key INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3531 of 4083

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857581

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004857584

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 3553 of 4083

TM-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is detected.

• Record DTC.

• Erase DTC. Refer to TM-30, "

OBD-II Diagnostic Trouble Code (DTC)".

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

4.PERFORM DIAGNOSTIC PROCEDURE

Perform “Diagnosis Procedure” for the displayed DTC.

>> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform “DTC CONFIRMATION PROCEDURE”.

Is DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

6.CHECK SYMPTOM 2

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 7.

NO >> INSPECTION END

7.ROAD TEST

Perform “ROAD TEST”. Refer to TM-189, "

Description".

>> GO TO 8.

8.CHECK SYMPTOM 3

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 2.

NO >> INSPECTION END

Diagnostic Work SheetINFOID:0000000001603986

INFORMATION FROM CUSTOMER

KEY POINTS• WHAT ..... Vehicle and A/T model

• WHEN ..... Date, Frequencies

• WHERE ..... Road conditions

• HOW ..... Operating conditions, Symptoms

Customer name MR/MS Model and Year VIN

Trans. Model EngineMileage

Malfunction Date Manuf. DateIn Service Date

Frequency �† Continuous �† Intermittent ( times a day)

Revision: March 2010 2008 QX56

Page 3576 of 4083

A/T SHIFT LOCK SYSTEMTM-29

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

A/T SHIFT LOCK SYSTEM

System DescriptionINFOID:0000000001696150

• The selector lever cannot be shifted from “P” (Park) unless the brake pedal is applied and the ignition knob switch is turned to the “ON” position.

• The ignition knob switch cannot be returned to the “OFF” position unless the selector lever is placed in “P”

(Park).

• The shift lock mechanism is controlled by t he ON-OFF operation of the shift lock solenoid.

• The key switch and ignition knob switch lock mechanism is controlled by the ON-OFF operation of the key

lock solenoid.

Component Parts LocationINFOID:0000000001696151

1. Emergency lever 2. Key lock solenoid3. Ignition knob switch

4. Shift lock control unit 5. Shift lock solenoid6. Detent switch

7. Shift lock release 8. Stop lamp switch

AWDIA0706ZZ

Revision: March 2010 2008 QX56

Page 3647 of 4083

TM-100

< COMPONENT DIAGNOSIS >

A/T SHIFT LOCK SYSTEM

Terminals And Reference Values

INFOID:0000000001604171

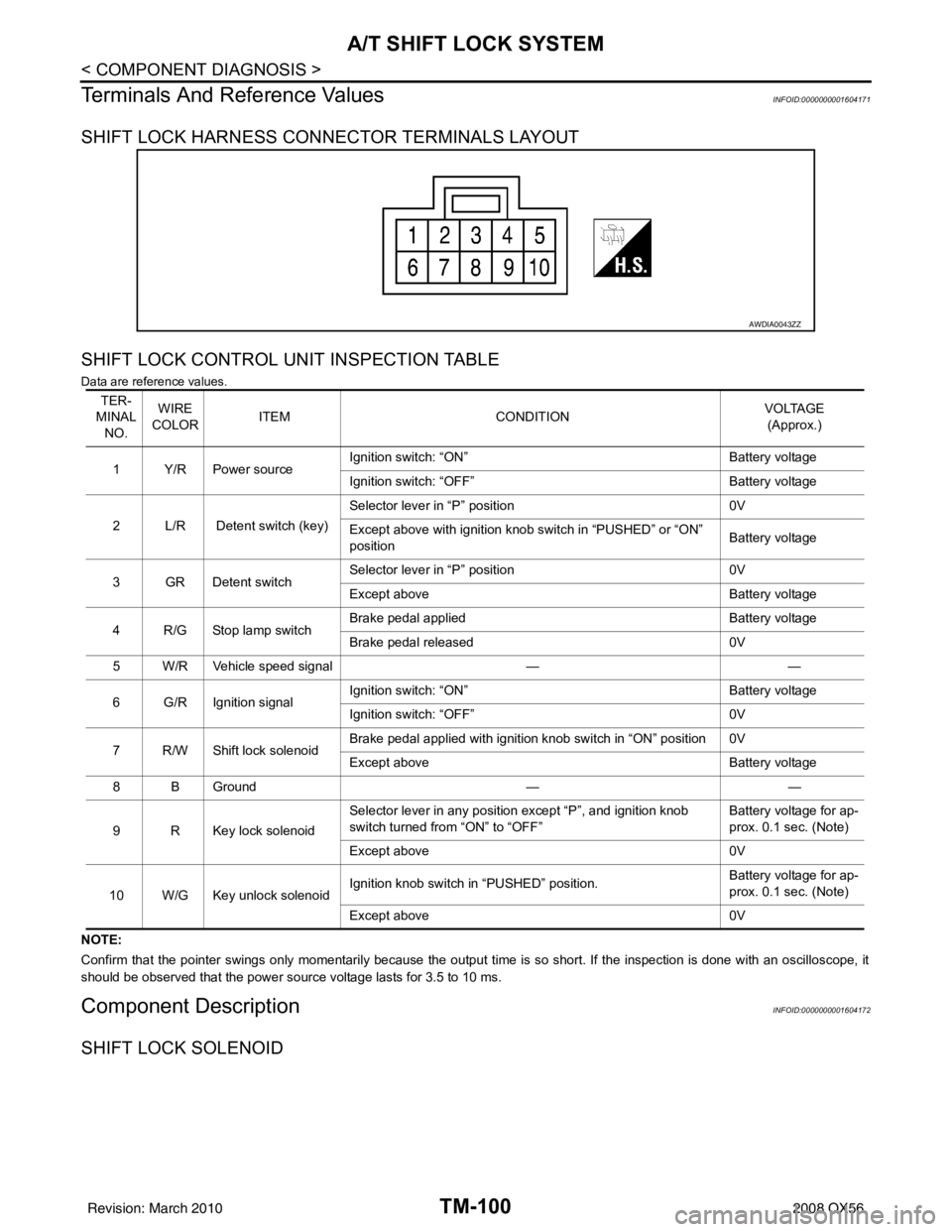

SHIFT LOCK HARNESS CONNECTOR TERMINALS LAYOUT

SHIFT LOCK CONTROL UNIT INSPECTION TABLE

Data are reference values.

NOTE:

Confirm that the pointer swings only momentarily because the output time is so short. If the inspection is done with an oscillo scope, it

should be observed that the power source voltage lasts for 3.5 to 10 ms.

Component DescriptionINFOID:0000000001604172

SHIFT LOCK SOLENOID

AWDIA0043ZZ

TER-

MINAL NO. WIRE

COLOR ITEM

CONDITION VOLTAGE

(Approx.)

1Y/RPower source Ignition switch: “ON”

Battery voltage

Ignition switch: “OFF” Battery voltage

2 L/R Detent switch (key) Selector lever in “P” position

0V

Except above with ignition knob switch in “PUSHED” or “ON”

position Battery voltage

3GRDetent switch Selector lever in “P” position

0V

Except above Battery voltage

4 R/G Stop lamp switch Brake pedal applied

Battery voltage

Brake pedal released 0V

5 W/R Vehicle speed signal ——

6 G/R Ignition signal Ignition switch: “ON”

Battery voltage

Ignition switch: “OFF” 0V

7 R/W Shift lock solenoid Brake pedal applied with ignition knob switch in “ON” position 0V

Except above

Battery voltage

8 B Ground ——

9 R Key lock solenoid Selector lever in any position except “P”, and ignition knob

switch turned from “ON” to “OFF”

Battery voltage for ap-

prox. 0.1 sec. (Note)

Except above 0V

10 W/G Key unlock solenoid Ignition knob switch in “PUSHED” position.

Battery voltage for ap-

prox. 0.1 sec. (Note)

Except above 0V

Revision: March 2010 2008 QX56

Page 3648 of 4083

A/T SHIFT LOCK SYSTEMTM-101

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

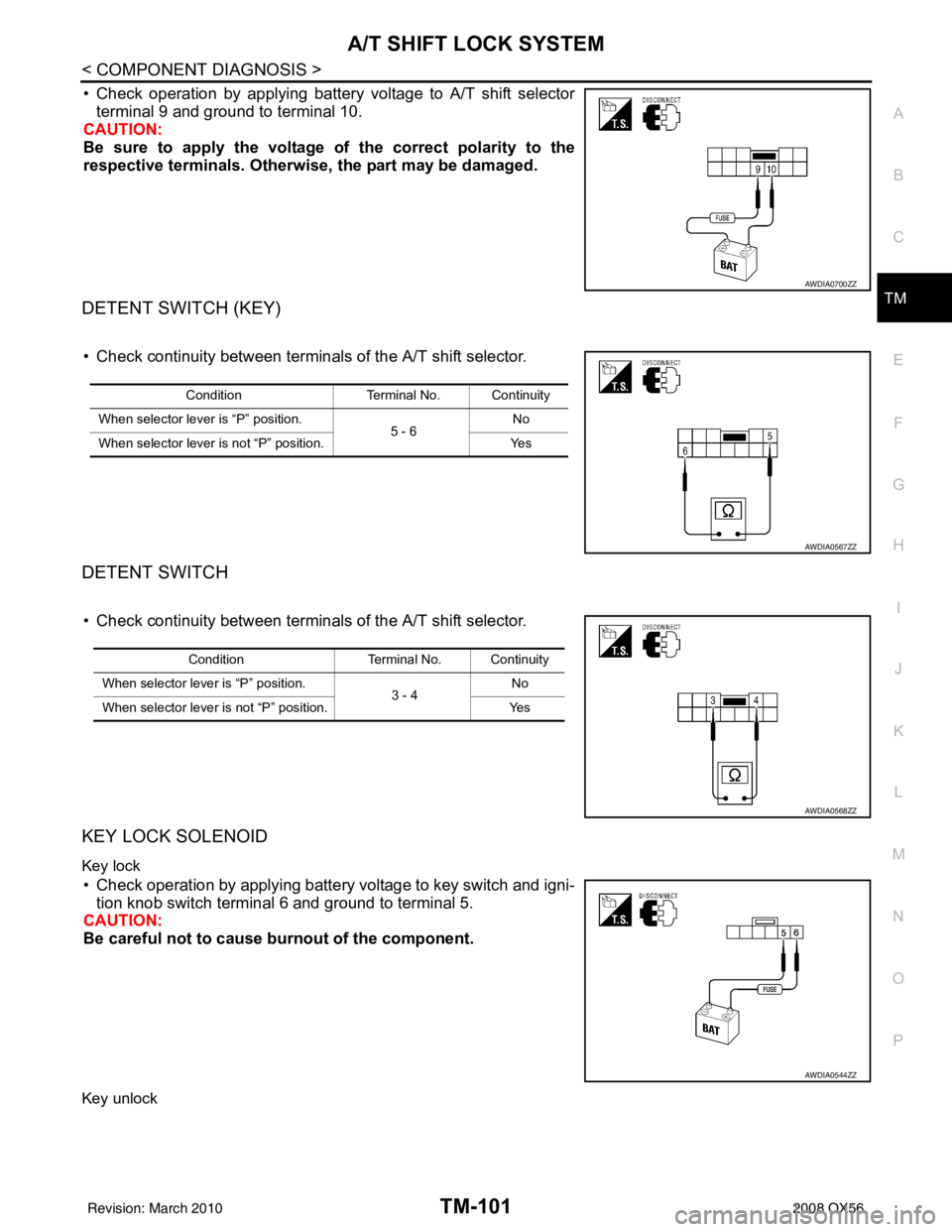

• Check operation by applying battery voltage to A/T shift selector terminal 9 and ground to terminal 10.

CAUTION:

Be sure to apply the voltage of the correct polarity to the

respective terminals. Otherwise, the part may be damaged.

DETENT SWITCH (KEY)

• Check continuity between terminals of the A/T shift selector.

DETENT SWITCH

• Check continuity between terminals of the A/T shift selector.

KEY LOCK SOLENOID

Key lock

• Check operation by applying battery voltage to key switch and igni-

tion knob switch terminal 6 and ground to terminal 5.

CAUTION:

Be careful not to cause burnout of the component.

Key unlock

AWDIA0700ZZ

Condition Terminal No. Continuity

When selector lever is “P” position. 5 - 6No

When selector lever is not “P” position. Yes

AWDIA0567ZZ

ConditionTerminal No. Continuity

When selector lever is “P” position. 3 - 4No

When selector lever is not “P” position. Yes

AWDIA0568ZZ

AWDIA0544ZZ

Revision: March 2010 2008 QX56

Page 3649 of 4083

TM-102

< COMPONENT DIAGNOSIS >

A/T SHIFT LOCK SYSTEM

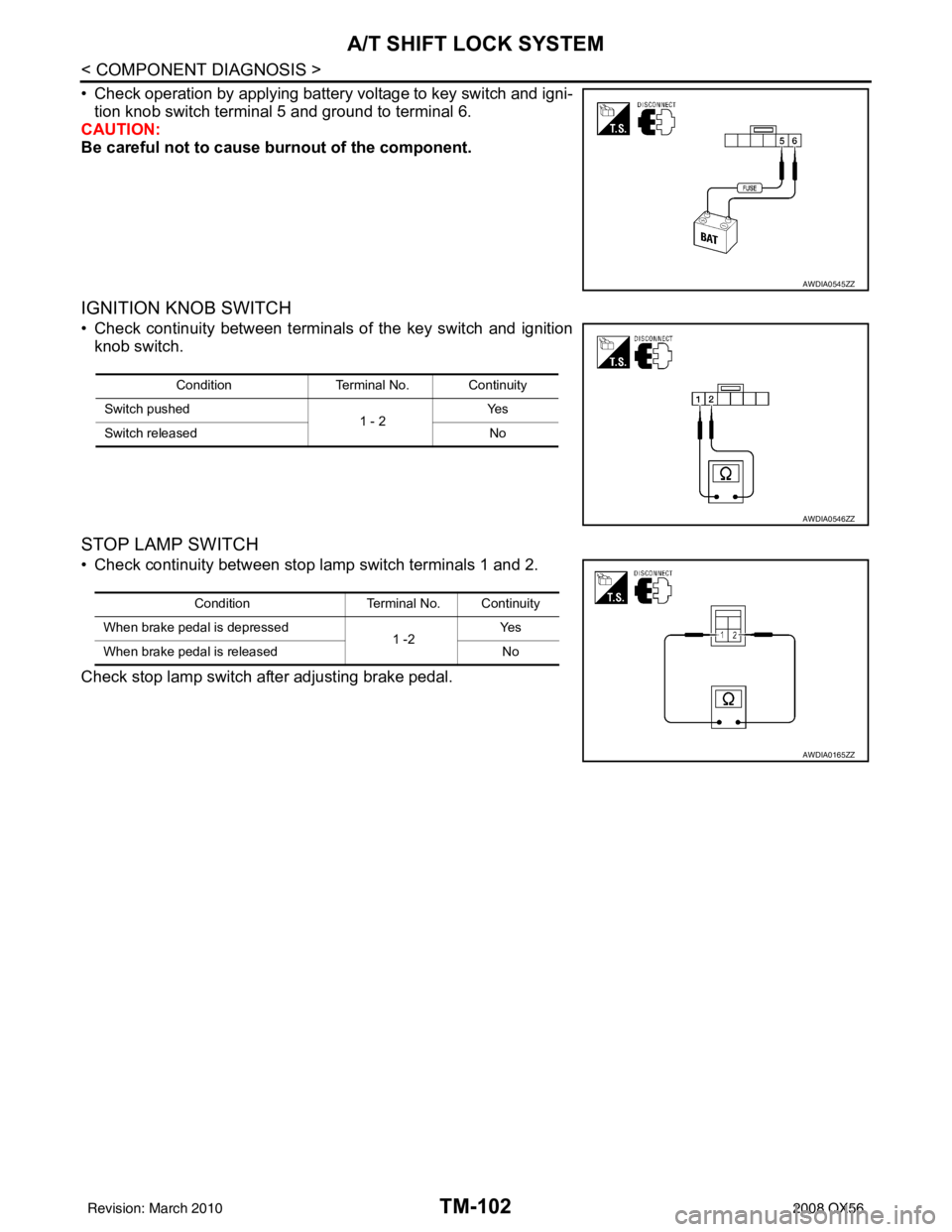

• Check operation by applying battery voltage to key switch and igni-tion knob switch terminal 5 and ground to terminal 6.

CAUTION:

Be careful not to cause burnout of the component.

IGNITION KNOB SWITCH

• Check continuity between terminals of the key switch and ignition

knob switch.

STOP LAMP SWITCH

• Check continuity between stop lamp switch terminals 1 and 2.

Check stop lamp switch after adjusting brake pedal.

AWDIA0545ZZ

Condition Terminal No. Continuity

Switch pushed 1 - 2Ye s

Switch released No

AWDIA0546ZZ

ConditionTerminal No. Continuity

When brake pedal is depressed 1 -2Ye s

When brake pedal is released No

AWDIA0165ZZ

Revision: March 2010 2008 QX56

Page 3720 of 4083

PRECAUTIONSTM-173

< PRECAUTION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006054118

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000004857582

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 3842 of 4083

VTL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004884177

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004884178

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 3878 of 4083

WCS

WCS-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION WCS

A

O P

CONTENTS

WARNING CHIME SYSTEM

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

FUNCTION DIAGNOSIS ...............................4

WARNING CHIME SYSTEM .......................... .....4

WARNING CHIME SYSTEM .......................................4

WARNING CHIME SYSTEM : System Diagram . ......4

WARNING CHIME SYSTEM : System Description

......

4

WARNING CHIME SYSTEM : Component Parts

Location ............................................................... ......

5

WARNING CHIME SYSTEM : Component De-

scription .....................................................................

5

LIGHT REMINDER WARNING CHIME ................. ......6

LIGHT REMINDER WARNING CHIME : System

Diagram .....................................................................

6

LIGHT REMINDER WARNING CHIME : System

Description ................................................................

6

LIGHT REMINDER WARNING CHIME : Compo-

nent Parts Location ...................................................

7

LIGHT REMINDER WARNING CHIME : Compo-

nent Description ........................................................

7

SEAT BELT WARNING CHIME ............................ ......7

SEAT BELT WARNING CHIME : System Diagram

......

8

SEAT BELT WARNING CHIME : System Descrip-

tion ...................................................................... ......

8

SEAT BELT WARNING CHIME : Component

Parts Location ...........................................................

9

SEAT BELT WARNING CHIME : Component De-

scription .....................................................................

9

KEY WARNING CHIME ......................................... ....10

KEY WARNING CHIME : System Diagram ............10

KEY WARNING CHIME : System Description ........10

KEY WARNING CHIME : Component Parts Loca-

tion ....................................................................... ....

11

KEY WARNING CHIME : Component Description ....11

DIAGNOSIS SYSTEM (METER) .......................12

Diagnosis Description ..............................................12

CONSULT-III Function (METER/M&A) ....................13

DIAGNOSIS SYSTEM (BCM) ...........................16

BUZZER ................................................................. ....16

BUZZER : CONSULT-III Function (BCM - BUZZ-

ER) ..........................................................................

16

COMPONENT DIAGNOSIS .........................17

POWER SUPPLY AND GROUND CIRCUIT ....17

COMBINATION METER ........................................ ....17

COMBINATION METER : Diagnosis Procedure .....17

BCM (BODY CONTROL MODULE) ...................... ....18

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ....

18

METER BUZZER CIRCUIT ...............................19

Description ...............................................................19

Component Function Check ....................................19

Diagnosis Procedure ..............................................19

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ..................................................................

20

Description ...............................................................20

Component Function Check ..................................20

Diagnosis Procedure ..............................................20

Component Inspection .............................................21

KEY SWITCH SIGNAL CIRCUIT ......................22

Description ...............................................................22

Component Function Check ..................................22

Diagnosis Procedure ..............................................22

Component Inspection .............................................23

Revision: March 2010 2008 QX56

Page 3879 of 4083

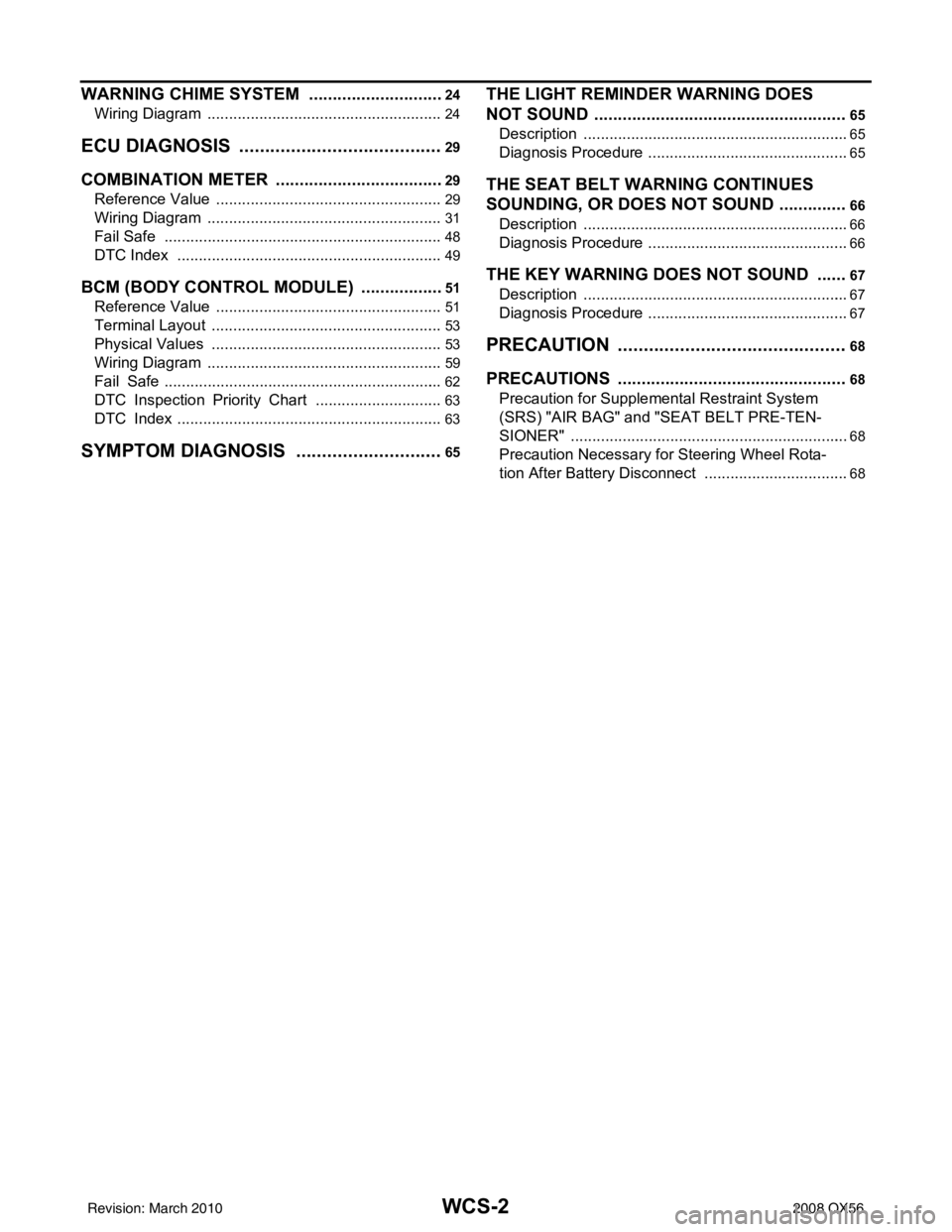

WCS-2

WARNING CHIME SYSTEM .............................24

Wiring Diagram .................................................... ...24

ECU DIAGNOSIS ..................................... ...29

COMBINATION METER ................................. ...29

Reference Value .................................................. ...29

Wiring Diagram .......................................................31

Fail Safe .................................................................48

DTC Index ..............................................................49

BCM (BODY CONTROL MODULE) ..................51

Reference Value .................................................. ...51

Terminal Layout ......................................................53

Physical Values ......................................................53

Wiring Diagram .......................................................59

Fail Safe .................................................................62

DTC Inspection Priority Chart ..............................63

DTC Index ........................................................... ...63

SYMPTOM DIAGNOSIS .............................65

THE LIGHT REMINDER WARNING DOES

NOT SOUND ................................................... ...

65

Description ........................................................... ...65

Diagnosis Procedure ...............................................65

THE SEAT BELT WARNING CONTINUES

SOUNDING, OR DOES NOT SOUND ...............

66

Description ........................................................... ...66

Diagnosis Procedure ...............................................66

THE KEY WARNING DOES NOT SOUND .......67

Description ........................................................... ...67

Diagnosis Procedure ...............................................67

PRECAUTION ............................................68

PRECAUTIONS .............................................. ...68

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

68

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

68

Revision: March 2010 2008 QX56