fuse box INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1053 of 4083

![INFINITI QX56 2008 Factory Service Manual P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

• 10A fuses No. 26 located in fuse and fusible link box and No. 59 locat INFINITI QX56 2008 Factory Service Manual P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

• 10A fuses No. 26 located in fuse and fusible link box and No. 59 locat](/img/42/57030/w960_57030-1052.png)

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

• 10A fuses No. 26 located in fuse and fusible link box and No. 59 located in the fuse and relay box.

• 20A fuse No. 53 located in the IPDM E/R.

• Harness for short or open between battery and transfer control unit harness connector terminals

47.

• Harness for short or open between battery and transfer control unit harness connector terminal

29.

• Harness for short or open between battery and transfer shut off relay harness connector E69 terminal 1, and 3.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 2 and transfer control unit harness connector terminal 30.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 5 and transfer control unit harness connector terminals 16 and 22.

• Battery and ignition switch.

• Transfer shut off relay. Refer to DLN-23, "

Component Inspection".

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connec- tor E142 terminals 3, 6, E143 terminal 45 and ground.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to DLN-80, "

Reference Value".

Are the inspection results normal?

YES >> GO TO 4.

NO >> Check transfer control unit pin terminals for damage or loose connection with harness connector. If any items are damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

Are the inspection results normal?

YES >> Inspection End.

NO >> Replace transfer control unit. Refer to DLN-128, "

Removal and Installation".

Component InspectionINFOID:0000000001737104

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shut off relay. Refer to DLN-16, "

Component Parts Location".

3. Apply 12V direct current between transfer shut off relay termi- nals 1 and 2.

4. Check continuity between relay terminals 3 and 5.

5. If inspection results are abnormal replace the transfer shut off relay.Continuity should exist.

SDIA2691E

Condition

Continuity

12V direct current supply between terminals 1 and 2 Yes

OFF No

SCIA1245E

Revision: March 2010 2008 QX56

Page 1071 of 4083

![INFINITI QX56 2008 Factory Service Manual P1817 ACTUATOR MOTORDLN-41

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harne INFINITI QX56 2008 Factory Service Manual P1817 ACTUATOR MOTORDLN-41

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harne](/img/42/57030/w960_57030-1070.png)

P1817 ACTUATOR MOTORDLN-41

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harness connec- tor E46 terminal 5 (A), transfer shift low relay harness connector

E47 terminal 5 (B) and ground.

Are the inspection results normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts. • 20A fuse (No. 57, located in the fuse and relay box).

• Harness for short or open between battery, transfer shift high relay harness connector terminal 5and transfer shift low relay harness connector terminal 5.

3.CHECK ACTUATOR MOTOR GROUND CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shift high relay and transfer shift low relay. Refer to DLN-16, "

Component Parts Loca-

tion".

3. Check continuity between transfer shift high relay harness con- nector E46 terminals 2, 4 (A) and transfer shift low relay harness

connector E47 terminals 2, 4 (B) and ground.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK TRANSFER SHIFT RELAY

1. Turn ignition switch OFF.

2. Remove transfer shift high relay and transfer shift low relay. Refer to DLN-16, "

Component Parts Loca-

tion".

3. Apply 12V direct current between transfer shift relay terminals 1

and 2.

4. Check continuity between relay terminals 3 and 4, 3 and 5.

Are the inspection results normal?

YES >> GO TO 5.

NO >> Replace the transfer shut off relay. Refer to DLN-16, "

Component Parts Location".

5.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND TRANSFER SHIFT RELAY

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the transfer control device (actuator motor) har-

ness connector.

3. Remove transfer shift high relay and transfer shift low relay.

4. Check continuity between the following terminals.

Connector Terminal Voltage (Approx.)

A: E46 5 - Ground

Battery voltage

B: E47 5 - Ground

WDIA0311E

Continuity should exist.

WDIA0312E

Terminal ConditionContinuity

3 - 4 12V direct current supply between terminals 1 and 2 No

OFF

Yes

3 - 5 12V direct current supply between terminals 1 and 2 Yes

OFF

No

WIIA0291E

Revision: March 2010 2008 QX56

Page 1079 of 4083

![INFINITI QX56 2008 Factory Service Manual P1819 TRANSFER CONTROL DEVICEDLN-49

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer control unit INFINITI QX56 2008 Factory Service Manual P1819 TRANSFER CONTROL DEVICEDLN-49

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer control unit](/img/42/57030/w960_57030-1078.png)

P1819 TRANSFER CONTROL DEVICEDLN-49

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer control unit harness connector terminals and ground.

Are the inspection results normal?

YES >> GO TO 2.

NO >> Check the following. If any items are damaged, repair or replace damaged parts. • 10A fuse (No. 26 located in the fuse and fusible link box).

• Harness for short or open between battery and transfer shut off relay harness connector E69

terminal 1.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 2 and

transfer control unit harness connector E143 terminal 30.

• Harness for short or open between battery and transfer shut off relay harness connector E69 terminal 3.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 5 and transfer control unit harness connector E142 terminal 22.

• Transfer shut off relay. Refer to DLN-23, "

Component Inspection".

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connec- tor E142 terminals 3, 6, E143 terminal 45 and ground.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK ACTUATOR MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shift high relay and transfer shift low relay. Refer to DLN-16, "

Component Parts Loca-

tion".

3. Check voltage between transfer shift high relay harness connec- tor E46 terminal 5 (A), transfer shift low relay harness connector

E47 terminal 5 (B) and ground.

Connector Terminal Voltage (Approx.)

E142 16 - Ground

Battery voltage

22 - Ground

E143 30 - Ground 0V

SDIA2835E

Continuity should exist.

SDIA2691E

ConnectorTerminal Voltage (Approx.)

A: E46 5 - Ground

Battery voltage

B: E47 5 - Ground

WDIA0310E

Revision: March 2010 2008 QX56

Page 1080 of 4083

![INFINITI QX56 2008 Factory Service Manual DLN-50

< COMPONENT DIAGNOSIS >[ATX14B]

P1819 TRANSFER CONTROL DEVICE

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harness connec-

tor E46 termi INFINITI QX56 2008 Factory Service Manual DLN-50

< COMPONENT DIAGNOSIS >[ATX14B]

P1819 TRANSFER CONTROL DEVICE

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harness connec-

tor E46 termi](/img/42/57030/w960_57030-1079.png)

DLN-50

< COMPONENT DIAGNOSIS >[ATX14B]

P1819 TRANSFER CONTROL DEVICE

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer shift high relay harness connec-

tor E46 terminal 5 (A), transfer shift low relay harness connector

E47 terminal 5 (B) and ground.

Are the inspection results normal?

YES >> GO TO 4.

NO >> Check the following. If any items are damaged, repair or replace damaged parts. • 20A fuse (No. 57 located in the fuse and relay box).

• Harness for short or open between battery, transfer shift high relay harness connector E46 ter-minal 5 and transfer shift low relay harness connector E47 terminal 5.

4.CHECK HARNESS BETWEEN TRANSFER CONT ROL UNIT AND TRANSFER SHIFT RELAY

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and transfer control device (actuator motor) harness

connector.

3. Remove transfer shift high relay and transfer shift low relay.

4. Check continuity between the following terminals.

- Transfer control unit harness connector E143 terminal 33 and transfer shift high relay harness connector E46 terminal 3.

- Transfer control unit harness connector E143 terminal 42 and

transfer shift low relay harness connector E47 terminal 3.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK TRANSFER SHIFT RELAY GROUND CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shift high relay and transfer shift low relay.

3. Check continuity between transfer shift high relay harness con- nector E46 terminals 2, 4, transfer shift low relay harness con-

nector E47 terminals 2, 4 and ground.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 6.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to DLN-80, "

Reference Value".

Are the inspection results normal?

YES-1 >> With CONSULT-III: GO TO 7.

YES-2 >> Without CONSULT-III: GO TO 8.

NO >> Check transfer control unit pin terminals fo r damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

7.PERFORM SELF-DIAGNOSIS (WITH CONSULT-III)

Connector Terminal Voltage (Approx.)

A: E46 5 - Ground

Battery voltage

B: E47 5 - Ground

WDIA0311E

Continuity should exist.

WDIA0315E

Continuity should exist.

WDIA0312E

Revision: March 2010 2008 QX56

Page 1093 of 4083

![INFINITI QX56 2008 Factory Service Manual P1824 TRANSFER MOTORDLN-63

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Are the inspection results normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK TRANSFER MOTOR RELAY POWER SUPPL INFINITI QX56 2008 Factory Service Manual P1824 TRANSFER MOTORDLN-63

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Are the inspection results normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK TRANSFER MOTOR RELAY POWER SUPPL](/img/42/57030/w960_57030-1092.png)

P1824 TRANSFER MOTORDLN-63

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Are the inspection results normal?

YES >> GO TO 7.

NO >> GO TO 2.

2.CHECK TRANSFER MOTOR RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Connect transfer control unit harness connector.

3. Disconnect transfer motor relay.

4. Check voltage between transfer motor relay harness connector terminals and ground.

5. Turn ignition switch ON. (Do not start engine.)

6. Check voltage between transfer motor relay harness connector terminals and ground.

Are the inspection results normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts.

• 20A fuse (No. 58 located in the fuse and relay box).

• 10A fuse (No. 26 located in the fuse and fusible link box).

• Harness for short or open between battery and transfer motor relay harness connector E154 ter- minal 5.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 5 and transfer motor relay harness connector E153 terminal 2.

E143 41 -

Ground • Accelera-

tor pedal

depressed

• Vehicle

stopped

•Engine running

•Brake pedal de-

pressed 4WD shift switch:

2WD

0V

4WD shift switch:

AUTO or 4LO (A/T

selector lever P or N

position) 0V

(Battery voltage

for approx. 2 sec.

after shifting to P

and N.)

4WD shift switch:

AUTO or 4LO (Ex-

cept for A/T selector

lever P or N position) Battery voltage

4WD shift switch: 4H

(A/T selector lever P

position) 0V

(Battery voltage

for approx. 2 sec.

after shifting to P.)

4WD shift switch: 4H

(Except for A/T se-

lector lever P posi-

tion) Battery voltage

Connector Terminal

ConditionVoltage (Approx.)

Connector Terminal Voltage (Approx.)

E153 2 - Ground 0V

E154 5 - Ground Battery voltage

WDIA0169E

ConnectorTerminal Voltage (Approx.)

E153 2 - Ground

Battery voltage

E154 5 - Ground

WDIA0170E

Revision: March 2010 2008 QX56

Page 1694 of 4083

![INFINITI QX56 2008 Factory Service Manual COOLING FANEC-395

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Diagnosis ProcedureINFOID:0000000001351874

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. D INFINITI QX56 2008 Factory Service Manual COOLING FANEC-395

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Diagnosis ProcedureINFOID:0000000001351874

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. D](/img/42/57030/w960_57030-1693.png)

COOLING FANEC-395

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

COOLING FAN

Diagnosis ProcedureINFOID:0000000001351874

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E120.

3. Check voltage between IPDM E/R terminal 22 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.DETECT MALFUNCTIONING PART

Check the following.

• 40A fusible link (located in the fuse and fusible link box)

• 25A fusible link (located in the IPDM E/R box) (late production)

• Harness for open or short between IPDM E/R and battery

>> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK COOLING FAN MOTOR CIRCUIT FOR OPEN OR SHORT

1. Disconnect cooling fan motor harness connector (1).

2. Check harness continuity between cooling fan motor terminal 1 and IPDM E/R terminal 24, cooling fan motor terminal 2 and

ground.

Refer to wiring diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK COOLING FAN MOTOR

Refer to EC-395, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace cooling fan motor.

5.CHECK INTERMITTENT INCIDENT

Perform GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

OK or NG

OK >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NG >> Repair or replace harness connectors.

Component InspectionINFOID:0000000001351875

COOLING FAN MOTOR

1. Disconnect cooling fan motor harness connector. Voltage: Battery voltage

PBIB2067E

Continuity should exist.

BBIA0742E

Revision: March 2010

2008 QX56

Page 1882 of 4083

ENGINE ASSEMBLYEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

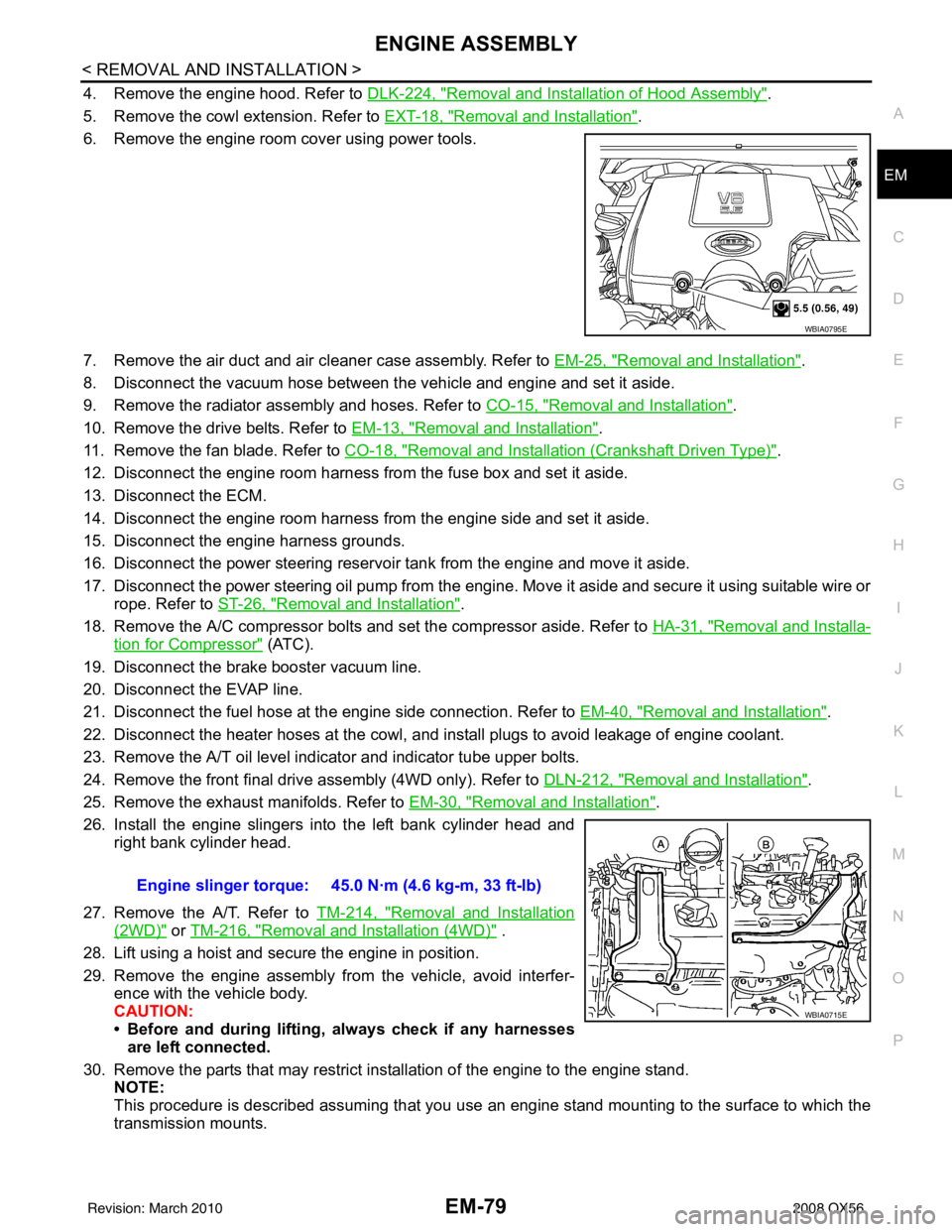

4. Remove the engine hood. Refer to

DLK-224, "Removal and Installation of Hood Assembly".

5. Remove the cowl extension. Refer to EXT-18, "

Removal and Installation".

6. Remove the engine room cover using power tools.

7. Remove the air duct and air cleaner case assembly. Refer to EM-25, "

Removal and Installation".

8. Disconnect the vacuum hose between the vehicle and engine and set it aside.

9. Remove the radiator assembly and hoses. Refer to CO-15, "

Removal and Installation".

10. Remove the drive belts. Refer to EM-13, "

Removal and Installation".

11. Remove the fan blade. Refer to CO-18, "

Removal and Installation (Crankshaft Driven Type)".

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir t ank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or rope. Refer to ST-26, "

Removal and Installation".

18. Remove the A/C compressor bolts and set the compressor aside. Refer to HA-31, "

Removal and Installa-

tion for Compressor" (ATC).

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to EM-40, "

Removal and Installation".

22. Disconnect the heater hoses at the cowl, and in stall plugs to avoid leakage of engine coolant.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to DLN-212, "

Removal and Installation".

25. Remove the exhaust manifolds. Refer to EM-30, "

Removal and Installation".

26. Install the engine slingers into the left bank cylinder head and right bank cylinder head.

27. Remove the A/T. Refer to TM-214, "

Removal and Installation

(2WD)" or TM-216, "Removal and Installation (4WD)" .

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicle, avoid interfer- ence with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnessesare left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand. NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Revision: March 2010 2008 QX56

Page 2305 of 4083

![INFINITI QX56 2008 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For fuse layout. Refer to

PG-70,

"Ter INFINITI QX56 2008 Factory Service Manual HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For fuse layout. Refer to

PG-70,

"Ter](/img/42/57030/w960_57030-2304.png)

HAC-52

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For fuse layout. Refer to

PG-70,

"Terminal Arrangement".

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 7.

2.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector.

3. Turn ignition switch ON.

4. Press the A/C switch.

5. Press the front blower control "+" switch to maximum speed.

6. Check voltage between front blower motor harness connector M62 terminal 2 and ground.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 3.

3.CHECK FRONT BLOWER MOTOR RELAY (S WITCH SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front blower motor relay.

3. Check voltage between front blower motor relay harness con- nector M107 terminal 5 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-54, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace front blower motor relay.

5.CHECK FRONT BLOWER MOTOR RELA Y (SWITCH SIDE) CIRCUIT FOR OPEN

Check continuity between front blower motor relay harness connec-

tor M107 terminal 3 and front blower motor harness connector M62

terminal 2.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair harness or connector.

6.CHECK FRONT BLOWER MOTOR RE LAY (COIL SIDE) POWER SUPPLY

Fuses are good.

2 - Ground

: Battery voltage

WJIA1331E

5 - Ground: Battery voltage

WJIA1886E

3 - 2 : Continuity should exist.

WJIA1360E

Revision: March 2010 2008 QX56

Page 2482 of 4083

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000001602122

REMOVAL

CAUTION:

Disconnect both the negative and po sitive battery terminals in advance.

1. Disconnect both negative and positive termi nals, then wait at least 3 minutes.

2. Remove front center console. Refer to IP-20, "

Removal and Installation".

3. Remove steering column assembly. Refer to ST-20, "

Removal and Installation".

4. Remove combination meter. Refer to MWI-76, "

Removal and Installation".

5. Remove instrument panel upper cover and disconnect rear sonar speaker (if equipped).

6. Remove cluster lid C. Refer to IP-15, "

Removal and Installation".

7. Remove display assembly. Refer to AV-164, "

Removal and Installation".

8. Remove instrument lower/upper panel RH and glove box. Refer to IP-17, "

Removal and Installation" and

IP-18, "

Removal and Installation".

9. Release the clips, disconnect the optical sensor harness and remove defroster grille.

10. Release the clips, disconnect the connecto rs and remove RH, LH, and center speakers.

11. Remove RH/LH front pillar finishers. Refer to INT-14, "

Removal and Installation".

12. Remove the passenger air bag module nuts and disconnect the connectors. Refer to SR-10, "

Removal

and Installation".

13. Disconnect remaining optional equipment connectors (if equipped).

14. Remove instrument panel and pad assembly screws.

15. Release instrument panel and pad assembly lifting rearward away from steering member, then carefully remove through front door opening.

1. Defroster grille 2. Center speaker grille3. Speaker center

4. Speaker grille outer 5. Speaker outer6. Instrument panel upper cover

7. Instrument panel and pad assembly 8. Side ventilator assembly LH 9. Combination meter

10. Instrument upper panel LH 11. Cluster lid A 12. Key cylinder escutcheon

13. Lower knee protector 14. Instrument lower panel LH 15. Steering column cover upper

16. Steering column cover lower 17. Cluster lid C lower 18. 4WD switch (if equipped)

19. Hazard switch 20. Cluster lid C21. Instrument lower cover RH

22. Fuse access cover 23. Glove box 24. Instrument lower panel RH

25. Audio switch RH 26. A/C and AV switch assembly 27. Audio unit

28. Audio switch LH 29. Center ventilator assembly LH 30. Display assembly

31. Center ventilator assembly RH 32. Side ventilator assembly RH 33. Instrument upper panel RH Metal clip Clip

ALJIA0083ZZ

Revision: March 2010 2008 QX56

Page 2487 of 4083

INSTRUMENT LOWER PANEL RH AND GLOVE BOXIP-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

INSTRUMENT LOWER PANE L RH AND GLOVE BOX

Exploded ViewINFOID:0000000001602127

Removal and InstallationINFOID:0000000001602128

REMOVAL

1. Remove the instrument lower cover RH.

⇐: Vehicle front

2. Remove the instrument lower panel RH screws.

3. Release the clips and remove instrument lower panel RH and glove box from instrument panel and pad assembly.

4. Release the clips and remove fuse access cover.

5. Remove glove box pivot pins and damper clip, then remove glove box from instrument panel RH.

INSTALLATION

Installation is in the reverse order of removal.

1. Instrument panel and pad assembly 2. Instrument lower panel RH 3. Glove box

4. Fuse access cover 5. Glove box pivot pin⇐Vehicle front

Clip

ALJIA0079ZZ

LLIA0072E

Revision: March 2010 2008 QX56