timing belt INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2 of 3924

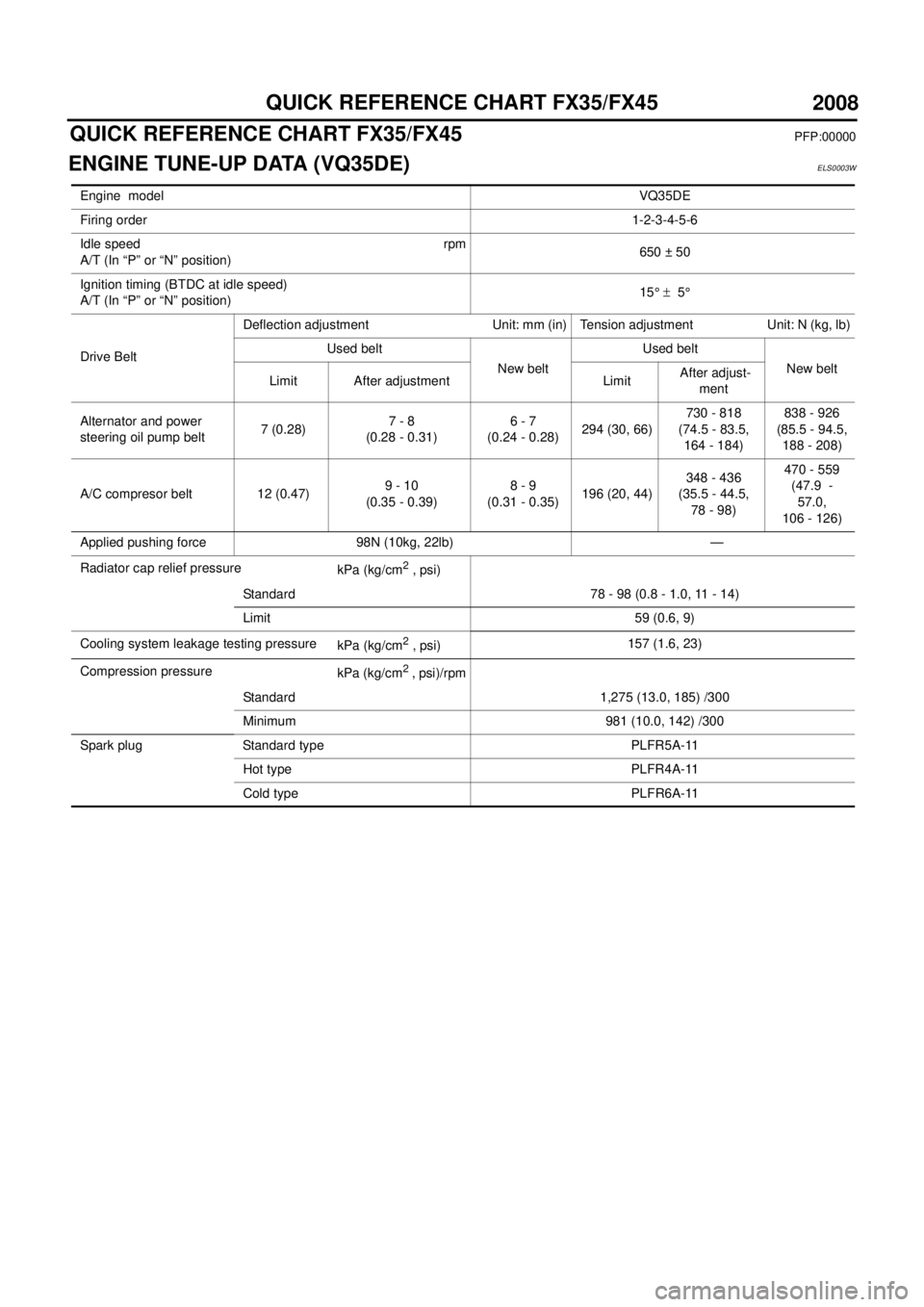

QUICK REFERENCE CHART FX35/FX45

QUICK REFERENCE CHART FX35/FX45PFP:00000

ENGINE TUNE-UP DATA (VQ35DE)ELS0003W

Engine modelVQ35DE

Firing order1-2-3-4-5-6

Idle speed

A/T (In “P” or “N” position)rpm

650 ± 50

Ignition timing (BTDC at idle speed)

A/T (In “P” or “N” position)15° ± 5°

Drive BeltDeflection adjustment Unit: mm (in) Tension adjustment Unit: N (kg, lb)

Used belt

New beltUsed belt

New belt

Limit After adjustment Limit After adjust-

ment

Alternator and power

steering oil pump belt7 (0.28)7 - 8

(0.28 - 0.31)6 - 7

(0.24 - 0.28)294 (30, 66)730 - 818

(74.5 - 83.5,

164 - 184)838 - 926

(85.5 - 94.5,

188 - 208)

A/C compresor belt 12 (0.47)9 - 10

(0.35 - 0.39)8 - 9

(0.31 - 0.35)196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 -

5 7 . 0 ,

106 - 126)

Applied pushing force 98N (10kg, 22lb) —

Radiator cap relief pressure

kPa (kg/cm

2 , psi)

Standard 78 - 98 (0.8 - 1.0, 11 - 14)

Limit 59 (0.6, 9)

Cooling system leakage testing pressure

kPa (kg/cm

2 , psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2 , psi)/rpm

Standard 1,275 (13.0, 185) /300

Minimum 981 (10.0, 142) /300

Spark plug Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

2008

Page 3 of 3924

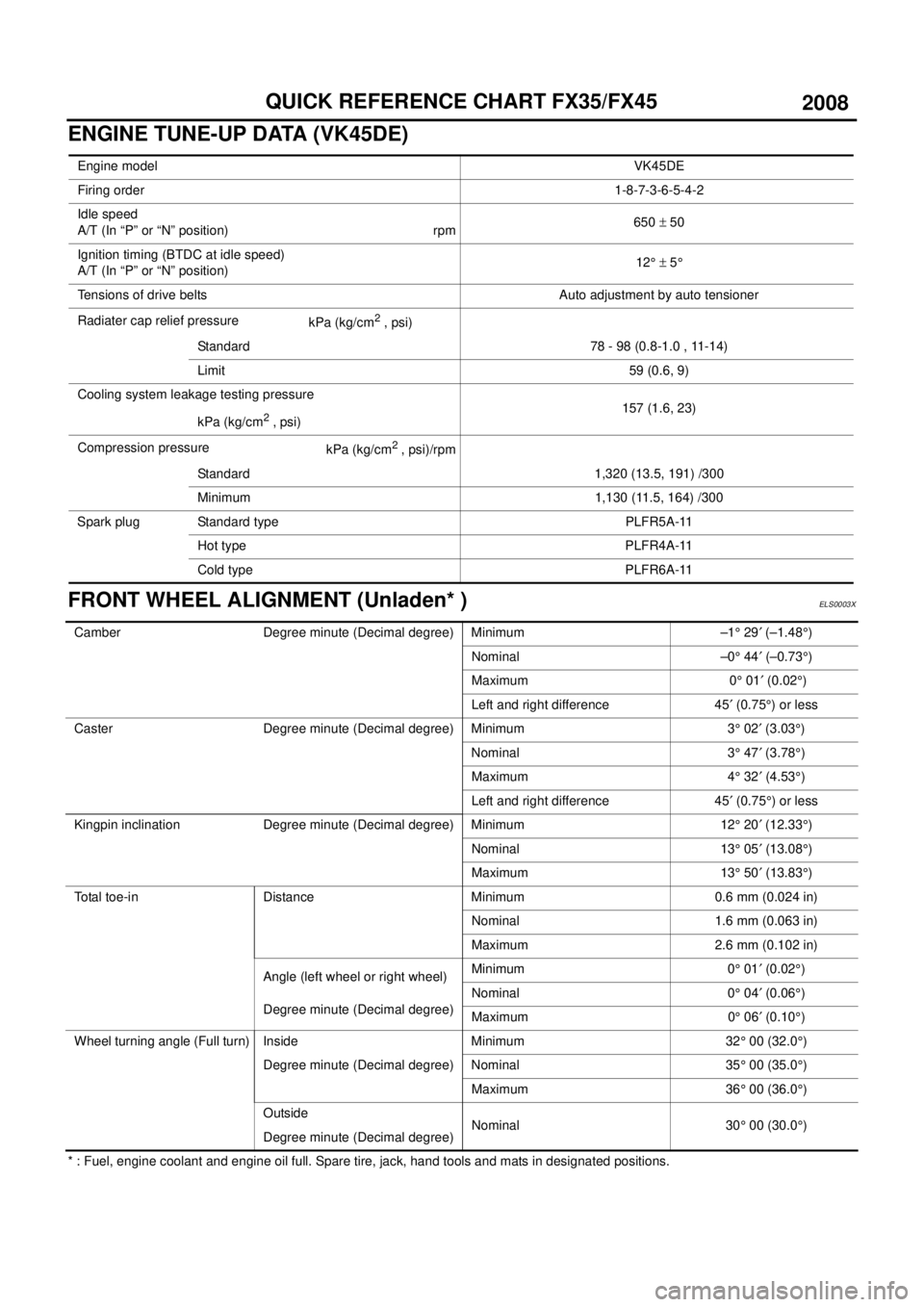

QUICK REFERENCE CHART FX35/FX45

ENGINE TUNE-UP DATA (VK45DE)

FRONT WHEEL ALIGNMENT (Unladen* )

ELS0003X

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.Engine modelVK45DE

Firing order1-8-7-3-6-5-4-2

Idle speed

A/T (In “P” or “N” position) rpm650 ± 50

Ignition timing (BTDC at idle speed)

A/T (In “P” or “N” position)12° ± 5°

Tensions of drive belts Auto adjustment by auto tensioner

Radiater cap relief pressure

kPa (kg/cm

2 , psi)

78 - 98 (0.8-1.0 , 11-14) Standard

Limit 59 (0.6, 9)

Cooling system leakage testing pressure

157 (1.6, 23)

kPa (kg/cm

2 , psi)

Compression pressure

kPa (kg/cm

2 , psi)/rpm

1,320 (13.5, 191) /300 Standard

Minimum 1,130 (11.5, 164) /300

Spark plug Standard type PLFR5A-11

Hot type PLFR4A-11

Cold type PLFR6A-11

Camber Degree minute (Decimal degree) Minimum –1° 29′ (–1.48°)

Nominal –0° 44′ (–0.73°)

Maximum 0° 01′ (0.02°)

Left and right difference 45′ (0.75°) or less

Caster Degree minute (Decimal degree) Minimum 3° 02′ (3.03°)

Nominal 3° 47′ (3.78°)

Maximum 4° 32′ (4.53°)

Left and right difference 45′ (0.75°) or less

Kingpin inclination Degree minute (Decimal degree) Minimum 12° 20′ (12.33°)

Nominal 13° 05′ (13.08°)

Maximum 13° 50′ (13.83°)

Total toe-in Distance Minimum 0.6 mm (0.024 in)

Nominal 1.6 mm (0.063 in)

Maximum 2.6 mm (0.102 in)

Angle (left wheel or right wheel)

Degree minute (Decimal degree)Minimum 0° 01′ (0.02°)

Nominal 0° 04′ (0.06°)

Maximum 0° 06′ (0.10°)

Wheel turning angle (Full turn) Inside Minimum 32° 00 (32.0°)

Degree minute (Decimal degree) Nominal 35° 00 (35.0°)

Maximum 36° 00 (36.0°)

Outside

Nominal 30° 00 (30.0°)

Degree minute (Decimal degree)

2008

Page 547 of 3924

ATC-142

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

CompressorINFOID:0000000001328235

LubricantINFOID:0000000001328236

RefrigerantINFOID:0000000001328237

Engine Idling SpeedINFOID:0000000001328238

Refer to EC-593, "Idle Speed and Ignition Timing" (VQ35DE) or EC-1196, "Idle Speed and Ignition Timing"

(VK45DE).

Belt TensionINFOID:0000000001328239

Refer to EM-149, "Standard and Limit" (VQ35DE) or EM-266, "Standard and Limit" (VK45DE).

Model Calsonic Kansei make CWV-618

Ty p e V-6 variable displacement

Displacement

cm

3 (cu in)/rev Max. 184 (11.228)

Min. 14.5 (0.885)

Cylinder bore × stroke

mm (in) 37 (1.46)

× [2.3 - 28.6 (0.091 - 1.126)]

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

ModelCalsonic Kansei make CWV-618

Name Nissan A/C System Oil Type S (DH-PS)

Capacity

m (US fl oz, lmp fl oz) Total in system 180 (6.0, 6.3)

Compressor (Service part) charging

amount

180 (6.0, 6.3)

Ty p e

HFC-134a (R-134a)

Capacity

kg (lb) 0.55 (1.21)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1093 of 3924

![INFINITI FX35 2008 Service Manual

CO-22

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

WATER PUMP

ComponentINFOID:0000000001325856

Removal and InstallationINFOID:0000000001325857

CAUTION:

When removing water pump assembly, be careful

INFINITI FX35 2008 Service Manual

CO-22

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

WATER PUMP

ComponentINFOID:0000000001325856

Removal and InstallationINFOID:0000000001325857

CAUTION:

When removing water pump assembly, be careful](/img/42/57017/w960_57017-1092.png)

CO-22

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

WATER PUMP

ComponentINFOID:0000000001325856

Removal and InstallationINFOID:0000000001325857

CAUTION:

When removing water pump assembly, be careful

not to get engine coolant on drive belts.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, connect hose and cl amp securely, then check for leaks using the radia-

tor cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Remove front engine undercover with power tool.

2. Remove drive belts. Refer to EM-15, "

Removal and Installation".

3. Drain engine coolant from radiator. Refer to CO-10, "

Changing Engine Coolant".

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

4. Remove air duct (inlet), power duct and air cleaner case assembly. Refer to EM-17, "

Component".

5. Remove water drain plug (front) on water pump side of cylinder block to drain engine coolant from engine inside.

6. Remove chain tensioner cover and water pump cover from front timing chain case. Use the seal cutter [SST: KV10111100 (J37228)] to cut liquid gasket for removal.

7. Remove timing chain tensioner (primary) as follows:

1. Timing chain tensioner (primary) 2. Chain tensioner cover 3. Water pump cover

4. Water pump 5. O-rings 6. Water drain plug (front)

SBIA0482E

PBIC2662E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1241 of 3924

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VQ35DE

SERVICE INFORMATION .. .........................

17

INDEX FOR DTC ............................................ ....17

DTC No. Index .................................................... ....17

Alphabetical Index ...................................................20

PRECAUTIONS ..................................................25

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

25

Precaution for Procedure without Cowl Top Cover ....25

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

25

Precaution ...............................................................26

PREPARATION ..................................................29

Special Service Tool ........................................... ....29

Commercial Service Tool ........................................30

ENGINE CONTROL SYSTEM ............................31

Schematic ........................................................... ....31

Multiport Fuel Injection (MFI) System .....................31

Electronic Ignition (EI) System ................................34

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

34

AIR CONDITIONING CUT CONTROL ...............36

Input/Output Signal Chart .................................... ....36

System Description .................................................36

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

37

System Description ............................................. ....37

Component Description ...........................................38

CAN COMMUNICATION ....................................39

System Description ............................................. ....39

EVAPORATIVE EMISSION SYSTEM ................40

Description .......................................................... ....40

Component Inspection ......................................... ....42

Removal and Installation .........................................44

How to Detect Fuel Vapor Leakage .........................44

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

46

System Description ..................................................46

Diagnosis Procedure ...............................................46

Component Inspection .............................................48

POSITIVE CRANKCASE VENTILATION .........51

Description ...............................................................51

Component Inspection .............................................51

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

53

Description ...............................................................53

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....54

Introduction ..............................................................54

Two Trip Detection Logic .........................................54

Emission-Related Diagnostic Information ................55

Malfunction Indicator Lamp (MIL) ............................71

OBD System Operation Chart .................................74

BASIC SERVICE PROCEDURE .......................80

Basic Inspection ......................................................80

Idle Speed and Ignition Timing Check .....................84

Procedure After Replacing ECM .............................84

VIN Registration ......................................................84

Accelerator Pedal Released Position Learning .......85

Throttle Valve Closed Position Learning .................85

Idle Air Volume Learning .........................................85

Fuel Pressure Check ...............................................87

TROUBLE DIAGNOSIS ....................................89

Trouble Diagnosis Introduction ................................89

DTC Inspection Priority Chart ..................................93

Fail-Safe Chart ........................................................95

Symptom Matrix Chart .............................................96

Engine Control Component Parts Location ...........100

Vacuum Hose Drawing ..........................................106

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1248 of 3924

EC-8

Component Inspection ...........................................545

ASCD INDICATOR ..........................................547

Component Description ....................................... ..547

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

547

Wiring Diagram ......................................................548

Diagnosis Procedure .............................................548

ELECTRICAL LOAD SIGNAL .........................550

Description ........................................................... ..550

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

550

Diagnosis Procedure .............................................550

FUEL INJECTOR .............................................552

Component Description ....................................... ..552

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

552

Wiring Diagram ......................................................553

Diagnosis Procedure .............................................554

Component Inspection ...........................................557

Removal and Installation .......................................557

FUEL PUMP .....................................................558

Description ........................................................... ..558

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

558

Wiring Diagram ......................................................559

Diagnosis Procedure .............................................560

Component Inspection ...........................................562

Removal and Installation .......................................562

ICC BRAKE SWITCH ......................................563

Component Description ....................................... ..563

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

563

Wiring Diagram ......................................................564

Diagnosis Procedure .............................................565

Component Inspection ...........................................567

IGNITION SIGNAL ...........................................569

Component Description ....................................... ..569

Wiring Diagram ......................................................570

Diagnosis Procedure .............................................575

Component Inspection ...........................................578

Removal and Installation .......................................580

REFRIGERANT PRESSURE SENSOR ..........581

Component Description ....................................... ..581

Wiring Diagram ......................................................582

Diagnosis Procedure .............................................583

Removal and Installation .......................................585

SNOW MODE SWITCH ...................................586

Description ........................................................... ..586

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

586

Wiring Diagram ......................................................587

Diagnosis Procedure .............................................587

Component Inspection ...........................................589

MIL AND DATA LINK CONNECTOR ...............591

Wiring Diagram .................................................... .591

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

593

Fuel Pressure ....................................................... .593

Idle Speed and Ignition Timing .............................593

Calculated Load Value ..........................................593

Mass Air Flow Sensor ...........................................593

Intake Air Temperature Sensor .............................593

Engine Coolant Temperature Sensor ...................593

Air Fuel Ratio (A/F) Sensor 1 Heater ....................593

Heated Oxygen sensor 2 Heater ..........................593

Crankshaft Position Sensor (POS) .......................594

Camshaft Position Sensor (PHASE) .....................594

Throttle Control Motor .......................................... .594

Fuel Injector ..........................................................594

Fuel Pump .............................................................594

VK45DE

SERVICE INFORMATION .. .......................

595

INDEX FOR DTC ............................................ ..595

DTC No. Index ..................................................... .595

Alphabetical Index .................................................598

PRECAUTIONS .............................................. ..603

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

603

Precaution for Procedure without Cowl Top Cover .603

On Board Diagnosis (OBD) System of Engine and

A/T ........................................................................

603

Precaution .............................................................604

PREPARATION ................................................607

Special Service Tool ............................................ .607

Commercial Service Tool ......................................608

ENGINE CONTROL SYSTEM ..........................609

Schematic ............................................................ .609

Multiport Fuel Injection (MFI) System ...................609

Electronic Ignition (EI) System ..............................612

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................

612

AIR CONDITIONING CUT CONTROL .............614

Input/Output Signal Chart .................................... .614

System Description ...............................................614

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ..............................................................

615

System Description .............................................. .615

Component Description ........................................616

CAN COMMUNICATION ..................................617

System Description .............................................. .617

EVAPORATIVE EMISSION SYSTEM ..............618

Description ........................................................... .618

Component Inspection ..........................................620

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1376 of 3924

![INFINITI FX35 2008 Service Manual

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec INFINITI FX35 2008 Service Manual

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec](/img/42/57017/w960_57017-1375.png)

EC-136

< SERVICE INFORMATION >[VQ35DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-96, "

Symptom Matrix Chart".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternat or, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1954 of 3924

![INFINITI FX35 2008 Service Manual

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec INFINITI FX35 2008 Service Manual

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnec](/img/42/57017/w960_57017-1953.png)

EC-714

< SERVICE INFORMATION >[VK45DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

OK >>

INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNE CT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F AL PHA-B2” in “SPEC” of “DATA MONITOR” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG >> Detect malfunctioning part according to EC-673, "

Symptom Matrix Chart".

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >> INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternat or, A/C compressor, etc. is excessive

- Noise from engine

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

Crushed air ducts

Malfunctioning seal of air cleaner element

Uneven dirt of air cleaner element

Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/F UEL SCHDL” in “SPEC” of “DATA MONITOR” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >> INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2485 of 3924

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

VQ35DE

SERVICE INFORMATION .. ..........................

4

PRECAUTIONS .............................................. .....4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Drain Engine Coolant and Engine

Oil ..............................................................................

4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................5

Precaution for Angle Tightening ................................5

Precaution for Liquid Gasket .....................................5

PREPARATION ...................................................7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

12

NVH Troubleshooting - Engine Noise ................. ....12

Use the Chart Below to Help You Find the Cause

of the Symptom .......................................................

12

DRIVE BELTS ....................................................14

Checking Drive Belts ........................................... ....14

Tension Adjustment ................................................14

Removal and Installation .........................................15

AIR CLEANER AND AIR DUCT ........................17

Component .......................................................... ....17

Removal and Installation .........................................17

Changing Air Cleaner Filter .....................................18

INTAKE MANIFOLD COLLECTOR ...................19

Component .......................................................... ....19

Removal and Installation .........................................19

INTAKE MANIFOLD ...........................................24

Component .......................................................... ....24

Removal and Installation .........................................24

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

26

Component ..............................................................26

Removal and Installation .........................................26

OIL PAN AND OIL STRAINER .........................30

Component (2WD Models) ......................................30

Removal and Installation (2WD Models) .................30

Component (AWD Models) ......................................35

Removal and Installation (AWD Models) .................36

IGNITION COIL .................................................42

Component ..............................................................42

Removal and Installation .........................................42

SPARK PLUG (PLATINUM-TIPPED TYPE) .....43

Component ..............................................................43

Removal and Installation .........................................43

FUEL INJECTOR AND FUEL TUBE ................45

Component ..............................................................45

Removal and Installation .........................................45

ROCKER COVER .............................................51

Component ..............................................................51

Removal and Installation .........................................51

FRONT TIMING CHAIN CASE .........................54

Removal and Installation .........................................54

TIMING CHAIN ..................................................64

Component .......................................................... ....64

Removal and Installation .........................................65

CAMSHAFT .......................................................83

Component ..............................................................83

Removal and Installation .........................................84

Valve Clearance ......................................................91

OIL SEAL ..........................................................97

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2486 of 3924

EM-2

Removal and Installation of Valve Oil Seal .............97

Removal and Installation of Front Oil Seal .............97

Removal and Installation of Rear Oil Seal ..............98

CYLINDER HEAD ............................................100

On-Vehicle Service .............................................. ..100

Component ............................................................101

Removal and Installation .......................................101

Disassembly and Assembly ...................................105

Inspection After Disassembly ................................107

ENGINE ASSEMBLY .......................................112

Component (2WD Models) .................................. ..112

Removal and Installation (2WD Models) ...............112

Component (AWD Models) ....................................117

Removal and Installation (AWD Models) ...............117

CYLINDER BLOCK .........................................122

Component .......................................................... ..122

Disassembly and Assembly ...................................123

How to Select Piston and Bearing .........................134

Inspection After Disassembly ................................138

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

149

Standard and Limit .............................................. ..149

VK45DE

SERVICE INFORMATION ..........................

160

PRECAUTIONS .............................................. .160

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

160

Precaution for Drain Engine Coolant and Engine

Oil ..........................................................................

160

Precaution for Disconnecting Fuel Piping ..............160

Precaution for Removal and Disassembly .............160

Precaution for Inspection, Repair and Replace-

ment .......................................................................

160

Precaution for Assembly and Installation ..............161

Parts Requiring Angle Tightening ..........................161

Precaution for Liquid Gasket .................................161

PREPARATION .............................................. .163

Special Service Tool ............................................ ..163

Commercial Service Tool ......................................164

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ..........................

167

NVH Troubleshooting - Engine Noise .................. ..167

Use the Chart Below to Help You Find the Cause

of the Symptom .....................................................

167

ENGINE ROOM COVER ..................................169

Component .......................................................... ..169

Removal and Installation .......................................169

DRIVE BELTS ..................................................170

Component .......................................................... ..170

Checking Drive Belts .............................................170

Tension Adjustment ...............................................170

Removal and Installation ...................................... .170

Component ...........................................................171

Drive Belt Auto Tensioner and Idler Pulley ...........172

AIR CLEANER AND AIR DUCT .......................173

Component .......................................................... .173

Removal and Installation .......................................173

Changing Air Cleaner Filter ...................................174

INTAKE MANIFOLD .........................................175

Component .......................................................... .175

Removal and Installation .......................................176

EXHAUST MANIFOLD AND THREE WAY

CATALYST .......................................................

179

Component .......................................................... .179

Removal and Installation .......................................179

OIL PAN AND OIL STRAINER ........................183

Component .......................................................... .183

Removal and Installation .......................................183

IGNITION COIL .................................................187

Component .......................................................... .187

Removal and Installation .......................................187

SPARK PLUG (PLATINUM-TIPPED TYPE) ....188

Component .......................................................... .188

Removal and Installation .......................................188

FUEL INJECTOR AND FUEL TUBE ................190

Component .......................................................... .190

Removal and Installation .......................................190

ROCKER COVER .............................................196

Component .......................................................... .196

Removal and Installation .......................................196

TIMING CHAIN .................................................199

Component .......................................................... .199

Removal and Installation .......................................200

CAMSHAFT ......................................................211

Component .......................................................... .211

Removal and Installation .......................................211

Valve Clearance ....................................................218

OIL SEAL ..........................................................222

Removal and Installation of Valve Oil Seal ...........222

Removal and Installation of Front Oil Seal ........... .222

Removal and Installation of Rear Oil Seal ............224

CYLINDER HEAD .............................................226

On-Vehicle Service .............................................. .226

Component ...........................................................227

Removal and Installation .......................................227

Disassembly and Assembly ..................................229

Inspection After Disassembly ................................232

ENGINE ASSEMBLY ..................................... ..237

Component .......................................................... .237

Removal and Installation .......................................237

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C