wiper fluid INFINITI FX35 2007 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: FX35, Model: INFINITI FX35 2007Pages: 4366, PDF Size: 55.42 MB

Page 16 of 4366

![INFINITI FX35 2007 Service Manual ACS-8

[ICC]

DESCRIPTION

Revision: 2006 July 2007 FX35/FX45

ABS actuator

and electric

unit (control

unit) VHCL SPEED SE

[km/h] or [mph] × Indicates vehicle speed calculated from wheel sensor b INFINITI FX35 2007 Service Manual ACS-8

[ICC]

DESCRIPTION

Revision: 2006 July 2007 FX35/FX45

ABS actuator

and electric

unit (control

unit) VHCL SPEED SE

[km/h] or [mph] × Indicates vehicle speed calculated from wheel sensor b](/img/42/57018/w960_57018-15.png)

ACS-8

[ICC]

DESCRIPTION

Revision: 2006 July 2007 FX35/FX45

ABS actuator

and electric

unit (control

unit) VHCL SPEED SE

[km/h] or [mph] × Indicates vehicle speed calculated from wheel sensor by ICC unit through CAN commu-

nication (ABS actuator and electric unit (control unit) transmits wheel speed sensor sig-

nal through CAN communication).

BCM WIPER SW

[OFF/LOW/HIGH] ×

Indicates wiper [OFF/LOW/HIGH] status (BCM transmits front wiper request signal

through CAN communication).

Brake pres-

sure sensor PRESS SENS

[bar] Indicates brake fluid pressure value calculated from signal voltage of pressure sensor.

Release

switch RELEASE SW NO

[ON/OFF] Indicates [ON/OFF] status as judged from release switch signal.

ON when brake is depressed.

OFF when brake is not depressed.

RELEASE SW NC

[ON/OFF] Indicates [ON/OFF] status as judged from release switch signal.

ON when brake is not depressed.

OFF when brake is depressed.

ICC brake

switch BRAKE SW

[ON/OFF] Indicates [ON/OFF] status as judged from ICC brake switch signal.

Stop lamp

switch STOP LAMP SW

[ON/OFF] Indicates [ON/OFF] status as judged from stop lamp switch signal.

Input

Data monitored

Item [unit] CAN Description

OutputData monitored

Item [unit] CAN Description

ICC warning

chime BUZZER O/P

[ON/OFF] ×

Indicates [ON/OFF] status of ICC warning chime output.

ICC brake hold

relay STP LMP DRIVE

[ON/OFF] Indicates [ON/OFF] status of brake hold relay drive output.

Output CONSULT-ll ICC

[ACTIVE TEST] Item CAN Description

Combination

meter ICC BUZZER 1

×Able to start ICC warning chime with a driving signal from ICC unit.

METER LAMP ×Able to turn ICC system display ON with a driving signal from ICC unit.

ICC brake hold

relay STOP LAMP Able to start ICC brake hold relay with a driving signal from ICC unit.

Booster sole-

noid BOOSTER SOL/V

3 Able to start booster solenoid with a driving signal from ICC unit.

Page 17 of 4366

![INFINITI FX35 2007 Service Manual DESCRIPTION ACS-9

[ICC]

C

D E

F

G H

I

J

L

M A

B

ACS

Revision: 2006 July 2007 FX35/FX45

Components DescriptionNKS003EL

CAN CommunicationNKS003EM

CAN (Controller Area Network) is a serial c INFINITI FX35 2007 Service Manual DESCRIPTION ACS-9

[ICC]

C

D E

F

G H

I

J

L

M A

B

ACS

Revision: 2006 July 2007 FX35/FX45

Components DescriptionNKS003EL

CAN CommunicationNKS003EM

CAN (Controller Area Network) is a serial c](/img/42/57018/w960_57018-16.png)

DESCRIPTION ACS-9

[ICC]

C

D E

F

G H

I

J

L

M A

B

ACS

Revision: 2006 July 2007 FX35/FX45

Components DescriptionNKS003EL

CAN CommunicationNKS003EM

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tric control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

Refer to LAN-49, "CAN System Specification Chart" .

Component Vehicle-to-

vehicle

distance

control mode Conventional

(fixed speed) cruise

control mode Brake assist

(with pre-

view func- tion) Description

ICC unit ××× Operates electric throttle control actuator and brake

booster based on that sensor signals and CAN commu-

nication data, then controls vehicle distance.

ICC sensor ×× Irradiates laser beam, and receives reflected laser

beam to measure distance from preceding vehicle.

ECM ××× Transmits throttle position signal and ICC steering

switch signal to ICC unit through CAN communication.

ABS actuator and electric

unit (control unit) ×××

Transmits wheel speed sensor signal to ICC unit

through CAN communication.

Brake pressure sensor ×× Detects fluid pressure in master cylinder.

Brake booster ×× Adjusts brake fluid pressure, based on command from

ICC unit.

BCM × Transmit front wiper request signal to ICC unit through

CAN communication.

TCM ×× Transmits gear position signal and output shaft revolu-

tion signal to ICC unit through CAN communication.

Unified meter and A/C amp. ××× Receives ICC system display signal, ICC warning lamp

signal and buzzer output signal from ICC unit through

CAN communication.

ICC brake switch, stop

lamp switch ××× Transmit operating signal to ICC unit when touching

brake pedal. ICC unit cancels cruise system at driver's

brake operation.

ICC brake hold relay × Receives stop lamp driving signal from ICC unit, and

turns stop lamp ON.

Parking brake switch ×× The cruise system is cancelled when applied.

Page 4339 of 4366

FRONT WIPER AND WASHER SYSTEM WW-33

C

D E

F

G H

I

J

L

M A

B

WW

Revision: 2006 July 2007 FX35/FX45

Removal and Installation of Front Wiper Arms, Adjustment of Wiper Arms Stop

Location

NKS004OX

REMOVAL

1. Turn front wiper switch ON to operate wiper motor, and then turn front wiper switch OFF (auto stop).

2. Open hood, remove front wiper arm caps, and remove washer tube from washer tube joint.

3. Remove front wiper arm nuts.

4. Raise front wiper arms, and remove front wiper arms from the vehicle.

INSTALLATION

1. Clean up the pivot area as shown in the figure. This will reduce possibility of front wiper arm nuts looseness.

2. Prior to front wiper arms installation, turn front wiper switch ON to operate wiper motor, and then turn front wiper switch OFF

(auto stop).

3. Install washer tube to washer tube joint.

4. Lift the blade up and then set it down onto windshield glass sur- face to set the blade center to clearance “L1” & “L2” immedi-

ately.

5. Tighten front wiper arm nuts to specified torque.

6. Spray washer fluid. Turn on wiper switch ON to operate wiper motor, and then turn front wiper switch OFF (auto stop).

7. Make sure that wiper blades stop within clearance “L1” & “L2”.

8. Install front wiper arm caps.

Removal and Installation of Front Wiper Drive Assembly NKS004OY

REMOVAL

1. Remove front wiper arms. Refer to WW-33, "REMOVAL" .

2. Remove cowl top cover. Refer to EI-23, "

COWL TOP" .

3. Remove washer tube.

4. Disconnect wiper motor connector.

5. Remove front wiper drive assembly mounting bolts, and remove front wiper drive assembly from the vehicle.

SEL024J

Front wiper arm nuts : 23.6 N·m (2.4 kg-m, 17 ft-lb)

Clearance “L1” : 49.4 ± 5.0 mm (1.945 ± 0.2 in)

Clearance “L2” : 43.0 ± 5.0 mm (1.693 ± 0.2 in)

PKIA9951E

SKIA5070E

Page 4343 of 4366

FRONT WIPER AND WASHER SYSTEM WW-37

C

D E

F

G H

I

J

L

M A

B

WW

Revision: 2006 July 2007 FX35/FX45

Inspection of Washer NozzleNKS004P0

CHECK VALVE

Blow check valve. Confirm that the air ventilates. Also confirm that

inhalation is impossible.

Inspection of Front Wiper and Washer Switch CircuitNKS004P8

Refer to LT- 11 8 , "Combination Switch Inspection" .

Removal and Installation of Front Wiper and Washer SwitchNKS00330

REMOVAL

1. Remove steering column upper cover. Refer to IP-10, "INSTRU-

MENT PANEL ASSEMBLY" .

2. Disconnect wiper and washer switch connector.

3. Pull wiper and washer switch toward the passenger door while pressing pawls in direction shown by the arrow in the figure, and

remove it from the base.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of Washer TankNKS00331

REMOVAL

1. Remove bolt and pull out washer tank inlet out of washer tank.

2. Remove front fillet molding (RH). Refer to EI-14, "

FRONT

BUMPER" .

3. Remove fender protector front (RH). Refer to EI-24, "

FENDER

PROTECTOR" .

4. Remove front bumper fascia assembly. Refer to EI-14, "

FRONT

BUMPER" .

5. Disconnect washer pump connector and wash fluid level sensor connector.

6. Remove washer tank mounting bolt and nuts.

PKIA3131E

PKIB6026E

SKIA5076E

PKIC9705E

Page 4357 of 4366

REAR WIPER AND WASHER SYSTEM WW-51

C

D E

F

G H

I

J

L

M A

B

WW

Revision: 2006 July 2007 FX35/FX45

Removal and Installation of Rear Wiper Arm, Adjustment of Wiper Arms Stop

Location

NKS004P1

REMOVAL

1. Turn rear wiper switch ON to operate wiper motor, then turn rear wiper switch OFF (auto stop).

2. Remove rear wiper arm cap, and remove rear wiper arm nut.

3. Remove rear wiper arm from the vehicle.

INSTALLATION

1. Clean up the pivot area as shown in the figure. This will reduce possibility of rear wiper arm nuts looseness.

2. Prior to rear wiper arms installation, turn rear wiper switch ON to operate wiper motor, and then turn rear wiper switch OFF (auto

stop).

3. Lift the blade up and then set it down onto back door window glass surface to set the blade center to lowest heat wire immedi-

ately.

4. Tighten rear wiper arm nuts to specified torque.

5. Spray washer fluid. Turn on rear wiper switch ON to operate wiper motor, and then turn rear wiper switch OFF (auto stop).

6. Ensure that wiper blade stop within the following range.

7. Install rear wiper arm cap.

Removal and Installation of Rear Wiper BladeNKS004P2

REMOVAL

1. Remove rear wiper arm. Refer to WW-51, "REMOVAL" .

2. Turn rear wiper blade 90 degrees against rear wiper arm, and pull it out downward for removal.

CAUTION:

Replace rear wiper blade as rear wiper blade assembly.

SKIA0082J

Rear wiper arm nut : 8.8 N·m (0.90 kg-m, 78 in-lb)

Lowest heat wire : ± 3.75 mm ( ± 0.148 in)

PKID0496E

SKIA6169E

Page 4360 of 4366

WW-54

REAR WIPER AND WASHER SYSTEM

Revision: 2006 July 2007 FX35/FX45

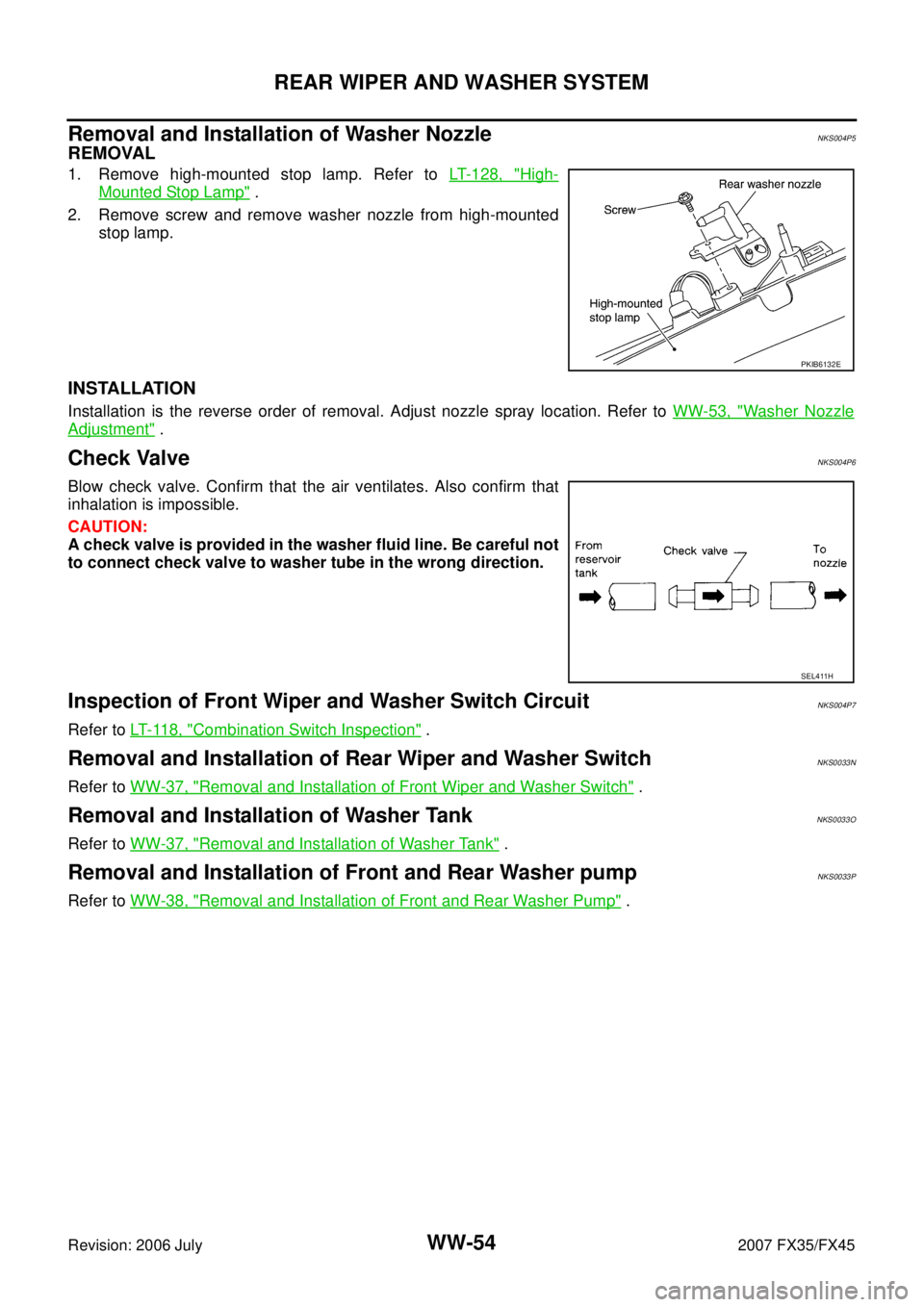

Removal and Installation of Washer NozzleNKS004P5

REMOVAL

1. Remove high-mounted stop lamp. Refer to LT- 1 2 8 , "High-

Mounted Stop Lamp" .

2. Remove screw and remove washer nozzle from high-mounted stop lamp.

INSTALLATION

Installation is the reverse order of removal. Adjust nozzle spray location. Refer to WW-53, "Washer Nozzle

Adjustment" .

Check ValveNKS004P6

Blow check valve. Confirm that the air ventilates. Also confirm that

inhalation is impossible.

CAUTION:

A check valve is provided in the washer fluid line. Be careful not

to connect check valve to washer tube in the wrong direction.

Inspection of Front Wiper and Washer Switch CircuitNKS004P7

Refer to LT- 11 8 , "Combination Switch Inspection" .

Removal and Installation of Rear Wiper and Washer SwitchNKS0033N

Refer to WW-37, "Removal and Installation of Front Wiper and Washer Switch" .

Removal and Installation of Washer TankNKS0033O

Refer to WW-37, "Removal and Installation of Washer Tank" .

Removal and Installation of Front and Rear Washer pumpNKS0033P

Refer to WW-38, "Removal and Installation of Front and Rear Washer Pump" .

PKIB6132E

SEL411H