sunroof INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 593 of 4083

BODY REPAIRBRM-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

5. Front pillar hinge brace (RH, LH)

6. Center pillar hinge brace

7. Outer front pillar reinforcement (RH, LH)

8. Center inner pillar (RH, LH)

9. Front inner pillar upper (RH, LH)

10. Inner roof side rail (RH, LH)

11. Roof with sunroof opening

12. Roof

13. Front roof rail

14. Sunroof reinforcement

15. Roof 1st bow

16. Roof 2nd bow

17. Roof 3rd bow

18. Roof 4th bow

19. Rear roof rail

20. Main back pillar (RH, LH)

21. Back pillar reinforcement (RH, LH)

22. Rear inner side panel (RH, LH)

23. Rear wheel housing (RH, LH)

24. Rear body side outer (RH, LH)

25. Front body side outer (RH, LH)

26. Front door assembly (RH, LH)

27. Rear door assembly (RH, LH)

28. Lift gate assembly

Revision: March 2010 2008 QX56

Page 1009 of 4083

![INFINITI QX56 2008 Factory Service Manual DLK-216

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s) INFINITI QX56 2008 Factory Service Manual DLK-216

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s)](/img/42/57030/w960_57030-1008.png)

DLK-216

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, se

curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: March 2010 2008 QX56

Page 2061 of 4083

EXT-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: March 2010 2008 QX56

Page 2454 of 4083

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-5

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: March 2010 2008 QX56

Page 2466 of 4083

HEADLININGINT-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

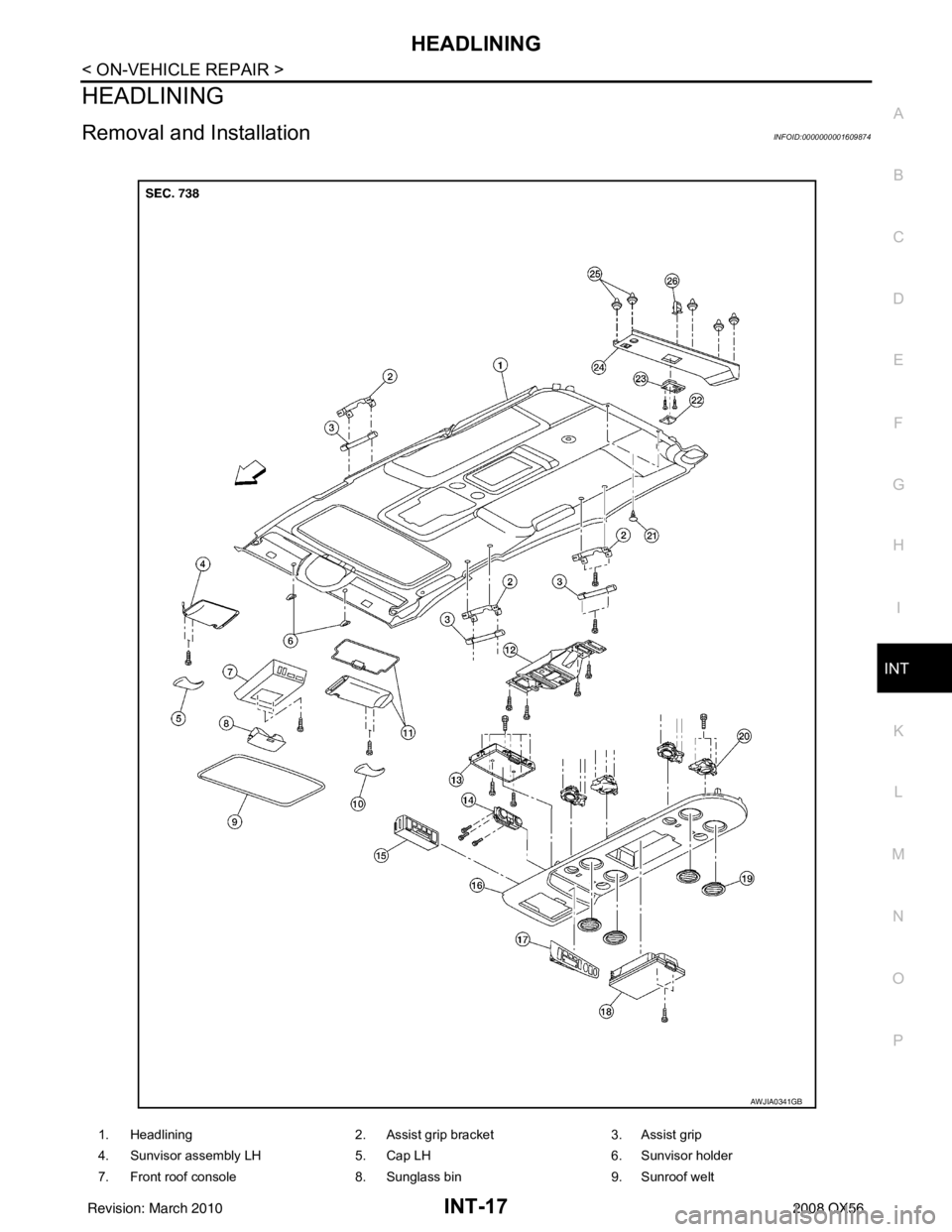

HEADLINING

Removal and InstallationINFOID:0000000001609874

1. Headlining 2. Assist grip bracket3. Assist grip

4. Sunvisor assembly LH 5. Cap LH 6. Sunvisor holder

7. Front roof console 8. Sunglass bin9. Sunroof welt

AWJIA0341GB

Revision: March 2010 2008 QX56

Page 2467 of 4083

INT-18

< ON-VEHICLE REPAIR >

HEADLINING

CAUTION:

Disconnect both terminals from battery in advance.

REMOVAL

1. Remove the body side trim. Refer to INT-14.

2. Remove the luggage floor trim. Refer to INT-19

.

3. Remove the sunvisor assemblies.

4. Remove the sunvisor clips.

5. Remove the sunroof welt.

6. Remove the front roof console. • Disconnect the harnesses.

7. Remove the rear roof console. • Disconnect the harnesses.

8. Remove the assist grips.

9. Remove the lamp assembly and the rear roof finisher. • Disconnect the harness.

10. Remove the headlining. • Remove the clips from the rear of headlining.

• Disconnect the harnesses.

11. Remove the rear air control. • Disconnect the harness.

12. Remove the rear audio control assembly. • Disconnect the harness.

13. Remove the lamp assemblies. • Disconnect the harnesses.

14. Remove the air vents.

15. Remove the front roof console bracket.

16. Remove the rear roof console front bracket.

17. Remove the assist grip brackets from roof.

INSTALLATION

Installation is in the reverse order of removal.

10. Cap RH 11. Sunvisor assembly RH12. Rear roof console bracket

13. Rear storage bin or DVD display 14. Rear air control 15. Rear audio control assembly

16. Rear roof console 17. Rear roof console finisher18. Rear storage bin

19. Air vent 20. Lamp assembly21. Plastic clip

22. Rear lamp lens 23. Rear lamp24. Rear roof finisher

25. Plastic clip 26. Metal clip Vehicle front

Revision: March 2010 2008 QX56

Page 2478 of 4083

IP-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: March 2010 2008 QX56

Page 2775 of 4083

PG-8

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000006095112

Required Procedure After Battery Disconnection

System ItemReference

Engine Control Idle Air Volume Learning Refer to EC-18

.

Brake Control Steering Angle Sensor Neutral Position Refer to BRC-8

.

Power Window Control Power Window System Initialization Refer to TSB.

Body, Lock & Security Automatic Back Door Initialization Refer to DLK-9

.

Roof Sunroof Memory Reset/Initialization Refer to RF-5

.

Seats Automatic Drive Positioner System Initialization Refer to Owner's Manual.

Audio-Visual System Audio (Radio Preset)

Refer to Owner's Manual.

Navigation System Refer to Owner's Manual.

Rear View Monitor Guiding Line Adjustment Refer to AV- 7

.

Revision: March 2010 2008 QX56

Page 2823 of 4083

PG-56

< COMPONENT DIAGNOSIS >

HARNESS

FRONT DOOR LH HARNESS

D3 R3 W/2 : Vanity lamp LHD2 R109 W/4 : Microphone

C3 R4 GR/10 : Sunroof motor assembly Room lamp sub-harness B

C2 R6 W/16 : To R101 D1 R200 W/16 : To B145

C3 R7 GR/10 : Auto anti-dazzling inside mirror D1 R201 BR/24 : To B146

B3 R8 W/2 : Vanity lamp RH C2 R202 W/12 : Video monitor

D3 R9 W/8 : To R107 D1 R203 W/3 : Personal lamp 2ND row

Room lamp sub-harness A D2 R204 W/16 : Rear audio remote control unit

C2 R101 W/16 : To R6 E1 R205 W/3 : Personal lamp 3RD row

C3 R102 GR/8 : Front room/map lamp assembly D2 R209 B/6 : Rear air control (rear)

D3 R104 GR/6 : Sunroof switch E1 R210 W/2 : Inside key antenna 4 (over head console area)

ALMIA0215GB

D1 W/24 : To M9 D9 GR/6 : Front power window motor LH

D2 W/16 : To M8 D10 W/16 : Door mirror remote control switch

D3 W10 : To M158 D11 W/2 : Front step lamp LH

D4 W/16 : Door mirror LH D12 W/2 : Front door speaker LH

D5 W/8 : Seat memory switch D14 B/6 : Front door lock assembly LH

D7 W/16 : Main power window and door lock/unlock

switch D15 B/6 : Front outside antenna

D8 W/3 : Main power window and door lock/unlock

switch

D16 GR/2 : Front door request switch LH

Revision: March 2010

2008 QX56

Page 2985 of 4083

RF-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION RF

A

B

RF

N

O P

CONTENTS

ROOF

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

5

BASIC INSPECTION ...................................................5

BASIC INSPECTION : Spec ial Repair Require-

ment .................................................................... ......

5

FUNCTION DIAGNOSIS ...............................6

SUNROOF SYSTEM ...................................... .....6

System Diagram ................................................. ......6

System Description ...................................................6

Component Parts Location ......................................7

Component Description ............................................7

DIAGNOSIS SYSTEM (BCM) .............................8

COMMON ITEM ..................................................... ......8

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .......................................................

8

RETAINED PWR .........................................................8

RETAINED PWR : CONSULT-III Function (BCM -

RETAINED PWR) .....................................................

8

COMPONENT DIAGNOSIS .........................10

POWER SUPPLY AND GROUND CIRCUIT .. ....10

SUNROOF MOTOR ASSEMBLY .......................... ....10

SUNROOF MOTOR ASSEMBLY :

Diagnosis Procedure ..............................................

10

SUNROOF MOTOR ASSEMBLY : Special Repair

Requirement ........................................................ ....

11

SUNROOF SWITCH CIRCUIT ..........................12

Description ...............................................................12

Component Function Check ..................................12

Diagnosis Procedure ...............................................12

DOOR SWITCH .................................................14

Description ...............................................................14

Component Function Check ....................................14

Diagnosis Procedure ...............................................14

Component Inspection .............................................15

ECU DIAGNOSIS .........................................16

BCM (BODY CONTROL MODULE) .................16

Reference Value .................................................. ....16

Terminal Layout .......................................................18

Physical Values ................................................... ....18

Wiring Diagram ........................................................24

Fail Safe ..................................................................27

DTC Inspection Priority Chart ...............................28

DTC Index ...............................................................28

SUNROOF SYSTEM .........................................30

Reference Value ......................................................30

Wiring Diagram ........................................................31

SYMPTOM DIAGNOSIS ..............................35

SUNROOF DOES NOT OPERATE PROPER-

LY ......................................................................

35

Diagnosis Procedure ........................................... ....35

AUTO OPERATION DOES NOT OPERATE ....36

Diagnosis Procedure ...............................................36

DOES NOT STOP FULLY-OPEN OR FULLY-

CLOSED POSITION ..........................................

37

Diagnosis Procedure ...............................................37

Revision: March 2010 2008 QX56