flush INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1020 of 3924

![INFINITI FX35 2008 User Guide

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI INFINITI FX35 2008 User Guide

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/42/57017/w960_57017-1019.png)

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612923

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001327654

Recommended fluid is brake fluid “DOT 3”. Refer to MA-9.

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause improper operation.

Using a flare nut crowfoot and torque wrench, securely tighten brake tube flare nuts.

Brake system is an important safe ty part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and elec tric unit (control unit) or bat-

tery negative terminal.

When installing brake piping, be sure to check torque.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

Precaution for Brake ControlINFOID:0000000001327655

During VDC/TCS/ABS operation, brake pedal lightly vi brates and a mechanical noise may be heard. This is

normal.

Just after starting vehicle after turning ignition switch ON, brake pedal may vibrate or motor operating noise

may be heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck booster operation, brake fluid level, and fluid leaks.

If tire size and type are used in an improper combinat ion, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, VDC/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1082 of 3924

![INFINITI FX35 2008 User Guide

ENGINE COOLANTCO-11

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

4. Che INFINITI FX35 2008 User Guide

ENGINE COOLANTCO-11

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

4. Che](/img/42/57017/w960_57017-1081.png)

ENGINE COOLANTCO-11

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling sys tem. Refer to "FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-123, "

Dis-

assembly and Assembly".

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug on heater hose.

4. Fill radiator, and reservoir tank if removed, to specified level. Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2-1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use Genuine NISSAN Long Li fe Antifreeze/Coolant or

equivalent mixed with water (dis tilled or demineralized).

Refer to MA-9, "

Fluids and Lubricants".

When engine coolant overflows air relief hole on heater hose, install air relief plug with new O-ring.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warm ing-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching r adiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop the engine and cool down to less than approximately 50 °C (122 °F).

Radiator drain plug:

: 1.18 N·m (0.12 kg-m, 10 in-lb)

SBIA0445E

Engine coolant capacity

(With reservoir tank at “MAX” level): Approximately 8.6 (9-1/8 US qt, 7-5/8 lmp qt)

SMA182B

Reservoir tank engine coolant capacity

(At “MAX” level): 0.8 (7/8 US qt, 3/4 lmp qt)

Air relief plug: : 1.19 N·m (0.12 kg-m, 11 in-lb)

SMA412B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1083 of 3924

![INFINITI FX35 2008 User Guide

CO-12

< SERVICE INFORMATION >[VQ35DE]

ENGINE COOLANT

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

8. Refill reservoir tank to “MA INFINITI FX35 2008 User Guide

CO-12

< SERVICE INFORMATION >[VQ35DE]

ENGINE COOLANT

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

8. Refill reservoir tank to “MA](/img/42/57017/w960_57017-1082.png)

CO-12

< SERVICE INFORMATION >[VQ35DE]

ENGINE COOLANT

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating step 4 through 7 until engine coolant level no

longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed, and radiator drain plug.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-123, "

Dis-

assembly and Assembly".

2. Remove air relief plug on heater hose.

3. Fill radiator with water until water spills from the ai r relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap.

4. Run the engine and warm it up to normal operating temperature.

5. Rev the engine two or three times under no-load.

6. Stop the engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator. Radiator drain plug:

: 1.18 N·m (0.12 kg-m, 10 in-lb)

SBIA0445E

Air relief plug: : 1.19 N·m (0.12 kg-m, 11 in-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1109 of 3924

![INFINITI FX35 2008 User Guide

CO-38

< SERVICE INFORMATION >[VK45DE]

ENGINE COOLANT

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refe INFINITI FX35 2008 User Guide

CO-38

< SERVICE INFORMATION >[VK45DE]

ENGINE COOLANT

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refe](/img/42/57017/w960_57017-1108.png)

CO-38

< SERVICE INFORMATION >[VK45DE]

ENGINE COOLANT

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to "FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, and radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-242, "

Dis-

assembly and Assembly".

2. Make sure that each hose clamp has been firmly tightened.

3. Remove air relief plug on heater hose.

4. Fill thermostat housing and reservoir tank to specified level. Refill engine coolant up to fill er neck of thermostat housing.

Pour engine coolant through engine coolant filler neck slowly of less than 2 (2-1/8 US qt, 1-3/4

Imp qt) a minute to allo w air in system to escape.

Use Genuine NISSAN Long Life Anti freeze/Coolant or equivalent mixed with water (distilled or

demineralized). Refer to MA-9, "

Fluids and Lubricants".

When engine coolant overflows air relief hole on heater hose, install air relief plug.

5. Install radiator cap.

6. Warm up until opening thermostat. Standard for warming- up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

7. Stop engine and cool down to less than approximately 50 °C (122 °F).

Cool down using a fan to reduce the time.

If necessary, refill engine coolant up to filler neck of thermostat housing. Radiator drain plug:

: 1.19 N·m (0.12 kg-m, 11 in-lb)

PBIC1530E

Engine coolant capacity

(With reservoir tank at “MAX” level):Approx. 10.0 (10-5/8 US qt, 8-3/4 Imp qt)

Reservoir tank engine coolant capacity

(At “MAX” level):0.8 (7/8 US qt, 3/4 lmp qt)

SMA412B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1110 of 3924

![INFINITI FX35 2008 User Guide

ENGINE COOLANTCO-39

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more time INFINITI FX35 2008 User Guide

ENGINE COOLANTCO-39

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more time](/img/42/57017/w960_57017-1109.png)

ENGINE COOLANTCO-39

< SERVICE INFORMATION > [VK45DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

8. Refill reservoir tank to “MAX” level line with engine coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap installed until engine coolant level no longer

drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank, and radiator drain plug. CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block ar e removed, close and tighten them. Refer to EM-242, "

Dis-

assembly and Assembly".

2. Remove air relief plug on heater hose.

3. Fill thermostat housing with water until water spills from the air relief hole, then close air relief plug. Fill

thermostat housing and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the system. Refer to "DRAINING ENGINE COOLANT".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator. Radiator drain plug:

: 1.19 N·m (0.12 kg-m, 11 in-lb)

PBIC1530E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2542 of 3924

![INFINITI FX35 2008 User Guide

EM-58

< SERVICE INFORMATION >[VQ35DE]

FRONT TIMING CHAIN CASE

29. Use a scraper to remove all traces of liquid gasket from water

pump cover, chain tensioner cover and intake valve timing con-

trol co INFINITI FX35 2008 User Guide

EM-58

< SERVICE INFORMATION >[VQ35DE]

FRONT TIMING CHAIN CASE

29. Use a scraper to remove all traces of liquid gasket from water

pump cover, chain tensioner cover and intake valve timing con-

trol co](/img/42/57017/w960_57017-2541.png)

EM-58

< SERVICE INFORMATION >[VQ35DE]

FRONT TIMING CHAIN CASE

29. Use a scraper to remove all traces of liquid gasket from water

pump cover, chain tensioner cover and intake valve timing con-

trol covers.

INSTALLATION

1. Install timing chain and related parts. Refer to EM-64, "Component".

2. Hammer dowel pins (right and left) into front timing chain case up to a point close to taper in order to shorten protrusion length.

3. Install front oil seal on front timing chain case. Apply new engine oil to the oil seal lip and dust seal lip.

Install it so that each seal lip is oriented as shown in the figure.

Using a suitable drift [outer diameter: 60 mm (2.36 in)], press-fit oil seal until it becomes flush with front timing chain case

end face.

Make sure the garter spring is in position and seal lip is not inverted.

4. Install water pump cover and chain tensioner cover to front timing chain case.

SEM926E

PBIC1101E

SEM715A

PBIC0790E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2563 of 3924

![INFINITI FX35 2008 User Guide

TIMING CHAINEM-79

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install it so that each seal lip is oriented as shown in the figure.

Using a suitable drift [outer diameter: 60 INFINITI FX35 2008 User Guide

TIMING CHAINEM-79

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install it so that each seal lip is oriented as shown in the figure.

Using a suitable drift [outer diameter: 60](/img/42/57017/w960_57017-2562.png)

TIMING CHAINEM-79

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install it so that each seal lip is oriented as shown in the figure.

Using a suitable drift [outer diameter: 60 mm (2.36 in)], press-

fit oil seal until it becomes flush with front timing chain case

end face.

Make sure the garter spring is in position and seal lip is not

inverted.

13. Install water pump cover and chain tensioner cover to front timing chain case. Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to front timing chain case as shown

in the figure.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-44, "

Recommended Chemical Product and Sealant".

14. Install front timing chain case as follows:

SEM715A

PBIC0790E

SEM744GA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2793 of 3924

FFD-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Service Notice or PrecautionINFOID:0000000001327476

• Check for the correct installation status prior to removal or disassembly. If matching marks are required, becertain they do not interfere with the function of the parts when applied.

Overhaul should be done in a clean work area, it is preferable to work in dustproof area.

Before disassembly, using steam or white gasoline, completely remove sand and mud from the exterior of

the unit, preventing them from entering into the unit during disassembly or assembly.

Check appearance of the disassembled parts for dam age, deformation, and unusual wear. Replace them

with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time when the unit is disassembled.

In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If tight-

ening sequence is specified, observe it.

Clean and flush the parts sufficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

When applying sealant, remove the old sealant from t he mounting surface; then remove any moisture, oil,

and foreign materials from the application and mounting surfaces.

Always use shop paper for cleaning the inside of components.

Avoid using cotton gloves or shop rags to prevent entering of lint.

During assembly, observe the specified tightening tor que, and apply new gear oil, petroleum jelly, or multi-

purpose grease as specified for each vehicle, if necessary.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2826 of 3924

FRONT FINAL DRIVE ASSEMBLYFFD-35

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FFD

N

O P

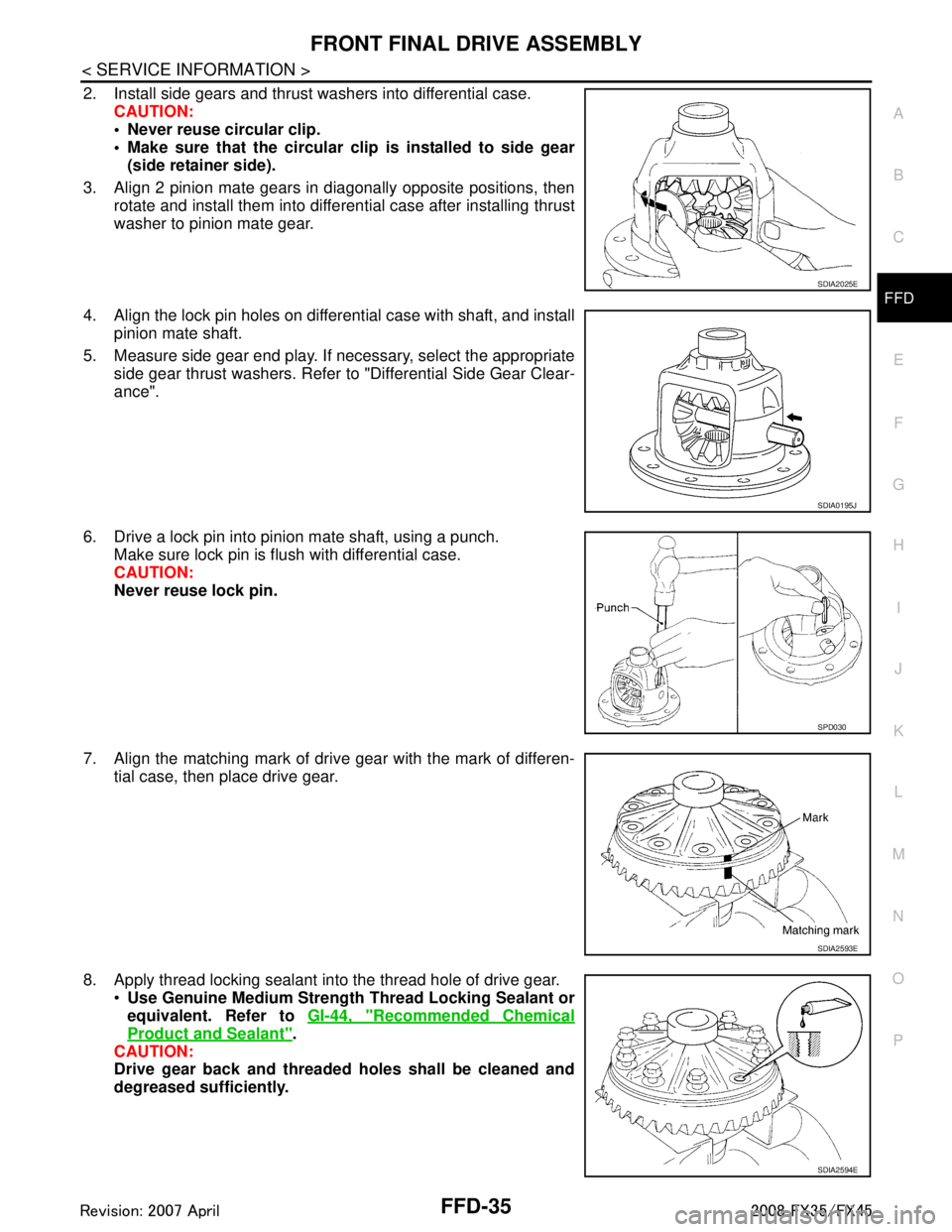

2. Install side gears and thrust washers into differential case. CAUTION:

Never reuse circular clip.

Make sure that the circular cl ip is installed to side gear

(side retainer side).

3. Align 2 pinion mate gears in diagonally opposite positions, then rotate and install them into differential case after installing thrust

washer to pinion mate gear.

4. Align the lock pin holes on differential case with shaft, and install pinion mate shaft.

5. Measure side gear end play. If necessary, select the appropriate side gear thrust washers. Refer to "Differential Side Gear Clear-

ance".

6. Drive a lock pin into pinion mate shaft, using a punch. Make sure lock pin is flush with differential case.

CAUTION:

Never reuse lock pin.

7. Align the matching mark of drive gear with the mark of differen- tial case, then place drive gear.

8. Apply thread locking sealant into the thread hole of drive gear. Use Genuine Medium Strength Thread Locking Sealant or

equivalent. Refer to GI-44, "

Recommended Chemical

Product and Sealant".

CAUTION:

Drive gear back and threaded holes shall be cleaned and

degreased sufficiently.

SDIA2025E

SDIA0195J

SPD030

SDIA2593E

SDIA2594E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3321 of 3924

MA-4

< SERVICE INFORMATION >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Accelerator pedalCheck the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-5

,

BR-14

Parking brake Check that the pedal has the proper travel and make sure that the vehicle is

held securely on a fairly steep hill when only the parking brake is applied. PB-3

Automatic transmis-

sion "Park" mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

, MA-19

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. —

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir. MA-32

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. SC-4

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-11, MA-19

Engine oil level Check the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. MA-15,

MA-22

Power steering fluid

level and lines Check the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-33

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-26

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C