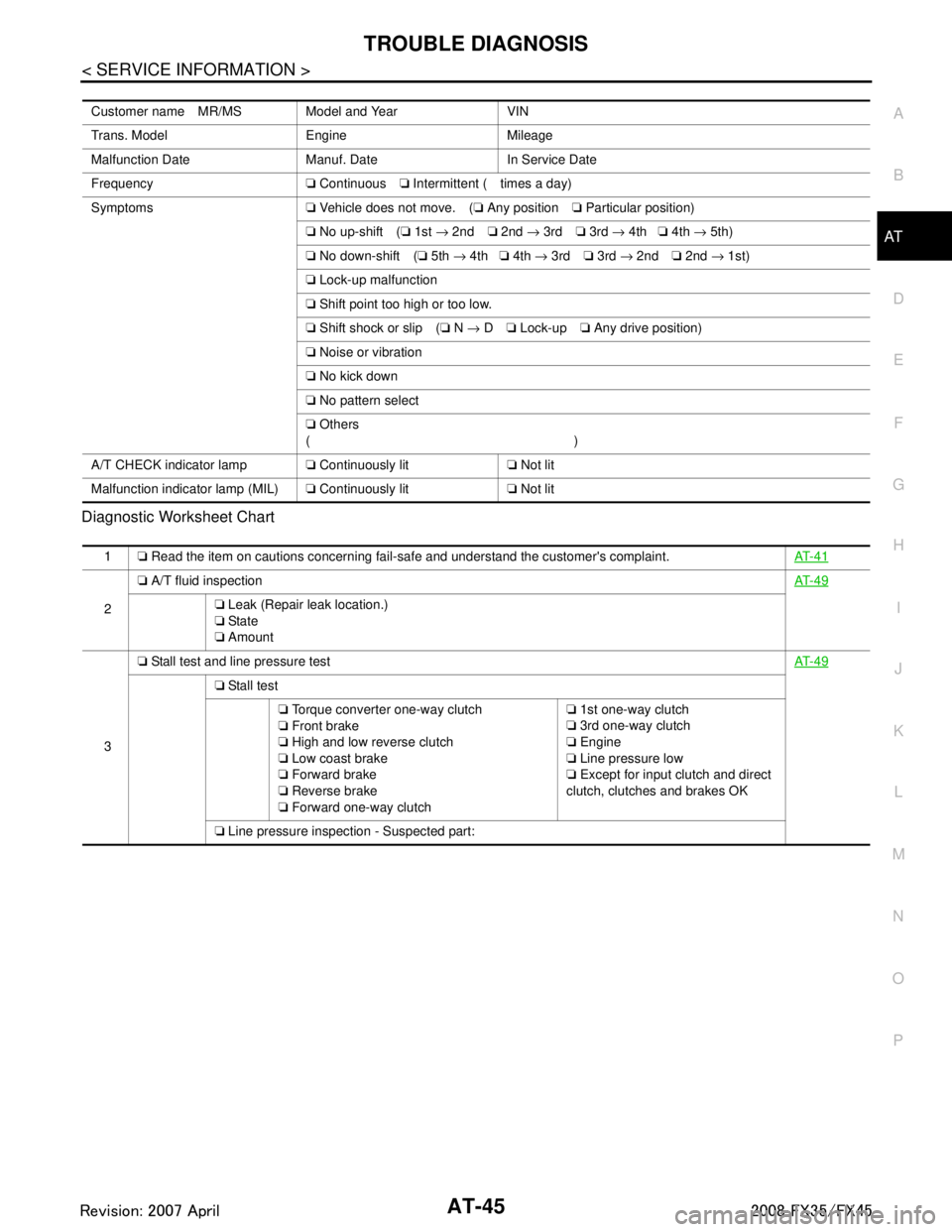

brakes INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1 of 3924

ABCDEFGHIJKLQUICK REFERENCE INDEX AGENERAL INFORMATIONGIGeneral InformationBENGINEEMEngine MechanicalLUEngine Lubrication SystemCOEngine Cooling SystemECEngine Control SystemFLFuel SystemEXExhaust SystemACCAccelerator Control SystemCTRANSMISSION/

TRANSAXLEATAutomatic TransmissionDDRIVELINE/AXLETFTransferPRPropeller ShaftFFDFront Final DriveRFDRear Final DriveFAXFront AxleRAXRear AxleESUSPENSIONFSUFront SuspensionRSURear SuspensionWTRoad Wheels & TiresFBRAKESBRBrake SystemPBParking Brake SystemBRCBrake Control SystemGSTEERINGPSPower Steering SystemHRESTRAINTSSBSeat BeltsSRSSupplemental Restraint System

(SRS)IBODYBLBody, Lock & Security SystemGWGlasses, Window System & Mir-

rorsRFRoofEIExterior & InteriorIPInstrument PanelSESeatJAIR CONDITIONERATCAutomatic Air ConditionerKELECTRICALSCStarting & Charging SystemLTLighting SystemDIDriver Information SystemWWWiper, Washer & HornBCSBody Control SystemLANLAN SystemAVAudio Visual, Navigation & Tele-

phone SystemACSAuto Cruise Control SystemPGPower Supply, Ground & Circuit Ele-

mentsLMAINTENANCEMAMaintenanceEdition: April 2007

Revision: April 2007

Page 14 of 3924

![INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a sele INFINITI FX35 2008 Service Manual

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a sele](/img/42/57017/w960_57017-13.png)

DESCRIPTIONACS-7

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

DESCRIPTION

OutlineINFOID:0000000001328805

The Intelligent Cruise Control (ICC) system automatically maintains a selected distance from the vehicle

ahead according to that vehicle's speed, or at the set speed, if the road ahead is clear.

The ICC function has two cruise control modes and brake assist (with preview function).

VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

With vehicle-to-vehicle distance control mode, the driver can maintain the same speed as other vehicles with-

out the constant need to adjust the set speed as the driver would with a normal cruise control system.

The system is intended to enhance the operation of the vehicle when following the vehicle traveling in the

same lane and direction.

If the distance sensor detects a sl ower moving vehicle ahead, the system wil l reduce speed so that the vehicle

ahead can be followed at the selected distance.

The system automatically controls the throttle and applie s the brakes (up to 25% of vehicle braking power) if

necessary.

The detection range of the sensor is approximately 120 m (390 ft) ahead.

Refer to Owner's Manual for Intelligent Cruise Control System operating instructions.

CONVENTIONAL (FIXED SPEED) CRUISE CONTROL MODE

Conventional (fixed speed) cruise contro l mode is cruising at preset speeds.

Refer to Owner's Manual for Intelligent Cruise Control System operating instructions.

BRAKE ASSIST (WITH PREVIEW FUNCTION)

When the force applied to brake pedal exceeds a certain level, the Brake Assist is activated and generates a

greater braking force than that of a convent ional brake booster even with light pedal force.

When the Preview Function identifies the need to apply the sudden brake by sensing the vehicle ahead in the

same lane and the distance and relative speed from it, it applies the brake pre-pressure before driver depress

the brake pedal and improves brake re sponse by reducing its free play.

Refer to Owner's Manual for BRAKE ASSIST (W ITH PREVIEW FUNCTION) operating instructions.

Functional DiagramINFOID:0000000001328806

Items of input/output signal to be checked with CONSULT-III

PKIC8700E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 34 of 3924

![INFINITI FX35 2008 Service Manual

TERMINALS AND REFERENCE VALUEACS-27

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000001328820

Te r INFINITI FX35 2008 Service Manual

TERMINALS AND REFERENCE VALUEACS-27

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000001328820

Te r](/img/42/57017/w960_57017-33.png)

TERMINALS AND REFERENCE VALUEACS-27

< SERVICE INFORMATION > [ICC]

C

D

E

F

G H

I

J

L

M A

B

ACS

N

O P

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000001328820

Te r m i n a l s

(Wire color) Item Condition

Voltage (V)

+– Ignition

switch Operation

1 (R/W)

2 (R/W)

GroundBattery power supply OFF — Battery voltage

5 (P) CAN-L — — —

6 (GY/L) Release switch power supply ON — Approx. 10

7 (GY/R) NEUT-SW ON Selector lever in “N” or “P” posi-

tions

Approx. 12

Selector lever in other positions Approx. 0

8 (G) 24 (R) Brake pressure sensor power

supply ON — Approx. 5

10 (B/R)

GroundBrake booster solenoid

(+) side

ON — Approx. 12

12 (L/W) Brake booster solenoid

(–) side ONSolenoid operating

Solenoid not operating Approx. 12

14 (L) CAN-H — — —

15 (LG/B) Brake release switch

(normal closed)

ONDepress the brake pedal Approx. 0

Release the brake pedal Approx. 10

17 (BR) 24 (R) Brake pressure sensor signal ON Release the brake pedal Approx. 0.5

Depress the brake pedal

Approx. 0.5 - 3

(Note) Voltage becomes higher

depending on effectiveness of depressing brakes.

PKIA9673E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 118 of 3924

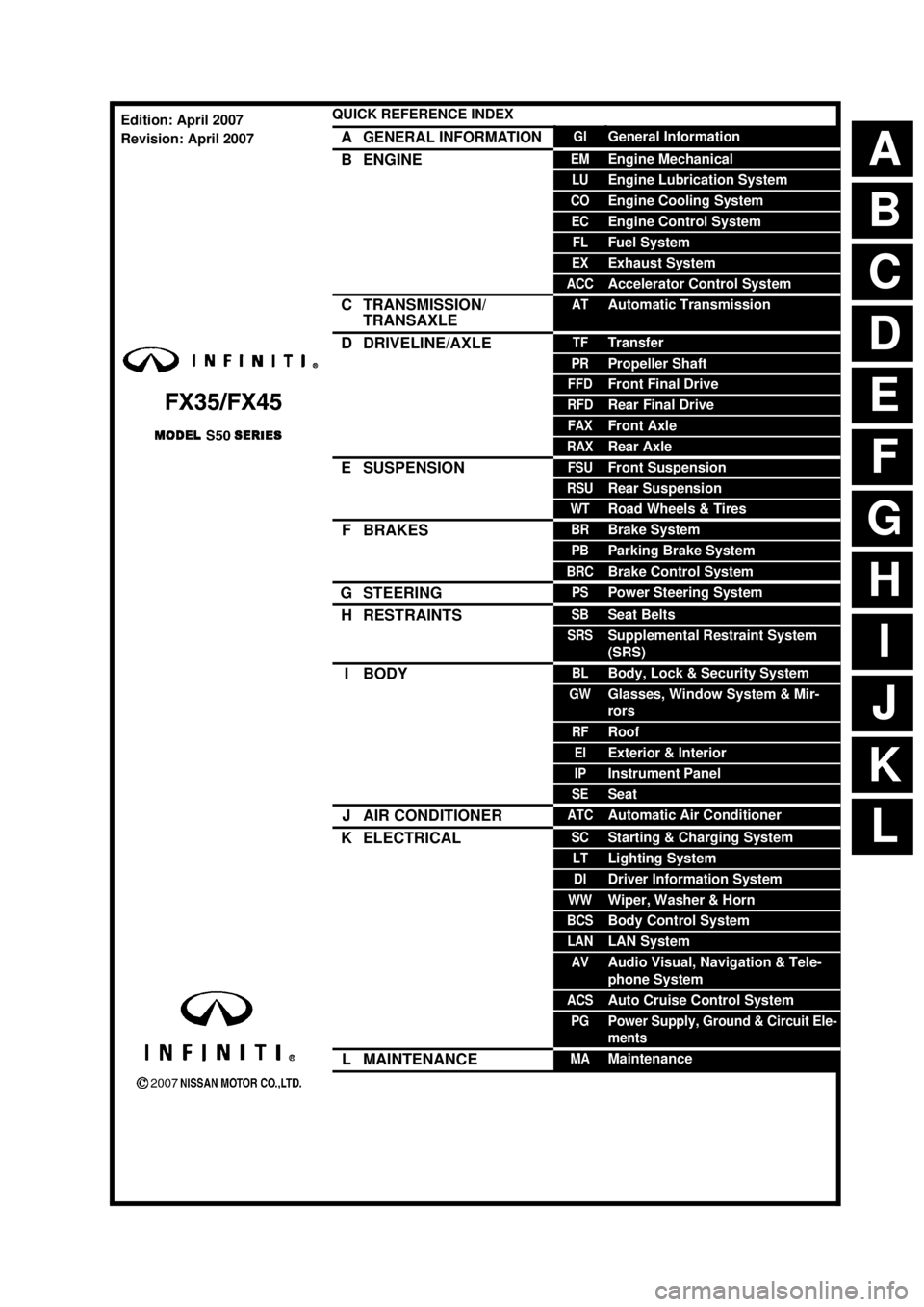

TROUBLE DIAGNOSISAT-45

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

Diagnostic Worksheet Chart

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency

❏ Continuous ❏ Intermittent ( times a day)

Symptoms ❏ Vehicle does not move. ( ❏ Any position ❏ Particular position)

❏ No up-shift ( ❏ 1st → 2nd ❏ 2nd → 3rd ❏ 3rd → 4th ❏ 4th → 5th)

❏ No down-shift ( ❏ 5th → 4th ❏ 4th → 3rd ❏ 3rd → 2nd ❏ 2nd → 1st)

❏ Lock-up malfunction

❏ Shift point too high or too low.

❏ Shift shock or slip ( ❏ N → D ❏ Lock-up ❏ Any drive position)

❏ Noise or vibration

❏ No kick down

❏ No pattern select

❏ Others

()

A/T CHECK indicator lamp ❏ Continuously lit ❏ Not lit

Malfunction indicator lamp (MIL) ❏ Continuously lit ❏ Not lit

1 ❏ Read the item on cautions concerning fail-safe and understand the customer's complaint. AT- 4 1

2❏

A/T fluid inspection AT- 4 9❏ Leak (Repair leak location.)

❏ State

❏ Amount

3 ❏

Stall test and line pressure test AT- 4 9

❏ Stall test

❏ Torque converter one-way clutch

❏ Front brake

❏ High and low reverse clutch

❏ Low coast brake

❏ Forward brake

❏ Reverse brake

❏ Forward one-way clutch ❏

1st one-way clutch

❏ 3rd one-way clutch

❏ Engine

❏ Line pressure low

❏ Except for input clutch and direct

clutch, clutches and brakes OK

❏ Line pressure inspection - Suspected part:

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 985 of 3924

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution for Procedure without Cowl Top Cover ......2

Precaution for Brake System ....................................2

PREPARATION ...................................................3

Commercial Service Tool .................................... ......3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ................................ ......4

BRAKE PEDAL .............................................. .....5

Inspection and Adjustment .................................. ......5

Component ................................................................6

Removal and Installation ...........................................6

BRAKE FLUID .....................................................8

On-Board Inspection ........................................... ......8

Drain and Refill ..........................................................8

Bleeding Brake System .............................................8

BRAKE TUBE AND HOSE ................................10

Hydraulic Circuit .................................................. ....10

Removal and Installation of Front Brake Tube and

Brake Hose .............................................................

10

Removal and Installation of Rear Brake Piping

and Brake Hose ......................................................

11

Inspection After Installation .....................................11

BRAKE MASTER CYLINDER ........................ ....12

On-Board Inspection ........................................... ....12

Component ..............................................................12

Removal and Installation .........................................12

Disassembly and Assembly ....................................13

BRAKE BOOSTER ...........................................14

On-Vehicle Service .............................................. ....14

Component ..............................................................14

Removal and Installation .........................................14

VACUUM LINES ...............................................16

Component ..............................................................16

Removal and Installation .........................................16

Inspection ................................................................16

FRONT DISC BRAKE .......................................18

On-Vehicle Inspection ......................................... ....18

Component ..............................................................18

Removal and Installation of Brake Pad ...................19

Removal and Installation of Brake Caliper Assem-

bly ........................................................................ ....

19

Disassembly and Assembly of Brake Caliper As-

sembly .....................................................................

20

Brake Burnishing Procedure ....................................23

REAR DISC BRAKE .........................................24

On-Vehicle Inspection ......................................... ....24

Component ..............................................................24

Removal and Installation of Brake Pad ...................25

Removal and Installation of Brake Caliper Assem-

bly ........................................................................ ....

25

Disassembly and Assembly of Brake Caliper As-

sembly .....................................................................

26

Brake Burnishing Procedure ....................................29

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

30

General Specification ..............................................30

Brake Pedal .............................................................30

Brake Booster ..........................................................30

Check Valve ............................................................30

Front Disc Brake ......................................................30

Rear Disc Brake ......................................................30

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1016 of 3924

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

SERVICE INFORMATION .. ..........................

3

DTC INDEX ..................................................... .....3

C1101-C1116 ...................................................... ......3

C1120-C1136 ............................................................3

C1140-C1170 ............................................................3

U1000 ........................................................................4

PRECAUTIONS ...................................................5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

Precaution for Brake System ....................................5

Precaution for Brake Control .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................7

ON-VEHICLE SERVICE ......................................8

Adjustment of Steering Angle Sensor Neutral Po-

sition .................................................................... ......

8

Calibration of Decel G Sensor (AWD Models) ..........8

SYSTEM DESCRIPTION ................................ ....10

Schematic ........................................................... ....10

Functions .................................................................10

Fail-Safe Function ...................................................11

Hydraulic Circuit Diagram .......................................12

CAN Communication ...............................................12

TROUBLE DIAGNOSIS .....................................13

Fail-Safe Function ............................................... ....13

How to Proceed with Diagnosis ..............................13

Component Part Location .......................................16

Schematic ...............................................................17

Wiring Diagram - VDC - ..........................................18

Control Unit Input/Output Signal Standard ..............23

CONSULT-III Functions (ABS) ................................26

Self-Diagnosis ..................................................... ....26

Data Monitor ........................................................ ....28

Active Test ...............................................................30

For Fast and Accurate Diagnosis ............................31

Basic Inspection ......................................................32

TROUBLE DIAGNOSIS FOR SYSTEM ............34

DTC C1101 RR RH SENSOR-1 ..............................34

DTC C1102 RR LH SENSOR-1 ..............................35

DTC C1103 FR RH SENSOR-1 ..............................35

DTC C1104 FR LH SENSOR-1 ...............................35

DTC C1105 RR RH SENSOR-2 ..............................36

DTC C1106 RR LH SENSOR-2 ..............................36

DTC C1107 FR RH SENSOR-2 ..............................36

DTC C1108 FR LH SENSOR-2 ...............................36

DTC C1109 BATTERY VOLTAGE [ABNORMAL] ....36

DTC C1110 CONTROLLER FAILURE ....................37

DTC C1111 PUMP MOTOR ....................................37

DTC C1113 G-SENSOR .........................................38

DTC C1115 ABS SENSOR [ABNORMAL SIG-

NAL] .........................................................................

39

DTC C1116 STOP LAMP SW .................................39

DTC C1120 FR LH IN ABS SOL .............................40

DTC C1121 FR LH OUT ABS SOL .........................41

DTC C1122 FR RH IN ABS SOL ......................... ....41

DTC C1123 FR RH OUT ABS SOL .........................42

DTC C1124 RR LH IN ABS SOL .............................42

DTC C1125 RR LH OUT ABS SOL ..................... ....42

DTC C1126 RR RH IN ABS SOL ............................42

DTC C1127 RR RH OUT ABS SOL ........................42

DTC C1130 ENGINE SIGNAL 1 .......................... ....42

DTC C1131 ENGINE SIGNAL 2 ..............................42

DTC C1132 ENGINE SIGNAL 3 ..............................42

DTC C1133 ENGINE SIGNAL 4 ..............................42

DTC C1136 ENGINE SIGNAL 6 ..............................42

DTC C1140 ACTUATOR RLY .................................43

DTC C1142 PRESS SEN CIRCUIT ........................43

DTC C1143 ST ANG SEN CIRCUIT ................... ....44

DTC C1144 ST ANG SEN SIGNAL .........................45

DTC C1145 YAW RATE SENSOR ..........................46

DTC C1146 SIDE G-SEN CIRCUIT ........................46

DTC C1155 BR FLUID LEVEL LOW .......................46

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1021 of 3924

![INFINITI FX35 2008 Service Manual

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on INFINITI FX35 2008 Service Manual

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on](/img/42/57017/w960_57017-1020.png)

BRC-6

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

If the following components are replaced with non-genui

ne components or converted, VDC OFF indicator

lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorber, strut, spring, bushing, etc.), Tires, wheels (exclude specified size),

components related to brake (pad, rotor, caliper, etc. ), components related to engine (muffler, ECM, etc.),

components related to body reinforcement (roll bar, tower bar, etc.).

Driving in the condition of breakage or excessive wear of suspension, tires or components related to the

brakes may cause VDC OFF indicator lamp and SLIP indicator lamp turn on, and the VDC system may not

operate properly.

When the TCS or VDC is activated by sudden accele ration or sudden turn, some noise may occur. The

noise is a result of the normal operation of the TCS and VDC.

When driving on roads which have extreme slopes (s uch as mountainous roads) or high banks (such as

sharp carves on a freeway), the VDC may not operate nor mally, or VDC OFF indicator lamp and SLIP indi-

cator lamp may turn on. However, this is not a malfunction, if normal operation can be resumed after restart-

ing engine.

Sudden turns (such as spin turns, acceleration turns) , drifting, etc. When VDC function is OFF (VDC OFF

SW ON) may cause the G sensor system indicate a malf unction. However, this is not a malfunction, if nor-

mal operation can be resumed after restarting engine.

Change 4 tires at a time. Be sure to use specified- size tires that have the same brand name and pattern.

Wheel sensor errors can be detected be self-diagnosis when tires have wide abrasion variations or the size

is different from the genuine tires.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1047 of 3924

![INFINITI FX35 2008 Service Manual

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir INFINITI FX35 2008 Service Manual

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir](/img/42/57017/w960_57017-1046.png)

BRC-32

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000001327676

BRAKE FLUID AMOUNT, LEAKS, AND BRAKE PADS INSPECTION

1. Check fluid level in the brake reservoir tank. If fluid level is low, refill brake fluid.

2. Check brake piping and around ABS actuator and electric uni t (control unit) for leaks. If there is leaking or

oozing fluid, check the following items.

If ABS actuator and electric unit (control unit) connec tion is loose, tighten piping to the specified torque

and re-perform the leak inspection to make sure there are no leaks.

If there is damage to the connection flare nut or AB S actuator and electric unit (control unit) screw,

replace the damaged part and re-perform the leak inspection to make sure there are no leaks.

When there is fluid leaking or oozing from a part other than ABS actuator and electric unit (control unit)

connection, if fluid is just oozing out, use a clean cl oth to wipe off the oozing fluid and re-check for leaks.

If fluid is still oozing out, replace the damaged part.

When there is fluid leaking or oozing at ABS actuator and electric unit (control unit), if fluid is just oozing

out, use a clean cloth to wipe off oozing fluid and re-che ck for leaks. If fluid is still oozing out, replace

ABS actuator and electric unit (control unit) body.

CAUTION:

ABS actuator and electric unit (contr ol unit) body can not be disassembled.

3. Check brake pad degree of wear. Refer to BR-18, "

On-Vehicle Inspection" in “Front Disc Brake” and BR-

24, "On-Vehicle Inspection" in “Rear Disc Brake”

POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

Make sure battery positive cable, negative cabl e and ground connection are not loose. If looseness is

detected, tighten the cables. In additi on, check the battery voltage to make sure it has not dropped and alter-

nator is normal.

ABS WARNING LAMP, VDC OFF INDICATOR LAMP, SLIP INDICATOR LAMP AND BRAKE WARN-

ING LAMP INSPECTION

Symptom Symptom description Result

Motor operation noise This is noise of motor in

side ABS actuator and electr ic unit (control unit).

Slight noise may occur during VDC, TCS, and ABS operation.

Normal

When the vehicle speed goes over 20 km/h (12.5 MPH), motor and valves

operating noise may be heard. It happens only once after ignition switch is

ON. This is a normal status of the system operation check.

System operation check noise When engine starts, slight “click” noise may be heard from engine room.

This is normal and is part of system operation check. Normal

VDC/TCS operation

(SLIP indicator lamp blinking) TCS may activate momentarily if wheel speed changes when driving over

location where friction coefficient varies, when up/downshifting, or when ful-

ly depressing accelerator pedal.

Normal

Cancel the VDC/TCS

function for the inspec-

tion on a chassis dyna-

mometer.

For inspection of speedometer or other instruments, press VDC OFF switch

to turn VDC/TCS function off.

When accelerator pedal is depressed on a chassis dynamometer (fixed

front-wheel type), vehicle speed will not increase. This is not normal. It is re-

sult of TCS being activated by stationary front wheels. Warning lamp may

also illuminate to indicate “sensor system error”. This is also normal, and is

the result of the stationary front wheels being detected. To be certain, restart

engine, and drive vehicle at 30 km/h (19 MPH) or more. Make sure warning

lamp does not illuminate.

ABS operation

(Longer stopping distance) On roads with low friction coefficients, such as snowy roads or gravel roads,

vehicles with ABS may require a longer stopping distance. Therefore, when

driving on such roads, avoid overconfidence and keep speed sufficiently

low.

Normal

Insufficient feeling of accelera-

tion Depending on road conditions, driver may feel that feeling of acceleration is

insufficient. This is because traction control, which controls engine and

brakes to achieve optimal traction, has the highest priority (for safety). As a

result, there may be times when acceleration is slightly less than usual for

the same accelerator pedal operation.

Normal

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1064 of 3924

![INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SYMPTOMSBRC-49

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS FOR SYMPTOMS

Excessive ABS Function Operation FrequencyINFOID:000000000 INFINITI FX35 2008 Service Manual

TROUBLE DIAGNOSIS FOR SYMPTOMSBRC-49

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS FOR SYMPTOMS

Excessive ABS Function Operation FrequencyINFOID:000000000](/img/42/57017/w960_57017-1063.png)

TROUBLE DIAGNOSIS FOR SYMPTOMSBRC-49

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TROUBLE DIAGNOSIS FOR SYMPTOMS

Excessive ABS Function Operation FrequencyINFOID:0000000001327692

1.CHECK FRONT AND REAR AXLE

Make sure there is no excessive looseness in the front and rear axles.

OK or NG

OK >> GO TO 2.

NG >> Check front or rear axle system.

2.CHECK WHEEL SENSOR

Perform following inspection for wheel sensor:

Sensor mount and damage inspection

Sensor rotor mount and damage inspection

Sensor connector connection inspection

Sensor harness inspection

OK or NG

OK >> GO TO 3.

NG >> Replace sensor or sensor rotor.

3.CHECK ABS WARNING LAMP DISPLAY

Make sure warning lamp turns off approximately 2 seconds after the ignition switch is turned ON or when driv-

ing.

OK or NG

OK >> Normal

NG >> Perform self-diagnosis. Refer to BRC-26, "

Self-Diagnosis".

Unexpected Pedal ReactionINFOID:0000000001327693

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke.

Is the stroke too long?

YES >> Bleed air from brake piping. Check brake pedal, brake booster, and master cylinder mount for play, looseness, and brakesystem for fluid leaks, etc. If any malfunctions are found, make repair.

NO >> GO TO 2.

2.CHECK FUNCTION

Disconnect ABS actuator and electric unit (control unit) c onnector E56 and make sure that braking force is suf-

ficient when ABS in not operating. After the inspection, reconnect connector.

OK or NG

OK >> CHECK WHEEL SENSOR. Refer to BRC-49, "Excessive ABS Function Operation Frequency".

NG >> Check brake system.

The Braking Distance Is LongINFOID:0000000001327694

CAUTION:

On slippery road surfaces, the st opping distance might be longer wi th the ABS operating than when

the ABS is not operating.

1.CHECK FUNCTION

Disconnect ABS actuator and electric unit (control unit) connector E56 to deactivate ABS. In this condition,

check stopping distance. After inspection, connect connector.

OK or NG

OK >> Bleed air from brake piping. Check brake system.

NG >> CHECK WHEEL SENSOR. Refer to BRC-49, "

Excessive ABS Function Operation Frequency".

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1079 of 3924

![INFINITI FX35 2008 Service Manual

CO-8

< SERVICE INFORMATION >[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear f INFINITI FX35 2008 Service Manual

CO-8

< SERVICE INFORMATION >[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear f](/img/42/57017/w960_57017-1078.png)

CO-8

< SERVICE INFORMATION >[VQ35DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— Overload on engine

Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain sy stem malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper —

—

Blocked radiator grille

Installed car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser Blocked air flow

Installed large fog lamp

Symptom Check items

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C