tire pressure INFINITI QX56 2009 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 4070 of 4171

WT-28

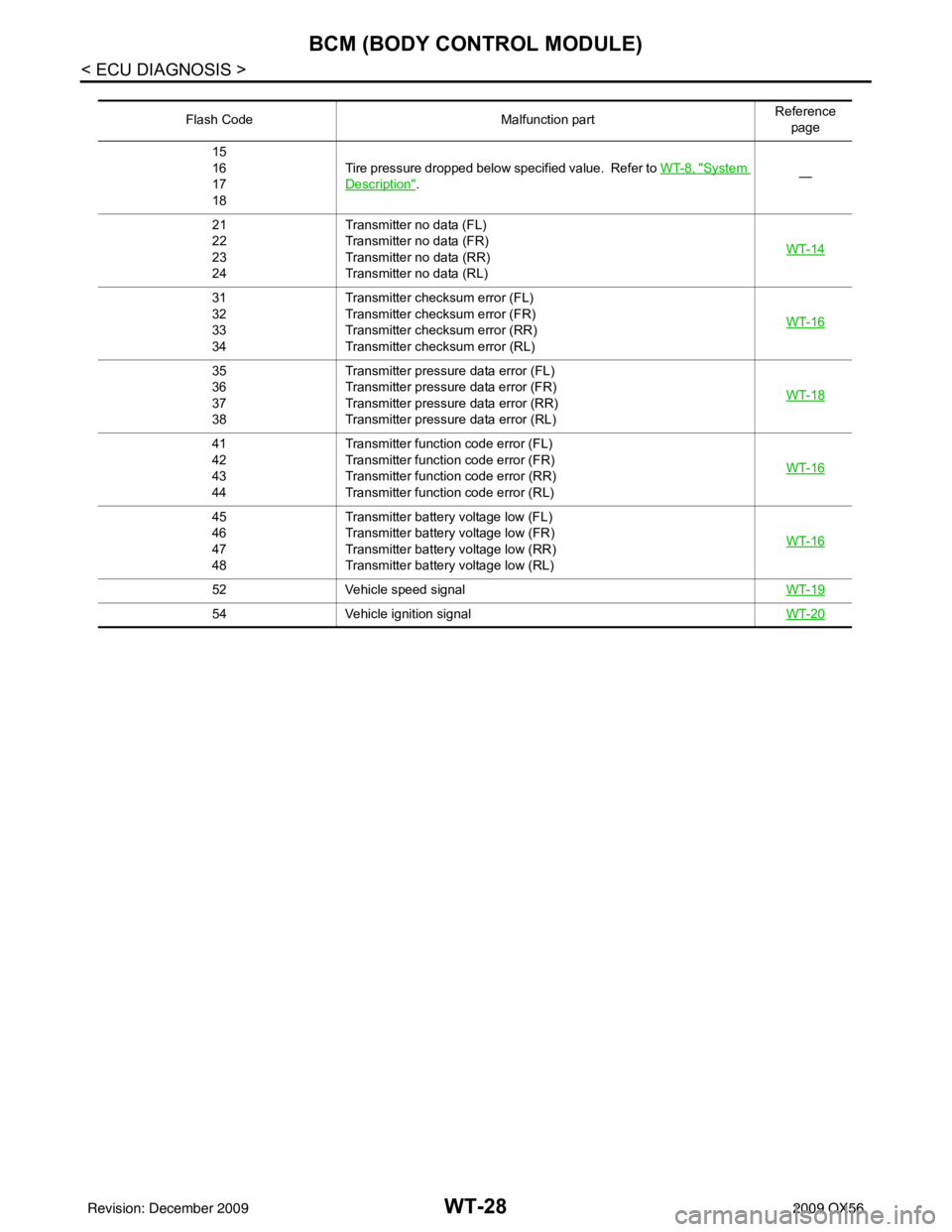

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

Flash CodeMalfunction partReference

page

15

16

17

18 Tire pressure dropped below specified value. Refer to

WT-8, "

System

Description". —

21

22

23

24 Transmitter no data (FL)

Transmitter no data (FR)

Transmitter no data (RR)

Transmitter no data (RL)

WT-14

31

32

33

34Transmitter chec

ksum error (FL)

Transmitter chec ksum error (FR)

Transmitter chec ksum error (RR)

Transmitter chec ksum error (RL) WT-16

35

36

37

38Transmitter pressure

data error (FL)

Transmitter pressure data error (FR)

Transmitter pressure data error (RR)

Transmitter pressure data error (RL) WT-18

41

42

43

44Transmitter function

code error (FL)

Transmitter function code error (FR)

Transmitter function code error (RR)

Transmitter function code error (RL) WT-16

45

46

47

48Transmitter battery voltage low (FL)

Transmitter battery voltage low (FR)

Transmitter battery voltage low (RR)

Transmitter battery voltage low (RL)

WT-16

52

Vehicle speed signal WT-19

54Vehicle ignition signal WT-20

Revision: December 20092009 QX56

Page 4071 of 4171

TPMS

WT-29

< SYMPTOM DIAGNOSIS >

C

D F

G H

I

J

K L

M A

B

WT

N

O P

SYMPTOM DIAGNOSIS

TPMS

Symptom TableINFOID:0000000003772391

Symptom Reference

Low tire pressure warning lamp does not come on when ignition switch is turned on. WT-30

Low tire pressure warning lamp stays on when ignition switch is turned on.WT-31

Low tire pressure warning lamp flashes when ignition switch is turned on.WT-32

Hazard warning lamps flash when ignition switch is turned on.WT-33

Tire pressure information in display unit does not exist.WT-35

ID registration cannot be completed.WT-35

Revision: December 20092009 QX56

Page 4072 of 4171

WT-30

< SYMPTOM DIAGNOSIS >

LOW TIRE PRESSURE WARNING LAMP DOES NOT TURN ON

LOW TIRE PRESSURE WARNING LAMP DOES NOT TURN ON

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

INFOID:0000000003772392

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-III, check display c ontents of BCM in SELF-DIAGNOSIS.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system.

NO >> GO TO 2

2.CHECK COMBINATION METER

Check combination meter operation. Refer to MWI-25, "

CONSULT-III Function (METER/M&A)".

Inspection results OK?

YES >> GO TO 3

NO >> Replace combination meter. Refer to MWI-102, "

Removal and Installation".

3.CHECK LOW TIRE PRESSURE WARNING LAMP

Disconnect BCM harness connector.

Does the low tire pressure warning lamp activate?

YES >> Replace BCM. Refer to BCS-56, "Removal and Installation".

NO >> Check combination meter operation.

Revision: December 20092009 QX56

Page 4073 of 4171

LOW TIRE PRESSURE WARNING LAMP STAYS ONWT-31

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

LOW TIRE PRESSURE WA RNING LAMP STAYS ON

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000003772393

DIAGNOSTIC PROCEDURE

1.BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors.

3. Check terminals for damage or loose connections.

Are any of the BCM c onnectors loose or damaged?

YES >> Repair or replace damaged parts.

NO >> GO TO 2

2.BCM POWER SUPPLY AND GROUND CIRCUITS

Check BCM power supply and ground circuits. Refer to BCS-32, "

Diagnosis Procedure".

Are the BCM power supply and ground circuits OK?

YES >> Replace BCM. Refer to BCS-56, "Removal and Installation".

NO >> Repair BCM circuits.

Revision: December 20092009 QX56

Page 4074 of 4171

WT-32

< SYMPTOM DIAGNOSIS >

LOW TIRE PRESSURE WARNING LAMP BLINKS

LOW TIRE PRESSURE WARNING LAMP BLINKS

Low Tire Pressure Warning Lamp Flashes When Ignition Switch Is Turned On

INFOID:0000000003772394

NOTE:

If low tire pressure warning lamp flashes as shown, the system is normal.

Flash Mode A

• This mode shows transmitter status is OFF-mode.

Carry out transmitter wake up operation. Refer to WT-5, "

Transmit-

ter Wake Up Operation".

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors.

3. Check terminals for damage or loose connections.

Inspection results OK?

YES >> GO TO 2

NO >> Repair or replace damaged parts.

2.CHECK TIRE PRESSURE WARNING CHECK CONNECTOR CIRCUIT

Check continuity between BCM harness connector M18 terminal 15

and ground.

Does continuity exist?

YES >> Repair circuit for short to ground.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installa-

tion".

SEIA0347E

Continuity should not exist.

ALEIA0014ZZ

Revision: December 20092009 QX56

Page 4076 of 4171

WT-34

< SYMPTOM DIAGNOSIS >

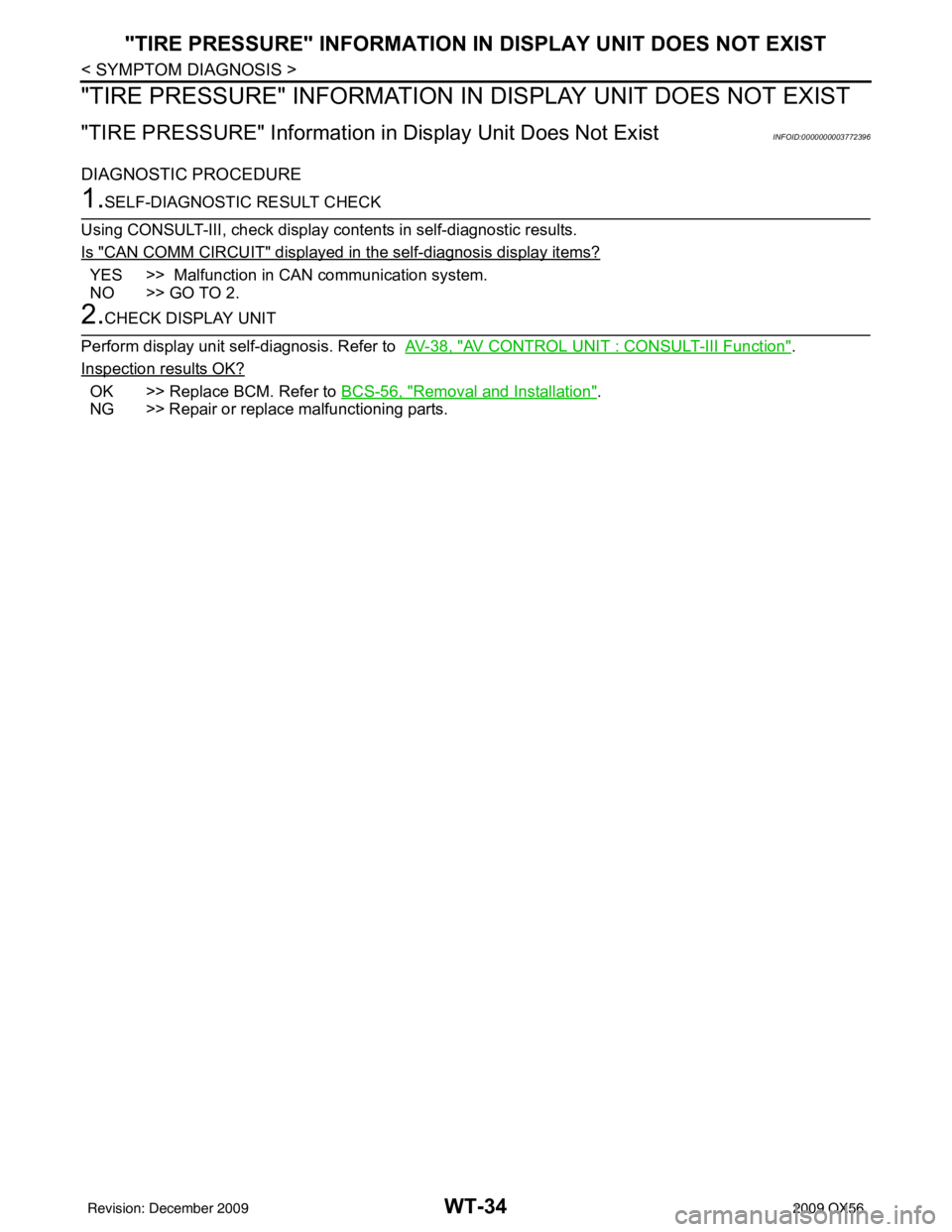

"TIRE PRESSURE" INFORMATION IN DISPLAY UNIT DOES NOT EXIST

"TIRE PRESSURE" INFORMATION IN DISPLAY UNIT DOES NOT EXIST

"TIRE PRESSURE" Information in Display Unit Does Not ExistINFOID:0000000003772396

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-III, check display contents in self-diagnostic results.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system.

NO >> GO TO 2.

2.CHECK DISPLAY UNIT

Perform display unit self-diagnosis. Refer to AV-38, "

AV CONTROL UNIT : CONSULT-III Function".

Inspection results OK?

OK >> Replace BCM. Refer to BCS-56, "Removal and Installation".

NG >> Repair or replace malfunctioning parts.

Revision: December 20092009 QX56

Page 4078 of 4171

WT-36

< SYMPTOM DIAGNOSIS >

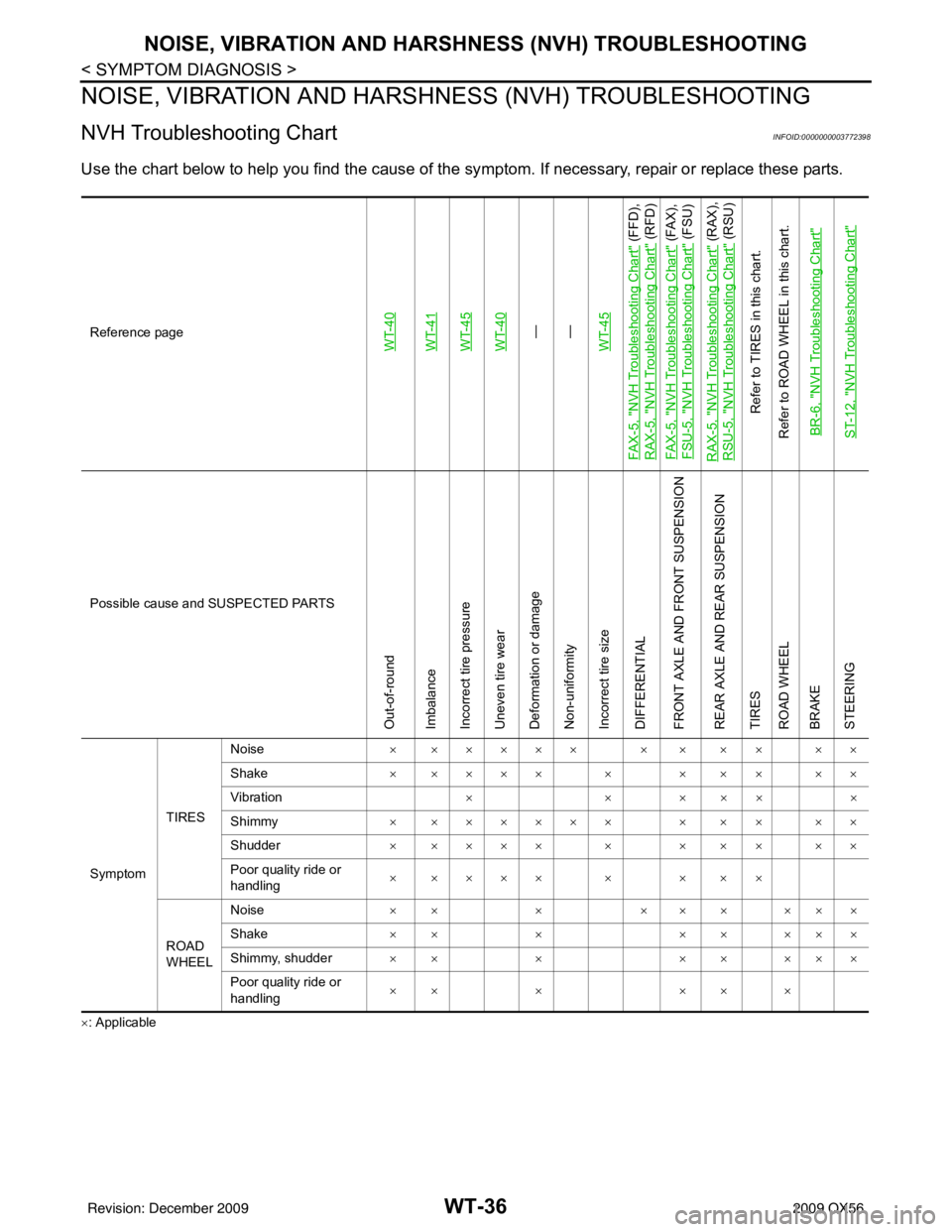

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003772398

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

WT-40WT-41WT-45WT-40—

—

WT-45

FA X - 5 , "

NVH Troubleshooting Chart

" (FFD),

RAX-5, "

NVH Troubleshooting Chart

" (RFD)

FA X - 5 , "

NVH Troubleshooting Chart

" (FAX),

FSU-5, "

NVH Troubleshooting Chart

" (FSU)

RAX-5, "

NVH Troubleshooting Chart

" (RAX),

RSU-5, "

NVH Troubleshooting Chart

" (RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

Symptom TIRESNoise

× ××××× × × × × ××

Shake × ×××× × × × × ××

Vibration ××× ×××

Shimmy × ×××××× × × × ××

Shudder × ×××× × × × × ××

Poor quality ride or

handling × ×××× × × × ×

ROAD

WHEEL Noise

×× × ××× ×××

Shake ×× × ×× ×××

Shimmy, shudder ×× × ×× ×××

Poor quality ride or

handling ×× ×

×× ×

Revision: December 20092009 QX56

Page 4085 of 4171

REMOVAL AND INSTALLATIONWT-43

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Transmitter (Pressure Sensor)INFOID:0000000003772405

REMOVAL

1. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

2. Gently bounce tire so that transmitter falls to bottom of tire. Place wheel and tire assembly on tire changing machine and

break both tire beads. Ensure that the transmitter remains at the

bottom of the tire while breaking the bead.

3. Turn tire so that valve hole is at bottom, and gently bounce the tire to ensure transmitter is near valve hole. Carefully lift tire onto

turntable and position valve hole (and transmitter) 270 degrees

from mounting/dismounting head.

4. Lubricate tire well, and remove top side of tire. Reach inside the tire and remove the transmitter.

5. Remove the second side of the tire as normal.

INSTALLATION

1. Place first side of tire onto rim.

2. Mount transmitter on rim and tighten nut to specification.

SEIA0047E

WEIA0046E

SEIA0049E

Transmitter nut : 7.7 N·m (0.79 kg-m, 68 in-lb)

WEIA0137E

Revision: December 20092009 QX56

Page 4087 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)WT-45

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

WT

N

O P

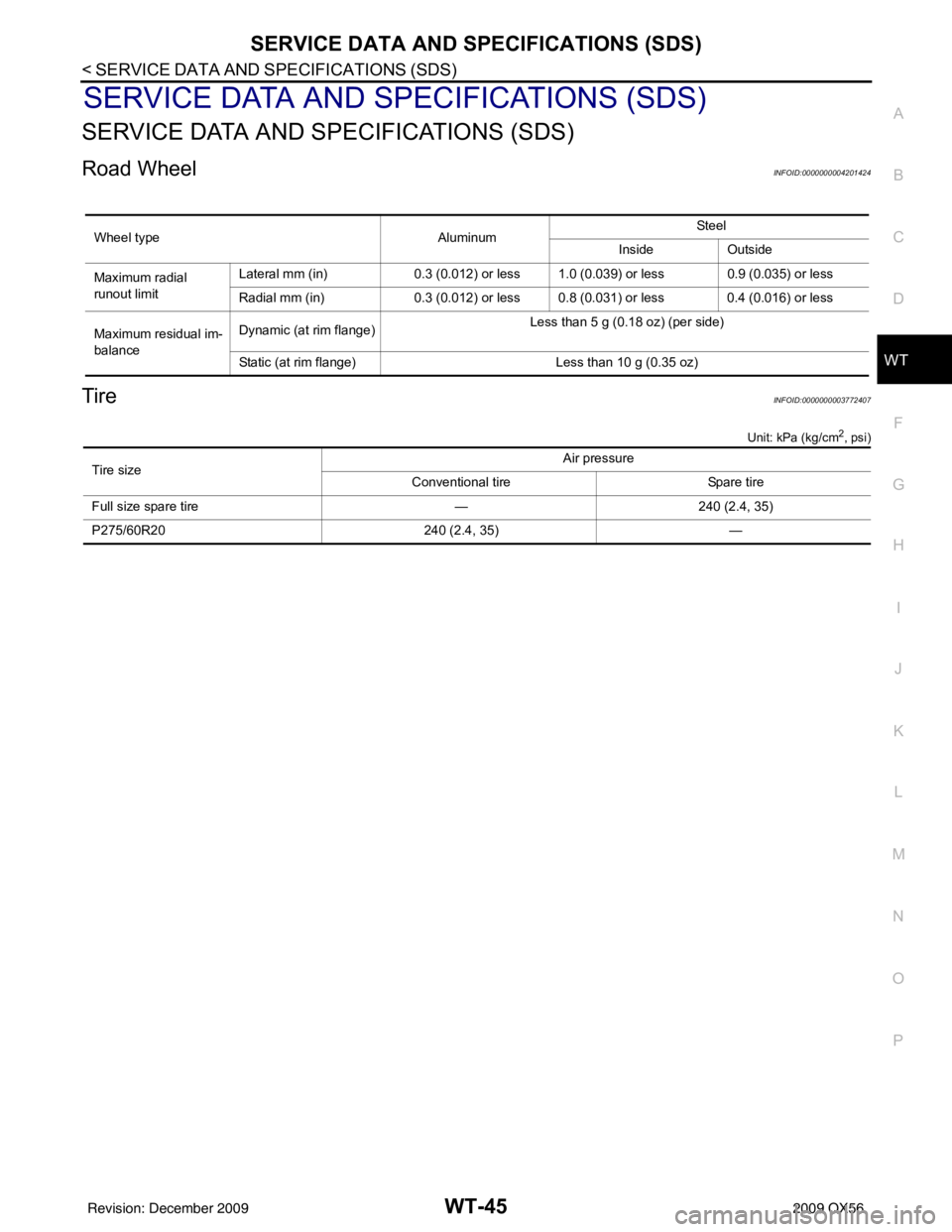

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Road WheelINFOID:0000000004201424

TireINFOID:0000000003772407

Unit: kPa (kg/cm2, psi)

Wheel type AluminumSte el

Inside Outside

Maximum radial

runout limit Lateral mm (in)

0.3 (0.012) or less 1.0 (0.039) or less 0.9 (0.035) or less

Radial mm (in) 0.3 (0.012) or less 0.8 (0.031) or less 0.4 (0.016) or less

Maximum residual im-

balance Dynamic (at rim flange)

Less than 5 g (0.18 oz) (per side)

Static (at rim flange) Less than 10 g (0.35 oz)

Tire size Air pressure

Conventional tire Spare tire

Full size spare tire —240 (2.4, 35)

P275/60R20 240 (2.4, 35)—

Revision: December 20092009 QX56

Page 4131 of 4171

WW-44

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

Te r m i n a lWire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF)

Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing)

0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 R/L Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF

—5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF

—0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56