torque INFINITI FX35 2008 User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 107 of 3924

AT-34

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

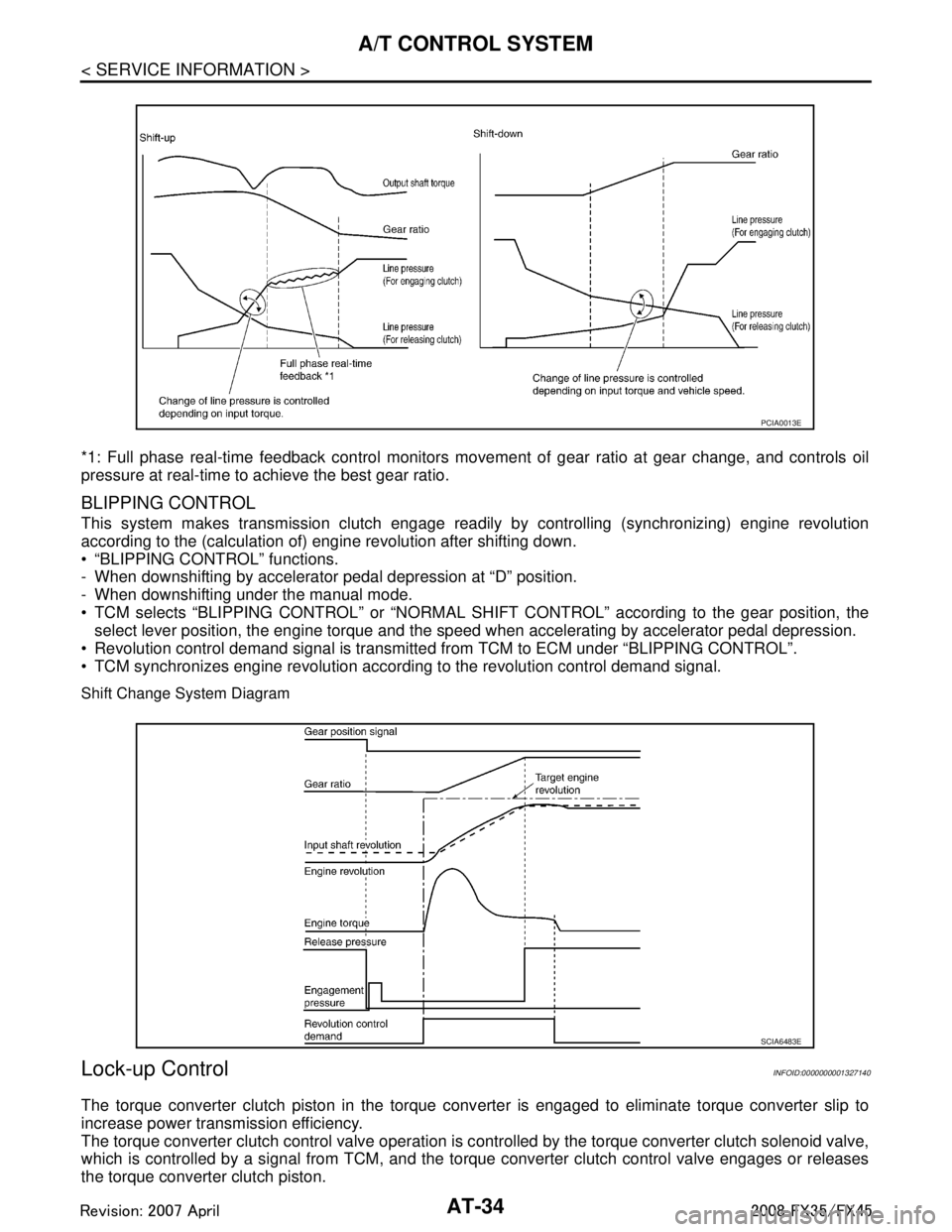

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

BLIPPING CONTROL

This system makes transmission clutch engage readily by controlling (synchronizing) engine revolution

according to the (calculation of) engine revolution after shifting down.

“BLIPPING CONTROL” functions.

- When downshifting by accelerator pedal depression at “D” position.

- When downshifting under the manual mode.

TCM selects “BLIPPING CONTROL” or “NORMAL SHIFT CONTROL” according to the gear position, the

select lever position, the engine torque and the speed when accelerating by accelerator pedal depression.

Revolution control demand signal is transmitted from TCM to ECM under “BLIPPING CONTROL”.

TCM synchronizes engine revolution according to the revolution control demand signal.

Shift Change System Diagram

Lock-up ControlINFOID:0000000001327140

The torque converter clutch piston in the torque conv erter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is c ontrolled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the to rque converter clutch control valve engages or releases

the torque converter clutch piston.

PCIA0013E

SCIA6483E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 108 of 3924

A/T CONTROL SYSTEMAT-35

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Lock-up Operation Condition Table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the torque

converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

When shifting from the lock-up released state to the lock- up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converte r clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch pi ston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid cu rrent is controlled with the TCM to put it into the half-

clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

Engine Brake ControlINFOID:0000000001327141

The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

selector lever D position M5 position M4 position M3 position

Gear position 54543

Lock-up ×– ×××

Slip lock-up ××–––

PCIA0014E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 109 of 3924

AT-36

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

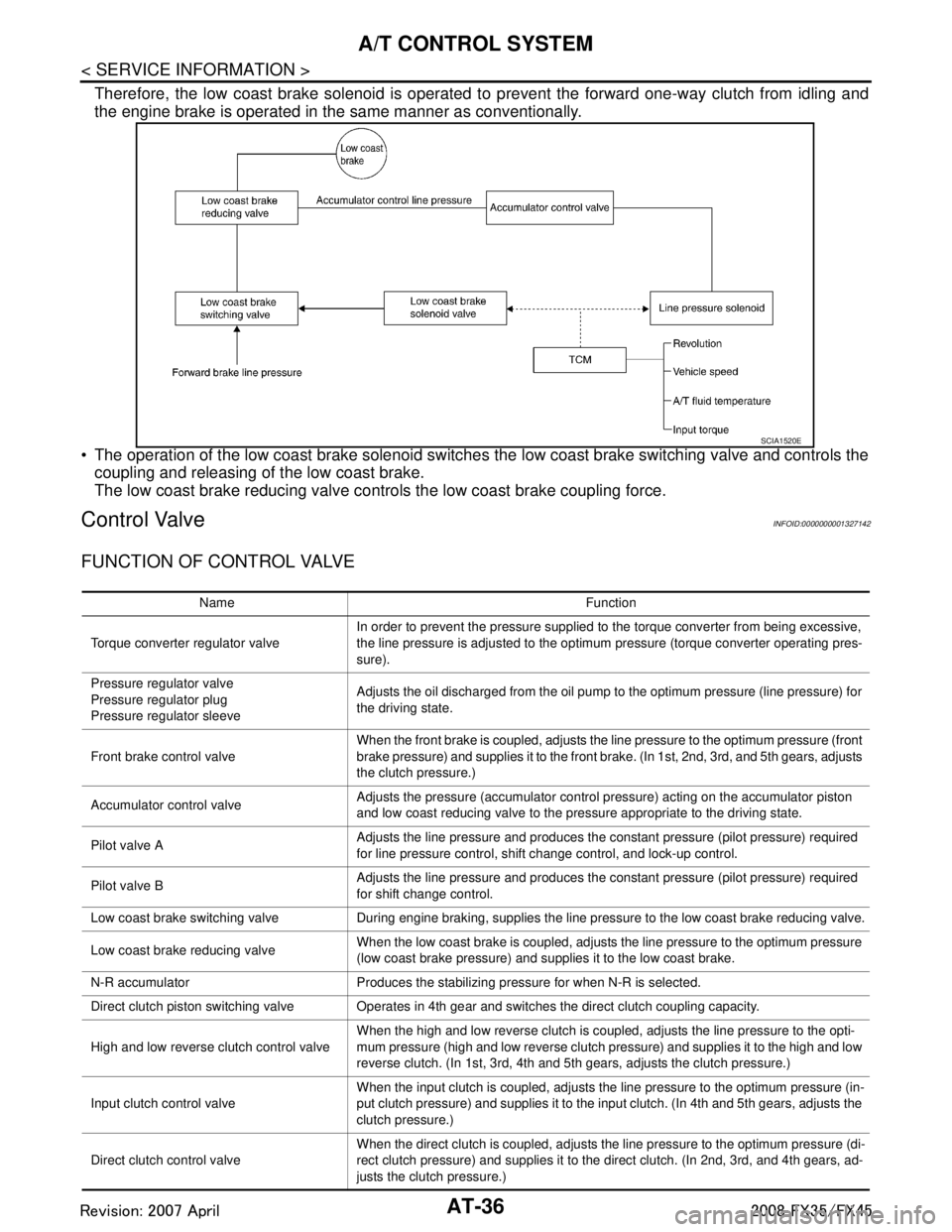

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve contro ls the low coast brake coupling force.

Control ValveINFOID:0000000001327142

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valve In order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regu lator valve

Pressure regulator plug

Pressure regu lator sleeve Adjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valve When the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

the clutch pressure.)

Accumulator control valve Adjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Pilot valve A Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for line pressure control, shift change control, and lock-up control.

Pilot valve B Adjusts the line pressure and produces the constant pressure (pilot pressure) required

for shift change control.

Low coast brake switching valve During engine braking, supplies the line pressure to the low coast brake reducing valve.

Low coast brake reducing valve When the low coast brake is coupled, adjusts the line pressure to the optimum pressure

(low coast brake pressure) and supplies it to the low coast brake.

N-R accumulator Produces the stabilizing pressure for when N-R is selected.

Direct clutch piston switching valve Operates in 4th ge ar and switches the direct clutch coupling capacity.

High and low reverse clutch control valve When the high and low reverse clutch is coupled, adjusts the line pressure to the opti-

mum pressure (high and low reverse clutch pressure) and supplies it to the high and low

reverse clutch. (In 1st, 3rd, 4th and 5th gears, adjusts the clutch pressure.)

Input clutch control valve When the input clutch is coupled, adjusts the line pressure to the optimum pressure (in-

put clutch pressure) and supplies it to the input clutch. (In 4th and 5th gears, adjusts the

clutch pressure.)

Direct clutch control valve When the direct clutch is coupled, adjusts the line pressure to the optimum pressure (di-

rect clutch pressure) and supplies it to the direct clutch. (In 2nd, 3rd, and 4th gears, ad-

justs the clutch pressure.)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 110 of 3924

A/T CONTROL SYSTEMAT-37

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

FUNCTION OF ATF PRESSURE SWITCH

TCC control valve

TCC control plug

TCC control sleeve Switches the lock-up to operating or released. Also, by performing the lock-up operation

transiently, lock-up smoothly.

Torque converter lubrication valve Operates during lock-up to switch the torque converter, cooling, and lubrication system

oil passage.

Cool bypass valve Allows excess oil to bypass cooler circuit without being fed into it.

Line pressure relief valve Discharges excess oil from line pressure circuit.

N-D accumulator Produces the stabilizing pressure for when N-D is selected.

Manual valve Sends line pressure to each circuit according to the select position. The circuits to which

the line pressure is not sent drain.

Name Function

Name Function

ATF pressure switch 2 (LC/B) Detects any malfunction in the low coast brake hydraulic pressure. When it detects any

malfunction, it puts the system into fail-safe mode.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 115 of 3924

AT-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

When there is an A/T first gear engine brake judgment malfunction, the low coast brake solenoid is switched

OFF to avoid the engine brake operation.

Line Pressure Solenoid

The solenoid is switched OFF and the line pressure is set to the maximum hydraulic pressure to make driving

possible.

Torque Converter Clutch Solenoid

The solenoid is switched OFF to release the lock-up.

Low Coast Brake Solenoid

When a malfunction (electrical or functional) occurs, in or der to make driving possible, if the solenoid is ON,

the transmission is held in 2nd gear; if the solenoid is OFF, the A/T is held in 4th gear. (Engine brake is not

applied in 1st and 2nd gear.)

Input Clutch Solenoid

If a malfunction (electrical or functi onal) occurs with the solenoid either ON or OFF, the A/T is held in 4th gear

to make driving possible.

Direct Clutch Solenoid

If a malfunction (electrical or functi onal) occurs with the solenoid either ON or OFF, the A/T is held in 4th gear

to make driving possible.

Front Brake Solenoid

If a malfunction (electrical or functi onal) occurs with the solenoid ON, in order to make driving possible, the A/

T is held in 5th gear; if the solenoid is OFF, 4th gear.

High and Low Reverse Clutch Solenoid

If a malfunction (electrical or functi onal) occurs with the solenoid either ON or OFF, the A/T is held in 4th gear

to make driving possible.

Turbine Revolution Sensor 1 or 2

The control is the same as if there were no turbi ne revolution sensors, 5th gear and manual mode are prohib-

ited.

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000001327150

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor , accelerator pedal position sensor (throttle position

sensor) or PNP switch and provides shift cont rol or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnos tic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose a error that occurs intermittently

rather than continuously. Most inte rmittent errors are caused by poor

electric connections or improper wiring. In this case, careful check-

ing of suspected circuits may help prevent the replacement of good

parts.

A visual check only may not find the cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the "WORK FLOW".

SAT631IB

SAT632I

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 118 of 3924

TROUBLE DIAGNOSISAT-45

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

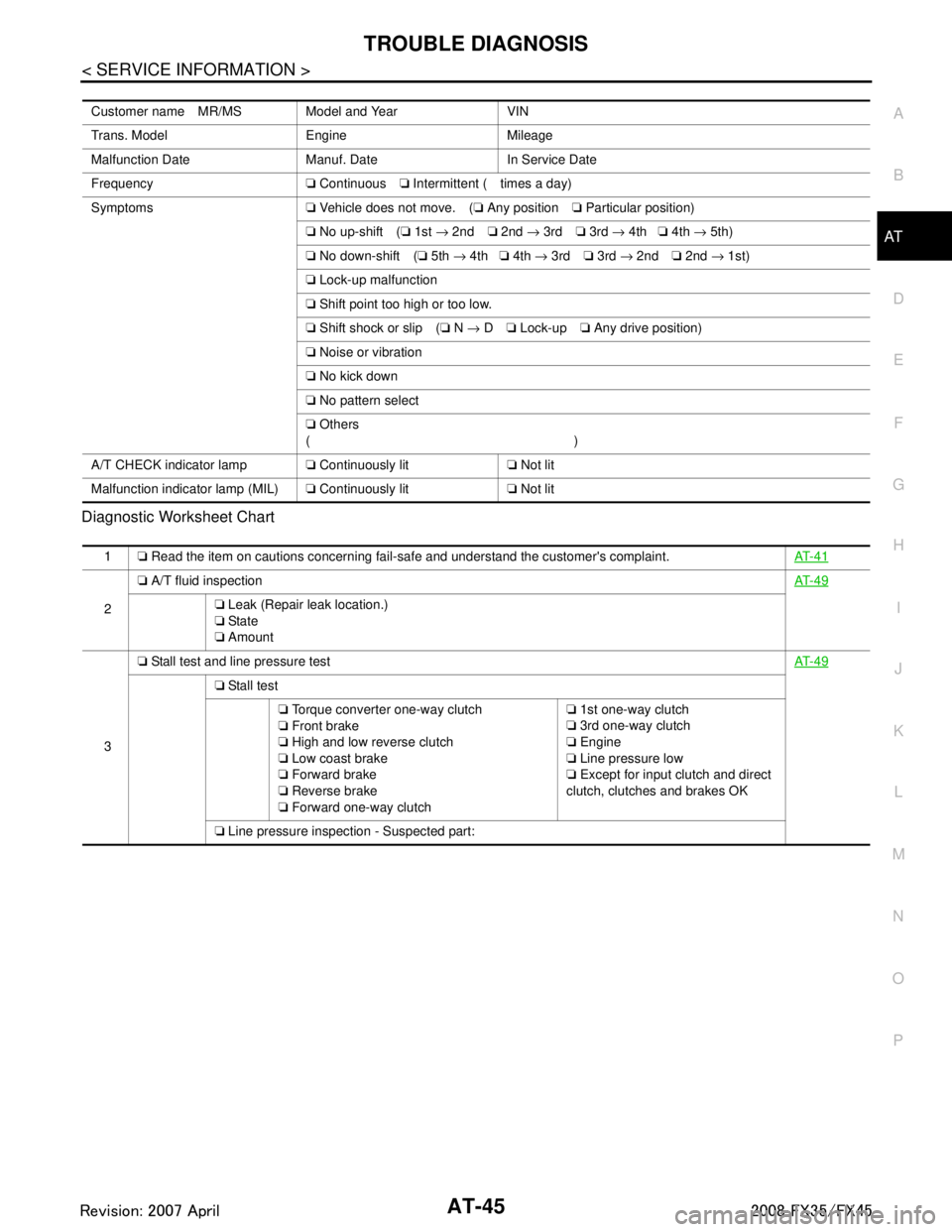

Diagnostic Worksheet Chart

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency

❏ Continuous ❏ Intermittent ( times a day)

Symptoms ❏ Vehicle does not move. ( ❏ Any position ❏ Particular position)

❏ No up-shift ( ❏ 1st → 2nd ❏ 2nd → 3rd ❏ 3rd → 4th ❏ 4th → 5th)

❏ No down-shift ( ❏ 5th → 4th ❏ 4th → 3rd ❏ 3rd → 2nd ❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip ( ❏ N → D ❏ Lock-up ❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

A/T CHECK indicator lamp ❏ Continuously lit ❏ Not lit

Malfunction indicator lamp (MIL) ❏ Continuously lit ❏ Not lit

1 ❏ Read the item on cautions concerning fail-safe and understand the customer's complaint. AT- 4 1

2❏

A/T fluid inspection AT- 4 9❏ Leak (Repair leak location.)

❏ State

❏ Amount

3 ❏

Stall test and line pressure test AT- 4 9

❏ Stall test

❏ Torque converter one-way clutch

❏ Front brake

❏ High and low reverse clutch

❏ Low coast brake

❏ Forward brake

❏ Reverse brake

❏ Forward one-way clutch ❏

1st one-way clutch

❏ 3rd one-way clutch

❏ Engine

❏ Line pressure low

❏ Except for input clutch and direct

clutch, clutches and brakes OK

❏ Line pressure inspection - Suspected part:

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 119 of 3924

AT-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

4❏

Perform all road tests and enter checks in required inspection items. AT- 4 9

4-1.Check before engine is started

AT- 5 3

❏ The A/T CHECK Indicator Lamp does come on. AT- 1 7 0.

❏ Perform self-diagnostics. Enter checks for detected items. AT- 8 4

, AT- 9 1.

❏ DTC U1000 CAN COMMUNICATION LINE AT- 9 4

.

❏ DTC P0615 START SIGNAL CIRCUIT AT- 9 7

.

❏ DTC P0700 TCM AT- 1 0 1

❏ DTC P0705 PARK/NEUTRAL POSITION SWITCH AT- 1 0 2.

❏ DTC P0717 TURBINE REVOLUTION SENSOR AT- 1 0 6

.

❏ DTC P0720 VEHICLE SPEED SENSO R A/T (REVOLUTION SENSOR) AT- 1 0 8

.

❏ DTC P0725 ENGINE SPEED SIGNAL AT- 11 2

.

❏ DTC P0731 A/T 1ST GEAR FUNCTION AT- 11 4

.

❏ DTC P0732 A/T 2ND GEAR FUNCTION AT- 11 6

.

❏ DTC P0733 A/T 3RD GEAR FUNCTION AT- 11 8

.

❏ DTC P0734 A/T 4TH GEAR FUNCTION AT- 1 2 0

.

❏ DTC P0735 A/T 5TH GEAR FUNCTION AT- 1 2 2

.

❏ DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE AT- 1 2 4

.

❏ DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) AT- 1 2 6

.

❏ DTC P0745 LINE PRESSURE SOLONOID VALVE AT- 1 2 8

.

❏ DTC P1705 THROTTLE POSITION SENSOR AT- 1 3 0

.

❏ DTC P1710 A/T FLUID TEMPERATURE SENSOR CIRCUIT AT- 1 3 2

.

❏ DTC P1721 VEHICLE SPEED SENSOR MTR AT- 1 3 7

.

❏ DTC P1730 A/T INTERLOCK AT- 1 3 9

.

❏ DTC P1731 A/T 1ST ENGINE BRAKING AT- 1 4 1

.

❏ DTC P1752 INPUT CLUTCH SOLENOID VALVE AT- 1 4 3

.

❏ DTC P1757 FRONT BRAKE SOLENOID VALVE AT- 1 4 5

.

❏ DTC P1762 DIRECT CLUTCH SOLENOID VALVE AT- 1 4 7

.

❏ DTC P1767 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE AT- 1 4 9

.

❏ DTC P1772 LOW COAST BRAKE SOLENOID VALVE AT- 1 5 1

.

❏ DTC P1774 LOW COAST BRAKE SOLENOID VALVE FUNCTION AT- 1 5 3

.

❏ DTC P1815 MANUAL MODE SWITCH AT- 1 5 5

.

4-2. Check at Idle

AT- 5 3

❏ AT- 1 7 0 , "Engine Cannot Be Started in "P" or "N" Position".

❏ AT- 1 7 1 , "

In "P" Position, Vehicle Moves When Pushed"

❏ AT- 1 7 2 , "In "N" Position, Vehicle Moves".

❏ AT- 1 7 3 , "

Large Shock ("N" to "D" Position)".

❏ AT- 1 7 5 , "

Vehicle Does Not Creep Backward in "R" Position".

❏ AT- 1 7 8 , "

Vehicle Does Not Creep Forward in "D" Position".

4-3. Cruise Test

AT- 5 3

Part 1

❏ AT- 1 8 0 , "

Vehicle Cannot Be Started from D1".

❏ AT- 1 8 2 , "

A/T Does Not Shift: D1→ D2".

❏ AT- 1 8 4 , "

A/T Does Not Shift: D2→ D3".

❏ AT- 1 8 6 , "

A/T Does Not Shift: D3→ D4".

❏ AT- 1 8 8 , "

A/T Does Not Shift: D4→ D5".

❏ AT- 1 9 0 , "

A/T Does Not Lock-up"

❏ AT- 1 9 2 , "A/T Does Not Hold Lock-up Condition".

❏ AT- 1 9 4 , "

Lock-up Is Not Released".

❏ AT- 1 9 4 , "

Engine Speed Does Not Return to Idle".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 120 of 3924

TROUBLE DIAGNOSISAT-47

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

44-3. Part 2

AT- 5 3

❏ AT- 1 8 0 , "Vehicle Cannot Be Started from D1".

❏ AT- 1 8 2 , "

A/T Does Not Shift: D1→ D2".

❏ AT- 1 8 4 , "

A/T Does Not Shift: D2→ D3".

❏ AT- 1 8 6 , "

A/T Does Not Shift: D3→ D4".

Part 3 AT- 5 3

❏ AT- 1 9 5 , "Cannot Be Changed to Manual Mode".

❏ AT- 1 9 6 , "

A/T Does Not Shift: 5th Gear → 4th Gear".

❏ AT- 1 9 7 , "

A/T Does Not Shift: 4th Gear → 3rd Gear".

❏ AT- 1 9 9 , "

A/T Does Not Shift: 3rd Gear → 2nd Gear".

❏ AT- 2 0 1 , "

A/T Does Not Shift: 2nd Gear → 1st Gear".

❏ AT- 2 0 2 , "

Vehicle Does Not Decelerate by Engine Brake".

❏ Perform self-diagnostics. Enter checks for detected items. AT- 8 4

, AT- 9 1.

❏ DTC U1000 CAN CO MMUNICATION LINE AT- 9 4

.

❏ DTC P0615 START SIGNAL CIRCUIT AT- 9 7

.

❏ DTC P0700 TCM AT- 1 0 1

❏ DTC P0705 PARK/NEUTRAL POSITION SWITCH AT- 1 0 2.

❏ DTC P0717 TURBINE REVOLUTION SENSOR AT- 1 0 6

.

❏ DTC P0720 VEHICLE SPEED SENS OR A/T (REVOLUTION SENSOR) AT- 1 0 8

.

❏ DTC P0725 ENGINE SPEED SIGNAL AT- 11 2

.

❏ DTC P0731 A/T 1ST GEAR FUNCTION AT- 11 4

.

❏ DTC P0732 A/T 2ND GEAR FUNCTION AT- 11 6

.

❏ DTC P0733 A/T 3RD GEAR FUNCTION AT- 11 8

.

❏ DTC P0734 A/T 4TH GEAR FUNCTION AT- 1 2 0

.

❏ DTC P0735 A/T 5TH GEAR FUNCTION AT- 1 2 2

.

❏ DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE AT- 1 2 4

.

❏ DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) AT-126

.

❏ DTC P0745 LINE PRESSURE SOLONOID VALVE AT- 1 2 8

.

❏ DTC P1705 THROTTLE POSITION SENSOR AT- 1 3 0

.

❏ DTC P1710 A/T FLUID TEMPERATURE SENSOR CIRCUIT AT- 1 3 2

.

❏ DTC P1721 VEHICLE SPEED SENSOR MTR AT- 1 3 7

.

❏ DTC P1730 A/T INTERLOCK AT- 1 3 9

.

❏ DTC P1731 A/T 1ST ENGINE BRAKING AT- 1 4 1

.

❏ DTC P1752 INPUT CLUTCH SOLENOID VALVE AT- 1 4 3

.

❏ DTC P1757 FRONT BRAKE SOLENOID VALVE AT- 1 4 5

.

❏ DTC P1762 DIRECT CLUTCH SOLENOID VALVE AT- 1 4 7

.

❏ DTC P1767 HIGH AND LOW REVERSE CLUTCH SOLENOID VALVE AT- 1 4 9

.

❏ DTC P1772 LOW COAST BRAKE SOLENOID VALVE AT- 1 5 1

.

❏ DTC P1774 LOW COAST BRAKE SOLENOID VALVE FUNCTION AT- 1 5 3

.

❏ DTC P1815 MANUAL MODE SWITCH AT-155

.

5 ❏ Inspect each system for items found to be NG in the self-diagnostics and repair or replace the malfunctioning parts.

6 ❏ Perform all road tests and enter the checks again for the required items. AT- 4 9

7❏

For any remaining NG items, perform the “diagnostics procedure” and repair or replace the malfunctioning

parts. See the chart for diagnostics by symptoms. (This chart also contains other symptoms and inspection pro-

cedures.) AT- 5 9

8

❏ Erase the results of the self-diagnostics from the TCM and the ECM. AT- 8 4,

AT-

91

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 124 of 3924

TROUBLE DIAGNOSISAT-51

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

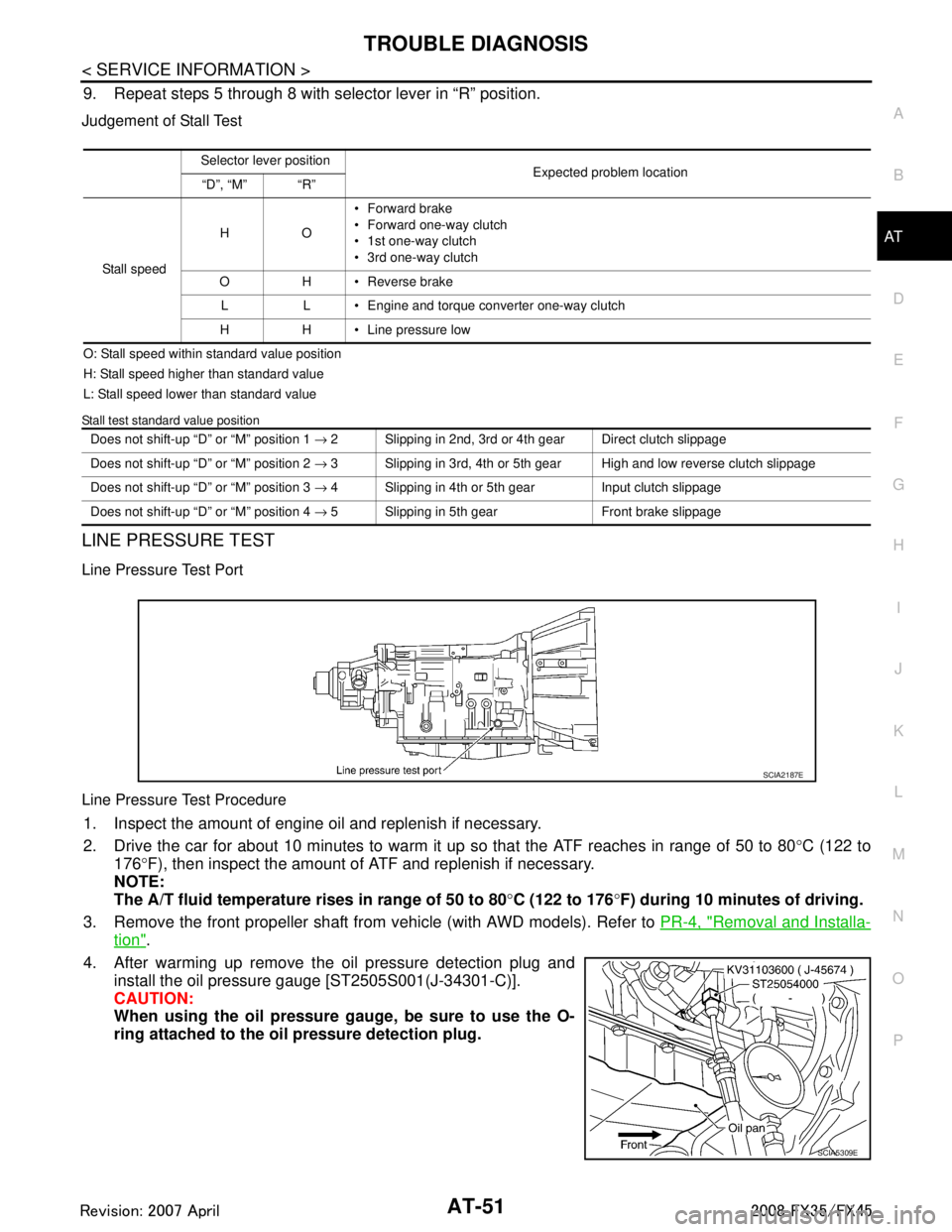

9. Repeat steps 5 through 8 with selector lever in “R” position.

Judgement of Stall Test

O: Stall speed within standard value position

H: Stall speed higher than standard value

L: Stall speed lower than standard value

Stall test standard value position

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the ATF reaches in range of 50 to 80°C (122 to

176 °F), then inspect the amount of ATF and replenish if necessary.

NOTE:

The A/T fluid temperature rises in range of 50 to 80°C (122 to 176 °F) during 10 minutes of driving.

3. Remove the front propeller shaft from vehicle (with AWD models). Refer to PR-4, "

Removal and Installa-

tion".

4. After warming up remove the oil pressure detection plug and install the oil pressure gauge [ST2505S001(J-34301-C)].

CAUTION:

When using the oil pressure ga uge, be sure to use the O-

ring attached to the oil pressure detection plug.

Selector lever position Expected problem location

“D”, “M” “R”

Stall speed HO

Forward brake

Forward one-way clutch

1st one-way clutch

3rd one-way clutch

O H Reverse brake L L Engine and torque converter one-way clutch

H H Line pressure low

Does not shift-up “D ” or “M” position 1 → 2 Slipping in 2nd, 3rd or 4th gear Direct clutch slippage

Does not shift-up “D ” or “M” position 2 → 3 Slipping in 3rd, 4th or 5th gear High and low reverse clutch slippage

Does not shift-up “D ” or “M” position 3 → 4 Slipping in 4th or 5th gear Input clutch slippage

Does not shift-up “D ” or “M” position 4 → 5 Slipping in 5th gear Front brake slippage

SCIA2187E

SCIA5309E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 125 of 3924

AT-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

5. Securely engage the parking brake so that the tires do not turn.

6. Start the engine, then measure the line pressure at both idle andthe stall speed.

CAUTION:

Keep the brake pedal pressed all the way down duringmeasurement.

When measuring the line pressure at the stall speed, refer to "STALL TEST".

7. After the measurements are complete, install the oil pressure detection plug and tighten to the specified torque.

CAUTION:

Do not reuse the O-ring.

Apply ATF to the O-ring.

Line Pressure

Judgement of Line Pressure Test

SCIA7463E

:7.3 N·m (0.74 kg-m, 65 in-lb)SAT493G

Engine speed Line pressure kPa (kg/cm

2, psi)

“R” position “D” and “M” positions

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Judgement Possible cause

Idle speed Low for all positions

(“P”, “R”, “N”, “D”,

“M”)

Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

Oil pump wear

Pressure regulator valve or plug sticking or spring fatigue

Oil strainer

⇒ oil pump ⇒ pressure regulator valve passage oil leak

Engine idle speed too low

Only low for a spe-

cific position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

High Possible causes include a sensor malfunction or malfunction in the line pressure adjustment func-

tion.

For example

Accelerator pedal position signal malfunction

ATF temperature sensor malfunction

Line pressure solenoid malfunction (sticking in OFF state, filter clog, cut line)

Pressure regulator valve or plug sticking

: