radio INFINITI FX35 2008 Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1065 of 3924

![INFINITI FX35 2008 Owners Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M INFINITI FX35 2008 Owners Manual

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 M](/img/42/57017/w960_57017-1064.png)

BRC-50

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SYMPTOMS

The ABS Function Does Not Operate

INFOID:0000000001327695

CAUTION:

The ABS does not operate when the sp eed is 10 km/h (6 MPH) or less.

1.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> CHECK WHEEL SENSOR. Refer to BRC-49, "Excessive ABS Function Operation Frequency".

NG >> Perform self-diagnosis. Refer to BRC-26, "

Self-Diagnosis".

Pedal Vibration or ABS Operation Sound OccursINFOID:0000000001327696

CAUTION:

Under the following conditions, when brake pedal is lightly depressed (just place a foot on it), ABS is

activated and vibration is felt. However, this is normal.

When shifting gears

When driving on slippery road

During cornering at high speed

When passing over bumps or grooves

When pulling away just after st arting engine [at approximately 10 km/h (6 MPH) or higher]

1.SYMPTOM CHECK 1

Check if pedal vibration or operati on sound occurs when engine is started.

OK or NG

OK >> Perform self-diagnosis. Refer to BRC-26, "Self-Diagnosis".

NG >> GO TO 2.

2.SYMPTOM CHECK 2

Check symptom when electrical component (headlamps, etc.) switches are operated.

Does the symptom occur when the electrical component (head lamp, etc.) switches are operated?

YES >> Check if there is a radio, antenna, antenna lead wi re, or wiring close to ABS actuator and electric

unit (control unit) (or its wiring), and if there is, move it farther away.

NO >> CHECK WHEEL SENSOR. Refer to BRC-49, "

Excessive ABS Function Operation Frequency".

Vehicle Jerks During VDC/TCS/ABS ControlINFOID:0000000001327697

1.CHECK ENGINE SPEED SIGNAL

Perform CONSULT-III “DATA MONITOR” to check engine speed.

Is engine speed at idle 400 rpm or higher?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> System is normal.

NG >> GO TO 3.

3.CHECK ECM SELF-DIAGNOSTIC RESULTS

Perform ECM self-diagnosis.

Are self-diagnosis items displayed?

YES >> Check the corresponding items. Refer to EC-89(VQ35DE), EC-666(VK45DE) in “Engine Control

(EC section)”.

NO >> GO TO 4.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1268 of 3924

![INFINITI FX35 2008 Owners Manual

EC-28

< SERVICE INFORMATION >[VQ35DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fue INFINITI FX35 2008 Owners Manual

EC-28

< SERVICE INFORMATION >[VQ35DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fue](/img/42/57017/w960_57017-1267.png)

EC-28

< SERVICE INFORMATION >[VQ35DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fuel hose clamps to the specified torque.

Do not depress accelerator pedal when starting.

Immediately after starting, do not rev up engine unnecessar-

ily.

Do not rev up engine just prior to shutdown.

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it m ay adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body.

SEC893C

PBIB1569E

SEF709Y

SEF708Y

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1846 of 3924

![INFINITI FX35 2008 Owners Manual

EC-606

< SERVICE INFORMATION >[VK45DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fu INFINITI FX35 2008 Owners Manual

EC-606

< SERVICE INFORMATION >[VK45DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fu](/img/42/57017/w960_57017-1845.png)

EC-606

< SERVICE INFORMATION >[VK45DE]

PRECAUTIONS

B1 indicates the bank 1, B2 indicates the bank 2 as shown in

the figure.

Do not operate fuel pump when there is no fuel in lines.

Tighten fuel hose clamps to the specified torque.

Do not depress accelerator pedal when starting.

Immediately after starting, do not rev up engine unnecessar-

ily.

Do not rev up engine just prior to shutdown.

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it m ay adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

radio can be kept smaller.

- Be sure to ground the radio to vehicle body.

PBIB1144E

PBIB1508E

SEF709Y

SEF708Y

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2865 of 3924

PRECAUTIONSGI-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Precaution for Procedur e without Cowl Top CoverINFOID:0000000001612933

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionINFOID:0000000001325654

Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any flammable

materials. Special care should be taken when handling any flam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or tran- saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

Before starting repairs which do not require battery power: Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of radio and each control unit is erased.

Battery posts, terminals and related accessories contain lead and

lead compounds. Wash hands after handling.

PIIB3706J

SGI285

SGI231

SEF289H

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2887 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-25

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

How to Perform Efficient Diagnos is for an Electrical IncidentINFOID:0000000001325672

WORK FLOW

INCIDENT SIMULATION TESTS

Introduction

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the c onditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

Vehicle vibration

Heat sensitive

Freezing

Water intrusion

Electrical load

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3 Get the proper diagnosis materials together including:

Power Supply Routing

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2889 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

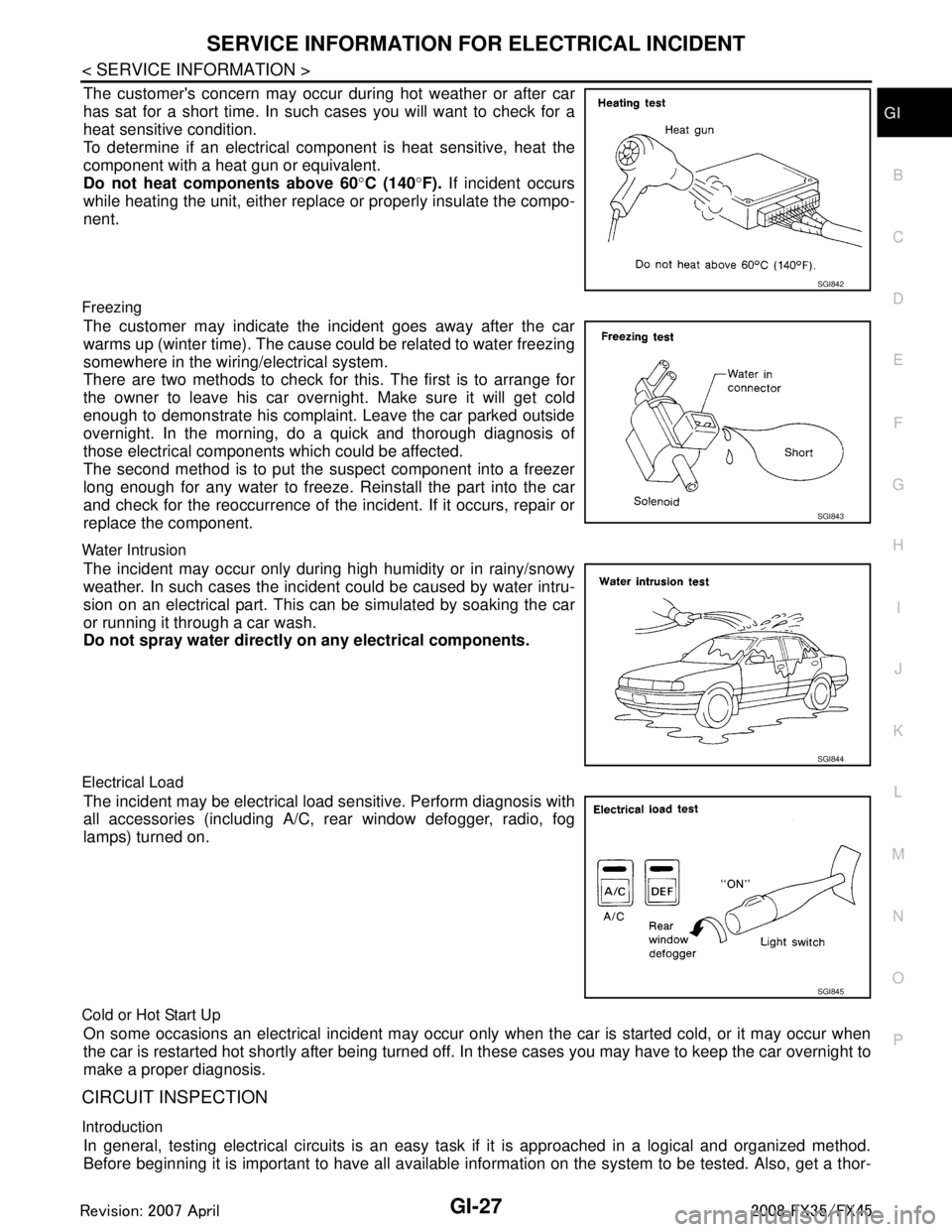

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical com ponent is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60 °C (140 °F). If incident occurs

while heating the unit, either replac e or properly insulate the compo-

nent.

Freezing

The customer may indicate the incident goes away after the car

warms up (winter time). The cause could be related to water freezing

somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for

the owner to leave his car overnight. Make sure it will get cold

enough to demonstrate his complaint. Leave the car parked outside

overnight. In the morning, do a quick and thorough diagnosis of

those electrical components which could be affected.

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

Water Intrusion

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This c an be simulated by soaking the car

or running it through a car wash.

Do not spray water directly on any electrical components.

Electrical Load

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

Cold or Hot Start Up

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

CIRCUIT INSPECTION

Introduction

In general, testing electrical circuits is an easy ta sk if it is approached in a logical and organized method.

Before beginning it is important to have all available in formation on the system to be tested. Also, get a thor-

SGI842

SGI843

SGI844

SGI845

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 3850 of 3924

WT-10

< SERVICE INFORMATION >

TIRE PRESSURE MONITORING SYSTEM

TIRE PRESSURE MONITORING SYSTEM

System ComponentINFOID:0000000001327576

System DescriptionINFOID:0000000001327577

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

REMOTE KEYLESS ENTRY RECEIVER

The remote keyless entry receiver receives the air pressure signal

transmitted by the transmitter in each wheel.

BCM (BODY CONTROL MODULE)

SEIA0599E

SEIA0521E

SEIA0431E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C