INFINITI M HYBRID 2013 Dismantling Guide

Manufacturer: INFINITI, Model Year: 2013, Model line: M HYBRID, Model: INFINITI M HYBRID 2013Pages: 52, PDF Size: 3.85 MB

Page 11 of 52

2. Basic High Voltage Information

2-1

Battery Information

The M35h HYBRID utilizes two batteries in order to supply both high and low voltage.

2-1.1 12V Battery • The M35h HYBRID contains a conventional lead-acid 12Vbattery.

• The 12V battery is located in the trunk, left of Li-ion battery, concealed by trim cover.

• The 12V battery is charged by the Li-ion battery through the DC/DC converter.

2-1.2 Li-ion Battery • The M35h HYBRID contains a Li-ion high voltage battery.

• The high voltage battery is mounted in the trunk areabehind the rear seat, enclosed in a metal case and

concealed by trim cover.

• The high voltage battery stores approximately 346 volts DC (400V max.) .

• The high voltage battery exhausts gases directly outside the vehicle through a vent hose.

• An air vent is located on the rear parcel shelf for battery cooling.

The high voltage battery supplies power to the following: • High voltage harnesses

• DC/DC converter

• Traction motor inverter

• Traction motor

• Electric air conditioner compressor AAYIA0064ZZ

AAYIA0065ZZ

AAYIA0066ZZ

11

Page 12 of 52

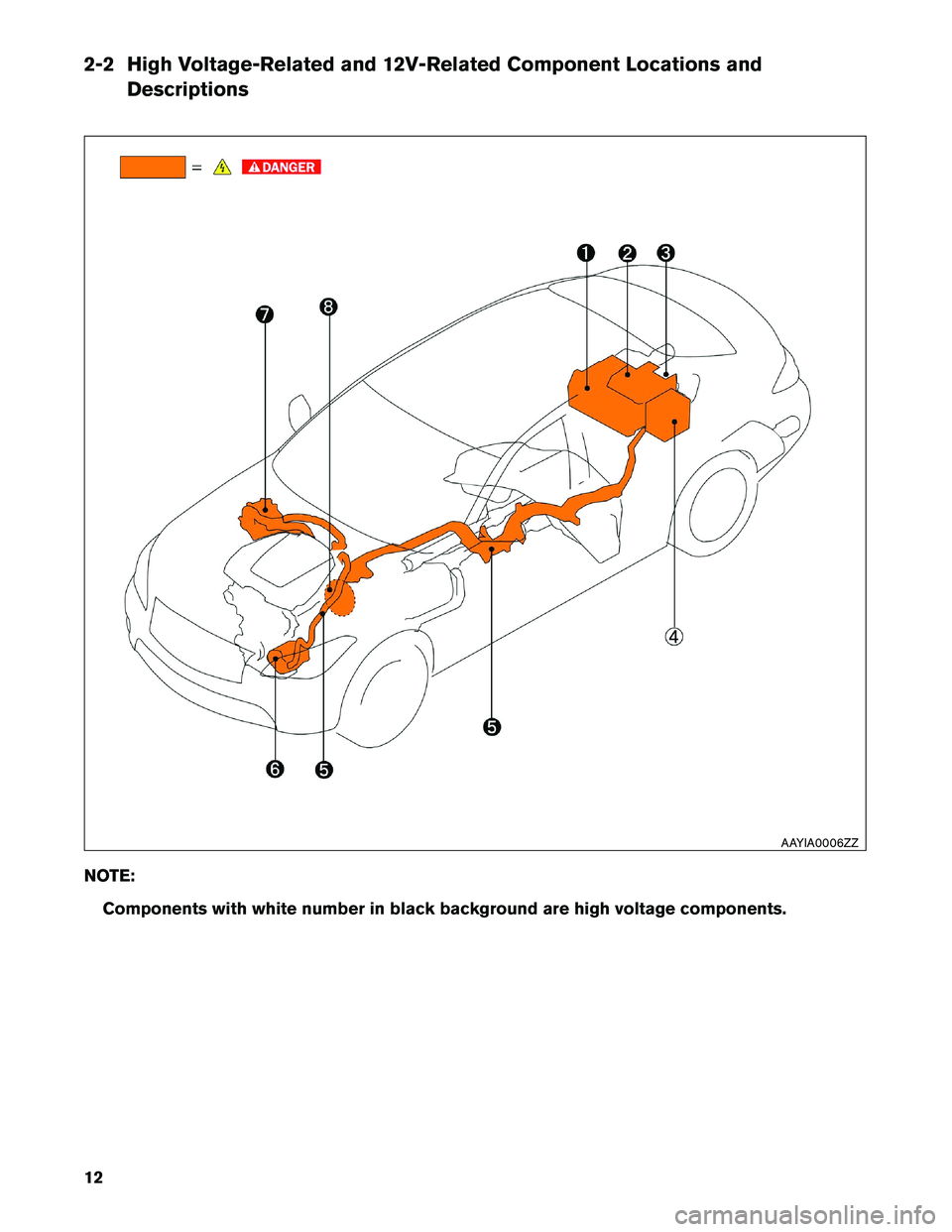

2-2 High Voltage-Related and 12V-Related Component Locations and

Descriptions

NO

TE:

Components with white number in black background are high voltage components. AAYIA0006ZZ

12

Page 13 of 52

No. Component

LocationDescription

a Lithium-ion

(Li-ion)

Battery Trunk area (behind

rear seat back) The Li-ion battery stores and outputs DC

power (Maximum voltage 400V) needed to

propel the vehicle.

b DC/DC Converter Trunk area (mounted

to top of Li-ion bat-

tery) The DC/DC converter reduces the voltage of

the Li-ion battery to provide power to the 12V

battery in order to operate the vehicle’s electric

components (headlights, audio system, etc.) .

c Service Plug Trunk area (below

parcel shelf; behind

access door in trim

panel) This is used to disable the high voltage system.

d 12V Battery Trunk area (below

parcel shelf; behind

trim panel left of

Li-ion battery) A lead-acid battery that supplies power to the

low voltage devices.

e High Voltage Har-

nesses Trunk area (on Li-ion

battery) , under floor

pan, engine com-

partment Orange-colored power cables carry high DC

voltage between each of the high voltage com-

ponents.

f Electric Air Condi-

tioner Compressor Engine compart-

ment (front driver

side) Air conditioner compressor

g Traction Motor

Inverter Engine compart-

ment (rear passen-

ger side) Converts the DC power stored in the Li-ion

battery to three-phase AC power and controls

motor torque (revolution) by regulating the

motor current. The inverter has a built in high

voltage capacitor.

h Traction Motor Built-into the trans-

mission Converts three-phase alternating current (AC)

power to drive power (torque) which propels

the vehicle.

2-3 Li-ion Battery Pack Specifications Li-ion Battery Specifications

Li-ion

battery voltage 346V (400V max.)

Number of Li-ion battery modules in the pack 12

Li-ion battery module voltage 28.8V each

Li-ion battery dimensions 33.35 x 17.83 x 15.43 in. (847 x 453 x 392 mm)

Li-ion battery weight 121.28 lbs (55 kg)

13

Page 14 of 52

2-4 High Voltage Safety Measures

Circuit insulation

The high voltage positive (+) and negative (-) circuits are insulated

from the metal chassis.

Reducing the risk of electrocution The high voltage components and harnesses have insulated cases or orange-colored coverings which provide insulation and easy identifica-

tion.

The high voltage battery case is electrically connected to the vehicle

ground. This connection helps protect the vehicle occupants and

vehicle dismantlers

from high voltage electrical shock.

IdentificationThe high voltage components are labeled “WARNING” similar to label

shown below. All high voltage harnesses are coated in orange.

2-4.1 Warning Label AAYIA0010ZZ

14

Page 15 of 52

2-5 High Voltage Safety System

The

high voltage safety system is intended to help keep vehicle occupants and emergency responders safe

from high voltage electricity. • A high voltage fuse provides short circuit protection inside the high voltage battery.

• The high voltage safety system is insulated from the metal chassis.

• Positive and negative high voltage power cables are connected to the high voltage battery and arecontrolled by normally open system main relays (SMR1 and SMR2) . When the vehicle is shut off,

the relays stop electrical flow from leaving the high voltage battery. However, it can take up to

ten (10) minutes for the high voltage capacitor to fully discharge. • The high voltage system and high voltage capacitor may remain powered for up to 10

minutes

after the vehicle is shut off.

• The high voltage battery retains high voltage at all times.

• A ground fault monitor continuously monitors for high voltage leakage to the metal chassis while the vehicle is running. If a malfunction is detected, the HPCM (hybrid powertrain control module) will

illuminate the hybrid system warning lamp in the instrument cluster.

•

The high voltage battery relays (SMR1 and SMR2) will automatically open to stop the electrical flow

in a frontal collision that is sufficient enough to activate the supplemental restraint system (SRS) . AAYIA0001GB

15

Page 16 of 52

2-6 High Voltage Circuit Shut-Off System

This

vehicle is equipped with a system to shut off the current from the Li-ion battery by the following

methods: Service plug

Positioned in the center area of the Li-ion battery, this plug shuts off the out-

put

of high voltage when manually removed.

System main relays Controlled by the ignition switch, these relays are powered by the 12V sys- tem and shut off high voltage from the Li-ion battery.

Emergency shut-off sys-

tem In the case of a collision (air bag deployment, etc.) or certain system malfunc-

tions this system shuts off the high voltage from the Li-ion battery.

2-7 Preventing Electrical Shock 1. If it is necessary to touch any of the high voltage harnesses or components, always wearappropriate PPE (refer to 3-1 Preparation Items) . Shut off the high voltage system by referring to

3-3.1 High Voltage System Shut-Down Procedure.

2.

To avoid the risk of electrocution, do not touch the inside of the Li-ion battery with bare hands

after shutting off the high voltage system. The Li-ion battery maintains charge even though the

high voltage system is shut down.

3. Cover damaged high voltage components with insulated tape.

16

Page 17 of 52

3. Preparation for Dismantling

• Failure to properly shut down the high voltage electrical system before the

Dismantling Procedures are performed will result in serious injury or death from

electrical shock. To prevent serious injury or death, DO NOT touch high voltage

harnesses or components without always wearing appropriate PPE.

• If it is necessary to touch any of the high voltage harnesses or components you must

always

wear appropriate PPE to avoid electrical shock. Shut down the high voltage

system by following the steps outlined in 3-3.1 High Voltage System Shut-Down Proce-

dure. Wait at least ten (10) minutes for complete discharge of the high voltage capacitor

after

the high voltage system has been shut down. • NEVER assume the M35h HYBRID is shut OFF simply because it is quiet.

•

If it becomes necessary for the dismantler to leave the vehicle, place a “DANGER” sign

(for example, refer to 5. Storing the Vehicle) on the vehicle to alert other people that the

vehicle

contains a high voltage battery.

• If the READY indicator is ON the high voltage system is active.

•

If possible, be sure to check the READY indicator on the instrument cluster and

verify

that the READY indicator is OFF and the high voltage system is stopped.

17

Page 18 of 52

3-1 Preparation Items

Preparation Items

Specification Purpose

PPE (personal protective

equipment):

Insulated gloves Up to 1,000V

For

protection from high voltage electri-

cal shock

Insulated shoes –

Safety

shield –

W

renches Size:10mm

T

o remove the 12V battery terminal

bolt.

Solvent resistant protec-

tion gloves

Solvent resistant

protection shoes –

To utilize in the event of a Li-ion battery

electrolytic solution leak.

–

Absorbent pad The same pad used for internal com-

bustion engine fluids can be used. To absorb any Li-ion battery electrolytic

solution leakage.

Standard fire fighting

equipment Standard fire fighting equipment.

Depending on type of fire (vehicle or

battery) use standard fire fighting

equipment (water or extinguisher) . To extinguish a fire.

Insulated tape Insulating To cover any damaged harnesses to

protect from and prevent electrical

shock. Tape should cover all bare or

damaged wire.

3-2 Discharge Procedures Failure to properly discharge the Li-ion battery before the dismantling procedures are

performed

will result in serious injury or death from electrical shock.

Li-ion battery discharging must take place before dismantling. Sufficient discharging can be achieved by

following these steps. 1. Place the shift selector into the Park (P) position

2. Apply the parking brake.

3. Set wheel chocks to ensure the vehicle is completely stopped.

18

Page 19 of 52

4. Apply foot brake and press the ignition switch to turn the system ON. Confirm READY

indicator in instrument cluster turns ON.

a. If the engine starts, leave the engine on until idling stops.

b. If the engine does NOT start, move on to next step.

5. Remove the shift lock cover (A) using a suitable tool.

6. Push down the shift lock (B) as shown in the illustration.

7. Push the shift selector button (C) and move the shift selector to Neutral (N) position (D) while holding down

the shift lock.

NOTE:

DO NOT press accelerator or foot brake after

moving the shift selector to the Neutral (N)

position. Otherwise Li-ion battery will start to be

charged.

8. Release the parking brake.

9. Turn ON electric devices such as headlamps, A/C (set to the coldest temperature) and rear window defogger to discharge the high voltage battery. Allow approximately 15 minutes to

discharge. Discharge is complete when the READY indicator (B) (green) turns OFF and

the

hybrid system warning indicator (C) (orange) turns ON.

10. Press the ignition switch (A) to turn the system OFF.

Please contact following number if the vehicle could not be discharged. • 1-800-662-6200 (US) or 1-800-361-4792 (Canada)

• Hours of operation are 8am-5pm (Monday-Friday) Eastern, Central and Pacific time zones. AAYIA0067ZZ

AAYIA0033ZZ

19

Page 20 of 52

3-3 How to Handle a Damaged Vehicle

3-3.1

High Voltage System Shut-Down Procedure

Any of the following procedures can shut down the high voltage system. The dismantling operation can only

begin after shutting down the high voltage system. If the vehicle is heavily damaged, for example the Li-ion

battery is deformed, broken or cracked, appropriate PPE must always be used and the Li-ion battery and

high voltage components must not be touched. • Failure to properly shut down the high voltage system before the dismantling

procedures

are performed will result in serious injury or death from electrical shock.

To prevent serious injury or death, DO NOT touch high voltage harnesses or

components without always wearing appropriate PPE.

• When contact with high voltage components or high voltage harnesses is

unavoidable,

or when there is risk of such contact, you must always wear appropriate

PPE.

20