oil pressure INFINITI QX56 2004 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: QX56, Model: INFINITI QX56 2004Pages: 3371, PDF Size: 78.5 MB

Page 2890 of 3371

REAR SUSPENSION MEMBER

RSU-31

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: August 20072004 QX56

Rear Load Leveling Air Suspension System

REMOVAL

1. Use the CONSULT-II “EXHAUST SOLENOID” active test to release the air pressure from the rear load

leveling air suspension system.

2. Disconnect the electrical connectors for the height sensor and the rear load leveling air suspension com-

pressor assembly.

3. Unclip the rubber cover to access the rear load leveling air suspension compressor assembly.

1. Seat belt latch anchor 2. Stabilizer bar bushing 3. Stabilizer bar clamp

4. Stabilizer bar 5. Connecting rod 6. Front lower link

7. Knuckle 8. Bushing 9. Rear lower link

10. Shock absorber 11. Suspension arm 12. Lower rubber seat

13. Coil spring 14. Upper rubber seat 15. Rear suspension member

16. Spare tire bracket 17. Bound bumper

LEIA0072E

1. Rear load leveling air suspension

hose, RH2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension

hose, LH5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly (includes the

bracket and rubber cover)

Page 2898 of 3371

REAR LOWER LINK & COIL SPRING

RSU-39

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: August 20072004 QX56

REAR LOWER LINK & COIL SPRINGPFP:551B0

Removal and Installation EES0011P

REMOVAL

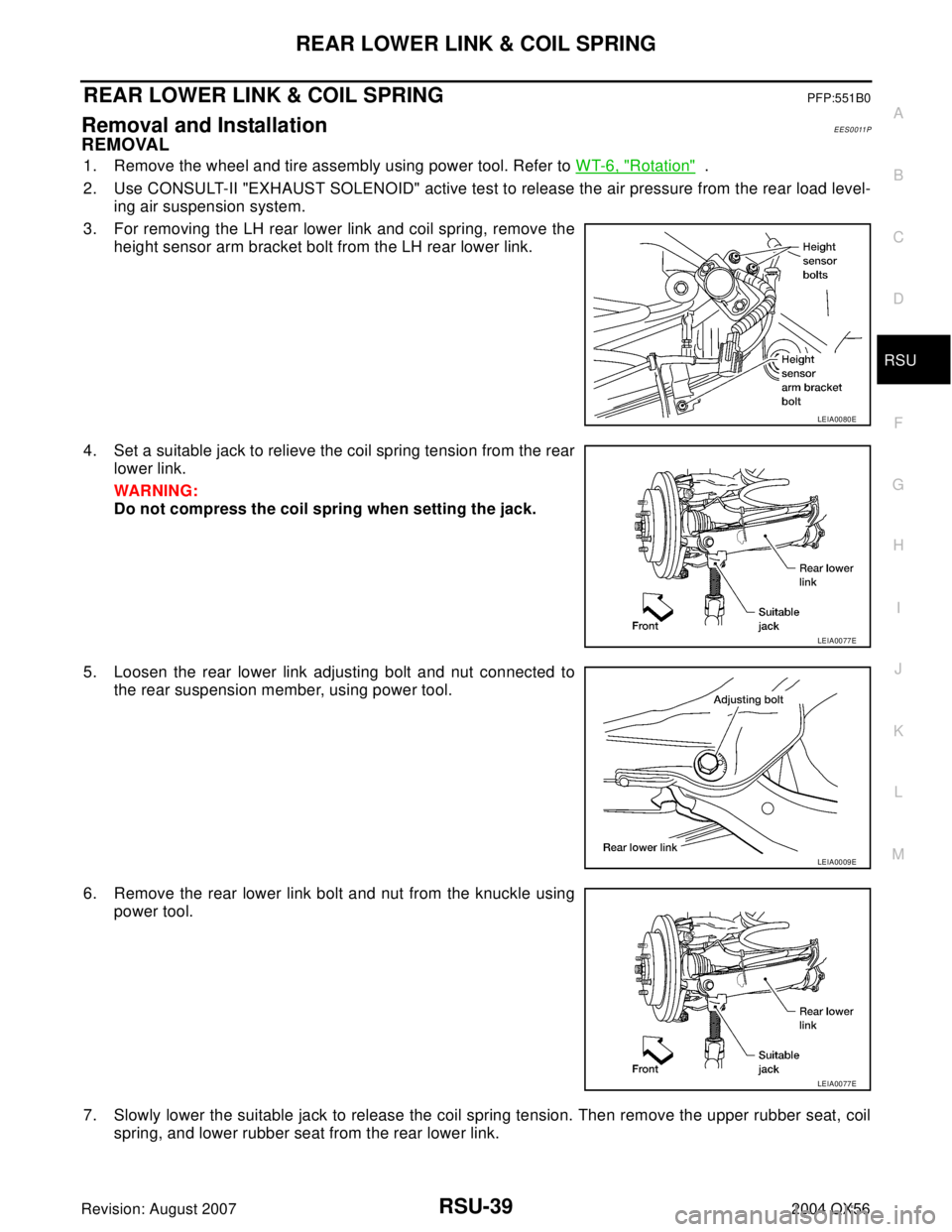

1. Remove the wheel and tire assembly using power tool. Refer to WT-6, "Rotation" .

2. Use CONSULT-II "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

3. For removing the LH rear lower link and coil spring, remove the

height sensor arm bracket bolt from the LH rear lower link.

4. Set a suitable jack to relieve the coil spring tension from the rear

lower link.

WAR NIN G:

Do not compress the coil spring when setting the jack.

5. Loosen the rear lower link adjusting bolt and nut connected to

the rear suspension member, using power tool.

6. Remove the rear lower link bolt and nut from the knuckle using

power tool.

7. Slowly lower the suitable jack to release the coil spring tension. Then remove the upper rubber seat, coil

spring, and lower rubber seat from the rear lower link.

LEIA0080E

LEIA0077E

LEIA0009E

LEIA0077E

Page 2949 of 3371

SC-28

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: August 20072004 QX56

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

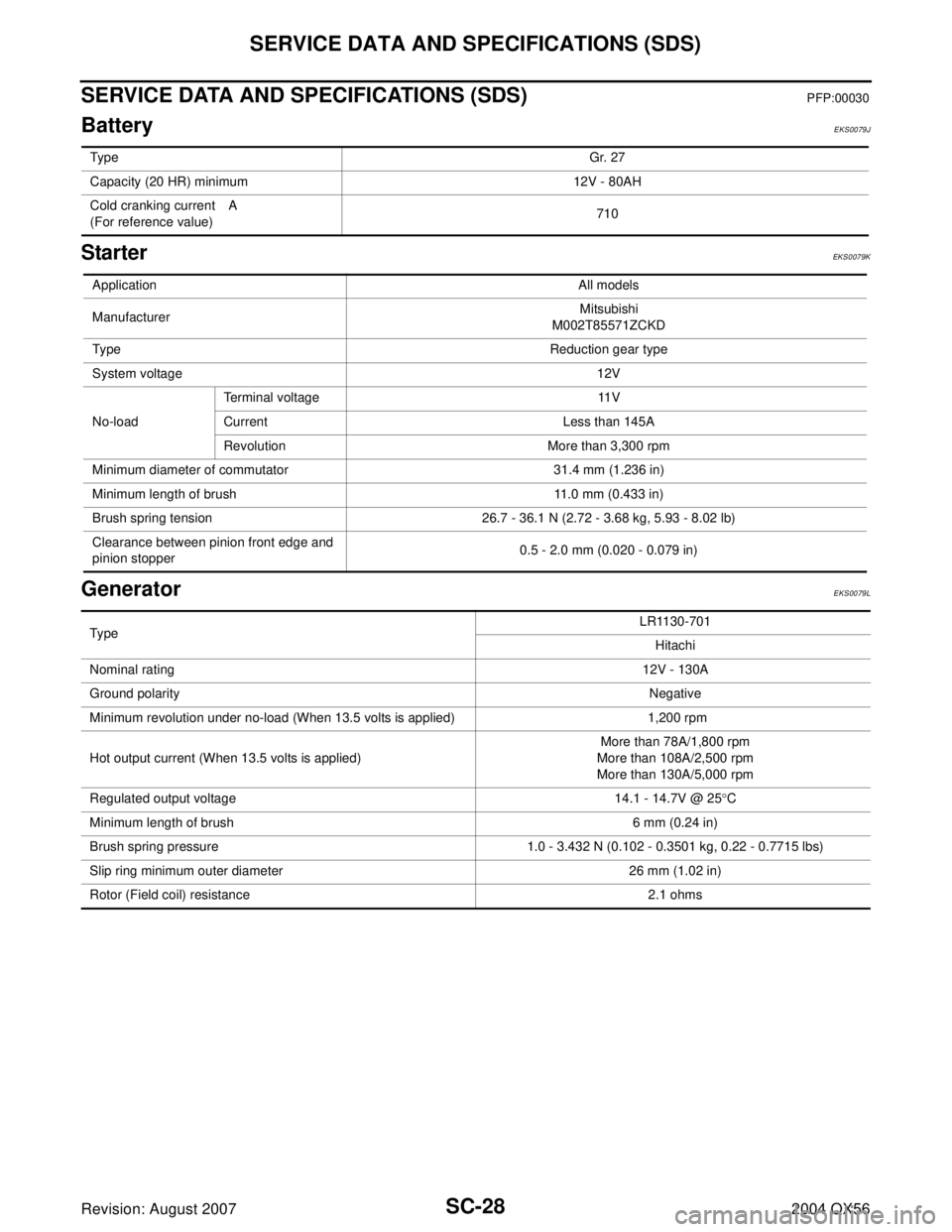

BatteryEKS0079J

StarterEKS0079K

GeneratorEKS0079L

Typ eGr. 27

Capacity (20 HR) minimum 12V - 80AH

Cold cranking current A

(For reference value)710

ApplicationAll models

ManufacturerMitsubishi

M002T85571ZCKD

Ty peReduction gear type

System voltage 12V

No-loadTerminal voltage 11V

Current Less than 145A

Revolution More than 3,300 rpm

Minimum diameter of commutator 31.4 mm (1.236 in)

Minimum length of brush 11.0 mm (0.433 in)

Brush spring tension 26.7 - 36.1 N (2.72 - 3.68 kg, 5.93 - 8.02 lb)

Clearance between pinion front edge and

pinion stopper0.5 - 2.0 mm (0.020 - 0.079 in)

Ty peLR1130-701

Hitachi

Nominal rating12V - 130A

Ground polarityNegative

Minimum revolution under no-load (When 13.5 volts is applied) 1,200 rpm

Hot output current (When 13.5 volts is applied)More than 78A/1,800 rpm

More than 108A/2,500 rpm

More than 130A/5,000 rpm

Regulated output voltage 14.1 - 14.7V @ 25°C

Minimum length of brush 6 mm (0.24 in)

Brush spring pressure 1.0 - 3.432 N (0.102 - 0.3501 kg, 0.22 - 0.7715 lbs)

Slip ring minimum outer diameter 26 mm (1.02 in)

Rotor (Field coil) resistance 2.1 ohms

Page 3127 of 3371

TF-2Revision: August 20072004 QX56 SWITCH ..................................................................... 62

Diagnostic Procedure ............................................. 62

TRANSFER MOTOR AND TRANSFER MOTOR

RELAY ....................................................................... 64

Diagnostic Procedure ............................................. 64

TRANSFER FLUID TEMPERATURE SENSOR ....... 66

Diagnostic Procedure ............................................. 66

ATP SWITCH, WAIT DETECTION SWITCH AND

NEUTRAL-4LO SWITCH .......................................... 69

Diagnostic Procedure ............................................. 69

CLUTCH PRESSURE SWITCH ................................ 72

Diagnostic Procedure ............................................. 72

LINE PRESSURE SWITCH ....................................... 74

Diagnostic Procedure ............................................. 74

DATA ERASE/DISPLAY ............................................ 76

Diagnostic Procedure ............................................. 76

SHIFT ACTUATOR ................................................... 77

Diagnostic Procedure ............................................. 77

SHIFT ACTUATOR POSITION SWITCH .................. 80

Diagnostic Procedure ............................................. 80

SHIFT ACTUATOR CIRCUIT .................................... 82

Diagnostic Procedure ............................................. 82

TROUBLE DIAGNOSES FOR SYMPTOMS ............. 85

Symptom 1. 4WD Shift Indicator Lamp Does Not

Turn ON (Although the ignition switch is turned ON,

all the 4WD indicator lamps do not turn ON for 1

second) ................................................................... 85

Symptom 2. 4WD Warning Lamp Does Not Turn ON

(Although the ignition switch is turned ON, the 4WD

warning lamp does not turn ON) ............................. 87

Symptom 3. 4WD Shift Indicator Lamp Does Not

Turn OFF (When 4WD shift switch is set from 4H

to 4LO, all the 4WD shift indicator lamps do not turn

off) ........................................................................... 88

Symptom 4. ATP Warning Lamp Does Not Turn ON

(When 4WD shift switch is set from 4H to 4LO with

the A/T selector lever in P position, the ATP warning

lamp does not turn on) ............................................ 89

Symptom 5. 4LO Indicator Lamp Does Not Turn ON

(When 4WD shift switch is set from 4H to 4LO posi-

tion, 4LO indicator lamp does not turn ON) ............ 90

Symptom 6. 4WD Shift Indicator Lamp Does Not

Indicate “LOCK” (When 4WD shift switch is set to

“4H”, 4WD shift indicator lamp does not indicate

“LOCK”) .................................................................. 91

Symptom 7. 4WD Shift Indicator Lamp Repeats

Flickering (4WD Shift Indicator Lamp Keeps Flick-

ering) ...................................................................... 92

Symptom 8. Tight Corner Braking Symptom (Tight

Corner Braking Symptom Occurs-Hydraulic Sys-

tem Failure) ............................................................ 93

Symptom 9. 4WD System Does Not Operate (The

Vehicle Cannot Be Put Into 4WD Mode-Hydraulic

System Failure) ...................................................... 94

Component Inspection ............................................ 95

4WD SHIFT SWITCH .......................................... 95

2-4WD SHIFT SOLENOID VALVE AND TRANS-

FER FLUID TEMPERATURE SENSOR .............. 95

4WD SOLENOID VALVE, CLUTCH PRESSURE SWITCH AND LINE PRESSURE SWITCH .........95

TRANSFER DROPPING RESISTOR ..................96

ATP SWITCH, NEUTRAL-4LO SWITCH AND

WAIT DETECTION SWITCH ...............................96

TRANSFER MOTOR ...........................................96

TRANSFER MOTOR RELAY ...............................97

TRANSFER SHIFT RELAY (HIGH & LOW) .........97

ACTUATOR AND ACTUATOR POSITION

SWITCH ...............................................................97

TRANSFER CONTROL UNIT ...................................98

Removal and Installation .........................................98

REMOVAL ............................................................98

INSTALLATION ....................................................98

FRONT OIL SEAL .....................................................99

Removal and Installation .........................................99

REMOVAL ............................................................99

INSTALLATION .................................................. 100

REAR OIL SEAL ..................................................... 101

Removal and Installation ....................................... 101

REMOVAL .......................................................... 101

INSTALLATION .................................................. 101

SIDE OIL SEAL ....................................................... 103

Removal and Installation ....................................... 103

REMOVAL .......................................................... 103

INSTALLATION .................................................. 103

TRANSFER CONTROL DEVICE ............................ 104

Removal and Installation ....................................... 104

AIR BREATHER HOSE ........................................... 105

Removal and Installation ....................................... 105

TRANSFER MOTOR ............................................... 106

Removal and Installation ....................................... 106

REMOVAL .......................................................... 106

INSTALLATION ..................................................... 106

TRANSFER OIL FILTER ......................................... 107

Removal and Installation ....................................... 107

REMOVAL .......................................................... 107

INSTALLATION .................................................. 107

REMOVAL AND INSTALLATION ............................ 109

Removal ................................................................ 109

Installation ............................................................. 109

OVERHAUL .............................................................110

Transfer Components ...........................................110

REAR CASE ............................................................112

Disassembly ..........................................................112

CENTER CASE .......................................................113

Disassembly ..........................................................113

FRONT DRIVE SHAFT AND DRIVE CHAIN .....115

MAINSHAFT AND CLUTCH DRUM ..................116

CLUTCH PISTON ..............................................118

CONTROL VALVE .............................................119

MAINSHAFT REAR BEARING .......................... 122

MAIN OIL PUMP ................................................ 122

SUB OIL PUMP ................................................. 123

OIL FILTER ........................................................ 124

FRONT CASE .......................................................... 125

Disassembly .......................................................... 125

SHIFT ROD COMPONENTS ............................. 125

PLANETARY CARRIER, SUN GEAR AND

INTERNAL GEAR .............................................. 127

Page 3140 of 3371

ALL-MODE 4WD SYSTEM

TF-15

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: August 20072004 QX56

Description of Electrical PartsEDS0017R

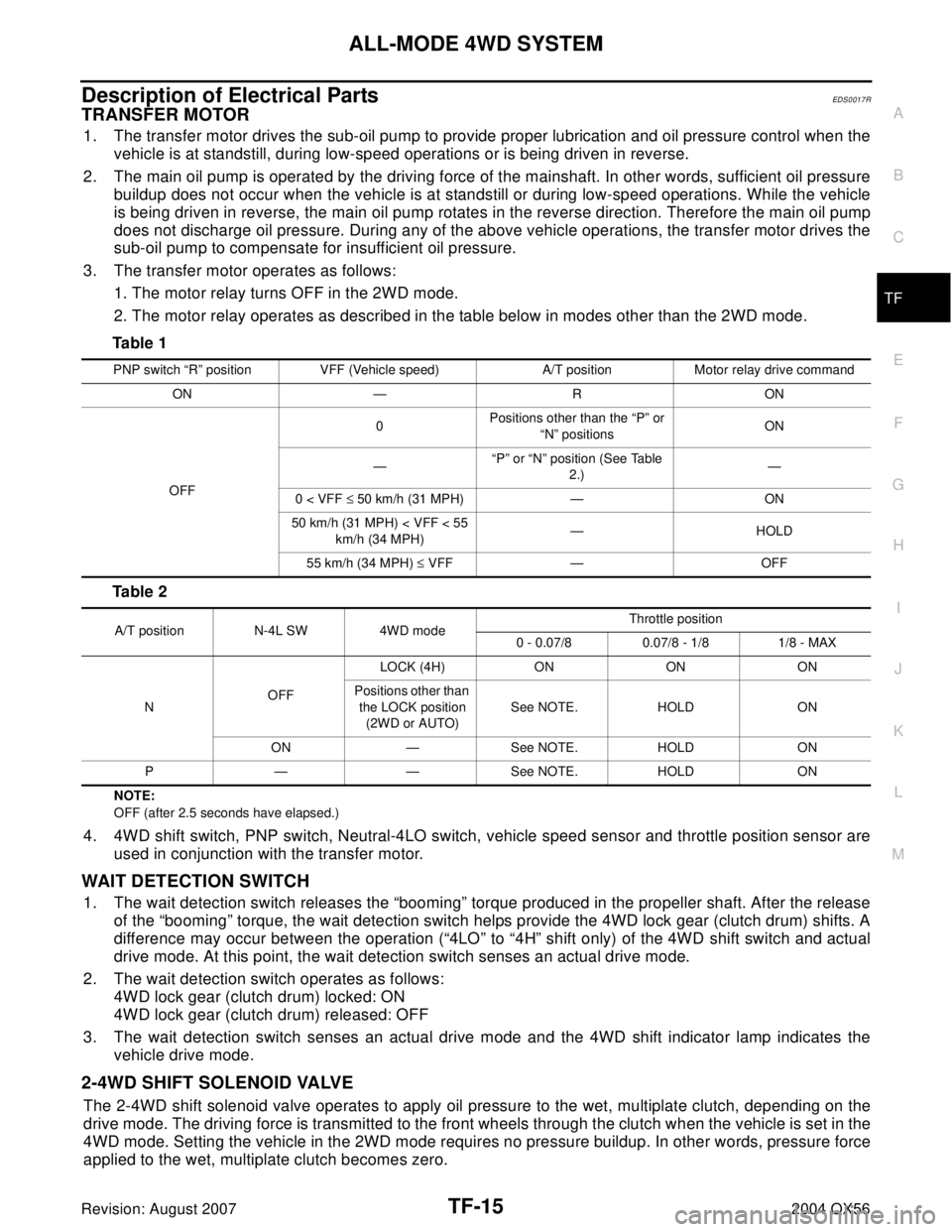

TRANSFER MOTOR

1. The transfer motor drives the sub-oil pump to provide proper lubrication and oil pressure control when the

vehicle is at standstill, during low-speed operations or is being driven in reverse.

2. The main oil pump is operated by the driving force of the mainshaft. In other words, sufficient oil pressure

buildup does not occur when the vehicle is at standstill or during low-speed operations. While the vehicle

is being driven in reverse, the main oil pump rotates in the reverse direction. Therefore the main oil pump

does not discharge oil pressure. During any of the above vehicle operations, the transfer motor drives the

sub-oil pump to compensate for insufficient oil pressure.

3. The transfer motor operates as follows:

1. The motor relay turns OFF in the 2WD mode.

2. The motor relay operates as described in the table below in modes other than the 2WD mode.

Ta b l e 1

Ta b l e 2

NOTE:

OFF (after 2.5 seconds have elapsed.)

4. 4WD shift switch, PNP switch, Neutral-4LO switch, vehicle speed sensor and throttle position sensor are

used in conjunction with the transfer motor.

WAIT DETECTION SWITCH

1. The wait detection switch releases the “booming” torque produced in the propeller shaft. After the release

of the “booming” torque, the wait detection switch helps provide the 4WD lock gear (clutch drum) shifts. A

difference may occur between the operation (“4LO” to “4H” shift only) of the 4WD shift switch and actual

drive mode. At this point, the wait detection switch senses an actual drive mode.

2. The wait detection switch operates as follows:

4WD lock gear (clutch drum) locked: ON

4WD lock gear (clutch drum) released: OFF

3. The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the

vehicle drive mode.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet, multiplate clutch, depending on the

drive mode. The driving force is transmitted to the front wheels through the clutch when the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet, multiplate clutch becomes zero.

PNP switch “R” position VFF (Vehicle speed) A/T position Motor relay drive command

ON — R ON

OFF0Positions other than the “P” or

“N” positionsON

—“P” or “N” position (See Table

2.)—

0 < VFF ≤ 50 km/h (31 MPH) — ON

50 km/h (31 MPH) < VFF < 55

km/h (34 MPH)—HOLD

55 km/h (34 MPH) ≤ VFF — OFF

A/T position N-4L SW 4WD modeThrottle position

0 - 0.07/8 0.07/8 - 1/8 1/8 - MAX

NOFFLOCK (4H) ON ON ON

Positions other than

the LOCK position

(2WD or AUTO)See NOTE. HOLD ON

ON — See NOTE. HOLD ON

P——See NOTE.HOLDON

Page 3141 of 3371

TF-16

ALL-MODE 4WD SYSTEM

Revision: August 20072004 QX56

LINE PRESSURE SWITCH

1. With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

The line pressure switch determines whether or not adequate line pressure has built up under different

operating conditions.

2. The line pressure switch turns ON when line pressure is produced.

3. The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

Page 3219 of 3371

TF-94

TROUBLE DIAGNOSES FOR SYMPTOMS

Revision: August 20072004 QX56

Symptom 9. 4WD System Does Not Operate (The Vehicle Cannot Be Put Into

4WD Mode-Hydraulic System Failure)

EDS0018M

1. CHECK INPUT SIGNAL

With CONSULT-II

1. Select “ECU INPUT SIGNALS” in Data Monitor.

2. Put A/T selector lever in D.

3. Turn 4WD shift switch to 4H and back to 2WD while reading out

ON/OFF status of "CL PRES SW".

Without CONSULT-II

Check voltage between transfer control unit harness connector E143

terminal 34 (BR) and ground.

Refer to TF-55, "

TRANSFER CONTROL UNIT INSPECTION

TABLE" .

OK or NG

OK >> 1. Check transfer fluid level.

2. Disassemble transfer unit and check the following.

–Transfer motor

–Main oil pump assembly

–Sub-oil pump assembly

–Oil strainer

–Control valve assembly

–2-4WD shift solenoid valve

–Oil filter element

–Lip seal

–Strainer O-ring

–Main oil pump drive gear

–Seal ring

–D-ring

–Clutch piston

–Clutch assembly

NG >> GO TO 2.

2. CHECK CLUTCH PRESSURE CIRCUIT

Check clutch pressure switch circuit.

Refer to TF-72, "

Diagnostic Procedure" .

OK or NG

OK >> GO TO 3.

NG >> Check, repair or replace faulty parts.

3. CHECK PROCEDURES FROM THE BEGINNING

Check again.

OK or NG

OK >> Inspection End.

NG >> Recheck each connector pin terminals for damage or loose connection.

WDIA0087E

Page 3236 of 3371

OVERHAUL

TF-111

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: August 20072004 QX56

46. Snap ring 47. Retaining pin 48. L-H fork

49. 2-4 fork 50. Shift fork spring 51. Fork guide

52. Retainer pin 53. Shift rod

1. Dust cover 2. Oil seal 3. Rear case

4. Air breather 5. Seal ring 6. Main oil pump cover

7. Inner gear 8. Outer gear 9. Main oil pump housing

10. D-ring 11. D-ring 12. Clutch piston

13. Thrust needle bearing race 14. Oil strainer 15. O-ring

16. Snap ring 17. Control valve assembly 18. Lip seal (7 pieces)

19. Washer 20. Filler plug 21. Filler stud

22. O-ring 23. Oil filter 24. ATP switch

25 Neutral-4LO switch 26. Oil pressure check plug 27. Harness bracket

28. Stem bleeder 29. Harness bracket 30. Center case

31. Mainshaft rear bearing 32. C-ring 33. Washer holder

34. Snap ring 35. Sub oil pump housing 36. Outer gear

37. Inner gear 38. Sub oil pump cover 39. O-ring

40. Transfer motor 41. Connector bracket

SDIA2091E

Page 3243 of 3371

TF-118

CENTER CASE

Revision: August 20072004 QX56

10. Tap mainshaft, using suitable tool to remove it from clutch drum

and clutch hub.

11. Remove needle bearing and spacer from the mainshaft.

12. Remove the snap ring from the clutch hub.

CLUTCH PISTON

1. Remove oil pressure check plug from oil pressure check port.

2. Apply air gradually from oil pressure check port, and remove

clutch piston from center case.

SMT914C

WDIA0101E

SDIA2 115 E

SDIA2 116 E

Page 3270 of 3371

CENTER CASE

TF-145

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: August 20072004 QX56

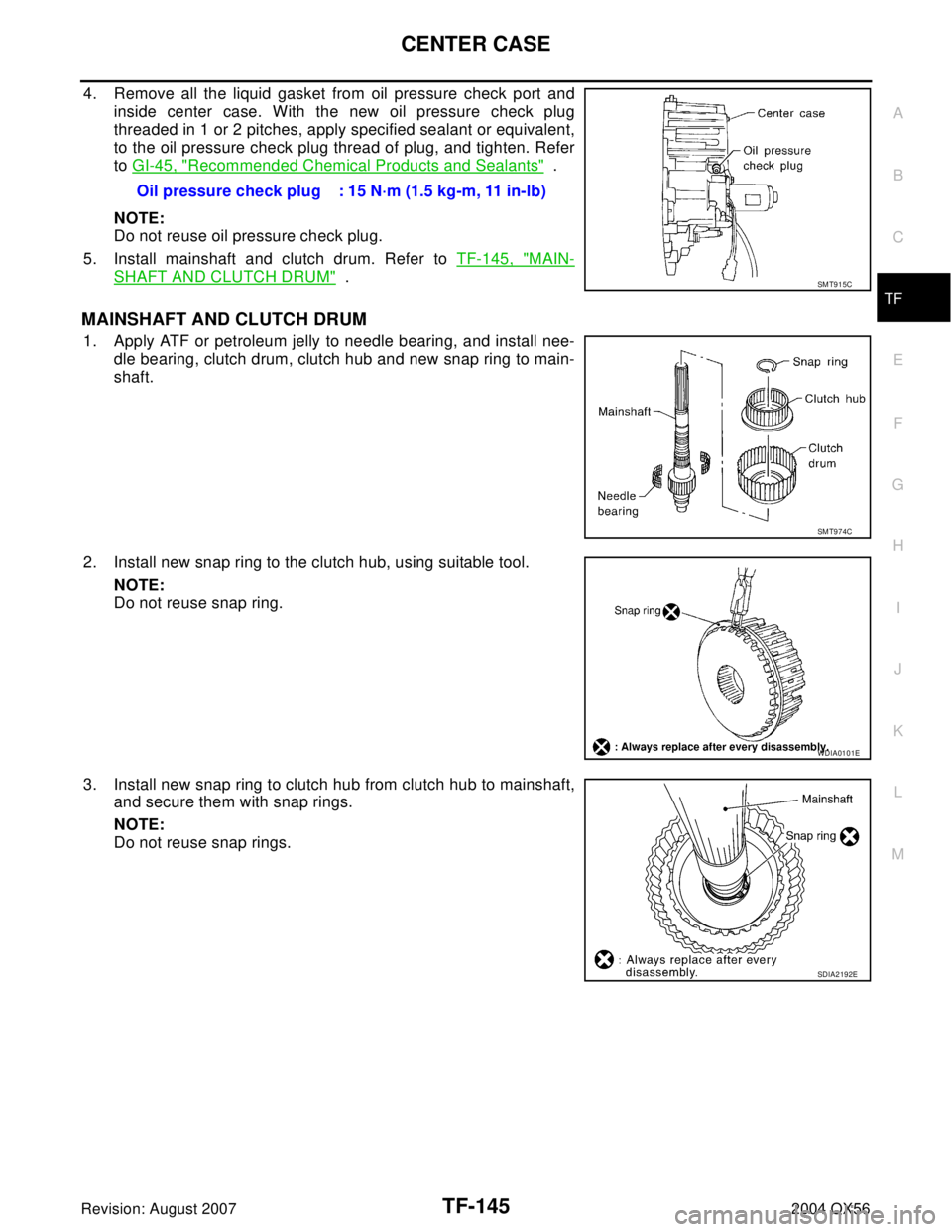

4. Remove all the liquid gasket from oil pressure check port and

inside center case. With the new oil pressure check plug

threaded in 1 or 2 pitches, apply specified sealant or equivalent,

to the oil pressure check plug thread of plug, and tighten. Refer

to GI-45, "

Recommended Chemical Products and Sealants" .

NOTE:

Do not reuse oil pressure check plug.

5. Install mainshaft and clutch drum. Refer to TF-145, "

MAIN-

SHAFT AND CLUTCH DRUM" .

MAINSHAFT AND CLUTCH DRUM

1. Apply ATF or petroleum jelly to needle bearing, and install nee-

dle bearing, clutch drum, clutch hub and new snap ring to main-

shaft.

2. Install new snap ring to the clutch hub, using suitable tool.

NOTE:

Do not reuse snap ring.

3. Install new snap ring to clutch hub from clutch hub to mainshaft,

and secure them with snap rings.

NOTE:

Do not reuse snap rings.Oil pressure check plug : 15 N·m (1.5 kg-m, 11 in-lb)

SMT915C

SMT974C

WDIA0101E

SDIA2192E