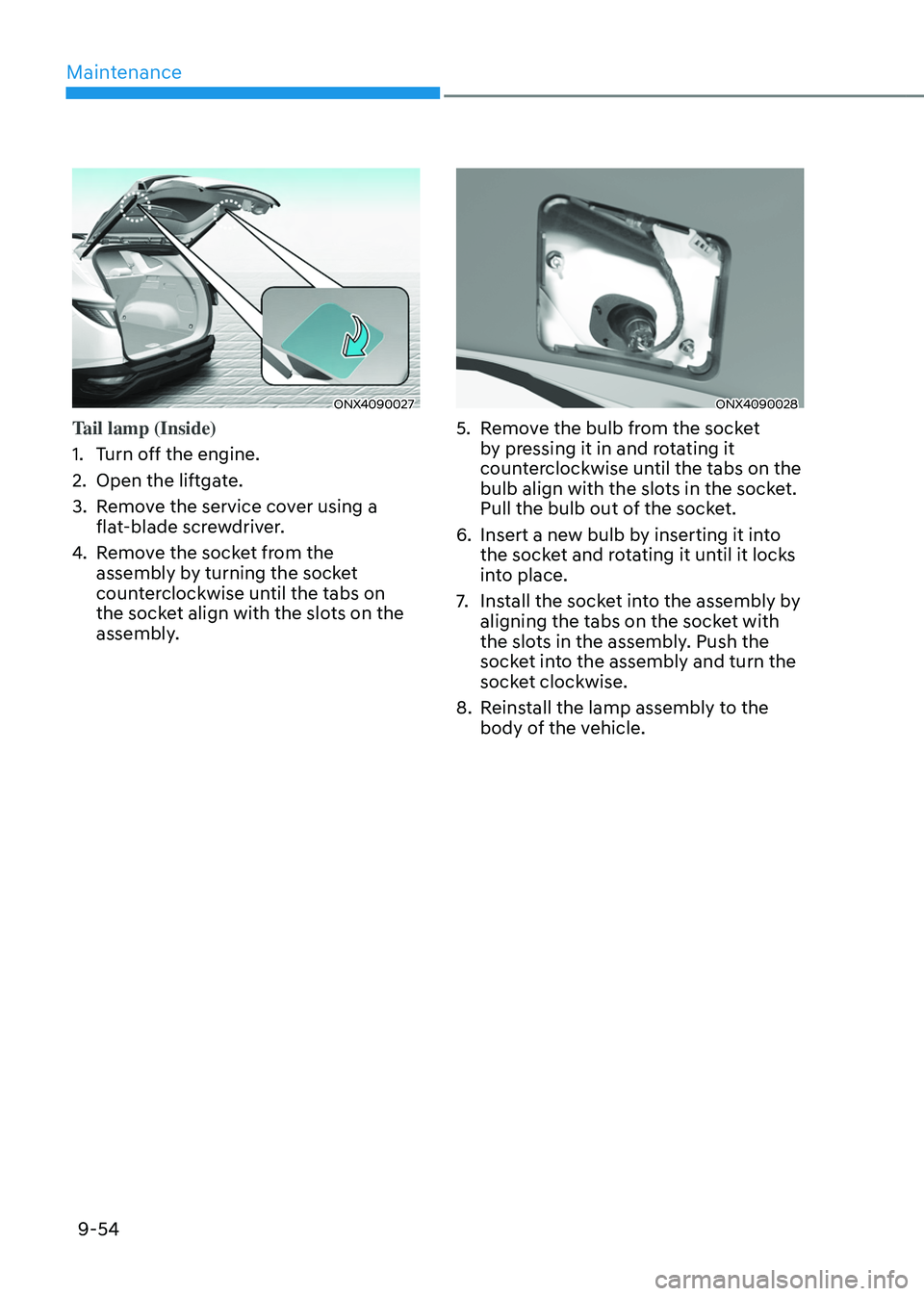

ONX4090027

Tail lamp (Inside)

1.

Turn o

ff the engine.

2.

Open the liftga

te.

3.

Remo

ve the service cover using a

flat-blade screwdriver.

4.

Remo

ve the socket from the

assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on the

assembly.

ONX4090028

5. Remove the bulb from the socket

b y pressing it in and rotating it

counterclockwise until the tabs on the

bulb align with the slots in the socket.

Pull the bulb out of the socket.

6.

Insert a new bulb b

y inserting it into

the socket and rotating it until it locks

into place.

7.

Install the sock

et into the assembly by

aligning the tabs on the socket with

the slots in the assembly. Push the

socket into the assembly and turn the

socket clockwise.

8.

Reins

tall the lamp assembly to the

body of the vehicle.

Page 607 of 630

Maintenance

9-60

NOTICE

ONX4090036

• Water washing in the engine

compartment including high

pressure water washing may cause

the failure of electrical circuits

located in the engine compartment.

• Never allow water or other liquids

to come in contact with electrical/

electronic components inside the

vehicle as this may damage them.

NOTICE

Matte paint finish vehicle (if equipped)

Automatic car wash which uses rotating

brushes should not be used as this can

damage the surface of your vehicle. A

steam cleaner which washes the vehicle

surface at high temperature may result

the oil to adhere and leave stains that is

difficult to remove.

Use a soft cloth (e.g. microfiber towel

or sponge) when washing your vehicle

and dry with a microfiber towel. When

you hand wash your vehicle, you should

not use a cleaner that finishes with wax.

If the vehicle surface is too dirty (sand,

dirt, dust, contaminant, etc.), clean the

surface with water before washing the

car.

Waxing

A good coat of wax is a barrier between

your paint and contaminate. Keeping

a good coat of wax on your vehicle will

help protect it.

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle before

waxing. Use a good quality liquid or

paste wax, and follow the manufacturer’s

instructions. Wax all metal trim to protect

it and to maintain its luster.

Removing oil, tar, and similar materials

with a spot remover will usually strip the

wax from the finish. Be sure to re-wax

these areas even if the rest of the vehicle

does not yet need waxing.

NOTICE

• Wiping dust or dirt off the body with

a dry cloth will scratch the finish.

• Do not use steel wool, abrasive

cleaners, or strong detergents

containing highly alkaline or

caustic agents on chrome-plated or

anodized aluminum parts. This may

result in damage to the protective

coating and cause discoloration or

paint deterioration.

NOTICE

Matte paint finish vehicle (if equipped)

Do not use any polish protector such as

a detergent, an abrasive and a polish.

In case wax is applied, remove the wax

immediately using a silicon remover

and if any tar or tar contaminant is on

the surface use a tar remover to clean.

However, be careful not to apply too

much pressure on the painted area.

Page 613 of 630

Maintenance

9-66

Emission control systEm

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the Service

Passport in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations. There

are three emission control systems, as

follows.

(1)

Crank

case emission control system

(2)

Ev

aporative emission control system

(3)

Exhaust emission con

trol system

In order to ensure the proper function

of the emission control systems, it

is recommended that you have your

vehicle inspected and maintained

by an authorized HYUNDAI dealer in

accordance with the maintenance

schedule in this manual.

NOTICE

For the Inspection and Maintenance

Test (with Electronic Stability Control

(ESC) system)

• To prevent the vehicle from misfiring

during dynamometer testing, turn

the Electronic Stability Control

(ESC) system off by pressing the ESC

switch (ESC OFF light illuminated).

• After dynamometer testing is

completed, turn the ESC system back

on by pressing the ESC switch again.

1. Crankcase emission control

sy

stem

The positive crankcase ventilation system

is employed to prevent air pollution

caused by blow-by gases being emitted

from the crankcase. This system supplies

fresh filtered air to the crankcase through

the air intake hose. Inside the crankcase,

the fresh air mixes with blow-by gases,

which then pass through the PCV valve

into the induction system.

2. Evaporative emission control

system

The Evaporative Emission Control System

is designed to prevent fuel vapors from

escaping into the atmosphere.

Canister

Fuel vapors generated inside the fuel

tank are absorbed and stored in the

onboard canister. When the engine is

running, the fuel vapors absorbed in the

canister are drawn into the surge tank

through the purge control solenoid valve.

Purge Control Solenoid Valve (PCSV)

The purge control solenoid valve

is controlled by the Engine Control

Module (ECM); when the engine coolant

temperature is low during idling, the

PCSV closes so that evaporated fuel

is not taken into the engine. After the

engine warms-up during ordinary

driving, the PCSV opens to introduce

evaporated fuel to the engine.