window INFINITI QX56 2008 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2201 of 4083

FRONT DOOR GLASS AND REGULATORGW-11

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

• Removal and installation of the power window motor from the regulator.

• Installation of a new glass window.

• Installation of a new glass run.

Check the label on the power window motor for the part number. If the power window motor part number

matches one of the following, the limit switch must be reset using the "INSTALLATION WITHOUT RESET

SWITCH" procedure.

• 80730-ZT01A

• 80731-ZT01A

• 80730-ZM70B

• 80731-ZM70B

If the power window motor part number does not match one of the part numbers above, the limit switch must

be reset using the "INSTALLATION WITH RESET SWITCH" procedure.

NOTE:

Some of the power window motors with the part num bers above may appear to have a reset switch, but it will

not reset the limit switch.

INSTALLATION WITHOUT RESET SWITCH - (Motors listed above)

Check the label on the power window motor for the pa rt number. If the power window motor part number does

not match one of the above, use the "INS TALLATION WITH RESET SWITCH" procedure.

NOTE:

Some of the power window motors may appear to have a re set switch, but it will not reset the limit switch.

1. Connect the door harness connector to the power window motor, and rotate the motor more than 5 turns

in the glass raising (up) direction.

2. Install the power window motor onto the regulator.

3. Install the regulator assembly into the door and secure regulator assembly with the nuts and bolt.

4. Install the glass into the door and align with the regulator, then install the glass bolts.

5. Raise the glass to the top position. CAUTION:

Do not operate the glass automatical ly to raise the glass to the top.

6. Reposition the vapor barrier.

7. Install the front door finisher panel. Refer to INT-11, "

Removal and Installation".

INSTALLATION WITH RESET SWITCH - (Motors not listed above)

1. Install the power window motor onto the regulator.

2. Install the regulator assembly into the door and secure regulator assembly with the nuts and bolt.

3. Connect the door harness connector to the power window motor.

4. Install the glass into the door and align with the regulator, then install the glass bolts.

Power Window Motor Up Direction

• LH motor rotate counterclockwise

• RH motor rotate clockwise

Regulator assembly nuts

and bolt : 7.5 N·m (0.77 kg-m, 66 in-lb)

Glass bolts : 6.1 N·m (0.62 kg-m, 54 in-lb)

Regulator assembly nuts

and bolt : 7.5 N·m (0.77 kg-m, 66 in-lb)

Glass bolts : 6.1 N·m (0.62 kg-m, 54 in-lb)

Revision: March 2010 2008 QX56

Page 2203 of 4083

REAR DOOR GLASS AND REGULATORGW-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

REAR DOOR GLASS AND REGULATOR

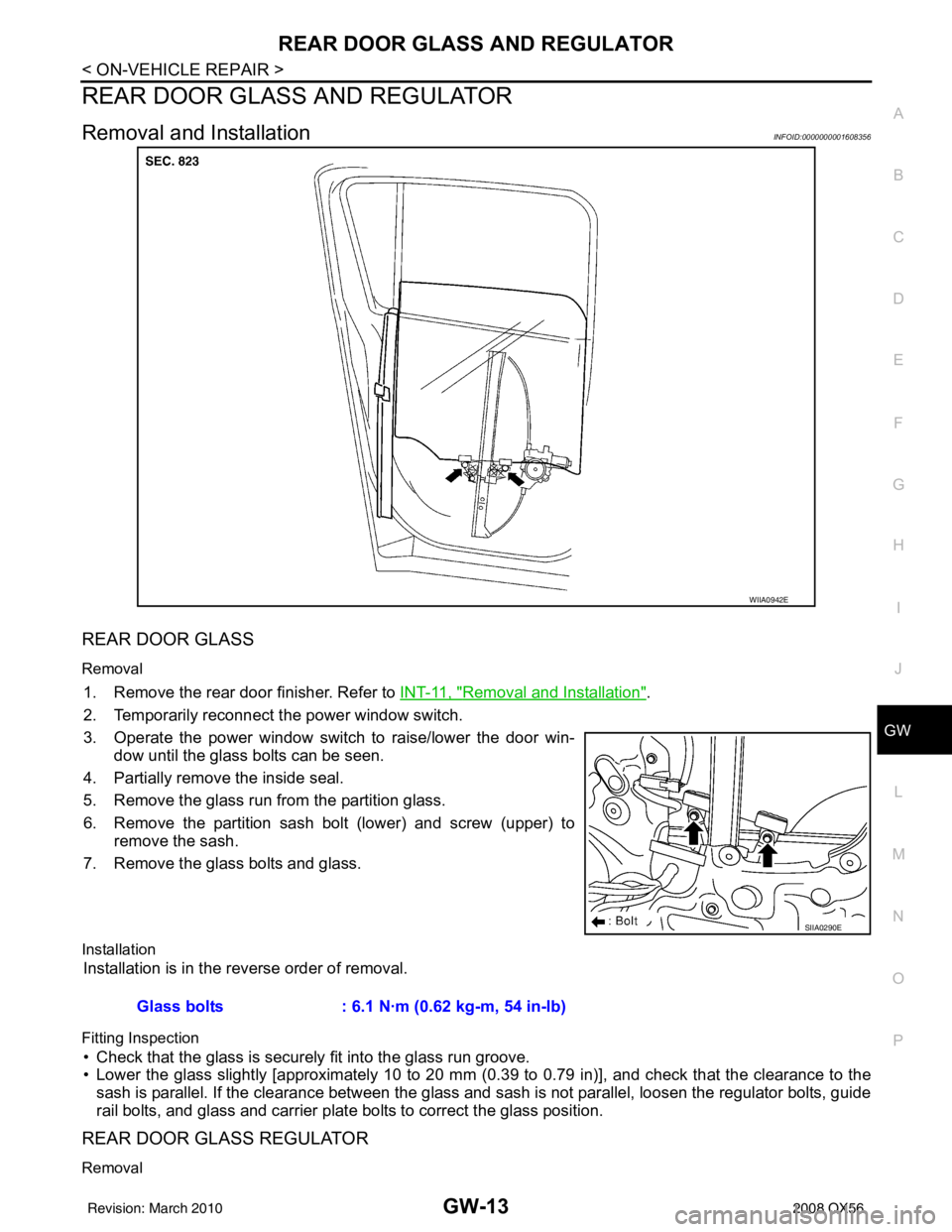

Removal and InstallationINFOID:0000000001608356

REAR DOOR GLASS

Removal

1. Remove the rear door finisher. Refer to INT-11, "Removal and Installation".

2. Temporarily reconnect the power window switch.

3. Operate the power window switch to raise/lower the door win- dow until the glass bolts can be seen.

4. Partially remove the inside seal.

5. Remove the glass run from the partition glass.

6. Remove the partition sash bolt (lower) and screw (upper) to remove the sash.

7. Remove the glass bolts and glass.

Installation

Installation is in the reverse order of removal.

Fitting Inspection

• Check that the glass is securely fit into the glass run groove.

• Lower the glass slightly [approximately 10 to 20 mm (0 .39 to 0.79 in)], and check that the clearance to the

sash is parallel. If the clearance between the glass and sash is not parallel, loosen the regulator bolts, guide

rail bolts, and glass and carrier plate bolts to correct the glass position.

REAR DOOR GLASS REGULATOR

Removal

WIIA0942E

SIIA0290E

Glass bolts : 6.1 N·m (0.62 kg-m, 54 in-lb)

Revision: March 2010 2008 QX56

Page 2204 of 4083

GW-14

< ON-VEHICLE REPAIR >

REAR DOOR GLASS AND REGULATOR

1. Remove the rear door finisher. Refer to INT-11, "Removal and Installation".

2. Temporarily reconnect the power window switch.

3. Operate the power window switch to raise/lower the door win- dow until the glass bolts can be seen.

4. Partially remove the inside seal.

5. Remove the glass bolts.

6. Raise the glass and hold in place with suitable tool.

7. Remove the bolts, and the regulator and guide channel.

8. Disconnect the connector from the regulator assembly.

Inspection after removal

Check the regulator assembly for the following items. If a malfunction is detected, replace or grease it.

• Gear wear

• Regulator deformation

• Spring damage

• Grease condition for each sliding part

Installation

1. Connect the harness connector to the regulator assembly and

install the regulator and guide channel.

2. Install the glass from outside to ensure that it is in both the front and rear glass channels. Tighten glass bolts to the specified

torque.

3. Install the inside seal.

4. Install the rear door finisher. Refer to INT-11, "

Removal and

Installation".

SIIA0290E

SIIA0291E

SIIA0291E

Glass bolts: 6.1 N·m (0.62 kg-m, 54 in-lb)

SIIA0290E

Revision: March 2010 2008 QX56

Page 2205 of 4083

SIDE WINDOW GLASSGW-15

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

SIDE WINDOW GLASS

Removal and InstallationINFOID:0000000001608359

REMOVAL

1. Remove the rear lower and upper finisher. Refer to INT-19, "Removal and Installation".

2. Disconnect the rear side window motor harness.

3. Remove the rear side window motor mounting bolts.

4. Remove the rear side window front mounting nuts.

INSTALLATION

1. Install the glass from outside to insure that it is even with the top and bottom of the opening. Tighten rear side window front mounting nuts to the specified torque.

2. Install rear side window motor mounting bolts. Tighten rear side window latch mounting bolts to the speci-

fied torque.

3. Connect the rear side window motor harness.

4. Install rear pillar upper and lower finisher. Refer to INT-19, "

Removal and Installation".

1. Rear side window glass2. Rear side window motor3. Weatherstrip

4. Inner panel 5. Outer panel

LIIA0965E

Glass mounting nuts : 4.2 N·m (0.43 kg-m, 37 in-lb)

Motor mounting bolts : 5.6 N·m (0.57 kg-m, 49 in-lb)

Revision: March 2010 2008 QX56

Page 2229 of 4083

HA-24

< ON-VEHICLE MAINTENANCE >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

Checking of Refrigerant LeaksINFOID:0000000001516646

PRELIMINARY CHECK

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage, and corrosion. Any A/C oil leakage may indicate an area of refrigerant leakage. Allow extra

inspection time in these areas when using either an el ectronic refrigerant leak detector (J-41995) or fluores-

cent dye leak detector (J-42220).

If any dye is observed using a fluorescent dye leak detector (J-42220), confirm the leak using a electronic

refrigerant leak detector (J-41995). It is possible that the dye is from a prior leak that was repaired and not

properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic refrigerant leak detector (J-41995), move the probe

along the suspected leak area at 25 - 50 mm (1 - 2 in) per second and no further than 6 mm (1/4 in) from the

component.

CAUTION:

Moving the electronic refrigerant l eak detector probe slower and closer to the suspected leak area will

improve the chances of finding a leak.

Checking System for L eaks Using the Fluorescent Dye Leak DetectorINFOID:0000000001516647

1. Check the A/C system for leaks using the fluorescent dye leak detector and safety goggles (J-42220) in a

low sunlight area (area without windows preferable). Il luminate all components, fittings and lines. The dye

will appear as a bright green/yellow area at the point of leakage. Fluorescent dye observed at the evapo-

rator drain opening indicates an evaporator core asse mbly leak (tubes, core or expansion valve).

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or cloth, then inspect the shop rag or cloth with the fl uorescent dye leak detector (J-42220) for dye residue.

3. After the leak is repaired, remove any residual dye using refrigerant dye cleaner (J-43872) to prevent

future misdiagnosis.

4. Perform a system performance check and then verify t he leak repair using a electronic refrigerant leak

detector (J-41995).

NOTE:

• Other gases in the work area or substances on the A/C components, for example, anti-freeze, wind-

shield washer fluid, solvents and oils, may falsely tri gger the leak detector. Make sure the surfaces to be

checked are clean.

• Clean with a dry cloth or blow off with shop air.

• Do not allow the sensor tip of the electronic refri gerant leak detector (J-41995) to contact with any sub-

stance. This can also cause false readings and may damage the detector.

Dye InjectionINFOID:0000000001516648

NOTE:

This procedure is only necessary when recharging the system or when the compressor has seized and must

be replaced.

1. Check the A/C system static (at rest) pressure . Pressure must be at least 345 kPa (3.52 kg/cm

2 , 50 psi).

2. Pour one bottle 7.4 cc (1/4 ounce) of the HFC-134a (R -134a) fluorescent leak detection dye (J-41447) into

the HFC-134a (R-134a) dye injector (J-41459).

CAUTION:

If repairing the A/C system or replacing a co mponent, pour the HFC-134a (R-134a) fluorescent leak

detection dye (J-41447) directly into the open system connection and proceed with the service

procedures.

3. Connect the refrigerant dye injector (J-41459) to the low-pressure service valve.

4. Start the engine and switch the A/C system ON.

5. When the A/C system is operating (compressor running), inject one bottle 7.4 cc (1/4 ounce) of HFC-134a (R-134a) fluorescent leak detection dye (J-41447) through the low-pressure service valve using HFC-

134a (R-134a) dye injector (J-41459). Refer to the manufacturer's operating instructions.

Revision: March 2010 2008 QX56

Page 2266 of 4083

![INFINITI QX56 2008 Factory Owners Manual AUTOMATIC AIR CONDITIONER SYSTEMHAC-13

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

A/C auto amp.

DISPLAY SCREEN

Displays the operational st atus of the system. INFINITI QX56 2008 Factory Owners Manual AUTOMATIC AIR CONDITIONER SYSTEMHAC-13

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

A/C auto amp.

DISPLAY SCREEN

Displays the operational st atus of the system.](/img/42/57030/w960_57030-2265.png)

AUTOMATIC AIR CONDITIONER SYSTEMHAC-13

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

A/C auto amp.

DISPLAY SCREEN

Displays the operational st atus of the system.

AUTO SWITCH

• The compressor, intake door, air mix doors, outlet doors and blower speed are automatically controlled so

that the in-vehicle temperature will reach, and be mainta ined at the set temperature selected by the operator.

• When pressing AUTO switch, air inlet, air outlet, blower speed, and discharge air temperature are automati- cally controlled.

TEMPERATURE CONTROL DIAL (DRIVER)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (PASSENGER)

Increases or decreases the set temperature.

RECIRCULATION ( ) SWITCH

• When REC switch is ON, REC switch indicator turns ON, and air inlet is set to REC.

• When REC switch is turned OFF, or when compressor is turned from ON to OFF, REC switch is automati-

cally turned OFF. REC mode can be re-entered by pressing REC switch again.

• REC switch is not operated when DEF switch is tur ned ON, at the D/F position, or in floor position.

DEFROSTER ( ) SWITCH

Positions the air outlet doors to the defrost position. Also positions the intake doors to the outside air position,

and turns A/C compressor ON.

REAR WINDOW DEFOGGER SWITCH

When switch is ON, rear window and door mirrors are defogged.

OFF SWITCH

The compressor and blower are OFF, the intake doors are set to the outside air position, and the air outlet

doors are set to the foot (75% foot and 25% defrost) position.

A/C SWITCH

The compressor is ON or OFF.

(Pressing the A/C switch when the AUTO switch is ON will turn off the A/C switch and compressor.)

MODE SWITCH

Controls the air discharge outlets.

FRONT BLOWER CONTROL SWITCHES

Manually control the blower speed.

AWIIA0081ZZ

Revision: March 2010 2008 QX56

Page 2366 of 4083

![INFINITI QX56 2008 Factory Owners Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Performance ChartINFOID:0000000001679832

TEST CONDITION

Testing must be performed as fol INFINITI QX56 2008 Factory Owners Manual INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Performance ChartINFOID:0000000001679832

TEST CONDITION

Testing must be performed as fol](/img/42/57030/w960_57030-2365.png)

INSUFFICIENT COOLINGHAC-113

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Performance ChartINFOID:0000000001679832

TEST CONDITION

Testing must be performed as follows:

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Recirculation (REC) switch (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

9.9 - 13.9 (50 - 57)

25 (77) 14.6 - 18.6 (58 - 65)

30 (86) 16.8 - 21.8 (62 - 71)

35 (95) 21.1 - 27.1 (70 - 81)

40 (104) 25.3 - 31.5 (78 - 89)

60 - 70 20 (68)

11.4 - 15.2 (53 - 59)

25 (77) 15.5 - 20.0 (60 - 68)

30 (86) 19.9 - 25.0 (68 - 77)

35 (95) 24.5 - 29.6 (76 - 85)

40 (104) 28.7 - 34.9 (84 - 95)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2 , psi) Low-pressure (Suction side)

kPa (kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

1020 - 1250

(10.4 - 12.7, 147.9 - 181.3) 160 - 190

(1.63 - 1.94, 23.2 - 27.6)

25 (77) 1236 - 1510

(12.6 - 15.4, 179.2 - 219) 206 - 245

(2.1 - 2.5, 29.9 - 35.6)

30 (86) 1569 - 1,922

(16.0 - 19.6, 227.6 - 278.8) 265 - 324

(2.7 - 3.3, 38.4 - 46.9)

35 (95) 1,697 - 2079

(17.3 - 21.2, 246.1 - 301.5) 304 - 363

(3.1 - 3.7, 44.1 - 52.6)

40 (104) 1971 - 2403

(20.1 - 24.5, 285.9 - 348.5) 373 - 451

(3.8 - 4.6, 54.0 - 65.4)

Revision: March 2010 2008 QX56

Page 2389 of 4083

INL-6

< FUNCTION DIAGNOSIS >

INTERIOR ROOM LAMP CONTROL SYSTEM

FUNCTION DIAGNOSIS

INTERIOR ROOM LAMP CONTROL SYSTEM

System DiagramINFOID:0000000001601375

System DescriptionINFOID:0000000001601376

OUTLINE

• Interior room lamps* are controlled by the interior room lamp timer control function of the BCM.

*Front room/map lamps, personal lamp 2nd row, personal lamp 3rd row (when lamp switch is in DOOR posi-

tion) and puddle lamps.

• Cargo lamp is controlled by the cargo lamp control function of the BCM.

• Step lamps* are controlled by the step lamp control function of the BCM. *Front step lamps, rear step lamps and foot lamps.

The timer control functions of the BCM activate based on inputs from the remote keyless entry receiver, the

key cylinder lock/unlock switch, the door switc hes or the key switch and ignition knob switch.

ROOM LAMP TIMER OPERATION

When the interior room lamp switch is in the DOOR position and when all conditions below are met, the BCM

begins timer control (maximum 30 seconds) for interior room lamp ON/OFF.

• When the front door LH is unlocked [with Intelligent Key, main power window and door lock/unlock switch, or

front door lock assembly (key cylinder switch)].

• When a door opens → closes and the Intelligent Key is not inserted in the ignition switch.

Timer control is cancelled under the following conditions.

• When the front door LH is locked [with Intelligent Key, main power window and door lock/unlock switch, or

front door lock assembly (key cylinder switch)].

• A door is opened (door switch turns ON).

• Ignition switch is turned ON.

Interior lamp operational settings can be c hanged with the function setting of CONSULT-III.

AWLIA0965GB

Revision: March 2010 2008 QX56

Page 2390 of 4083

INTERIOR ROOM LAMP CONTROL SYSTEMINL-7

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

INTERIOR LAMP BATTERY SAVER CONTROL

If an interior lamp is left ON and does not turn OFF even when the doors are closed, the BCM turns off power

to the interior lamps automatically to save the batte ry 30 minutes after the ignition switch is turned OFF.

The BCM controls power and ground to all interior lamps.

After the battery saver system turns the la mps OFF, the lamps will illuminate again when

• a signal is received from an Intelligent Key or main power window and door lock/unlock switch, or when the

front door LH lock assembly (key cylinder switch) is locked or unlocked

• a door is opened or closed

• the Intelligent Key is removed from or inserted into the ignition switch.

The Interior lamp battery saver control time peri od can be changed with the function setting of CONSULT-III.

Component Parts LocationINFOID:0000000001601377

1. BCM M18, M19, M20 (view with instru-

ment lower panel LH removed) 2. Key switch and ignition knob switch

M12 3. Front door switch LH B8

Front door switch RH B108

4. Rear door switch LH B18 Rear door switch RH B116 5. Glass hatch ajar switch D707 6. Back door latch (door ajar switch)

D503

7. Front room/map lamp assembly R102 8. Vanity lamp LH R3 Vanity lamp RH R89. Door mirror (puddle lamp) LH D4

Door mirror (puddle lamp) RH D107

10. Ignition keyhole illumination M150 11. Foot lamp LH M99 Foot lamp RH M10012. Front step lamp LH D11

Front step lamp RH D109

AWLIA1062ZZ

Revision: March 2010 2008 QX56

Page 2391 of 4083

INL-8

< FUNCTION DIAGNOSIS >

INTERIOR ROOM LAMP CONTROL SYSTEM

Component Description

INFOID:0000000001601378

13. Rear step lamp LH D206 Rear step lamp RH D306 14. Cargo lamp B153 15. Personal lamp 3rd row R205

16. Personal lamp 2nd row R203

Part name Description

BCM Provides power and ground and controls timer functions for the

interior room lamps, step lamps and cargo lamp.

Key switch and ignition knob switch Provides key in ignition status to the BCM.

Door switches Provides door OPEN/CLOSED status to the BCM.

Glass hatch switch Provides glass hatch OPEN/CLOSED status to the BCM.

Back door latch Provides back door OPEN/CLOSED status to the BCM.

Power window and door lock/unlock switch RH Provides door lock/unlock position switch RH status to the BCM.

Main power window and door lock/unlock switch [front door lock

assembly LH (key cylinder switch)]. Provides door lock/unlock position switch LH status to the BCM.

Revision: March 2010

2008 QX56