torque INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3880 of 4171

TM-232

< DISASSEMBLY AND ASSEMBLY >

DISASSEMBLY

DISASSEMBLY

DisassemblyINFOID:0000000004187489

CAUTION:

Do not disassemble parts behind Drum Support. Refer to TM-8, "Cross-Sectional View (2WD models)"

.

1. Drain A/T fluid through drain plug.

2. Remove torque converter by holding it firmly and turing while pulling straight out.

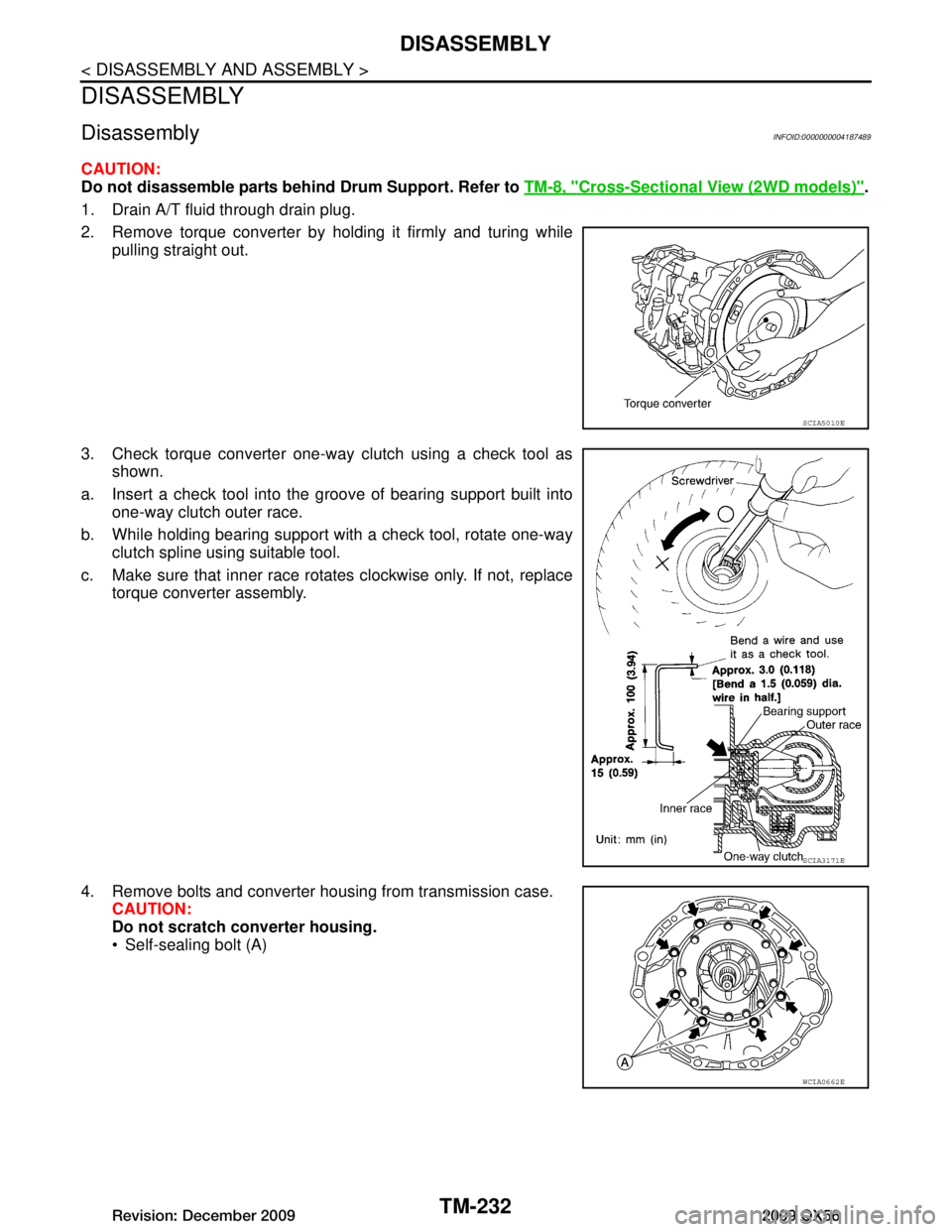

3. Check torque converter one-way clutch using a check tool as shown.

a. Insert a check tool into the groove of bearing support built into one-way clutch outer race.

b. While holding bearing support with a check tool, rotate one-way clutch spline using suitable tool.

c. Make sure that inner race rotates clockwise only. If not, replace torque converter assembly.

4. Remove bolts and converter housing from transmission case. CAUTION:

Do not scratch converter housing.

Self-sealing bolt (A)

SCIA5010E

SCIA3171E

WCIA0662E

Revision: December 20092009 QX56

Page 3899 of 4171

REPAIR FOR COMPONENT PARTSTM-251

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

3. Install new oil pump housing oil seal to the oil pump housing until it is flush with the face of oil pump housing using Tool.

CAUTION:

Do not reuse oil seal.

Apply ATF to oil seal.

4. Install oil pump housing in oil pump cover. Tighten oil pump housing bolts to the specified torque. Refer to TM-220, "Compo-

nent".

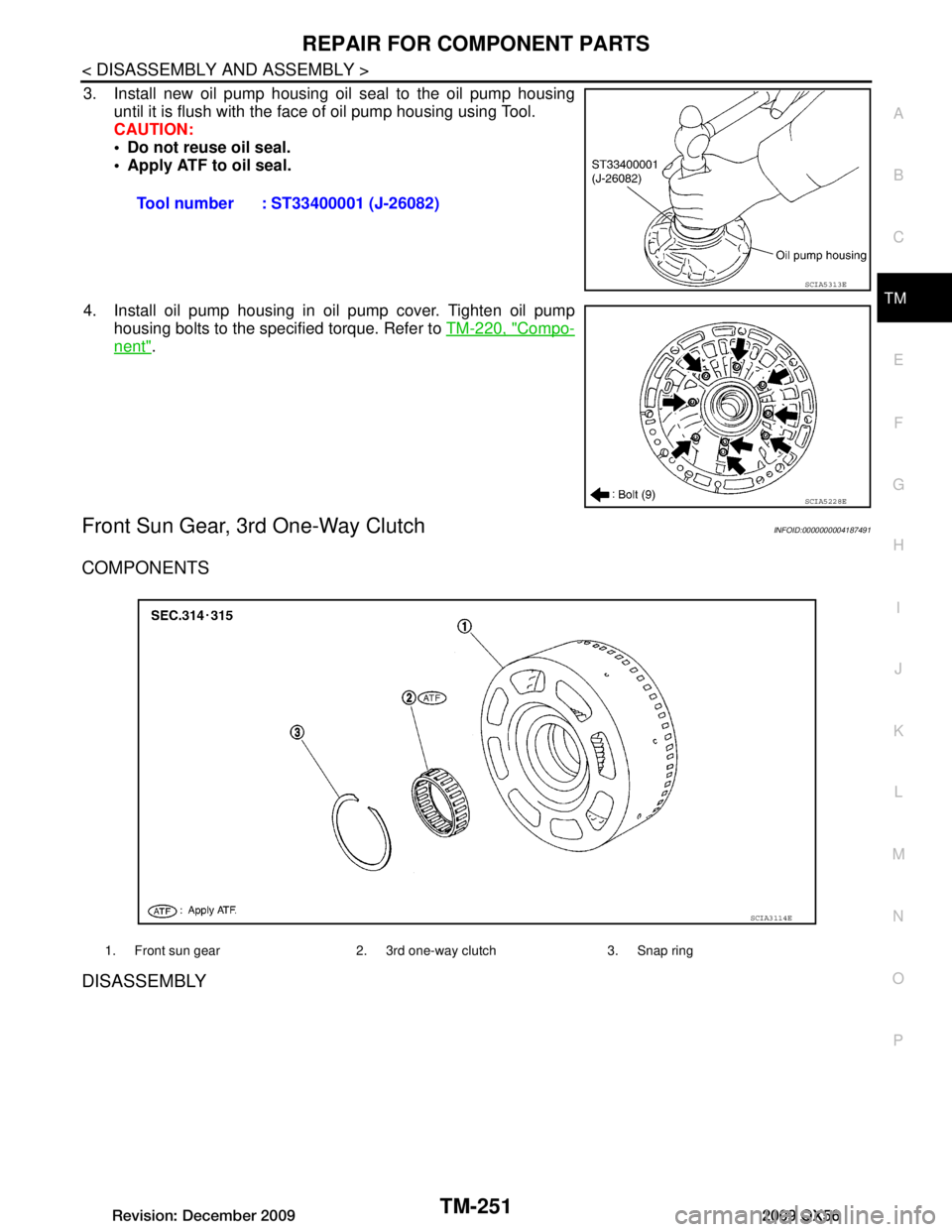

Front Sun Gear, 3rd One-Way ClutchINFOID:0000000004187491

COMPONENTS

DISASSEMBLY

Tool number : ST33400001 (J-26082)

SCIA5313E

SCIA5228E

1. Front sun gear 2. 3rd one-way clutch 3. Snap ring

SCIA3114E

Revision: December 20092009 QX56

Page 3921 of 4171

ASSEMBLYTM-273

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

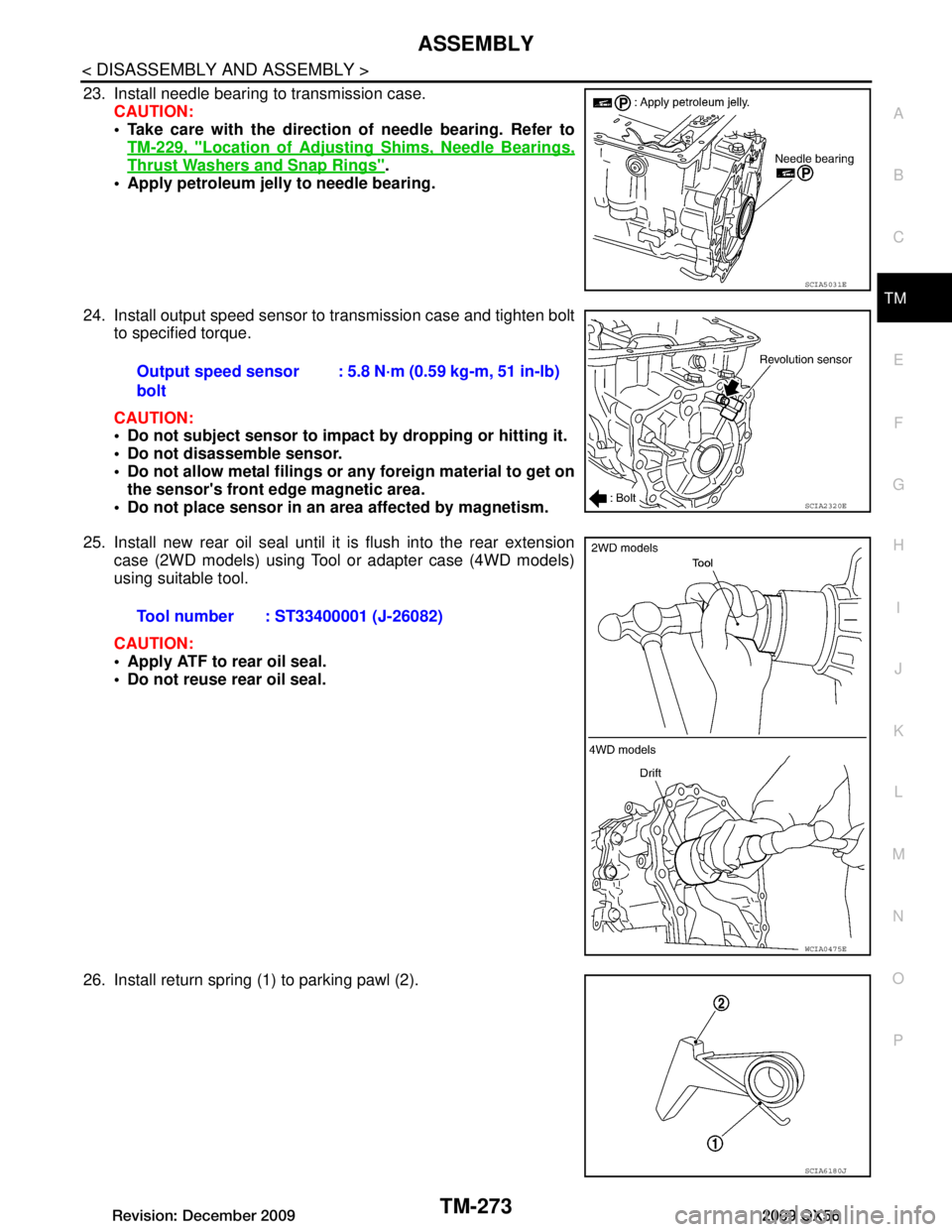

23. Install needle bearing to transmission case. CAUTION:

Take care with the direction of needle bearing. Refer toTM-229, "Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

Apply petroleum jelly to needle bearing.

24. Install output speed sensor to transmission case and tighten bolt to specified torque.

CAUTION:

Do not subject sensor to impact by dropping or hitting it.

Do not disassemble sensor.

Do not allow metal filings or any foreign material to get on

the sensor's front edge magnetic area.

Do not place sensor in an area affected by magnetism.

25. Install new rear oil seal until it is flush into the rear extension case (2WD models) using Tool or adapter case (4WD models)

using suitable tool.

CAUTION:

Apply ATF to rear oil seal.

Do not reuse rear oil seal.

26. Install return spring (1) to parking pawl (2).

SCIA5031E

Output speed sensor

bolt : 5.8 N·m (0.59 kg-m, 51 in-lb)

SCIA2320E

Tool number : ST33400001 (J-26082)

WCIA0475E

SCIA6180J

Revision: December 20092009 QX56

Page 3924 of 4171

TM-276

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

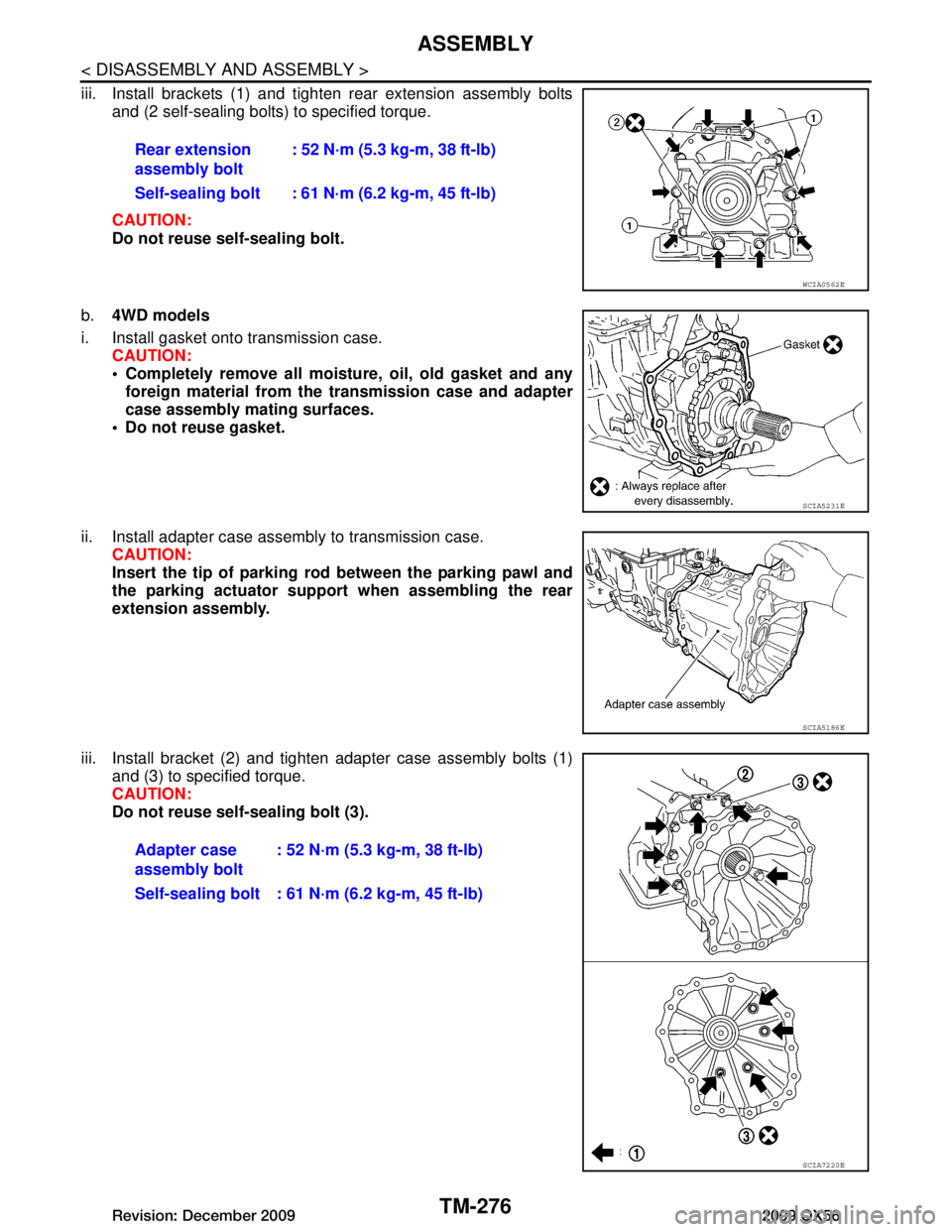

iii. Install brackets (1) and tighten rear extension assembly boltsand (2 self-sealing bolts) to specified torque.

CAUTION:

Do not reuse self-sealing bolt.

b. 4WD models

i. Install gasket onto transmission case. CAUTION:

Completely remove all moistu re, oil, old gasket and any

foreign material from the transmission case and adapter

case assembly mating surfaces.

Do not reuse gasket.

ii. Install adapter case assembly to transmission case. CAUTION:

Insert the tip of parking rod between the parking pawl and

the parking actuator support when assembling the rear

extension assembly.

iii. Install bracket (2) and tighten adapter case assembly bolts (1) and (3) to specified torque.

CAUTION:

Do not reuse self-sealing bolt (3).Rear extension

assembly bolt

: 52 N·m (5.3 kg-m, 38 ft-lb)

Self-sealing bolt : 61 N·m (6.2 kg-m, 45 ft-lb)

WCIA0562E

SCIA5231E

SCIA5186E

Adapter case

assembly bolt : 52 N·m (5.3 kg-m, 38 ft-lb)

Self-sealing bolt : 61 N·m (6.2 kg-m, 45 ft-lb)

SCIA7220E

Revision: December 20092009 QX56

Page 3929 of 4171

ASSEMBLYTM-281

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

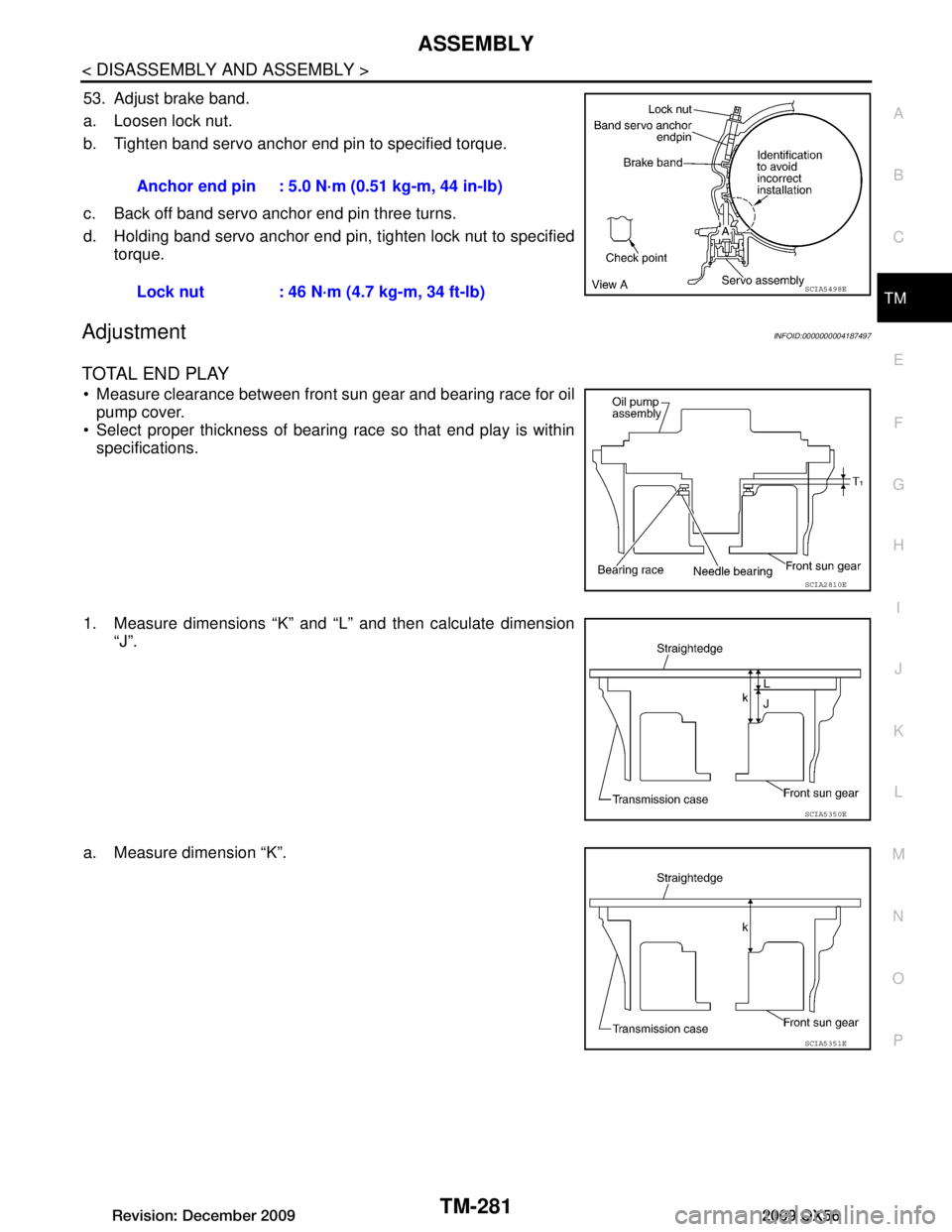

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back off band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to specified torque.

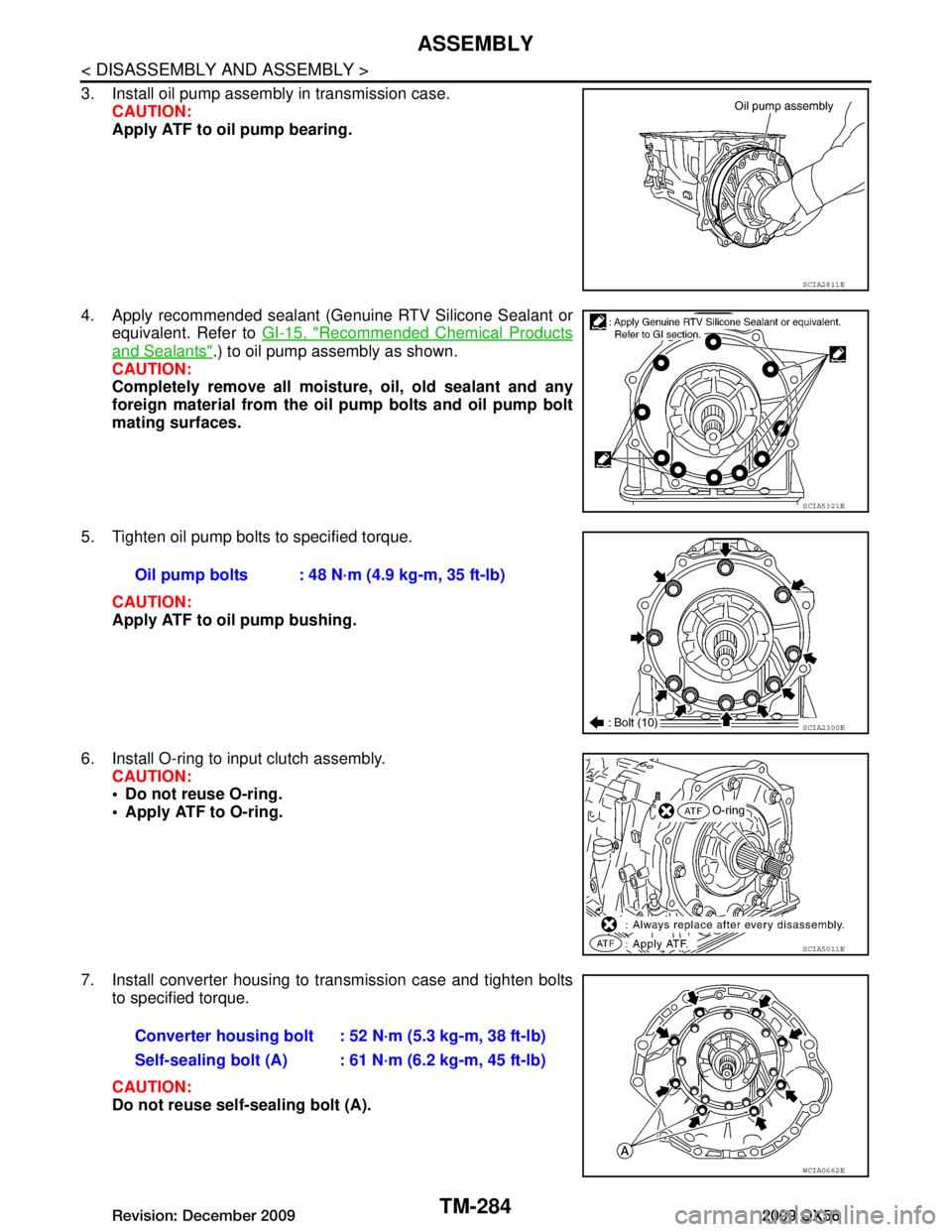

AdjustmentINFOID:0000000004187497

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for oilpump cover.

Select proper thickness of bearing race so that end play is within specifications.

1. Measure dimensions “K” and “L” and then calculate dimension “J”.

a. Measure dimension “K”. Anchor end pin : 5.0 N·m (0.51 kg-m, 44 in-lb)

Lock nut : 46 N·m (4.7 kg-m, 34 ft-lb)

SCIA5498E

SCIA2810E

SCIA5350E

SCIA5351E

Revision: December 20092009 QX56

Page 3932 of 4171

TM-284

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

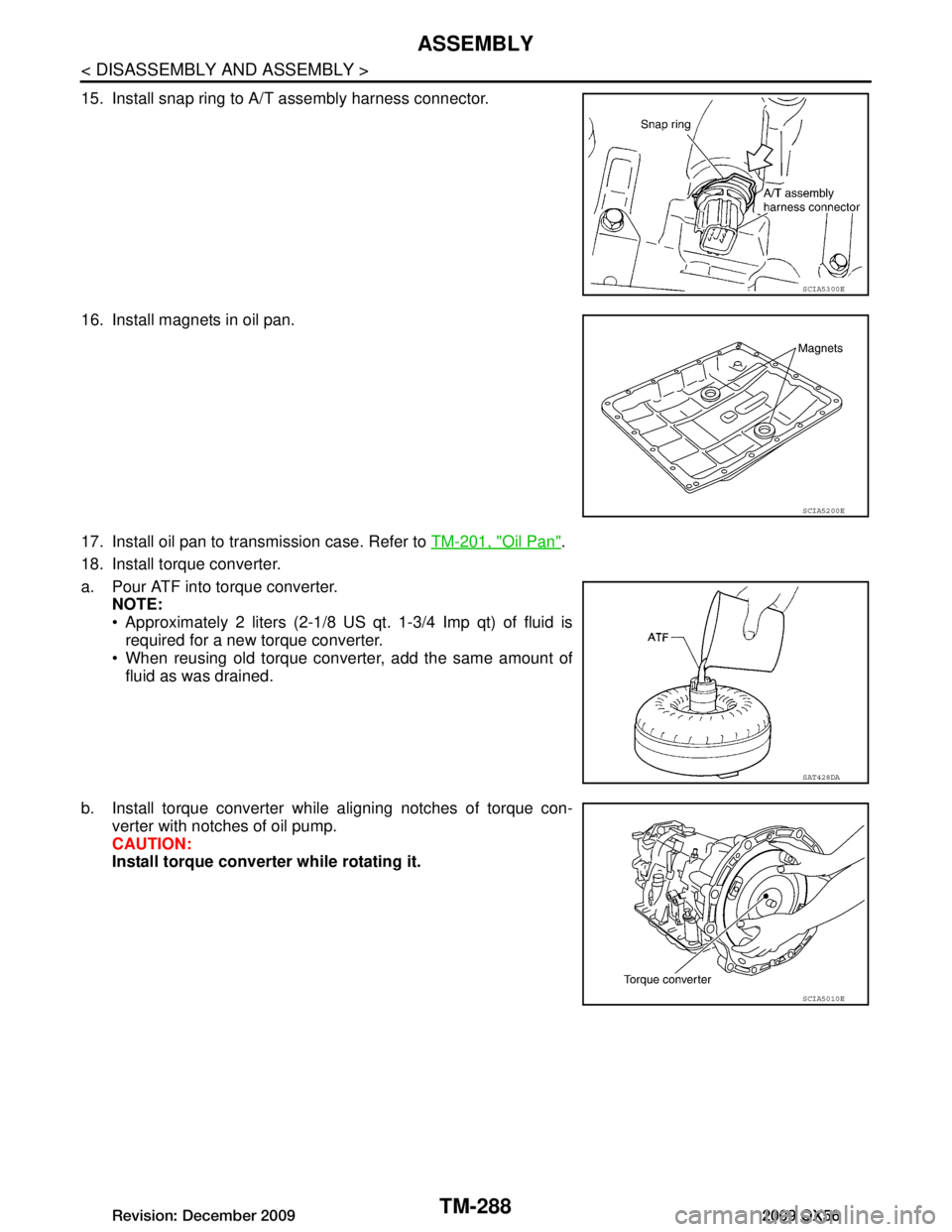

3. Install oil pump assembly in transmission case.CAUTION:

Apply ATF to oil pump bearing.

4. Apply recommended sealant (Genuine RTV Silicone Sealant or equivalent. Refer to GI-15, "Recommended Chemical Products

and Sealants".) to oil pump assembly as shown.

CAUTION:

Completely remove all moistu re, oil, old sealant and any

foreign material from the oil pump bolts and oil pump bolt

mating surfaces.

5. Tighten oil pump bolts to specified torque. CAUTION:

Apply ATF to oil pump bushing.

6. Install O-ring to input clutch assembly. CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

7. Install converter housing to transmission case and tighten bolts to specified torque.

CAUTION:

Do not reuse self-sealing bolt (A).

SCIA2811E

SCIA5321E

Oil pump bolts : 48 N·m (4.9 kg-m, 35 ft-lb)

SCIA2300E

SCIA5011E

Converter housing bolt : 52 N·m (5.3 kg-m, 38 ft-lb)

Self-sealing bolt (A) : 61 N·m (6.2 kg-m, 45 ft-lb)

WCIA0662E

Revision: December 20092009 QX56

Page 3934 of 4171

TM-286

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

e. Install A/T fluid temperature sensor 2 to bracket.

f. Install A/T fluid temperature sensor 2 (with bracket) to controlvalve with TCM and tighten bolt to specified torque.

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve.

g. Install control valve with TCM in transmission case. 1. : Brake band

CAUTION:

Make sure that input speed sensor is securely installed

into input speed sensor hole (A).

Hang down output speed sen sor harness toward outside

so as not to disturb installati on of control valve with TCM.

Adjust A/T assembly harness co nnector of control valve

with TCM to terminal hole of transmission case.

Assemble it so that manual valve cutout is engaged with manual plate projection.

SCIA5264E

Bracket bolt : 7.9 N·m (0.81 kg-m, 70 in-lb)

SCIA5253E

JSDIA1318ZZ

SCIA5035E

Revision: December 20092009 QX56

Page 3935 of 4171

ASSEMBLYTM-287

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

h. Install bolts (A), (B) and (C) to control valve with TCM. : Front

i. Tighten bolt (A), (B) and (C) temporarily to prevent dislocation. After that tighten them in order (A → B → C), and then tighten

other bolts.

: Front

10. Connect A/T fluid temperature sensor 2 connector (A).

11. Securely fasten terminal cord assembly and A/T fluid tempera- ture sensor 2 harness with terminal clips.

12. Connect output speed sensor connector (1).

13. Securely fasten output speed sensor harness with terminal clip.

14. Pull down A/T assembly harness connector. CAUTION:

Do not damage connector.

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8077E

Bolt symbol A B C

Number of bolts 5 6 1

Length mm (in) 42 (1.65) 55 (2.17) 40 (1.57)

Tightening torque

N·m (km-g, in-lb) 7.9 (0.81, 70)With ATF applied

7.9 (0.81, 70)

SCIA8078E

SCIA8124E

JSDIA1319ZZ

SCIA5299E

Revision: December 20092009 QX56

Page 3936 of 4171

TM-288

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

15. Install snap ring to A/T assembly harness connector.

16. Install magnets in oil pan.

17. Install oil pan to transmission case. Refer to TM-201, "Oil Pan"

.

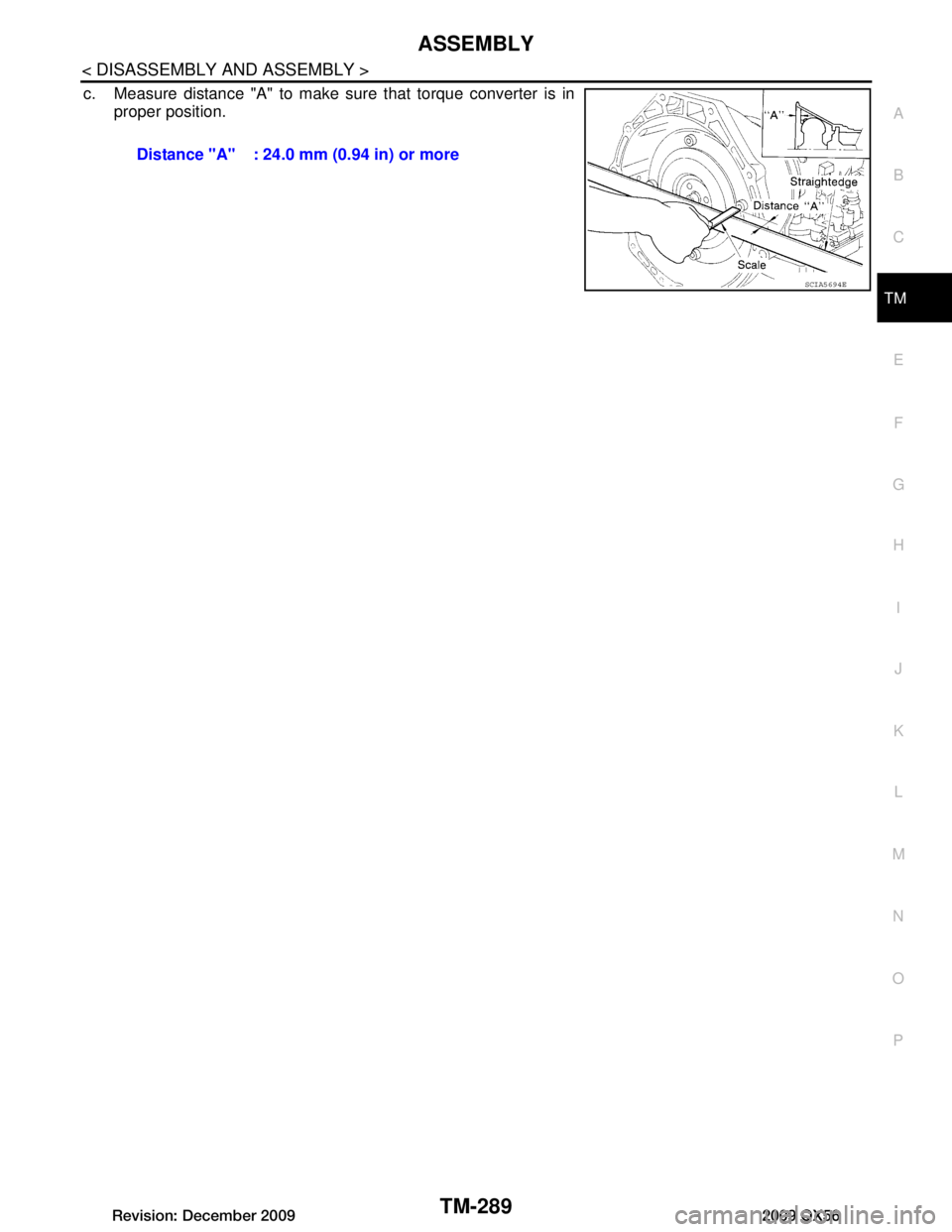

18. Install torque converter.

a. Pour ATF into torque converter. NOTE:

Approximately 2 liters (2-1/8 US qt. 1-3/4 Imp qt) of fluid is

required for a new torque converter.

When reusing old torque converter, add the same amount of

fluid as was drained.

b. Install torque converter while aligning notches of torque con- verter with notches of oil pump.

CAUTION:

Install torque converte r while rotating it.

SCIA5300E

SCIA5200E

SAT428DA

SCIA5010E

Revision: December 20092009 QX56

Page 3937 of 4171

ASSEMBLYTM-289

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

c. Measure distance "A" to make sure that torque converter is in proper position.

Distance "A" : 24.0 mm (0.94 in) or more

SCIA5694E

Revision: December 20092009 QX56