seat memory INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 3675 of 3924

SE-36

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

19 G/R Front lifting sensor signal InputON (front lifting motor operation)

Other than above 0 or 5

22 R/B Power seat memory switch 1

signal

InputMemory switch 1: ON 0

Memory switch 1: OFF 5

23 Y/W Power seat memory switch in-

dictor 1 signal

OutputMemory switch 1: ON 1

Memory switch 1: OFF Battery voltage

24 L/R Seat sliding switch

FORWARD signal InputWhen seat sliding switch

FORWARD operation

0

Other than above Battery voltage

25 L/OR Seat reclining switch

FORWARD signal

InputWhen seat reclining switch

FORWARD operation

0

Other than above Battery voltage

26 L/P Front lifting switch UP signal Input When front lifting switch

UP operation

0

Other than above Battery voltage

27 L Rear lifting switch UP signal Input When rear lifting switch

UP operation

0

Other than above Battery voltage

28C B/W Ground (sensor) — — 0

29 G Reclining sensor signal Input ON (reclining motor operation)

Other than above 0 or 5

30 R/W Rear lifting sensor signal Input ON (rear lifting motor operation)

Other than above 0 or 5

34 L/W Set switch signal Input Set witch: ON 0

Set witch: OFF 5

35 L/B Power seat memory switch 2

signal InputMemory switch 2: ON 0

Memory switch 2: OFF 5

36 Y/G Power seat memory switch in-

dictor 2 signal OutputMemory switch 2: ON 1

Memory switch 2: OFF Battery voltage

Te r -

minal Wire

Color ItemSignal Input/

Output Condition Voltage (V)

(Approx.)

SIIA0691J

SIIA0692J

SIIA0693J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3681 of 3924

SE-42

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

If active test is performed, reset seat memory and key fob interlock drive positioner after performing work.

Display Item List

Check CAN Communication SystemINFOID:0000000001532368

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of BCM.

TILT SW-UP “ON/OFF” ON/OFF status judged from the tilt switch (UP) signal is displayed.

TILT SW-DOWN “ON/OFF” ON/OFF status judged from the tilt switch (DOWN) signal is displayed.

SET SW “ON/OFF” ON/OFF status judged from the setting switch signal is displayed.

MEMORY SW1 “ON/OFF” ON/OFF status judged from th e seat memory switch 1 signal is displayed.

MEMORY SW2 “ON/OFF” ON/OFF status judged from th e seat memory switch 2 signal is displayed.

P POSI SW “ON/OFF” The selector lever position “ON (P position) / OFF (other than P position)” judged

from the park position switch signal is displayed.

STARTER SW “ON/OFF” Ignition key switch ON (START, ON) /OFF (ignition switch IGN, ACC, or OFF) sta-

tus judged from the ignition switch signal is displayed.

SLIDE PULSE — Value (32768) when battery connects is as standard. If it moves backward, the val-

ue increases. If it moves forward, the value decreases.

RECLN RULSE — Value (32768) when battery connects is as standard. If it moves backward, the val-

ue increases. If it moves forward, the value decreases.

LIFT FR PULSE — Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

LIFT RR PULSE — Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

TILT SEN “V” The tilt position (voltage) judged from the tilt sensor signal is displayed.

TELESCO SEN “V” The telescoping position (voltage) judged from the telescoping sensor signal is dis-

played.

MIR/SE RH R–L “V” Voltage output from RH do or mirror sensor (LH/RH) is displayed.

MIR/SE RH U–D “V” Voltage output from RH door mirror sensor (UP/DOWN) is displayed.

MIR/SE LH R–L “V” Voltage output from LH door mirror sensor (LH/RH) is displayed.

MIR/SE LH U–D “V” Voltage output from LH door mirror sensor (UP/DOWN) is displayed. Monitor item [OPERAT

ION or UNIT] Contents

Test item Description

TILT MOTOR The tilt motor is activated by receiving the drive signal.

TELESCO MOTOR The telescopic motor is activated by receiving the drive signal.

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

SEAT RECLINING The reclining motor is activated by receiving the drive signal.

SEAT LIFTER FR The front end lifter motor is activated by receiving the drive signal.

SEAT LIFTER RR The rear end lifter motor is activated by receiving the drive signal.

MEMORY SW INDCTR The memory sw itch indicator is lit by receivin g the drive signal.

MIRROR MOTOR RH The RH mirror motor moves the mirror UP/DOW

N and LEFT/RIGHT by receiving the drive

signal.

MIRROR MOTOR LH The LH mirror motor moves the mirror UP/DOW

N and LEFT/RIGHT by receiving the drive

signal.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3683 of 3924

SE-44

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check Sliding Motor Circuit

INFOID:0000000001328111

1.CHECK SEAT SLIDING MECHANISM

Check the following.

Operation malfunction caused by sliding rail deformation or pinched harness or other foreign materials

Operation malfunction caused by foreign materials adhered to the sliding motor or sliding rail connector rod

Operation malfunction and interference wit h other parts by poor installation

OK or NG

OK >> GO TO 2 (With CONSULT-III). GO TO 3 (Without CONSULT-III).

NG >> Repair the malfunctioning part and check again.

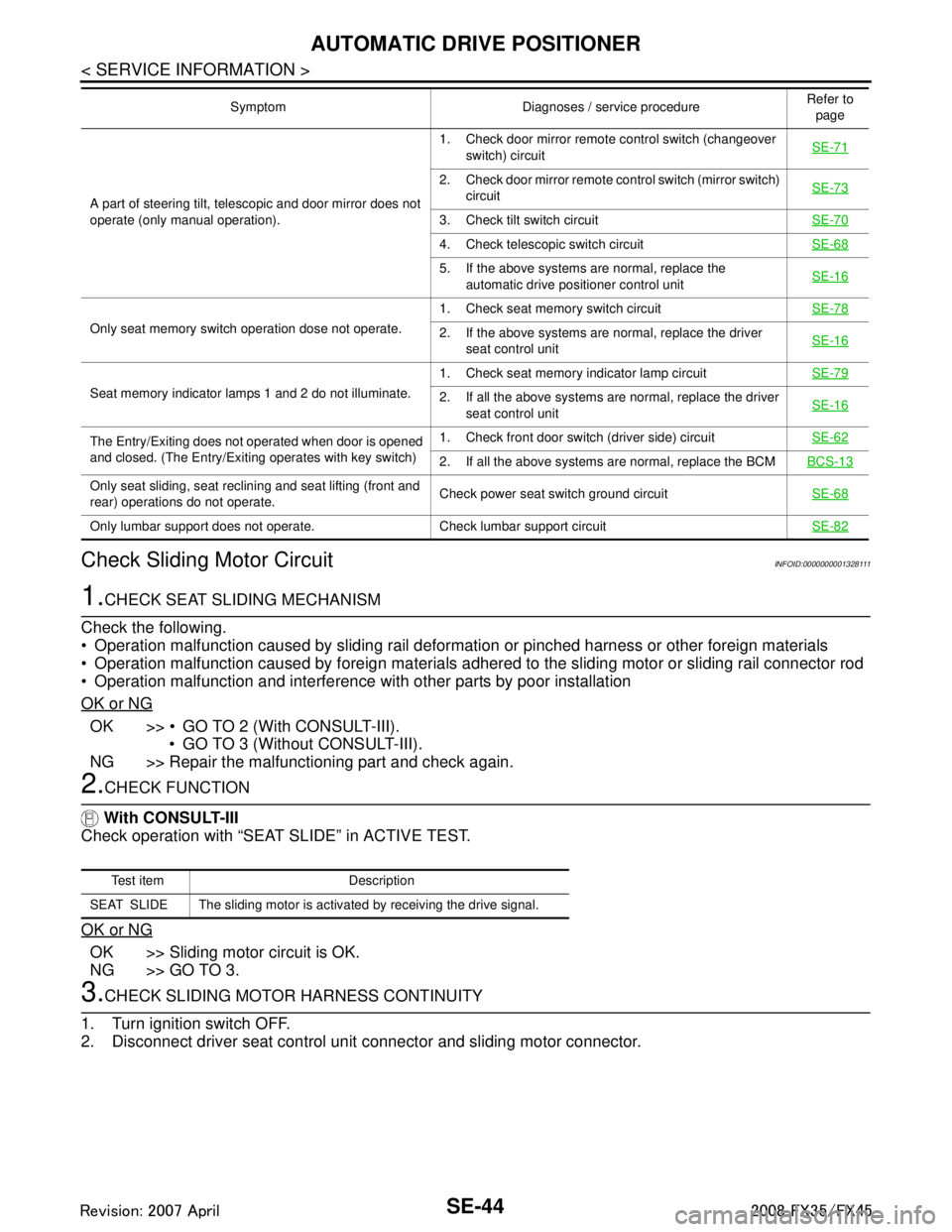

2.CHECK FUNCTION

With CONSULT-III

Check operation with “SEAT SLIDE” in ACTIVE TEST.

OK or NG

OK >> Sliding motor circuit is OK.

NG >> GO TO 3.

3.CHECK SLIDING MOTOR HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector and sliding motor connector.

A part of steering tilt, telescopic and door mirror does not

operate (only manual operation). 1. Check door mirror remote

control switch (changeover

switch) circuit SE-71

2. Check door mirror remote co

ntrol switch (mirror switch)

circuit SE-73

3. Check tilt switch circuit

SE-70

4. Check telescopic switch circuitSE-68

5. If the above systems are normal, replace the

automatic drive positioner control unit SE-16

Only seat memory switch operation dose not operate. 1. Check seat memory switch circuit

SE-782. If the above systems are normal, replace the driver

seat control unit SE-16

Seat memory indicator lamps 1 and 2 do not illuminate. 1. Check seat memory indicator lamp circuit

SE-792. If all the above systems are normal, replace the driver

seat control unit SE-16

The Entry/Exiting does not operated when door is opened

and closed. (The Entry/Exiting operates with key switch) 1. Check front door switch

(driver side) circuit SE-62

2. If all the above systems are normal, replace the BCM BCS-13

Only seat sliding, seat reclining and seat lifting (front and

rear) operations do not operate.Check power seat switch ground circuit

SE-68

Only lumbar support does not operate. Check lumbar support circuit SE-82

Symptom Diagnoses / service procedureRefer to

page

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3717 of 3924

SE-78

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

4.CHECK HARNESS CONTINUITY

1. Disconnect key switch connector and BCM connector.

2. Check continuity between key switch connector M23 terminal 1 and BCM connector M3 terminal 37.

3. Check continuity between key switch connector M23 terminal 1 and ground.

OK or NG

OK >> Key switch circuit is OK.

NG >> Repair or replace harness between key switch and BCM.

Check Seat Memory Switch CircuitINFOID:0000000001328141

1.CHECK FUNCTION

With CONSULT-III

With “SET SW, MEMORY SW1, MEMO RY SW2” on the DATA MONITOR, operate the switch to check ON/

OFF operation.

OK or NG

OK >> Seat memory switch circuit is OK.

NG >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH

1. Turn ignition switch OFF.

2. Disconnect seat memory switch connector.

3. Check continuity between seat memory s witch connector D22 terminal 1, 2, 3 and 4.

OK or NG

OK >> GO TO 3.

NG >> Replace seat memory switch.

3.CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector. 1 (B/W) – 37 (B/W) : Cont

inuity should exist.

1 (B/W) – Ground : Conti nuity should not exist.

PIIA5094E

Monitor item

[OPERATION or UNIT] Contents

MEMORY SW1 “ON/OFF” ON/OFF status judged from the seat memory

switch 1 signal is displayed.

MEMORY SW2 “ON/OFF” ON/OFF status judged from the seat memory

switch 2 signal is displayed.

SET SW “ON/OFF” ON/OFF status judged from the setting switch

signal is displayed.

Connec-

tor Terminals Condition Continuity

D22 1

4Memory switch 1: ON Yes

Memory switch 1: OFF No

2 Memory switch 2: ON Yes

Memory switch 2: OFF No

3 Set switch: ON Yes

Set switch: OFF No

PIIA4575E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3718 of 3924

AUTOMATIC DRIVE POSITIONERSE-79

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

SE

N

O P

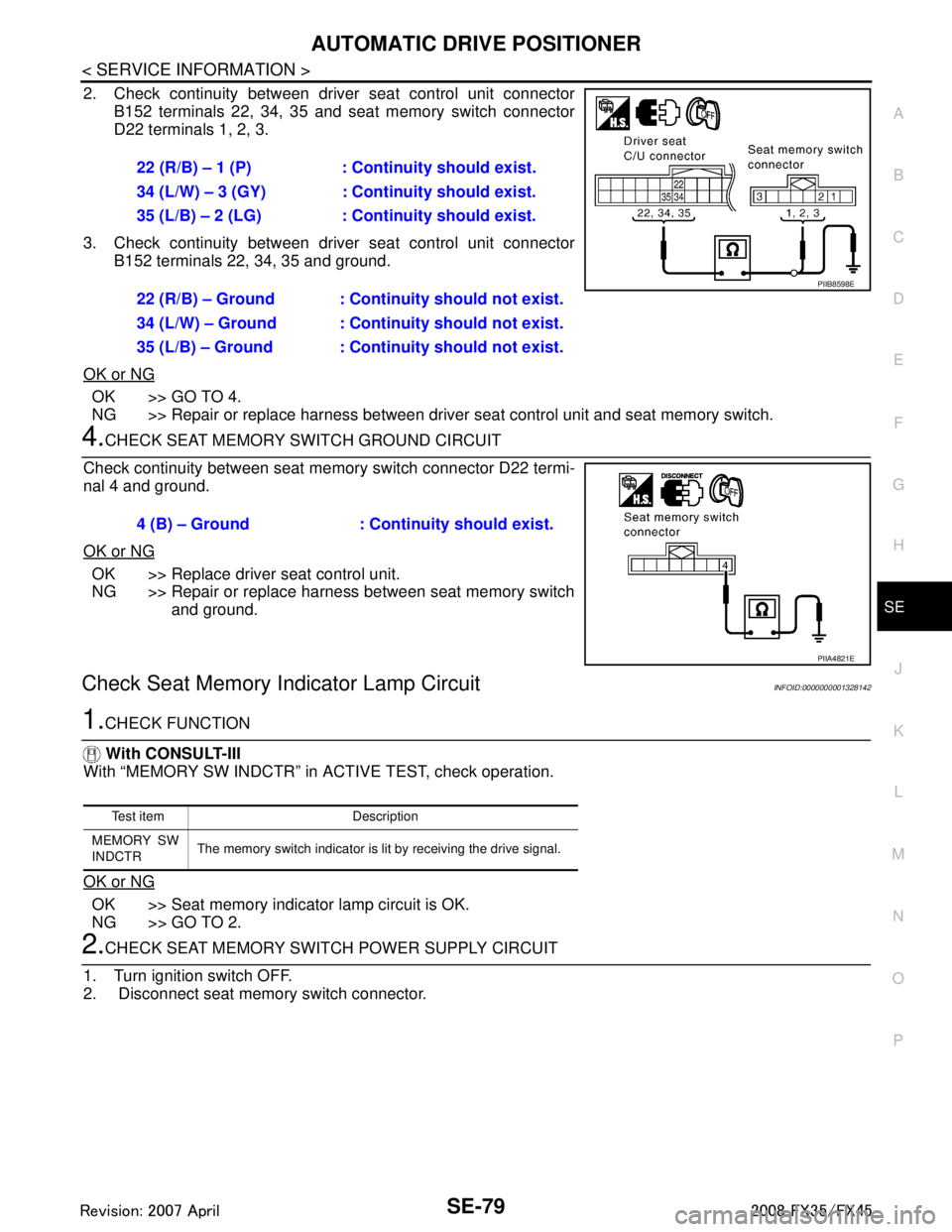

2. Check continuity between driver seat control unit connector B152 terminals 22, 34, 35 and seat memory switch connector

D22 terminals 1, 2, 3.

3. Check continuity between driver seat control unit connector B152 terminals 22, 34, 35 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between driver seat control unit and seat memory switch.

4.CHECK SEAT MEMORY SWITCH GROUND CIRCUIT

Check continuity between seat memory switch connector D22 termi-

nal 4 and ground.

OK or NG

OK >> Replace driver seat control unit.

NG >> Repair or replace harness between seat memory switch and ground.

Check Seat Memory I ndicator Lamp CircuitINFOID:0000000001328142

1.CHECK FUNCTION

With CONSULT-III

With “MEMORY SW INDCTR” in ACTIVE TEST, check operation.

OK or NG

OK >> Seat memory indicator lamp circuit is OK.

NG >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect seat memory switch connector. 22 (R/B) – 1 (P) : Continuity should exist.

34 (L/W) – 3 (GY) : Cont

inuity should exist.

35 (L/B) – 2 (LG) : Cont inuity should exist.

22 (R/B) – Ground : Continuity should not exist.

34 (L/W) – Ground : Continuity should not exist.

35 (L/B) – Ground : Continuity should not exist.

PIIB8598E

4 (B) – Ground : Continuity should exist.

PIIA4821E

Test item Description

MEMORY SW

INDCTR The memory switch indicator is lit by receiving the drive signal.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3719 of 3924

SE-80

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

3. Check voltage between seat memory switch connector D22 ter-minal 5 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between fuse block (J/B) and seat memory switch.

3.CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector.

2. Check continuity between driv er seat control unit connector

B152 terminals 23, 36 and seat memory switch connector D22

terminals 6, 7.

3. Check continuity between driv er seat control unit connector

B152 terminals 23, 36 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness between driver seat control unit and seat memory switch.

4.CHECK SEAT MEMORY SWITCH INDICATOR SIGNAL

Check voltage between driver seat control unit connector B152 ter-

minals 23, 36 and ground.

OK or NG

OK >> Seat memory indicator lamp circuit is OK.

NG >> Replace seat memory switch.

Check UART Communication Line CircuitINFOID:0000000001328143

1.CHECK UART LINE HERNESS

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector and automatic drive positioner control unit connector.

5 (R) – Ground : Battery voltage

PIIA4595E

23 (Y/W) – 6 (PU) : Continuity should exist.

36 (Y/G) – 7 (L) : Continuity should exist.

23 (Y/W) – Ground : Continuity should not exist.

36 (Y/G) – Ground : Continuity should not exist.

PIIB8599E

23 (Y/W) – Ground : Battery voltage

36 (Y/G) – Ground : Battery voltage

PIIA5078E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3721 of 3924

SE-82

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

When voltage signal dose not appear with a constant voltage (approx. 5V), replace automatic

driver seat control unit.

When voltage signal dose not appear with a constant voltage (approx. 0V), replace driver seat

control unit.

4.CHECK DRIVER SEAT CONTROL UNIT

Dose the automatic drive positioner operate, when the driver seat control unit exchanged?

Does seat memory function operate?

YES >> Replace automatic drive positioner control unit.

NG >> Replace driver seat control unit.

Check Lumbar Support CircuitINFOID:0000000001328144

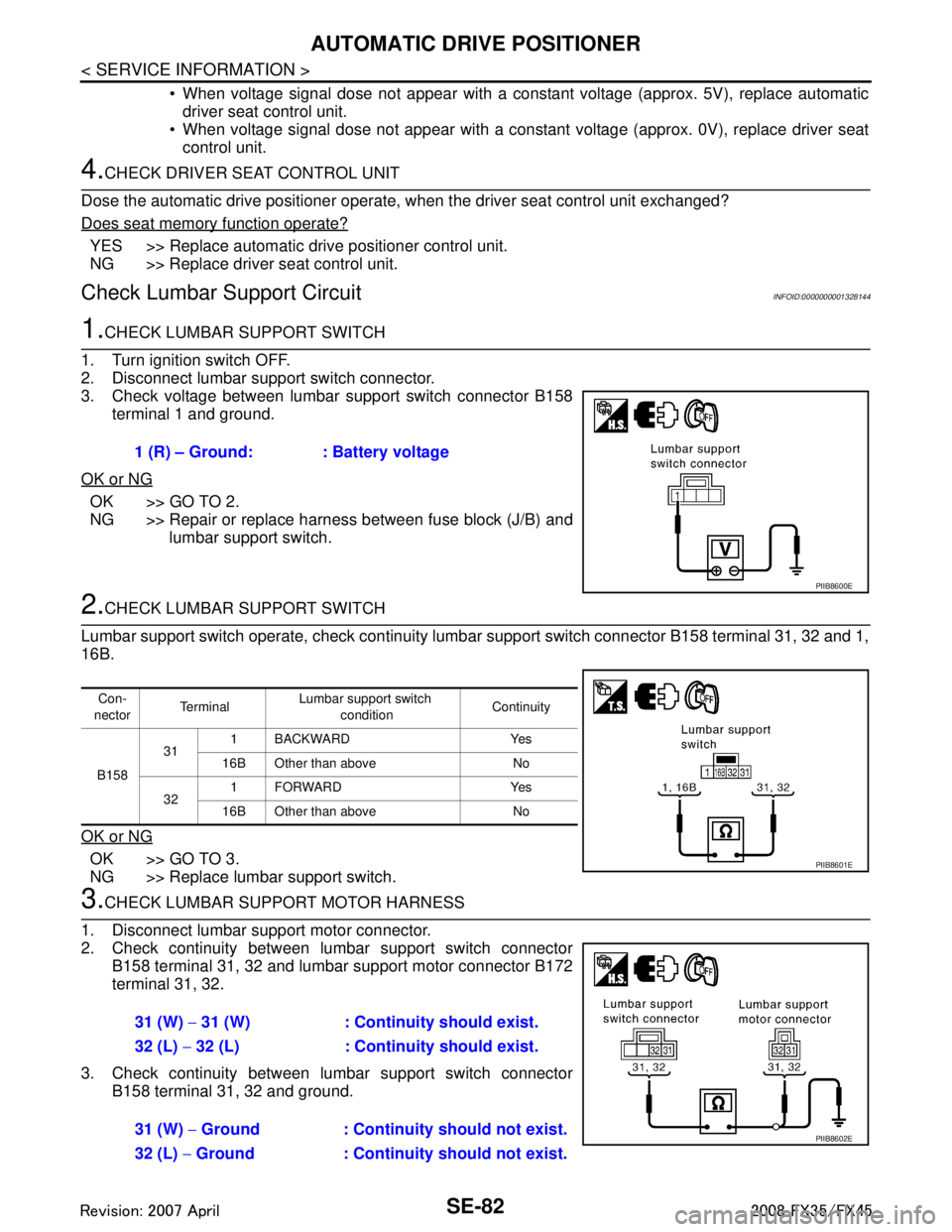

1.CHECK LUMBAR SUPPORT SWITCH

1. Turn ignition switch OFF.

2. Disconnect lumbar support switch connector.

3. Check voltage between lumbar support switch connector B158 terminal 1 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace harness between fuse block (J/B) and lumbar support switch.

2.CHECK LUMBAR SUPPORT SWITCH

Lumbar support switch operate, check continuity lum bar support switch connector B158 terminal 31, 32 and 1,

16B.

OK or NG

OK >> GO TO 3.

NG >> Replace lumbar support switch.

3.CHECK LUMBAR SUPPORT MOTOR HARNESS

1. Disconnect lumbar support motor connector.

2. Check continuity between lumbar support switch connector B158 terminal 31, 32 and lumbar support motor connector B172

terminal 31, 32.

3. Check continuity between lumbar support switch connector B158 terminal 31, 32 and ground.1 (R) – Ground: : Battery voltage

PIIB8600E

Con-

nector Te r m i n a l

Lumbar support switch

condition Continuity

B158 31

1 BACKWARD Yes

16B Other than above No

32 1FORWARD Yes

16B Other than above No

PIIB8601E

31 (W) − 31 (W) : Continuity should exist.

32 (L) − 32 (L) : Continuity should exist.

31 (W) − Ground : Continuity should not exist.

32 (L) − Ground : Continuity should not exist.

PIIB8602E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3761 of 3924

![INFINITI FX35 2008 User Guide

SRS-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis with CONSULT-III

INFOID:0000000001524168

DIAGNOSTIC PROCEDURE

DTC No. Index (“SELF-DIAG [ CURRENT]” “SELF-DIAG [PAST]” or INFINITI FX35 2008 User Guide

SRS-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis with CONSULT-III

INFOID:0000000001524168

DIAGNOSTIC PROCEDURE

DTC No. Index (“SELF-DIAG [ CURRENT]” “SELF-DIAG [PAST]” or](/img/42/57017/w960_57017-3760.png)

SRS-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis with CONSULT-III

INFOID:0000000001524168

DIAGNOSTIC PROCEDURE

DTC No. Index (“SELF-DIAG [ CURRENT]” “SELF-DIAG [PAST]” or TROUBLE DIAG RECORD)

Air bag is deployed.

Seat belt pre-tensioner is deployed. Go to

SRS-47, "For Frontal Colli-

sion" or SRS-48, "For Side Collision"

Diagnosis sensor unit is malfunction-

ing.

Air bag power supply circuit is mal-

functioning.

SRS air bag warning lamp circuit is malfunctioning. Go to

SRS-32, "

Trouble Diagnosis:

"AIR BAG" Warning Lamp Does Not

Turn OFF".

Diagnosis sensor unit is malfunction- ing.

Air bag warning lamp circuit is mal-

functioning. Go to

SRS-32, "

Trouble Diagnosis:

"AIR BAG" Warning Lamp Does Not

Turn ON".

“AIR BAG” warning lamp operation — User mode

—

SRS condition Reference item

SHIA0013E

SHIA0014E

Diagnostic mode Description

SELF-DIAG RESULT The self-d iagnosis result is Displayed. (SELF-DIAG [ CURRENT], [PAST], [RECORD])

ECU DISCRIMINATED No. The parts number of diagnosis sensor units displayed.

Diagnostic item Explanation Repair order

“Recheck SRS at each replacement”

NO DTC IS DETECT-

ED. When malfunction is in-

dicated by the “AIR

BAG” warning lamp in

User mode. Low battery voltage (Less than 9V)

Self-diagnostic result “SELF-DIAG

[PAST]” (previously stored in the

memory) might not be erased after re-

pair.

Intermittent malfunction has been de- tected in the past. Go to

SRS-21, "

CONSULT-III Func-

tion".

No malfunction is detected. —

DIAGNOSIS SENSOR

UNIT (CONTROL UNIT)

[B1001-B1015] Diagnosis sensor is out of order. Replace diagnosis sensor unit.

(ACU)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3780 of 3924

SIDE AIR BAG (SATELLITE) SENSOR

SRS-43

< SERVICE INFORMATION >

C

D E

F

G

I

J

K L

M A

B

SRS

N

O P

SIDE AIR BAG (S ATELLITE) SENSOR

Removal and InstallationINFOID:0000000001327769

WARNING:

Before servicing SRS, turn igniti on switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Remove seat belt pre-tensioner. Refer to SB-3, "Removal and Installation of Front Seat Belt".

2. Remove side air bag (Satellite) sensor fixing nuts.

3. Remove the side air bag (Satellite) sensor connector.

CAUTION:

Do not use old nuts; replace with new ones.

Check side air bag (Satellite) senso r to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of da mage, replace it with new one.

Do not disassemble side ai r bag (Satellite) sensor.

Replace side air bag (Satellite) sensor if it has been dropped or sustained an impact.

Replace the satellite sensor of de ployed SRS front side air bag and deployed SRS side curtain air

bag.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the satellite sensor harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still detected after th e above operation, perform self-diagnosis to repair

malfunctions. Refer to SRS-23, "

SRS Operation Check".

PHIA0314E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3781 of 3924

SRS-44

< SERVICE INFORMATION >

DIAGNOSIS SENSOR UNIT

DIAGNOSIS SENSOR UNIT

Removal and InstallationINFOID:0000000001327771

WARNING:

Before servicing SRS, turn ignition switch OFF, disconnect both ba ttery cables and wait at least 3

minutes.

Do not use air tools or el ectric tools for servicing.

REMOVAL

1. Disconnect each harness connector for the ai r bag module and seat belt pre-tensioner.

2. Remove center console. Refer to IP-11, "

Removal and Installation".

3. Disconnect diagnosis sensor unit connector.

4. Remove TORX bolts from the diagnosis sensor unit.

CAUTION:

Do not use old TORX bolts. Replace with new ones.

Check diagnosis sensor unit bracket to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible things of damage, replace with new one.

Replace diagnosis sensor unit if it has been dropped or sustained an impact.

Replace the diagnosis sensor unit of deployed SRS air bag and deployed SRS front seat belt pre-ten-

sioner.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be careful not to damage the diagnosis sensor harness.

After the work is completed, make sure no system malfunction is detected by air bag warning lamp.

In case that malfunction is detected by the air ba g warning lamp, reset by the self-diagnosis function

and delete the memory by CONSULT −III.

In case that malfunction is still de tected after the above operation, perform self-diagnosis to repair

malfunctions. Refer to SRS-23, "

SRS Operation Check".

ECU DISCRIMINATED NO.

After replacing the diagnosis sensor unit, confirm that t he diagnosis sensor unit identification is correct for the

vehicle as equipped.

PHIA0315E

Specification ECU DISCRIMINATED No.

Models with driver and passenger air bags, seat belt pre-tensioner, side air bags and curtain air bags FB04

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C