battery volt INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3345 of 4083

SN-20

< COMPONENT DIAGNOSIS >

SONAR SYSTEM OFF SWITCH CIRCUIT INSPECTION

3. Check continuity between sonar control unit harness connector(A) and sonar system OFF switch harness connector (B).

4. Check continuity between sonar system OFF switch harness connector and ground.

Are the inspection results normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000004832353

SONAR SYSTEM OFF SWITCH

1. Disconnect the sonar system OFF switch connector.

2. Check continuity between the following switch terminals.

SONAR SYSTEM OFF INDICATOR

1. Disconnect the sonar system OFF switch connector.

2. Apply battery voltage to switch terminal 5.

3. Check the sonar system OFF indicator operation when switch terminal 6 is connected to battery ground.

Connector Terminal Connector Terminal Continuity

B56 (A) 5

M116 (B) 5

Ye s

11 1

AWNIA1881ZZ

ConnectorTerminalContinuity

M116 1, 5

Ground No

2, 6 Yes

ALNIA1088ZZ

Sonar system OFF switch Terminals Continuity

Depressed 1 - 2Ye s

Released No

AWNIA0181ZZ

Terminals Condition Operation

Sonar system

OFF switch 5

Battery voltage

Indicator ON

6G ro u nd

AWNIA0182ZZ

Revision: March 2010 2008 QX56

Page 3346 of 4083

SN

SONAR CONTROL UNIT FOR REAR SONAR SYSTEMSN-21

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

SONAR CONTROL UNIT FO R REAR SONAR SYSTEM

Reference ValueINFOID:0000000001754070

SONAR CONTROL UNIT TERMINAL LAYOUT

TERMINALS AND REFERENCE VA LUES FOR SONAR CONTROL UNIT

WKIA5222E

Te r m i n a l

(wire color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

3 (R) Sonar buzzer return ON —0 - 12 (variable)

4 (BR/Y) Sonar system OFF

indicator output ON

Sonar system OFF

switch ON

0

OFF Battery voltage

5 (G/W) Reverse signal ONTransmission gear se-

lector lever

R position

Battery voltage

Transmission gear se-

lector lever Not R position

0

6 (B) Sonar control unit

ground ——

0

7 (L) Sonar buzzer drive

signal

ON

— Battery voltage

8 (G/R) Sonar control unit

power ON

— Battery voltage

9 (GR) Rear sonar sensor

signal - RH outer

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

10 (P) Rear sonar sensor

signal - LH outer

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

11 ( O ) Rear sonar sensor

signal - LH inner

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

12 (LG) Rear sonar sensor

signal - RH inner

ON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

13 (LG) Sonar system OFF

switch signal

ONSonar system OFF

switch ON

0

OFF Battery voltage

Revision: March 2010 2008 QX56

Page 3347 of 4083

SN-22

< ECU DIAGNOSIS >

SONAR CONTROL UNIT FOR REAR SONAR SYSTEM

15 (Y)Rear sonar sensor

ground

ON

— 0

16 (LG/B) Rear sonar sensor

power ON Ignition switch ON

Battery voltage

Te r m i n a l

(wire color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

Revision: March 2010

2008 QX56

Page 3356 of 4083

SN

SONAR CONTROL UNIT FOR FRONT AND REAR SONAR SYSTEMSN-31

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

SONAR CONTROL UNIT FOR FR ONT AND REAR SONAR SYSTEM

Reference ValueINFOID:0000000001754073

SONAR CONTROL UNIT HARNESS TERMINAL LAYOUT

TERMINALS AND REFERENCE VA LUES FOR SONAR CONTROL UNIT

ALNIA0395ZZ

Te r m i n a l

(color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

1 (G/R) Sonar control unit

power ON

— Battery voltage

2 (L) Sonar buzzer drive

signal

ON Object sensed

Battery voltage

3 (G/W) Reverse signal ONTransmission gear selector lever in R posi-

tion

Battery voltage

Transmission gear selector lever not in R

position 0

4 (B) Sonar control unit

ground ——

—

5 (BR/Y) Sonar system OFF

indicator output ON

Sonar system OFF

switch ON

0

OFF Battery voltage

6 (R) Rear sonar buzzer

return

ON

— 0 - 12 (variable)

8 (G/W) K-line ON— —

9 (LG/B) Rear sonar sensor

power ON Ignition switch ON

Battery voltage

11 ( L G ) Sonar system OFF

switch signal

ONSonar system OFF

switch ON

0

OFF Battery voltage

12 (Y) Rear sonar sensor

ground ON

— —

13 (LG) Rear sonar sensor

signal - RH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

14 (O) Rear sonar sensor

signal - LH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• Distance obstacles Battery voltage

15 (P) Rear sonar sensor

signal - LH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

Revision: March 2010

2008 QX56

Page 3357 of 4083

SN-32

< ECU DIAGNOSIS >

SONAR CONTROL UNIT FOR FRONT AND REAR SONAR SYSTEM

16 (GR)Rear sonar sensor

signal - RH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstacles Battery voltage

17 (LG/B) Front sonar sensor

power

ON Ignition switch ON

Battery voltage

18 (GR/R) Park position signal ON Vehicle in PARK 12

19 (GR) Front sonar sensor

signal - RH outer ON• Sonar system OFF switch ON

• Transmission gear selector lever in a for-

ward drive gear

• Distance obstacles Battery voltage

20 (LG) Front sonar sensor

signal - RH inner ON• Sonar system OFF switch ON

• Transmission gear selector lever in re-

verse or a forward drive gear

• No obstacles Battery voltage

21 (W/R) Vehicle speed signal ON Speedometer operated

[When vehicle speed is approx. 40 km/h (25

MPH)]NOTE:

Maximum voltage may be 12V due

to specifications (connected units).

23 (R) Front sonar buzzer

return ON

— 0 - 12 (variable)

24 (P) Front sonar sensor

signal - LH outer

ON• Sonar system OFF switch ON

• Transmission gear selector lever in re-

verse or a forward drive gear

• No obstacles Battery voltage

25 (O) Front sonar sensor

signal - LH inner

ON• Sonar system OFF switch ON

• Transmission gear selector lever in a for-

ward drive gear

• Distance obstacles Battery voltage

26 (Y) Front sonar sensor

ground ON

— —

Te r m i n a l

(color) Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation

PKIC0643E

Revision: March 2010

2008 QX56

Page 3530 of 4083

STR-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION STR

A

STR

N

O P

CONTENTS

STARTING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

DIAGNOSIS AND REPAIR WORKFLOW ..... .....5

Work Flow ........................................................... ......5

FUNCTION DIAGNOSIS ...............................8

STARTING SYSTEM ...................................... .....8

System Diagram .................................................. ......8

System Description ...................................................8

Component Parts Location ........................................8

Component Description ............................................9

COMPONENT DIAGNOSIS .........................10

B TERMINAL CIRCUIT .....................................10

Description ........................................................... ....10

Diagnosis Procedure ...............................................10

S CONNECTOR CIRCUIT .................................11

Description ...............................................................11

Diagnosis Procedure ...............................................11

STARTING SYSTEM .........................................12

Wiring Diagram .................................................... ....12

SYMPTOM DIAGNOSIS ..............................16

STARTING SYSTEM .........................................16

Symptom Table ................................................... ....16

ON-VEHICLE REPAIR .................................17

STARTER MOTOR ...........................................17

Removal and Installation ..................................... ....17

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

18

STARTER MOTOR ...........................................18

Starter .................................................................. ....18

Revision: March 2010 2008 QX56

Page 3532 of 4083

PRECAUTIONSSTR-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Power Generation Variable Voltage Control SystemINFOID:0000000001538874

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge m ay occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: March 2010 2008 QX56

Page 3535 of 4083

STR-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the starting system test with Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CRANKING VOLTAGE NORMAL>>GO TO 2

CRANKING VOLTAGE LOW>>GO TO 5

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Refer to Technical Service Bulletin.

REPLACE BATTERY>>Before replacing battery, clean t he battery cable clamps and battery posts. Perform

battery test again. Refer to Technical Service Bulletin. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates properly.

Does the engine crank normally?

YES >> GO TO 3

NO >> GO TO 4

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. Inspection end.

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer to EM and EC sections. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specification.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Is the voltage less than the specified value?

YES >> GO TO 7

NO >> GO TO 6

6.STARTER OPERATION

Check the starter operation.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. Inspection end.

NO >> GO TO 7

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-10, "

Diagnosis Procedure".

Is

“B” terminal circuit normal?

Engine coolant temperature [ °C ( °F)] Voltage [V]

− 30 to − 20 (−22 to − 4) 8.6

− 19 to −10 ( −2 to 14) 9.1

− 9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Revision: March 2010 2008 QX56

Page 3539 of 4083

STR-10

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001696228

Terminal "2" (B) is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000001696229

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL 2 POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal 2 connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal 2

and ground.

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift the transmission into park or neutral.

2. Check voltage between battery positive terminal and starter motor connector F27 terminal 2 while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter motor for high resistance.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> Terminal 2 circuit is OK. Further inspection necessary. Refer to STR-5, "

Work Flow".

NO >> Check the starter motor case to engine mounting for

high resistance.

(+) (-) Voltage

Connector Terminal

F27 2 Ground Battery voltage

AWBIA0122GB

(-) (+) Condition Voltage

Connector Terminal

F27 2 Battery (+)

terminal While cranking the

engine Less than 0.2V

AWBIA0123GB

(+)

(-)Condition Voltage

Starter motor case Battery (-) terminal While cranking the

engine Less than 0.2V

AWBIA0124GB

Revision: March 2010

2008 QX56

Page 3540 of 4083

S CONNECTOR CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000001696230

Terminal "1" (S) is the power supply for the starter mo

tor magnetic switch. Terminal 1 is supplied with power

when the ignition switch is turned to the START position while the selector lever is in the P or N position.

Diagnosis ProcedureINFOID:0000000001696231

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

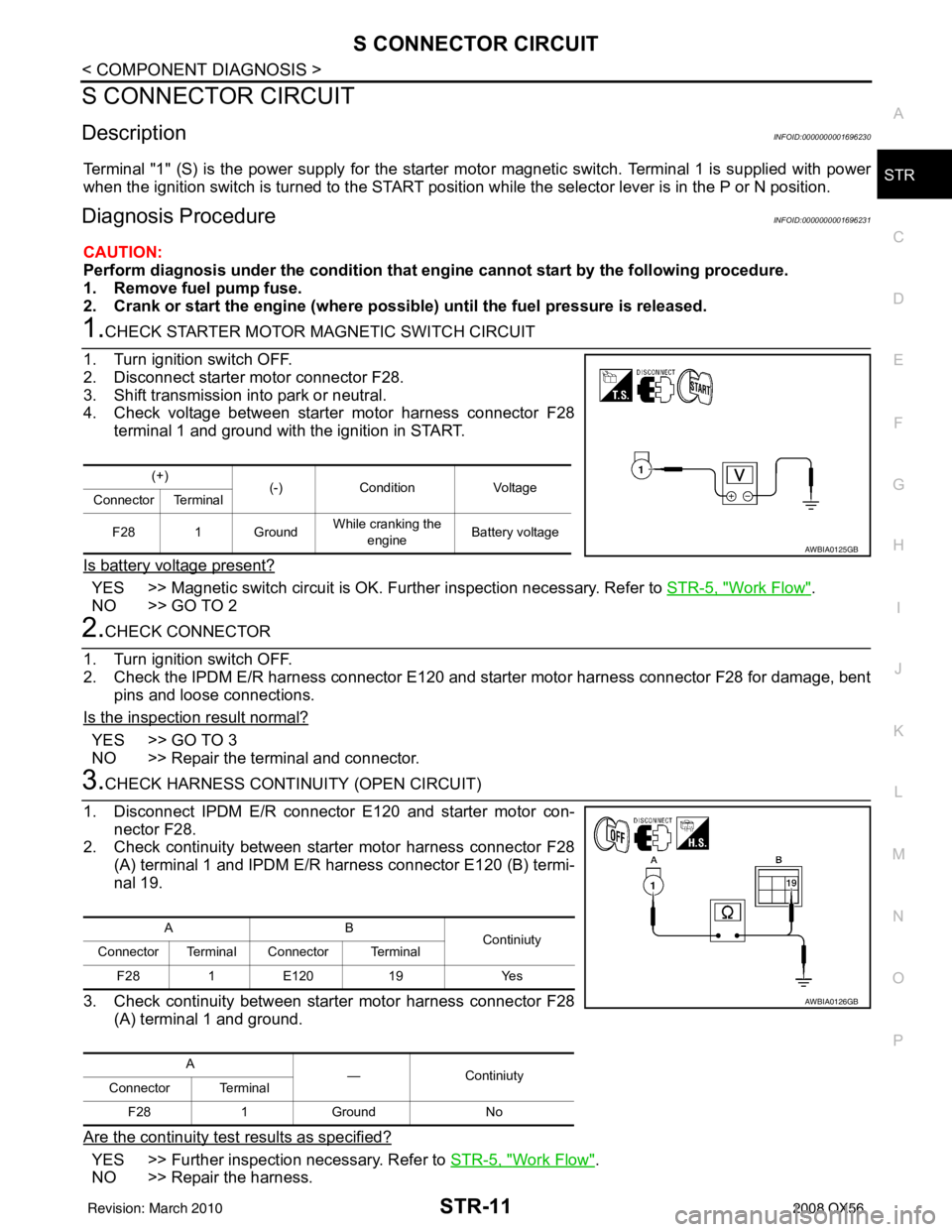

1.CHECK STARTER MOTOR MAGNETIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift transmission into park or neutral.

4. Check voltage between starter motor harness connector F28 terminal 1 and ground with the ignition in START.

Is battery voltage present?

YES >> Magnetic switch circuit is OK. Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> GO TO 2

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the IPDM E/R harness connector E120 and starter motor harness connector F28 for damage, bent pins and loose connections.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector E120 and starter motor con- nector F28.

2. Check continuity between starter motor harness connector F28 (A) terminal 1 and IPDM E/R harness connector E120 (B) termi-

nal 19.

3. Check continuity between starter motor harness connector F28 (A) terminal 1 and ground.

Are the continuity test results as specified?

YES >> Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> Repair the harness.

(+) (-)Condition Voltage

Connector Terminal

F28 1 Ground While cranking the

engine Battery voltage

AWBIA0125GB

AB

Continiuty

Connector Terminal Connector Terminal

F28 1E120 19 Yes

A —Continiuty

Connector Terminal

F28 1Ground No

AWBIA0126GB

Revision: March 2010 2008 QX56