brake rotor INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 7 of 4083

QUICK REFERENCE CHART: QX56

2008

Brake SpecificationsINFOID:0000000006237755

Unit: mm (in)

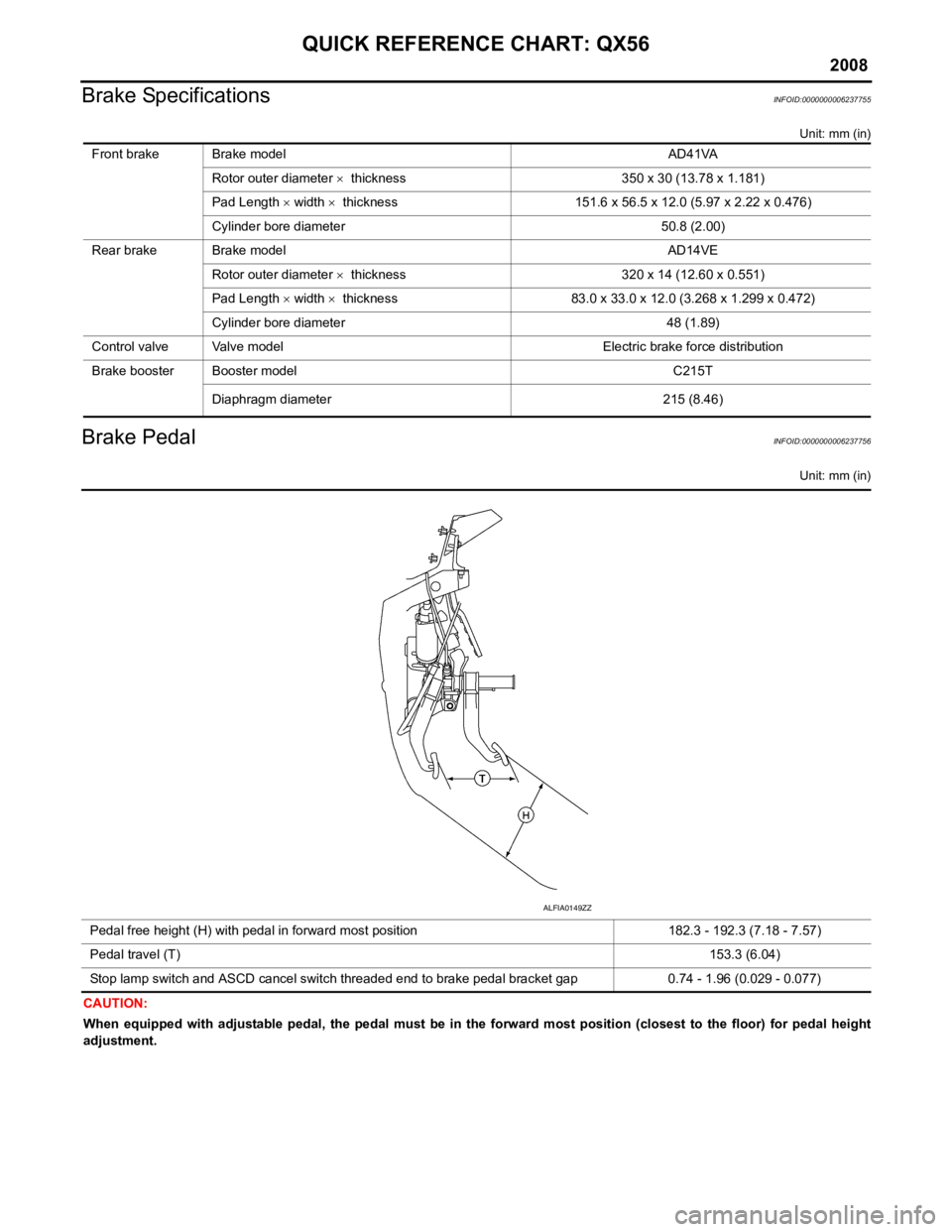

Brake PedalINFOID:0000000006237756

Unit: mm (in)

CAUTION:

When equipped with adjustable pedal, the pedal must be in the forward most position (closest to the floor) for pedal height

adjustment. Front brake Brake model AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.181)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 50.8 (2.00)

Rear brake Brake model AD14VE Rotor outer diameter × thickness 320 x 14 (12.60 x 0.551)

Pad Length × width × thickness 83.0 x 33.0 x 12.0 (3.268 x 1.299 x 0.472)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Pedal free height (H) with pedal in forward most position 182.3 - 192.3 (7.18 - 7.57)

Pedal travel (T) 153.3 (6.04)

Stop lamp switch and ASCD cancel switch threaded end to brake pedal bracket gap 0.74 - 1.96 (0.029 - 0.077)

ALFIA0149ZZ

Page 8 of 4083

2008

QUICK REFERENCE CHART: QX56

Front Disc Brake

INFOID:0000000006237753

Unit: mm (in)

Rear Disc BrakeINFOID:0000000006237754

Unit: mm (in)

Fluids and LubricantsINFOID:0000000006237752

Brake model AD41VA

Brake pad Standard thickness (new) 12.0 (0.476)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 30 (1.181)

Repair limit thickness 28 (1.102)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.03 (0.001)

Brake model

AD14VE

Brake pad Standard thickness (new) 12.0 (0.472)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 14.0 (0.551)

Repair limit thickness 12.5 (0.492)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Description

Capacity (Approximate)

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal

Engine oil

Drain and refill With oil filter change

6.5 6 7/8 qt 5 3/4 qt

Without oil filter change 6.2 6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt 6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt

Rear final drive oil 1.75 3 3/4 pt 3 1/8 pt

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt

Front final drive oil 1.6 3 3/8 pt 2 7/8 pt

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt

Brake fluid — — —

Brake grease — — —

Multi-purpose grease — — —

Windshield washer fluid 4.9 5 1/8 qt 4 3/8 qt

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz

Page 421 of 4083

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Brake System ....................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

BASIC INSPECTION ....................................7

FRONT DISC B RAKE .................................... .....7

BRAKE PAD .......................................................... ......7

BRAKE PAD : Inspection ..........................................7

DISC ROTOR ......................................................... ......7

DISC ROTOR : Inspection ........................................7

REAR DISC BRAKE ...................................... .....9

BRAKE PAD .......................................................... ......9

BRAKE PAD : Inspection ..........................................9

DISC ROTOR ......................................................... ......9

DISC ROTOR : Inspection ........................................9

BRAKE BOOSTER ............................................10

Inspection ............................................................ ....10

VACUUM LINES ............................................. ....11

Inspection ............................................................ ....11

BRAKE MASTER CYLINDER ..........................12

On Board Inspection ................................................12

BRAKE TUBE AND HOSE ...............................13

Hydraulic Circuit ......................................................13

FRONT BRAKE ..................................................... ....13

FRONT BRAKE : Inspection ......................... ...........13

REAR BRAKE ........................................................ ....14

REAR BRAKE : Inspection ........................ ..............14

ON-VEHICLE MAINTEN ANCE ....................15

BRAKE PEDAL .................................................15

Inspection and Adjustment .................................. ....15

BRAKE FLUID ..................................................17

On Board Inspection ............................................ ....17

Drain and Refill ........................................................17

Bleeding Brake System ...........................................17

ON-VEHICLE REPAIR .................................19

BRAKE PEDAL .................................................19

Removal and Installation ..................................... ....19

BRAKE TUBE AND HOSE ...............................21

Hydraulic Circuit ......................................................21

Removal and Installation of Front Brake Piping

and Brake Hose .......................................................

21

Removal and Installation of Rear Brake Piping

and Brake Hose .......................................................

22

Inspection After Installation .....................................23

BRAKE MASTER CYLINDER ..........................25

Removal and Installation .........................................25

BRAKE BOOSTER ...........................................26

Removal and Installation ..................................... ....26

VACUUM LINES ...............................................28

Revision: March 2010 2008 QX56

Page 422 of 4083

BR-2

Removal and Installation ........................................28

FRONT DISC BRAKE ........................................29

Exploded View of Brake Pads ............................. ...29

Removal and Installation of Brake Pads .................29

Brake Burnishing Procedure ...................................30

Exploded View of Brake Caliper .............................31

Removal and Installation of Brake Caliper and Ro-

tor ...........................................................................

31

REAR DISC BRAKE ..........................................34

Exploded View of Brake Pads ............................. ...34

Removal and Installation of Brake Pad ..................34

Brake Burnishing Procedure ...................................35

Exploded View of Brake Caliper .............................35

Removal and Installation of Brake Caliper and

Disc Rotor ............................................................ ...

36

DISASSEMBLY AND ASSEMBLY .............37

BRAKE MASTER CYLINDER ........................ ...37

Disassembly and Assembly ................................. ...37

FRONT DISC BRAKE .......................................39

Disassembly and Assembly ................................. ...39

REAR DISC BRAKE ....................................... ...42

Disassembly and Assembly ................................. ...42

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................. ...............

45

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

45

General Specification ........................................... ...45

Brake Pedal ............................................................45

Brake Booster .........................................................46

Check Valve ............................................................46

Front Disc Brake .....................................................46

Rear Disc Brake ......................................................46

Revision: March 2010 2008 QX56

Page 424 of 4083

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000001604475

• Always use recommended brake fluid. Refer to MA-12, "Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

• Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

• Use flare nut wrench when removing and installing brake tube.

• Always check tightening torque when installing brake lines.

• Before working, turn ignition switch to OFF and disconnect con- nectors for ABS actuator and electric unit (control unit) or battery

terminals.

• Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer to BR-35, "

Brake Burnishing

Procedure".

WARNING:

• Clean brake pads and shoes wi th a waste cloth, then wipe

with a dust collector.

SBR686C

Revision: March 2010 2008 QX56

Page 425 of 4083

PREPARATIONBR-5

< PREPARATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

PREPARATION

PREPARATION

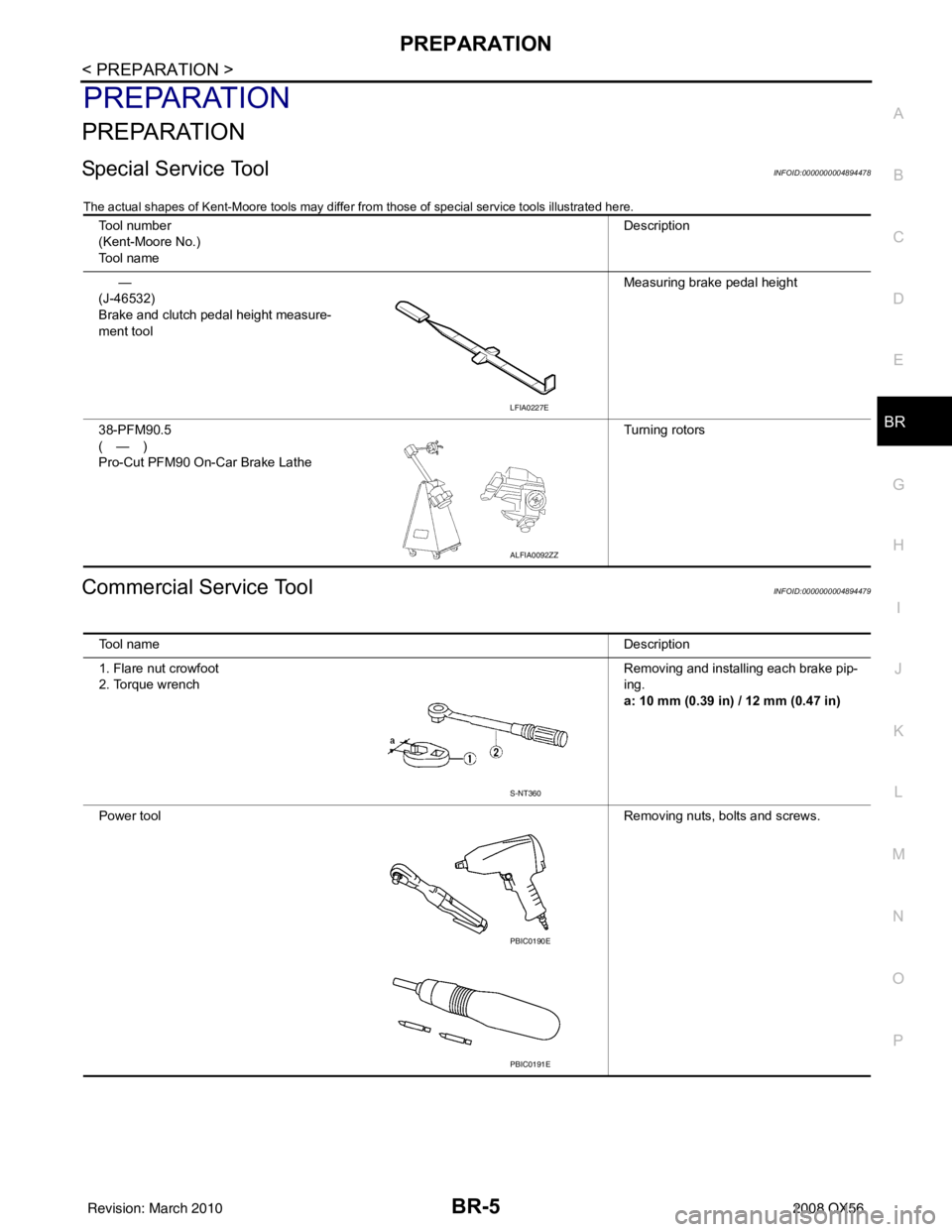

Special Service ToolINFOID:0000000004894478

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000004894479

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-46532)

Brake and clutch pedal height measure-

ment tool Measuring brake pedal height

38-PFM90.5

(—)

Pro-Cut PFM90 On-Car Brake Lathe Turning rotors

LFIA0227E

ALFIA0092ZZ

Tool name

Description

1. Flare nut crowfoot

2. Torque wrench Removing and installing each brake pip-

ing.

a: 10 mm (0.39 in) / 12 mm (0.47 in)

Power tool Removing nuts, bolts and screws.

S-NT360

PBIC0190E

PBIC0191E

Revision: March 2010 2008 QX56

Page 427 of 4083

FRONT DISC BRAKEBR-7

< BASIC INSPECTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BASIC INSPECTION

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : InspectionINFOID:0000000004894482

PA D W E A R

Check pad thickness from the inspection holes on cylinder body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : InspectionINFOID:0000000004894483

VISUAL

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace as necessary.

RUNOUT

1. Attach disc rotor to wheel hub using wheel nuts (at two or more positions).

2. Inspect runout using a dial gauge placed at 10 mm (0.39 in) inside the disc edge.

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to FA X - 6 , "

On-Vehicle Inspec-

tion and Service".

3. When runout exceeds limit value, displace mounting positions of disc rotor by one hole. And then find a position of the minimum value for runout.

4. If runout is outside the specified value after performing the above operation, turn disc rotor using Tool.

THICKNESS

Standard thickness : Refer to BR-46, "Front Disc

Brake".

Repair limit thickness : Refer to BR-46, "

Front Disc

Brake".

WFIA0522E

Runout limit : Refer to BR-46, "Front Disc

Brake".

(with it attached to the vehicle)

Tool number : 38-PFM90.5 ( — )

BRA0580D

Revision: March 2010 2008 QX56

Page 428 of 4083

BR-8

< BASIC INSPECTION >

FRONT DISC BRAKE

Check thickness of the disc rotor using a micrometer. Replace disc

rotor if thickness is less than the wear limit.Standard thickness : Refer to BR-46, "

Front

Disc Brake".

Repair limit thickness : Refer to BR-46, "

Front

Disc Brake".

Thickness variation

(Measured at 8 positions) : Refer to

BR-46, "

Front

Disc Brake".

SBR020B

Revision: March 2010 2008 QX56

Page 429 of 4083

REAR DISC BRAKEBR-9

< BASIC INSPECTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : InspectionINFOID:0000000004894484

PA D W E A R

Check pad thickness from the inspection holes on cylinder body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : InspectionINFOID:0000000004894485

VISUAL

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace as necessary.

RUNOUT

1. Attach disc rotor to wheel hub using wheel nuts (at two or more positions).

2. Inspect runout using dial gauge placed at 10 mm (0.39 in) inside disc edge.

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to RAX-6, "

On-Vehicle Inspec-

tion and Service".

3. When runout exceeds limit value, displace mounting positions of disc rotor by one hole. And then find a position of the minimum value for runout.

4. If runout is outside the specified value after performing the above operation, turn disc rotor using Tool.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

disc rotor if the thickness is less than the wear limit. Standard thickness : Refer to

BR-46, "

Rear Disc

Brake".

Repair limit thickness : Refer to BR-46, "

Rear Disc

Brake".

BRA0010D

Runout limit : Refer to BR-46, "Rear Disc Brake".

(With it attached to the vehicle)

Tool number : 38-PFM90.5 ( — )

BRA0697D

Standard thickness : Refer to BR-46, "Rear

Disc Brake".

Repair limit thickness : Refer to BR-46, "

Rear

Disc Brake".

Thickness variation

(Measured at 8 positions) : Refer to

BR-46, "

Rear

Disc Brake".

SFIA2284E

Revision: March 2010 2008 QX56

Page 449 of 4083

FRONT DISC BRAKEBR-29

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

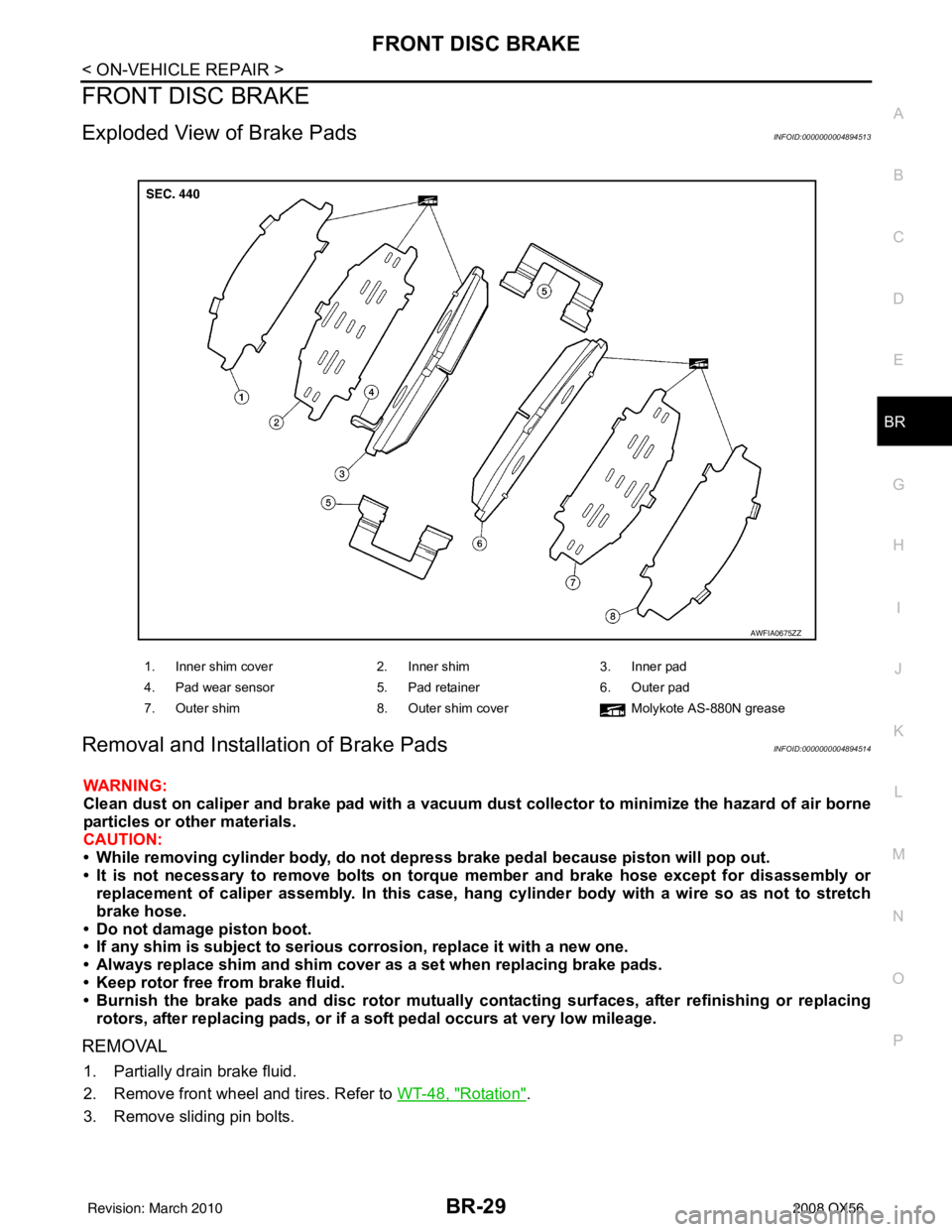

Exploded View of Brake PadsINFOID:0000000004894513

Removal and Installation of Brake PadsINFOID:0000000004894514

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Partially drain brake fluid.

2. Remove front wheel and tires. Refer to WT-48, "

Rotation".

3. Remove sliding pin bolts.

1. Inner shim cover 2. Inner shim3. Inner pad

4. Pad wear sensor 5. Pad retainer6. Outer pad

7. Outer shim 8. Outer shim cover Molykote AS-880N grease

AWFIA0675ZZ

Revision: March 2010 2008 QX56