ABS INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 162 of 3924

TROUBLE DIAGNOSISAT-89

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1 POSITION SW (ON/OFF) X —

SLCT LVR POSI — X Selector lever position is recognized by the TCM.

For fail-safe operation, the specific value used

for control is displayed.

OD CONT SW (ON/OFF) X —

Not mounted but displayed.

POWERSHIFT SW (ON/OFF) X —

HOLD SW (ON/OFF) X —

MANU MODE SW (ON/OFF) X —

NON M-MODE SW (ON/OFF) X —

UP SW LEVER (ON/OFF) X —

DOWN SW LEVER (ON/OFF) X —

SFT UP ST SW (ON/OFF) — —

Not mounted but displayed.

SFT DWN ST SW (ON/OFF) — —

ASCD-OD CUT (ON/OFF) — —

ASCD-CRUISE (ON/OFF) — —

ABS SIGNAL (ON/OFF) — —

ACC-OD CUT (ON/OFF) — — ICC (intelligent cruise control)

ACC-SIGNAL (ON/OFF) — —

TCS GR/P KEEP (ON/OFF) — —

TCS SIGNAL 2 (ON/OFF) — —

TCS SIGNAL 1 (ON/OFF) — —

TCC SOLENOID (A) — X

LINE PRES SOL (A) — X

I/C SOLENOID (A) — X

FR/B SOLENOID (A) — X

D/C SOLENOID (A) — X

HLR/C SOL (A) — X

ON OFF SOL (ON/OFF) — — LC/B solenoid

TCC SOL MON (A) — —

L/P SOL MON (A) — —

I/C SL MON (A) — —

FR/B SOL MON (A) — —

D/C SOL MON (A) — —

HLR/C SOL MON (A) — —

ON OFF SOL MON (ON/OFF) — — LC/B solenoid

P POSI IND (ON/OFF) — — Monitored item (Unit)

Select Monitor Item

Remarks

ECU IN-

PUT SIG- NALS MAIN SIG-

NALS SELEC-

TION

FROM

MENU

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 286 of 3924

KEY INTERLOCK CABLEAT-213

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

1. Unlock slider by squeezing lock tabs on slider from adjuster holder.

2. Remove casing cap from bracket of control device assembly and remove interlock rod from adjuster holder.

3. Remove holder (A) from key cylinder (1) and remove key inter- lock cable (2).

(B) : Clips

INSTALLATION

1. Set key interlock cable (2) to key cylinder (1) and install holder(A).

2. Clamp key interlock cable (2) and fix to key interlock cable (2) with clips (B).

3. Turn ignition key to “LOCK” position.

4. Set selector lever to “P” position.

SCIA1230E

SCIA7761E

SCIA7761E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 409 of 3924

ATC-4

< SERVICE INFORMATION >

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000001612932

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Working with HFC-134a (R-134a)INFOID:0000000001328153

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed and compressor malfunct ion is likely to occur, refer to “CONTAMINATED REFRIGERANT”

below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refriger-

ant Recovery/Recycling Rech arging equipment and Refrigerant Identifier.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

The specified HFC-134a (R-134a) lu bricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precauti ons must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehic le, never remove the caps (unseal) until just before

connecting the components. Connect all refriger ant loop components as quickly as possible to min-

imize the entry of moisture into system.

- Only use the specified lubricant fr om a sealed container. Immediately reseal containers of lubricant.

Without proper sealing, lubrican t will become moisture saturated and should not be used.

- Never allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrene foam parts.

Damage may result.

CONTAMINATED REFRIGERANT

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, take appropriate steps

shown below:

Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

Explain that recovery of the contaminated refri gerant could damage service equipment and refrigerant sup-

ply.

Suggest the customer return the vehicle to the locati on of previous service where the contamination may

have occurred.

In case of repairing, recover the refrigerant using only dedicated equipment and containers. Never

recover contaminated refrigerant into the existing service equipment. If the facility does not have ded-

icated recovery equipment, contact a local refrigerant pr oduct retailer for available service. This refrigerant

must be disposed of in accordance with all federal and local regulations. In addition, replacement of all

refrigerant system components on the vehicle is recommended.

If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact Nissan Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionINFOID:0000000001328154

WARNING:

Avoid breathing A/C refrigerant and lubricant vap or or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) from the A/C syst em, using certified service equipment meeting

requirements of SAE J-2210 [HFC-134a (R-134a) recycling equipment], or J-2209 [HFC-134a (R-134a)

recovery equipment]. If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and saf ety information may be obtained from refrigerant and lubricant

manufacturers.

PIIB3706J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 866 of 3924

BL-132

< SERVICE INFORMATION >

DOOR

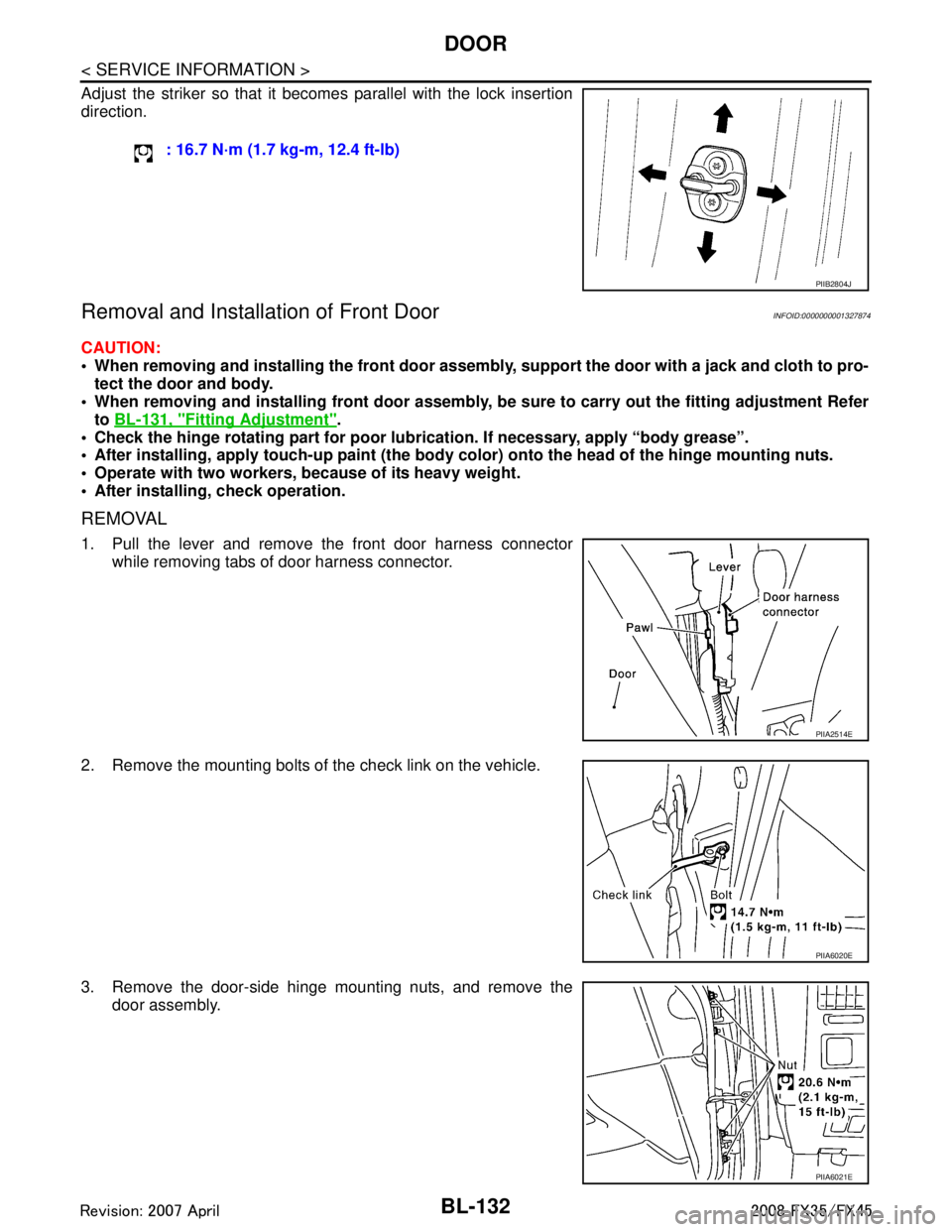

Adjust the striker so that it becomes parallel with the lock insertion

direction.

Removal and Installation of Front DoorINFOID:0000000001327874

CAUTION:

When removing and installing the front door assembl y, support the door with a jack and cloth to pro-

tect the door and body.

When removing and installing front door assembly, be sure to carry out the fitting adjustment Refer

to BL-131, "

Fitting Adjustment".

Check the hinge rotating part for poor lubrication. If necessary, apply “body grease”.

After installing, apply touch-up paint (the body color) onto the head of the hinge mounting nuts.

Operate with two workers, because of its heavy weight.

After installing, check operation.

REMOVAL

1. Pull the lever and remove the front door harness connector

while removing tabs of door harness connector.

2. Remove the mounting bolts of the check link on the vehicle.

3. Remove the door-side hinge mounting nuts, and remove the door assembly. : 16.7 N·m (1.7 kg-m, 12.4 ft-lb)

PIIB2804J

PIIA2514E

PIIA6020E

PIIA6021E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 942 of 3924

BL-208

< SERVICE INFORMATION >

BODY REPAIR

Corrosion Protection

INFOID:0000000001327945

DESCRIPTION

To provide improved corrosion prevention, the foll owing anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

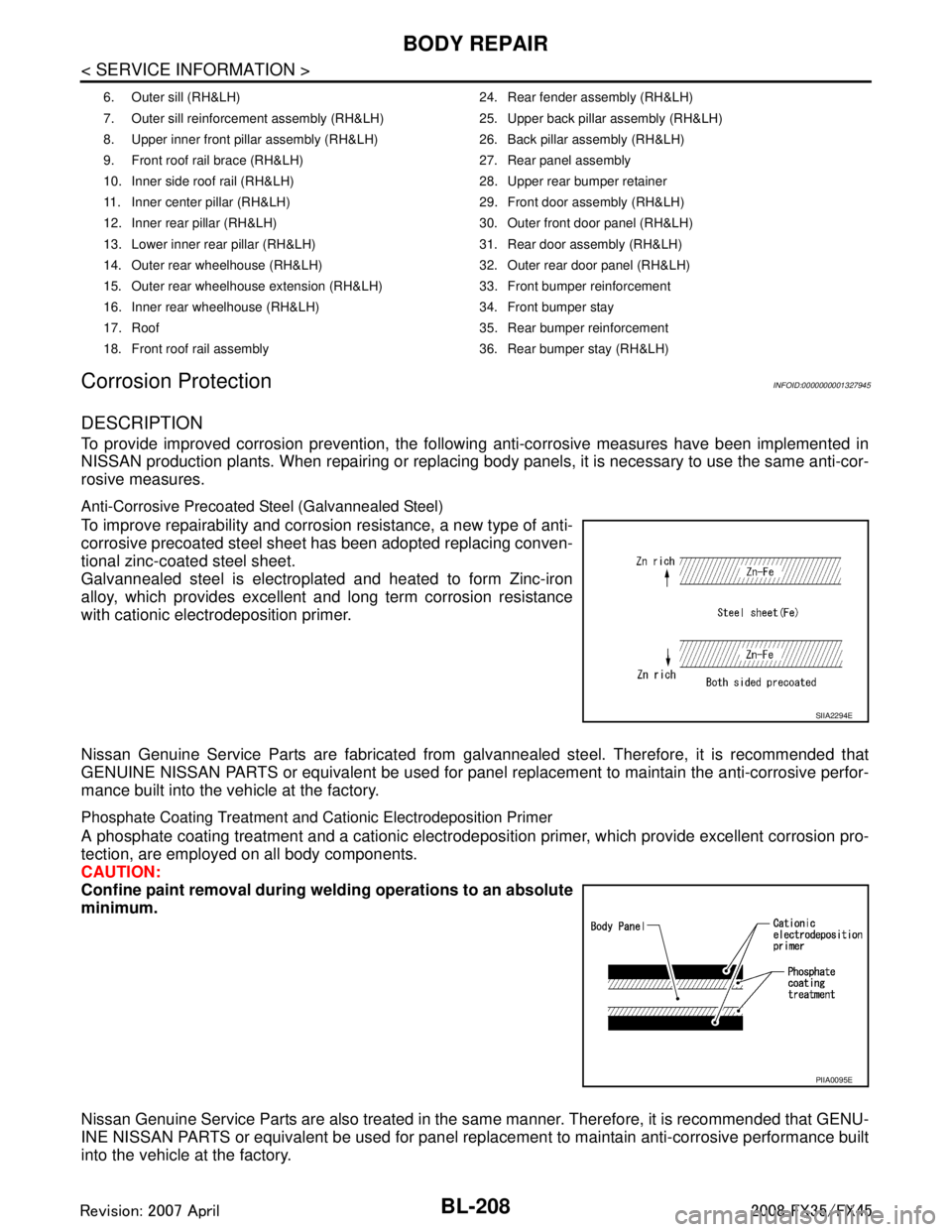

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodepositi on primer, which provide excellent corrosion pro-

tection, are employed on all body components.

CAUTION:

Confine paint removal during weld ing operations to an absolute

minimum.

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or equivalent be used for panel replacement to maintain anti-corrosive performance built

into the vehicle at the factory.

6. Outer sill (RH&LH) 24. Rear fender assembly (RH&LH)

7. Outer sill reinforcement assembly (RH&LH) 25. Upper back pillar assembly (RH&LH)

8. Upper inner front pillar assembly (RH&LH) 26. Back pillar assembly (RH&LH)

9. Front roof rail brace (RH&LH) 27. Rear panel assembly

10. Inner side roof rail (RH&LH) 28. Upper rear bumper retainer

11. Inner center pillar (RH&LH) 29. Front door assembly (RH&LH)

12. Inner rear pillar (RH&LH) 30. Outer front door panel (RH&LH)

13. Lower inner rear pillar (RH&LH) 31. Rear door assembly (RH&LH)

14. Outer rear wheelhouse (RH&LH) 32. Outer rear door panel (RH&LH)

15. Outer rear wheelhouse extension (RH&LH) 33. Front bumper reinforcement

16. Inner rear wheelhouse (RH&LH) 34. Front bumper stay

17. Roof 35. Rear bumper reinforcement

18. Front roof rail assembly 36. Rear bumper stay (RH&LH)

SIIA2294E

PIIA0095E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 960 of 3924

BL-226

< SERVICE INFORMATION >

BODY REPAIR

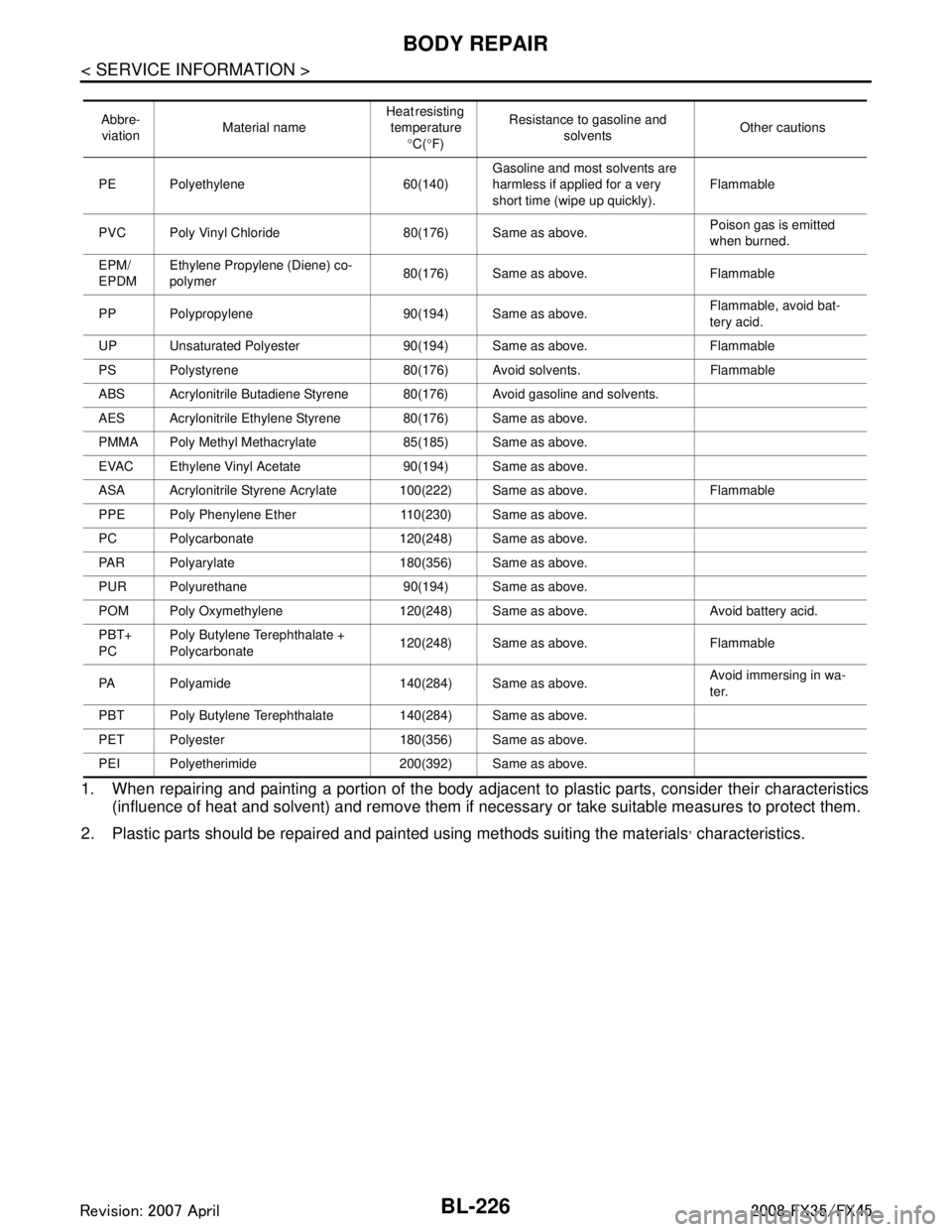

1. When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics

(influence of heat and solvent) and remove them if neces sary or take suitable measures to protect them.

2. Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

Abbre- viation Material name Heat resisting

temperature °C( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60(140) Gasoline and most solvents are

harmless if applied for a very

short time (wipe up quickly).Flammable

PVC Poly Vinyl Chloride 80(176) Same as above. Poison gas is emitted

when burned.

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80(176) Same as above. Flammable

PP Polypropylene 90(194) Same as above. Flammable, avoid bat-

tery acid.

UP Unsaturated Polyester 90(194) Same as above. Flammable

PS Polystyrene 80(176) Avoid solvents. Flammable

ABS Acrylonitrile Butadiene Styrene 80(176) Avoid gasoline and solvents.

AES Acrylonitrile Ethylene Styrene 80(176) Same as above.

PMMA Poly Methyl Methacrylate 85(185) Same as above.

EVAC Ethylene Vinyl Acetate 90(194) Same as above.

ASA Acrylonitrile Styrene Acrylate 100(222) Same as above. Flammable

PPE Poly Phenylene Ether 110(230) Same as above.

PC Polycarbonate 120(248) Same as above.

PAR Polyarylate 180(356) Same as above.

PUR Polyurethane 90(194) Same as above.

POM Poly Oxymethylene 120(248) Same as above. Avoid battery acid.

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120(248) Same as above. Flammable

PA Polyamide 140(284) Same as above. Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140(284) Same as above.

PET Polyester 180(356) Same as above.

PEI Polyetherimide 200(392) Same as above.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 986 of 3924

BR-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612918

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000001612920

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000001327604

Clean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

Recommended fluid is brake fluid “DOT 3”. MA-9, "

Fluids and Lubricants".

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut crowfoot and torque wrench when installing brake

tube.

When installing brake piping, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec- tors for ABS actuator and electric unit (control unit) or battery neg-

ative terminal.

Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer to BR-23, "

Brake Burnishing Procedure" (Front disc brake),

BR-29, "

Brake Burnishing Procedure" (Rear disc brake).

WARNING:

Clean brake pads and shoes with a waste cl oth, then clean with a dust collector.

PIIB3706J

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 992 of 3924

BR-8

< SERVICE INFORMATION >

BRAKE FLUID

BRAKE FLUID

On-Board InspectionINFOID:0000000001327610

LEVEL CHECK

Make sure the fluid level in reservoir tank is within the standard(between MAX and MIN lines).

Visually check around reservoir tank for fluid leakage.

If fluid level is excessively low, check brake system for leakage.

Release parking brake pedal and see if brake warning lamp goes off. If not, check brake system for fluid leakage.

Drain and RefillINFOID:0000000001327611

CAUTION:

Refill with new brake fluid “DOT3”.

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of bo dy, immediately wipe it off and them wash it away with water

immediately.

Before working, disconnect connectors of ABS actua tor and electric unit (control unit) or battery

negative terminal.

1. Connect a vinyl tube to each bleed valve.

2. Depress brake pedal, loosen each bleed valve, and gradually remove brake fluid.

3. Make sure there is no foreign material in reservoir tank, and refill with new brake fluid.

4. Rest foot on brake pedal. Loosen bleed valve. Slowly depress pedal until it stops. Tighten bl eed valve. Release brake pedal.

Repeat this process a few times, then pause to add new brake

fluid to master cylinder. Continue until new brake fluid flows out.

5. Bleed Air. Refer to BR-8, "

Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000001327612

CAUTION:

SFIA1032E

BRA0007D

SBR995

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 993 of 3924

BRAKE FLUIDBR-9

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

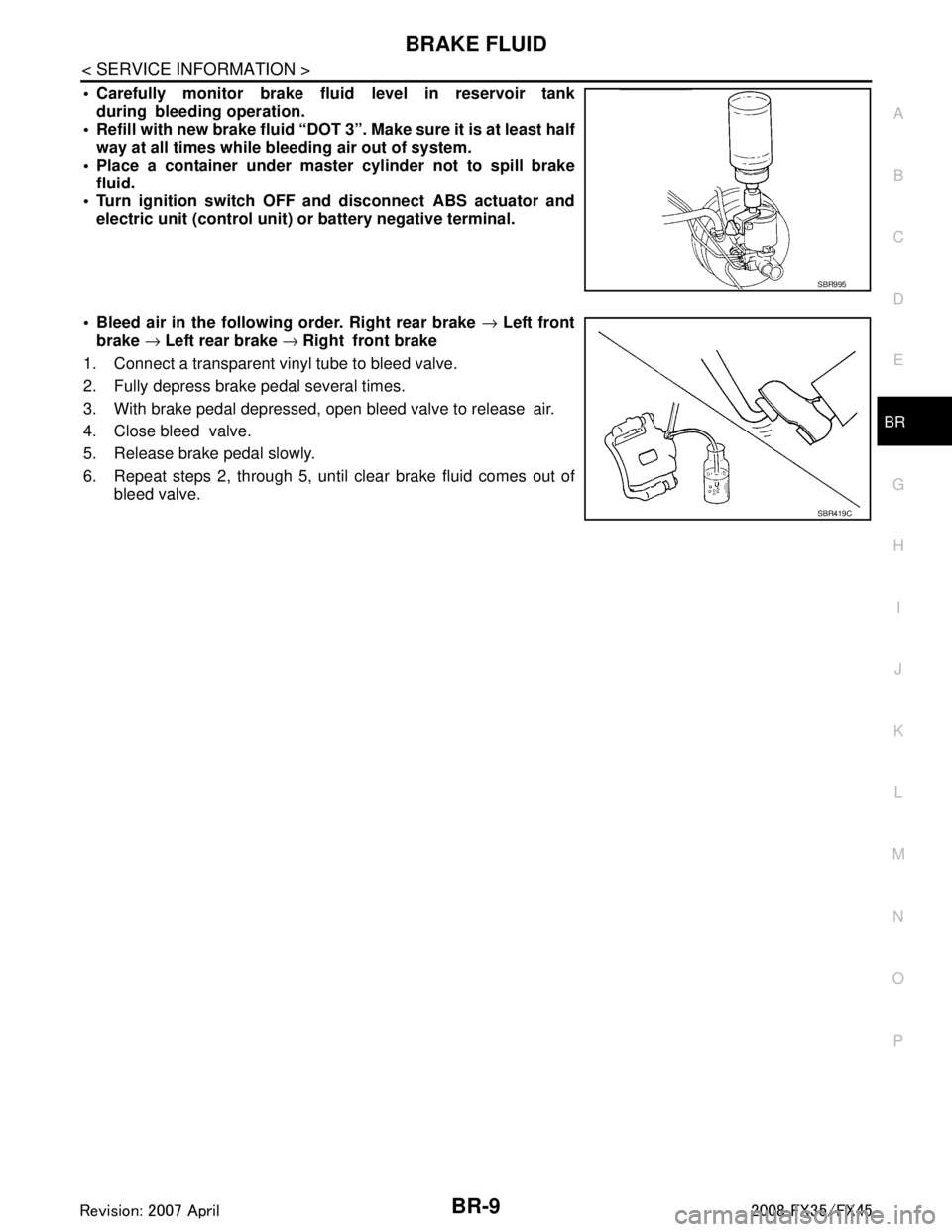

Carefully monitor brake fluid level in reservoir tank during bleeding operation.

Refill with new brake fluid “DOT 3”. Make sure it is at least half

way at all times while bleeding air out of system.

Place a container under master cylinder not to spill brake fluid.

Turn ignition switch OFF and disconnect ABS actuator and

electric unit (control unit) or battery negative terminal.

Bleed air in the following order. Right rear brake → Left front

brake → Left rear brake → Right front brake

1. Connect a transparent vinyl tube to bleed valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open bleed valve to release air.

4. Close bleed valve.

5. Release brake pedal slowly.

6. Repeat steps 2, through 5, until clear brake fluid comes out of bleed valve.

SBR995

SBR419C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 997 of 3924

BRAKE MASTER CYLINDERBR-13

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. Remove master cylinder assembly mounting nut, re move master cylinder assembly from the vehicle.

Refer to BR-14, "

Removal and Installation".

INSTALLATION

CAUTION:

Refill with new brake fluid “DOT3”.

Do not reuse drained brake fluid.

1. Install in the reverse order of removal, and tight en mounting nuts to the specified torque. Refer to BR-14,

"Component".

2. Refill brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System".

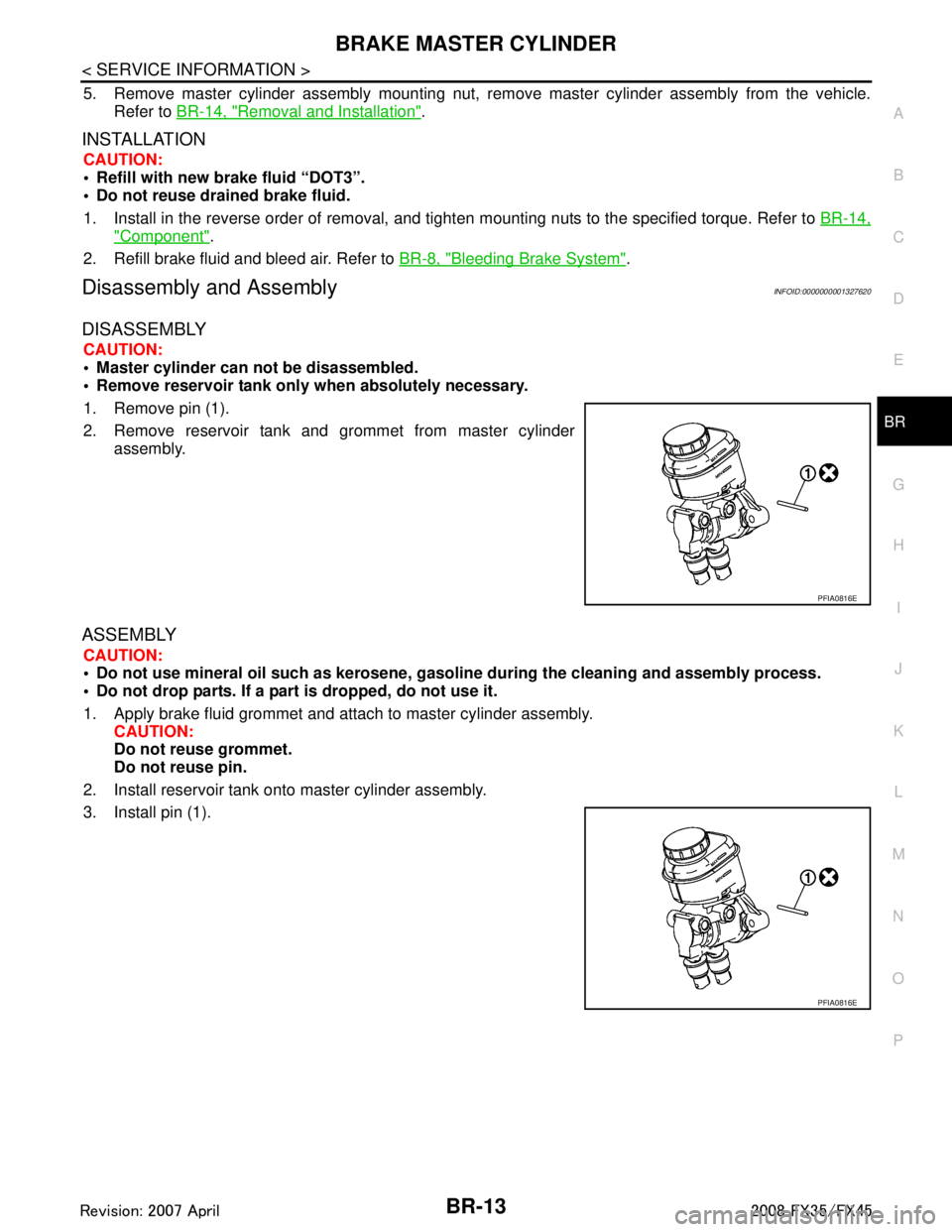

Disassembly and AssemblyINFOID:0000000001327620

DISASSEMBLY

CAUTION:

Master cylinder can not be disassembled.

Remove reservoir tank only when absolutely necessary.

1. Remove pin (1).

2. Remove reservoir tank and grommet from master cylinder

assembly.

ASSEMBLY

CAUTION:

Do not use mineral oil such as kerosene, g asoline during the cleaning and assembly process.

Do not drop parts. If a part is dropped, do not use it.

1. Apply brake fluid grommet and attach to master cylinder assembly.

CAUTION:

Do not reuse grommet.

Do not reuse pin.

2. Install reservoir tank onto master cylinder assembly.

3. Install pin (1).

PFIA0816E

PFIA0816E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C