coolant temperature INFINITI QX56 2008 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1783 of 4083

![INFINITI QX56 2008 Factory Repair Manual EC-484

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5EM-30

,

EX-

5Three way INFINITI QX56 2008 Factory Repair Manual EC-484

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5EM-30

,

EX-

5Three way](/img/42/57030/w960_57030-1782.png)

EC-484

< SYMPTOM DIAGNOSIS >[VK56DE]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket 55555 55 5EM-30

,

EX-

5Three way catalyst

Lubrica-

tion Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

55555 55 5EM-33

,

LU-

14 , LU-11 ,

LU-12

Oil level (Low)/Filthy oil LU-8, "In-

spection"

Cooling Radiator/Hose/Radiator filler cap

55555 55 45 CO-15

Thermostat

5CO-22

Water pump CO-20

Water galleryCO-6

Cooling fan5CO-18,

CO-

19

Coolant level (Low)/Contaminat-

ed coolant 5

CO-10

IVIS (INFINITI Vehicle Immobilizer System —

NATS) 11

SEC-8

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: March 2010 2008 QX56

Page 1784 of 4083

![INFINITI QX56 2008 Factory Repair Manual NORMAL OPERATING CONDITIONEC-485

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NORMAL OPERATING CONDITION

Fuel Cut Control (at No

Load and High Engine Speed)INFOID:0000000001351235

I INFINITI QX56 2008 Factory Repair Manual NORMAL OPERATING CONDITIONEC-485

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NORMAL OPERATING CONDITION

Fuel Cut Control (at No

Load and High Engine Speed)INFOID:0000000001351235

I](/img/42/57030/w960_57030-1783.png)

NORMAL OPERATING CONDITIONEC-485

< SYMPTOM DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

NORMAL OPERATING CONDITION

Fuel Cut Control (at No

Load and High Engine Speed)INFOID:0000000001351235

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 1,800 rpm under no load (for example, the shift position is neutral and engine

speed over is 1,800 rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies

based on engine speed.

Fuel cut will be operated until the engine speed reaches 1,500 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration control listed under EC-28, "

System Description".

Sensor Input signal to ECMECM functionActuator

TCM Neutral position

Fuel cut control Fuel injector

Accelerator pedal position sensor

Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed

Wheel sensor Vehicle speed*

Revision: March 2010 2008 QX56

Page 1802 of 4083

![INFINITI QX56 2008 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)EC-503

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS INFINITI QX56 2008 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)EC-503

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS](/img/42/57030/w960_57030-1801.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EC-503

< SERVICE DATA AND SPECIFICATIONS (SDS) [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000001366032

Idle Speed and Ignition TimingINFOID:0000000001366033

*: Under the following conditions:

• Air conditioner switch: OFF

• Electric load: OFF (Lights and heater fan)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000001366034

Mass Air Flow SensorINFOID:0000000001366035

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorINFOID:0000000001366036

Engine Coolant Temperature SensorINFOID:0000000001366037

A/F Sensor 1 HeaterINFOID:0000000001366038

Fuel pressure at idling kPa (kg/cm2, psi)

Approximately 350 (3.57, 51)

Target idle speed

No-load* (in P or N position) 650±50 rpm

Air conditioner: ON In P or N position 700 rpm or more

Ignition timing In P or N position 15° ± 5 ° BTDC

Condition Calculated load value % (Using CONSULT-IIl or GST)

At idle 14.0 - 33.0

At 2,500 rpm 12.0 - 25.0

Supply voltageBattery voltage (11 - 14V)

Output voltage at idle 1.0 - 1.3V*

Mass air flow (Using CONSULT-IIl or GST) 3.0 - 9.0 g·m/sec at idle*

9.0 - 28.0 g·m/sec at 2,500 rpm*

Temperature °C ( °F) Resistance kΩ

25 (77) 1.800 - 2.200

Temperature °C ( °F) Resistance kΩ

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Resistance [at 25°C (77 °F)] 1.98 - 2.66Ω

Revision: March 2010 2008 QX56

Page 1871 of 4083

EM-68

< ON-VEHICLE REPAIR >

CYLINDER HEAD

CYLINDER HEAD

Exploded ViewINFOID:0000000006055158

Removal and InstallationINFOID:0000000006055159

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to EM-78, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner and idler pulley. Refer to EM-14, "

Drive Belt Auto Tensioner and Idler Pulley".

• Generator assembly and bracket. Refer to CHG-22, "

Removal and Installation".

• Fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

• Intake manifold. Refer to EM-26, "

Removal and Installation".

• Thermostat housing and hose. Refer to CO-22, "

Removal and Installation".

• Rocker cover. Refer to EM-38, "

Removal and Installation".

• Oil pan and oil strainer. Refer to EM-33, "

Removal and Installation".

3. Remove the crankshaft pulley, front cover, oil pump, and timing chain. Refer to EM-45, "

Removal and

Installation".

4. Remove the camshaft sprockets and camshafts. Refer to EM-53, "

Removal and Installation".

5. Remove the cylinder head bolts in reverse of order shown.

6. Remove the cylinder heads.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Diameter

1. Harness bracket 2. Engine coolant temperature sensor 3. Washer

4. Cylinder head gasket (LH) 5. Cylinder head (RH) 6. Cylinder head bolt

7. Cylinder head gasket (RH) 8. Cylinder head (LH)

KBIA2528E

PBIC0068E

Revision: March 2010 2008 QX56

Page 2158 of 4083

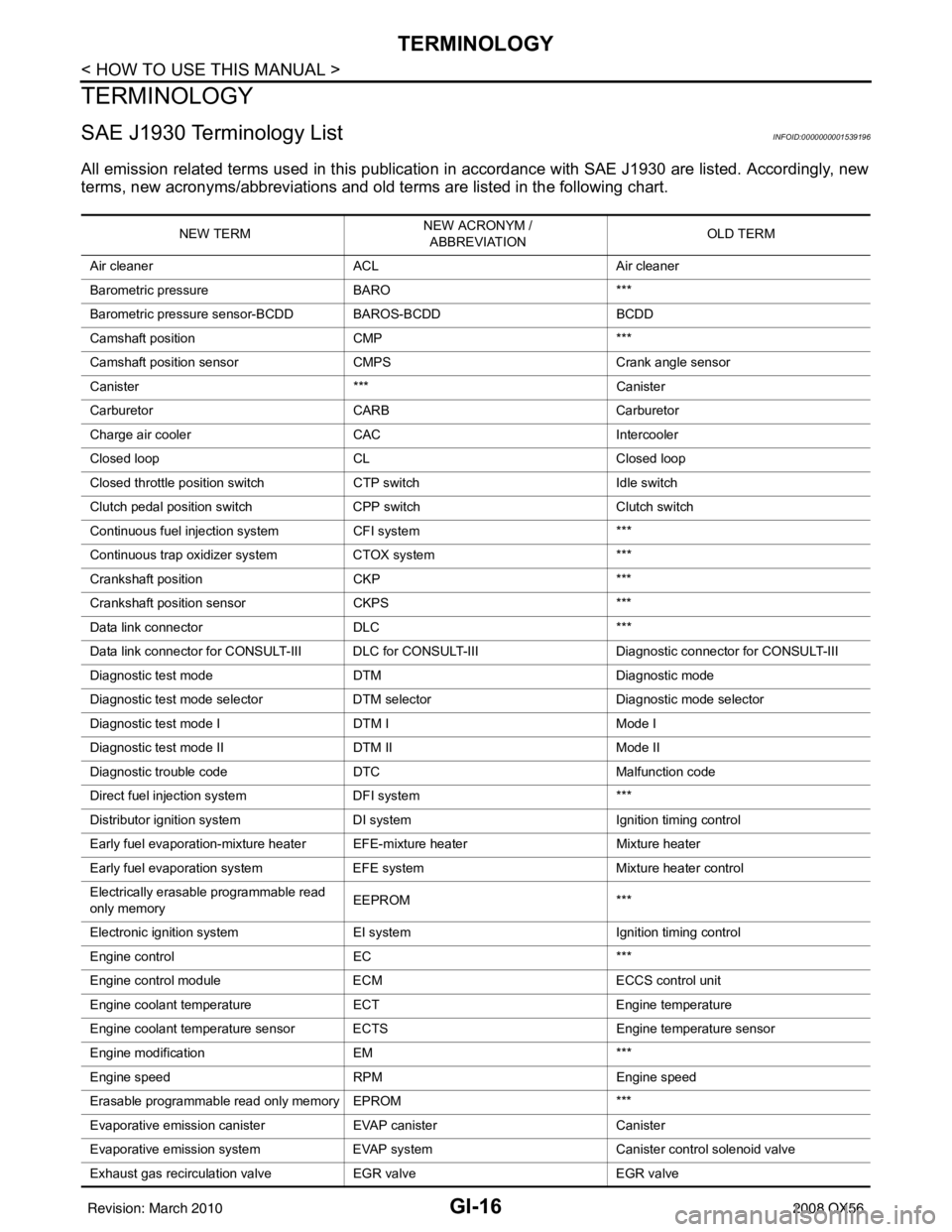

GI-16

< HOW TO USE THIS MANUAL >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000001539196

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPSCrank angle sensor

Canister *** Canister

Carburetor CARBCarburetor

Charge air cooler CACIntercooler

Closed loop CLClosed loop

Closed throttle position switch CTP switchIdle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP***

Crankshaft position sensor CKPS***

Data link connector DLC***

Data link connector for CONSULT-III DLC for CONSULT-IIIDiagnostic connector for CONSULT-III

Diagnostic test mode DTMDiagnostic mode

Diagnostic test mode selector DTM selectorDiagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM IIMode II

Diagnostic trouble code DTCMalfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM

***

Electronic ignition system EI systemIgnition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Revision: March 2010 2008 QX56

Page 2302 of 4083

![INFINITI QX56 2008 Factory Repair Manual BLOWER MOTOR CONTROL SYSTEMHAC-49

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001679795

SYSTEM DES INFINITI QX56 2008 Factory Repair Manual BLOWER MOTOR CONTROL SYSTEMHAC-49

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001679795

SYSTEM DES](/img/42/57030/w960_57030-2301.png)

BLOWER MOTOR CONTROL SYSTEMHAC-49

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000001679795

SYSTEM DESCRIPTION

Component Parts

Blower speed control system components are:• A/C auto amp.

• A/C and AV switch assembly

• Variable blower control

• Front blower motor relay

• Front blower motor

• In-vehicle sensor

• Ambient sensor

• Optical sensor

• Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calc ulated by the A/C auto amp. and variable blower control

based on input from the in-vehicle sensor, optical sens or, intake sensor and ambient sensor, and potentio tem-

perature control (PTC).

When the air flow is increased, the blower motor s peed is adjusted gradually to prevent a sudden increase in

air flow.

In addition to manual air flow control and the usual automat ic air flow control, starting air flow control, low

water temperature starting control and high passenger compartment temperature starting control are avail-

able.

Starting Blower Speed Control

Start up from cold soak condition (Automatic mode).

In a cold start up condition where the engine coolant temperature is below 50 °C (122° F), the blower will not

operate at blower speed 1 for a short period of time ( up to 210 seconds). The exact start delay time varies

depending on the ambient and engine coolant temperatures.

In the most extreme case (very low ambient temper ature) the blower starting delay will be 210 seconds as

described above. After the coolant temperature reaches 50 °C (122 °F), or the 210 seconds has elapsed, the

blower speed will increase to the objective blower speed.

Start up from usual operating or hot soak condition (Automatic mode).

The blower will begin operation momentarily after the AUTO switch is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

AWIIA0173GB

Revision: March 2010 2008 QX56

Page 2304 of 4083

![INFINITI QX56 2008 Factory Repair Manual BLOWER MOTOR CONTROL SYSTEMHAC-51

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 5.

INFINITI QX56 2008 Factory Repair Manual BLOWER MOTOR CONTROL SYSTEMHAC-51

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 5.](/img/42/57030/w960_57030-2303.png)

BLOWER MOTOR CONTROL SYSTEMHAC-51

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 5.

5.PERFORM A/C AND AV SWITCH ASSEMBLY SELF-DIAGNOSIS

Perform self-diagnosis to check the A/C and AV switch assembly. Refer to HAC-22, "

A/C and AV Switch

Assembly Self-Diagnosis".

Is the inspection results normal?

YES >> GO TO 6.

NO >> Replace A/C and AV switch assembly. Refer to VTL-7, "

Removal and Installation".

6.CHECK BLOWER MOTOR OPERATION

Check and verify blower motor operates manually in all speeds.

Does blower motor operate in all speeds?

YES >> GO TO 7.

NO >> Refer to HAC-51, "

Front Blower Motor Diagnosis Procedure".

7.CHECK ENGINE COOLANT TEMPERATURE SENSOR CIRCUIT

Check engine coolant temperature sensor circuit. Refer to EC-125, "

Diagnosis Procedure".

Is the inspection results normal?

YES >> GO TO 8.

NO >> Replace engine coolant temperature sensor.

8.RECHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-4, "

Operational Check (Front)".

Does another symptom exist?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair" .

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

Front Blower Motor Diagnosis ProcedureINFOID:0000000001679797

SYMPTOM: Blower motor operation is malfunctioning.

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

blower speed control.

1.CHECK FUSES

AWIIA0174GB

Revision: March 2010 2008 QX56

Page 2329 of 4083

![INFINITI QX56 2008 Factory Repair Manual HAC-76

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

WATER VALVE CIRCUIT

WATER VALVE CIRCUIT

DescriptionINFOID:0000000001679811

COMPONENT DESCRIPTION

Water Valve

The water valve (1) cuts the flow INFINITI QX56 2008 Factory Repair Manual HAC-76

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

WATER VALVE CIRCUIT

WATER VALVE CIRCUIT

DescriptionINFOID:0000000001679811

COMPONENT DESCRIPTION

Water Valve

The water valve (1) cuts the flow](/img/42/57030/w960_57030-2328.png)

HAC-76

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

WATER VALVE CIRCUIT

WATER VALVE CIRCUIT

DescriptionINFOID:0000000001679811

COMPONENT DESCRIPTION

Water Valve

The water valve (1) cuts the flow of engine coolant to the front and

rear heater cores to allow for maximum cooling during A/C opera-

tion. It is controlled by the A/C auto amp.

Water Valve Diagnosis ProcedureINFOID:0000000001679812

DIAGNOSTIC PROCEDURE FOR WATER VALVE

1.CHECK WATER VALVE POWER AND GROUND CIRCUITS

1. Disconnect water valve connector F68.

2. Turn ignition switch ON.

3. Rotate temperature control dial (driver) to 32 °C (90° F).

4. Check voltage between water valve harness connector F68 ter- minal 1 and terminal 2 while rotating temperature control dial

(driver) to 18 °C (60° F).

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK WATER VALVE CONTROL OUTPUT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector M50.

3. Check continuity between water valve harness connector F68 (A) terminal 2 and A/C auto amp. harness connector M50 (B)

terminal 46.

4. Check continuity between water valve harness connector F68 (A) terminal 2 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and Installation".

NO >> Repair harness or connector.

3.CHECK WATER VALVE POWER AND GROUND CIRCUITS

WJIA1791E

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

Water valve: F68 2 1Rotate temperature

control dial Battery

voltage

WJIA1794E

2 - 46 : Continuity should exist.

2 - Ground : Continuity should not exist.

AWIIA0203ZZ

Revision: March 2010 2008 QX56

Page 2370 of 4083

![INFINITI QX56 2008 Factory Repair Manual INSUFFICIENT HEATINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001679835

SYMPTOM: Insufficie INFINITI QX56 2008 Factory Repair Manual INSUFFICIENT HEATINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001679835

SYMPTOM: Insufficie](/img/42/57030/w960_57030-2369.png)

INSUFFICIENT HEATINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000001679835

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32 °C (90 °F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-4, "

Operational Check (Front)".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-22, "

A/C Auto Amp. Self-Diagnosis".

Is the inspection results normal?

YES >> GO TO 4.

NO >> Refer to HAC-23, "

A/C System Self-Diagnosis Code Chart".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-10, "

Inspection".

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-10, "

Inspection".

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-31, "

Air Mix Door Motor Component Function

Check".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> • Inlet hose cold: GO TO 11. • Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to EC-126, "

Component Inspection".

Revision: March 2010 2008 QX56

Page 2371 of 4083

![INFINITI QX56 2008 Factory Repair Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Che INFINITI QX56 2008 Factory Repair Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Che](/img/42/57030/w960_57030-2370.png)

HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

Is the inspection result normal?

YES >> System OK.

NO >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

Is the inspection result normal?

YES >> System OK.

NO >> 1. Back flush heater core. 2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-11, "

Changing Engine Coolant".

4. GO TO 10 to retest.

10.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> System OK.

NO >> Replace heater core. Refer to VTL-19, "

Removal and Installation".

11 .CHECK WATER VALVE

Check the operation of the water valve. Refer to HAC-76, "

Water Valve Diagnosis Procedure".

Is the inspection result normal?

YES >> System OK.

NO >> Replace water valve.

Revision: March 2010 2008 QX56