ignition INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2667 of 4083

MWI-22

< FUNCTION DIAGNOSIS >

COMPASS

COMPASS

DescriptionINFOID:0000000001691282

DESCRIPTION

With the ignition switch in the ON position, and the mode (N) switch

ON, the compass display will indicate the direction the vehicle is

heading.

Vehicle direction is displayed as follows:

• N: north

• E: east

• S: south

•W: west

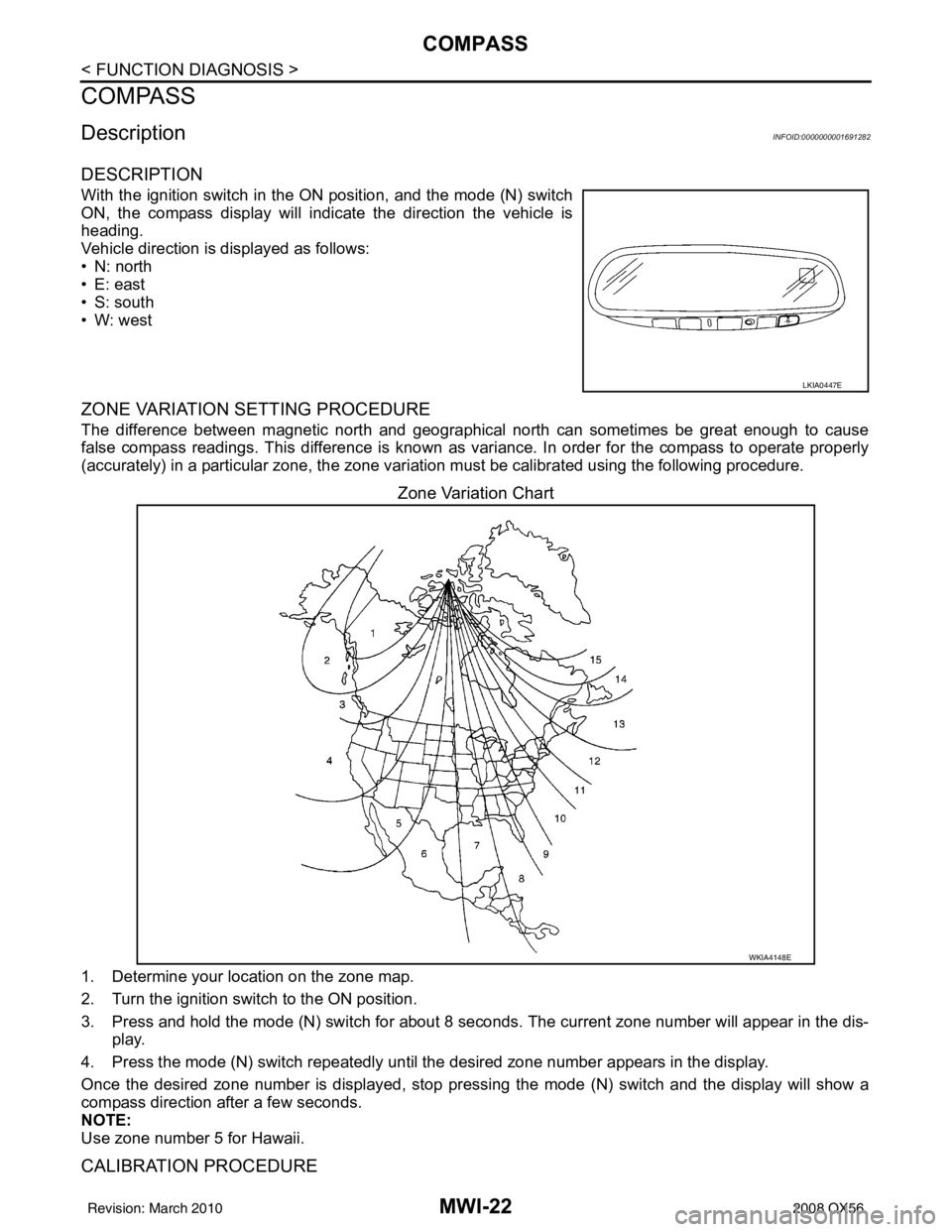

ZONE VARIATION SETTING PROCEDURE

The difference between magnetic north and geographical north can sometimes be great enough to cause

false compass readings. This difference is known as variance. In order for the compass to operate properly

(accurately) in a particular zone, the zone variation must be calibra ted using the following procedure.

Zone Variation Chart

1. Determine your location on the zone map.

2. Turn the ignition switch to the ON position.

3. Press and hold the mode (N) switch for about 8 sec onds. The current zone number will appear in the dis-

play.

4. Press the mode (N) switch repeatedly until the desired zone number appears in the display.

Once the desired zone number is displayed, stop pre ssing the mode (N) switch and the display will show a

compass direction after a few seconds.

NOTE:

Use zone number 5 for Hawaii.

CALIBRATION PROCEDURE

LKIA0447E

WKIA4148E

Revision: March 2010 2008 QX56

Page 2669 of 4083

MWI-24

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

Diagnosis DescriptionINFOID:0000000001691283

SELF-DIAGNOSIS MODE

The following items can be checked during Combination Meter Self-Diagnosis Mode.

• Gauge sweep and present gauge values.

• Illuminates all odometer/trip meters and A/T indicator segments.

• Illuminates all micro controlled lamps/LEDs regardless of switch position.

• Displays estimated present battery voltage.

• Displays seat belt buckle switch LH status.

OPERATION PROCEDURE

NOTE:

• Once entered, combination meter self-diagnosis mode will function with the ignition switch in ON or START.

Combination meter self-diagnosis mode will exit upon turning the ignition switch to OFF or ACC.

• If the diagnosis function is activated with trip A displa yed, the mileage on trip A is reset to 0000.0. (Trip B

operates the same way.)

To initiate combination meter self-diagnosis mode, refer to the following procedure.

1. Turn the ignition switch ON, while pressing the odometer/trip meter switch for 5 - 8 \

seconds. When the diagnosis function is activated, the odometer/trip meter will display tESt.

NOTE:

Check combination meter power supply and ground circuit when self-diagnosis mode of combination meter

does not start. Refer to MWI-30, "

COMBINATION METER : Diagnosis Procedure". Replace combination

meter if normal. Refer to MWI-76, "

Removal and Installation".

COMBINATION METER SELF-DIAGNOSIS MODE FUNCTIONS

To interpret combination meter self-diagnosis mode functions, refer to the following table.

EventOdometer Display Description of Test/Data Notes:

Odometer/trip meter A/B

switch held from 5 to 8

seconds (or until re-

leased) tESt

Initiating self-diagnosis mode

Switch released GAGE Performs sweep of all

gauges, then displays

present gauge values.Gauges sweep within 10 seconds

Switch pressed (All segments illuminated) Lights all LCD segments.

Compare with picture.

Switch pressed bulbIlluminates all micro-con-

trolled lamps/LEDs. Part may not be configured for all

lamps (functions) th

at turn on dur-

ing test. This is normal.

Switch pressed r XXXX, FAIL Return to normal opera-

tion of all lamps/LEDs and

displays “r XXXX”.If a malfunction exists, “FAIL” will

flash.

Switch pressed nrXXXX Displays Hex ROM rev as

stored in NVM.

Switch pressed EE XX, FAIL Displays “EE XX”.If a malfunction exists, “FAIL” will

flash.

Switch pressed dtXXXX Hex coding of final manu-

facturing test date.

AWNIA0203ZZ

Revision: March 2010

2008 QX56

Page 2675 of 4083

MWI-30

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000001691290

1.CHECK FUSES

Check for blown combination meter fuses.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector M24.

2. Check voltage between combination meter harness connector M24 terminals 21, 37, 40 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Check harness for open between combination meter and fuse.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect combination meter connector M23.

3. Check continuity between combination meter harness connector M23 terminal 47, 52 and ground, and connector M24 terminal 20

and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check ground harness.

BCM (BODY CONTROL MODULE)

Unit Power source Fuse No.

Combination meter Battery 19

Ignition switch ON or START 14

Ignition switch ACC or ON 4

TerminalsIgnition switch position

(+) (–) OFF ACC ON START

Connector Terminal

M24 21

Ground 0V 0V

Battery

voltage Battery

voltage

37 0VBattery

voltage Battery

voltage 0V

40 Battery

voltage Battery

voltage Battery

voltage Battery

voltage

AWNIA0204ZZ

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

A: M23 47

Ground Yes

52

B: M24 20

AWNIA0205ZZ

Revision: March 2010 2008 QX56

Page 2676 of 4083

MWI

POWER SUPPLY AND GROUND CIRCUITMWI-31

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000001696511

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch

OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: March 2010 2008 QX56

Page 2677 of 4083

MWI-32

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

agnosis Procedure

INFOID:0000000001696512

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between IPDM E/R harness connectors and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

Terminal No. Signal nameFuses and fusible link No.

1 Battery A, D

2 Battery C

12 Ignition switch ON or START 59

TerminalsIgnition switch position

(+) (−) OFF ON START

Connector Terminal

E118 (A) 1

Ground Battery

voltage Battery

voltage Battery

voltage

2 Battery

voltage Battery

voltage Battery

voltage

E119 (B) 12 0VBattery

voltage Battery

voltage

AWMIA0023ZZ

IPDM E/R

GroundContinuity

Connector Terminal

E122 (A) 38

Ye s

E124 (B) 59

AWMIA0024ZZ

Revision: March 2010 2008 QX56

Page 2678 of 4083

MWI

FUEL LEVEL SENSOR SIGNAL CIRCUITMWI-33

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

FUEL LEVEL SENSOR SIGNAL CIRCUIT

DescriptionINFOID:0000000001691293

The fuel level sensor unit and fuel pump detects the approx imate fuel level in the fuel tank and transmits the

fuel level signal to the combination meter.

Component Function CheckINFOID:0000000001691294

1.COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Using “FUEL METER” of “DATA MONITOR”, comp are the value of DATA MONITOR with fuel gauge

pointer of combination meter.

Does the data monitor value approximately match the fuel gauge indication?

YES >> Inspection End.

NO >> Replace combination meter. Refer to MWI-76, "

Removal and Installation".

Diagnosis ProcedureINFOID:0000000001691295

1.CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Check combination meter and fuel level sensor unit terminals (meter-side and harness-side) for poor con- nection.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace terminals or connectors.

2.CHECK FUEL LEVEL SENSOR UNIT CIRCUIT

1. Disconnect combination meter connector and fuel level sensor unit connector.

2. Check continuity between combination meter harness connector

(B) and fuel level sensor unit and fuel pump harness connector

(A).

3. Check continuity between fuel level sensor unit and fuel pump harness connector (A) and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair harness or connector.

Fuel gauge pointer Reference value of data monitor [lit.]

Full Approx. 93

3/4 Approx. 73

1/2 Approx. 52

1/4 Approx. 30

Empty Approx. 11

AB

Continuity

Connector Terminal Connector Terminal

C5 2 M24 3 Yes

A GroundContinuity

Connector Terminal

C5 2 No

AWNIA0206ZZ

Revision: March 2010 2008 QX56

Page 2680 of 4083

MWI

OIL PRESSURE SWITCH SIGNAL CIRCUIT

MWI-35

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

OIL PRESSURE SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000001691297

Detects the engine oil pressure and transmits the oil pressure switch signal to the IPDM E/R.

Component Function CheckINFOID:0000000001691298

1.COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Monitor “OIL W/L” of “DATA MONITOR” while operating ignition switch.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000001691299

1.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E122 and oil pressure switch

connector F4.

3. Check continuity between IPDM E/R harness connector E122

(A) terminal 42 and oil pressure switch harness connector F4 (B)

terminal 1.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001691300

1.CHECK OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace the oil pressure switch. OIL W/L

When ignition switch is in ON

position (Engine stopped)

: ON

When engine is running : OFF

Continuity should exist.

WKIA5607E

Condition Oil pressure [kPa (kg/cm2, psi)]Continuity

Engine stopped Less than 29 (0.3, 4) Yes Engine running More than 29 (0.3, 4) No

ELF0044D

Revision: March 2010 2008 QX56

Page 2682 of 4083

MWI

WASHER LEVEL SWITCH SIGNAL CIRCUITMWI-37

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

WASHER LEVEL SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000001691305

Transmits the washer level switch signal to the combination meter.

Diagnosis ProcedureINFOID:0000000001691306

1.CHECK WASHER FLUID LEVEL SWITCH SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and washer fluid level switch connector.

3. Check continuity between combination meter harness connector M24 (A) terminal 23 and washer fl uid level switch harness con-

nector E106 (B) terminal 1.

4. Check continuity between combination meter harness connector M24 (A) terminal 23 and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair harness or connector.

2.CHECK WASHER FLUID LE VEL SWITCH GROUND CIRCUIT

Check continuity between washer fluid level switch harness connec-

tor E106 terminal 2 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001691307

1.CHECK WASHER FLUID LEVEL SWITCH

Check continuity between washer fluid level switch terminals 1 and

2.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace washer fluid level switch. 23 - 1

: Continuity should exist.

23 - Ground : Continuity should not exist.

AWNIA0209ZZ

2 - Ground: Continuity should exist.

AWNIA0112ZZ

TerminalWasher fluid level Continuity

1 - 2 Low

Yes

Other No

AWNIA0113ZZ

Revision: March 2010 2008 QX56

Page 2687 of 4083

MWI-42

< ECU DIAGNOSIS >

COMBINATION METER

ECU DIAGNOSIS

COMBINATION METER

Reference ValueINFOID:0000000001691309

TERMINAL LAYOUT

PHYSICAL VALUES

WKIA5724E

Te r m i -nal Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

3 Y/L Fuel level sensor signal — —Refer to MWI-12, "

FUEL GAUGE : System

Description".

4 B/P Fuel level sensor ground ON —0

6 BR/W Generator ONGenerator voltage low

0

Generator voltage normal Battery voltage

10 L CAN-H —— —

11 P C A N - L —— —

13 P Air bag warning lamp in-

put ONAir bag warning lamp ON

4

Air bag warning lamp OFF 0

15 BR CK SUSP warning lamp

input —CK SUSP warning lamp

ON

0

CK SUSP warning lamp

OFF Battery voltage

20 B Ground —— 0

21 O/L Ignition switch ON or

START ON

— Battery voltage

23 W/L Washer fluid level switch ON Washer fluid level low

0

Washer fluid level normal Battery voltage

24 O/B Seat belt buckle switch

LH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

25 P/L Seat belt buckle switch

RH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

31 G Parking brake switch ON Parking brake applied

0

Parking brake released Battery voltage

32 P/B Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

33 R/G Stop lamp switch —Brake pedal depressed

Battery voltage

Brake pedal released 0

Revision: March 2010 2008 QX56

Page 2688 of 4083

MWI

COMBINATION METERMWI-43

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

35 G/O Security indicator input OFF Security indicator ON 0

Security indicator OFF

Battery voltage

37 O Ignition switch ACC or

ON

—

— Battery voltage

40 Y/R Battery power supply — —Battery voltage

46 BR Illumination output ——Refer to INL-9, "

System Description".

47 B Ground —— 0

50 W/R Vehicle speed signal out-

put (8-pulse) ONSpeedometer operated

[When vehicle speed is ap-

prox. 40 km/h (25 MPH)] NOTE:

Maximum voltage may be 12V due to spec-

ifications (connected units).

52 B Ground —— 0

Te r m i -

nal Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

PKIC0643E

Revision: March 2010

2008 QX56