torque INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 465 of 4171

REAR DISC BRAKEBR-35

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

By pushing in piston, br ake fluid returns to master cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the piston.

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts. CAUTION:

Do not get grease on the brake pads or brake rotor friction surfaces.

3. Install pads to cylinder body.

4. Install cylinder body to torque member

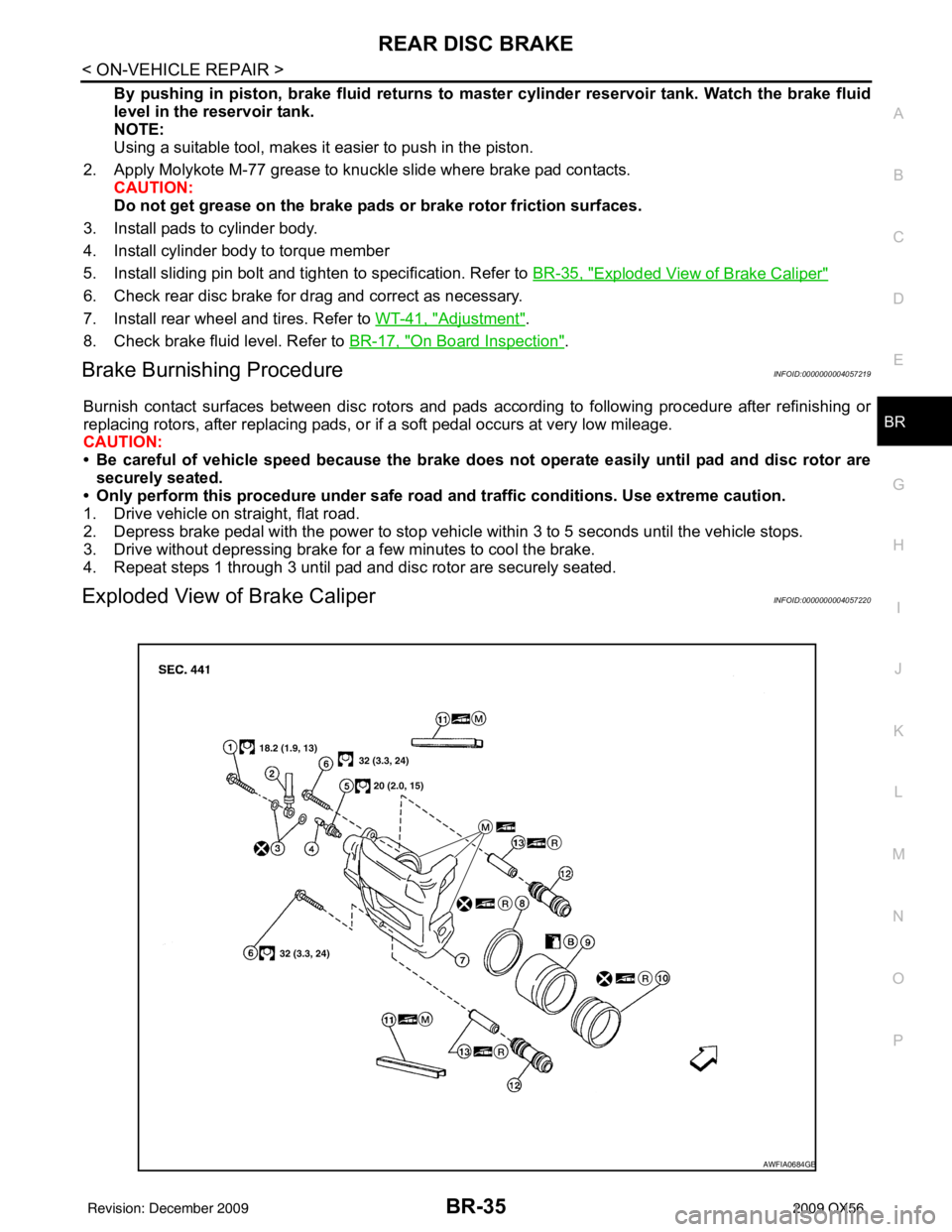

5. Install sliding pin bolt and tighten to specification. Refer to BR-35, "

Exploded View of Brake Caliper"

6. Check rear disc brake for drag and correct as necessary.

7. Install rear wheel and tires. Refer to WT-41, "

Adjustment".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000004057219

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

Exploded View of Brake CaliperINFOID:0000000004057220

AWFIA0684GB

Revision: December 20092009 QX56

Page 469 of 4171

FRONT DISC BRAKEBR-39

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

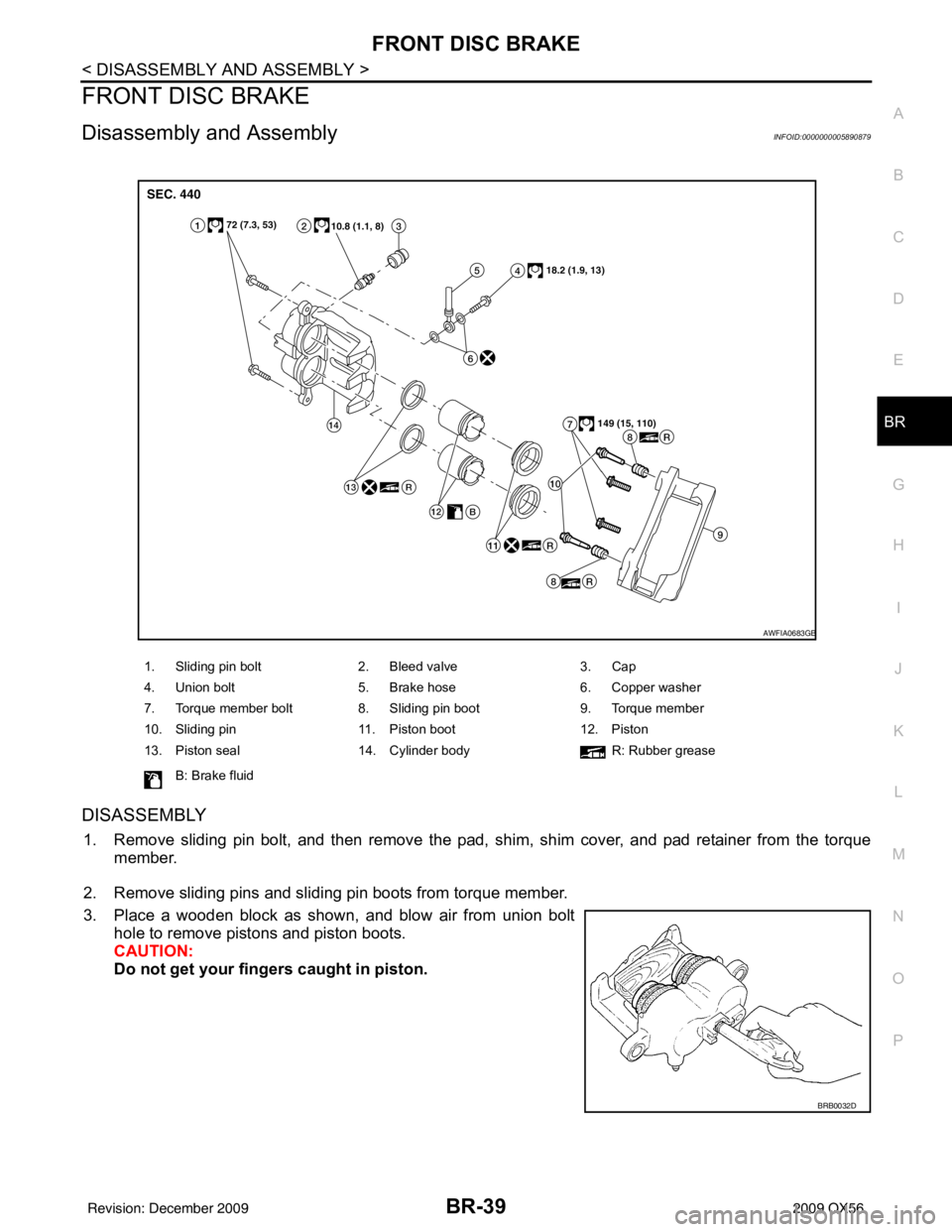

Disassembly and AssemblyINFOID:0000000005890879

DISASSEMBLY

1. Remove sliding pin bolt, and then remove the pad, shim, shim cover, and pad retainer from the torque member.

2. Remove sliding pins and sliding pin boots from torque member.

3. Place a wooden block as shown, and blow air from union bolt hole to remove pistons and piston boots.

CAUTION:

Do not get your fingers caught in piston.

1. Sliding pin bolt 2. Bleed valve 3. Cap

4. Union bolt 5. Brake hose 6. Copper washer

7. Torque member bolt 8. Sliding pin boot 9. Torque member

10. Sliding pin 11. Piston boot 12. Piston

13. Piston seal 14. Cylinder body R: Rubber grease

B: Brake fluid

AWFIA0683GB

BRB0032D

Revision: December 20092009 QX56

Page 470 of 4171

BR-40

< DISASSEMBLY AND ASSEMBLY >

FRONT DISC BRAKE

4. Remove piston seals from cylinder body, using a suitable tool.CAUTION:

• Be careful not to damage cylinder inner wall.

• Do not reuse piston seals.

CALIPER INSPECTION

Cylinder Body

Check inside surface of cylinder for score, rust, wear, damage or foreign materials. If any of the above condi-

tions are observed, replace cylinder body.

Minor damage from rust or foreign materials may be el iminated by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

CAUTION:

Use new brake fluid for cleaning. Do not use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. If damage or def ormation is present, replace the affected part.

Piston

Check piston for score, rust, wear, damage or presence of foreign materials. Replace if any of the above con-

ditions are observed.

CAUTION:

Piston sliding surface is plated, do not polish with emery paper even if rust or foreign materials are

stuck to sliding surface.

Sliding Pins, and Sliding Pin Boots

Check sliding pin and sliding pin boot for wear, damage, and cracks. If damage or deformation is present,

replace the affected part.

CAUTION:

Trailing/upper slidi ng pin must be replaced at each service.

ASSEMBLY

1. Install bleed valve and cap.

2. Apply rubber grease to new piston seals and insert seals into

grooves on cylinder body.

CAUTION:

Do not reuse piston seals.

SFIA0141E

SFIA2399E

Revision: December 20092009 QX56

Page 471 of 4171

FRONT DISC BRAKEBR-41

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Apply rubber grease to piston boots. Cover the piston ends with piston boots, and then install cylinder side lip on piston boots

securely into the grooves on cylinder body.

CAUTION:

Do not reuse piston boots.

4. Apply clean brake fluid to pistons (1), then install pistons into cyl- inder body and insert piston boot (2) side lip into groove of pis-

tons as shown.

CAUTION:

Press the pistons evenly to prevent damage to cylinder

wall.

5. Apply rubber grease and install sliding pins, bushing and sliding pin boots to torque member.

6. Install cylinder body. Tighten sliding pin bolts to the specified torque.

SFIA2432E

JPFIA0041ZZ

Revision: December 20092009 QX56

Page 473 of 4171

REAR DISC BRAKEBR-43

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

4. Using a suitable tool, remove piston seal from cylinder body as shown.

CAUTION:

Be careful not to damage cylinder body inner wall.

CALIPER INSPECTION

Cylinder Body

Check inside surface of cylinder body for score, rust wear, damage or foreign materials. If any of the above

conditions are observed, replace cylinder body.

Minor damage from rust or foreign materials may be eliminated by polishing surface with a fine emery paper.

Replace cylinder body if necessary.

CAUTION:

• Use new brake fluid to clean. Do not use mi neral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

Check piston for score, rust, wear, damage or presence of foreign materials. Replace if any of the above con-

ditions are observed.

CAUTION:

• Piston sliding surface is plated, do not polish with emery paper even if rust of foreign materials are

stuck to sliding surface.

Sliding Pin Bolts and Sliding Pin Boots

Make sure there is no wear, damage, or cracks in sliding sleeve and sliding sleeve boots, and if there are,

replace them.

ASSEMBLY

1. Install the bleed valve and cap.

2. Apply rubber grease to the new piston seal (1) and insert the new piston seal (1) into the groove on the cylinder body.

CAUTION:

Do not reuse piston seal.

3. Apply rubber grease to the new piston boot (1). Cover the piston end (2) with the piston boot (1), and then install the cylinder side

lip on the piston boot (1) securely into the groove on the cylinder

body.

CAUTION:

• Do not reuse piston boot.

• Press pistons in evenly and vary the pressing points toprevent the cylinder inner wall from being damaged.

PFIA0269E

JPFIA0039ZZ

JPFIA0040ZZ

Revision: December 20092009 QX56

Page 492 of 4171

![INFINITI QX56 2009 Factory User Guide TCS

BRC-15

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TCS

System DiagramINFOID:0000000003772488

System DescriptionINFOID:0000000003772489

• Traction Control System is a f INFINITI QX56 2009 Factory User Guide TCS

BRC-15

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TCS

System DiagramINFOID:0000000003772488

System DescriptionINFOID:0000000003772489

• Traction Control System is a f](/img/42/57031/w960_57031-491.png)

TCS

BRC-15

< FUNCTION DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

TCS

System DiagramINFOID:0000000003772488

System DescriptionINFOID:0000000003772489

• Traction Control System is a function that electronically controls engine torque, brake fluid pressure and A/T gear position to ensure the optimum slippage ratio at drive wheels by computing wheel speed signals from 4

wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels (rear

wheels), it compares wheel speed signals from all 4 wheel s. At this time, LH and RH rear brake fluid pres-

sure are controlled, while fuel being cut to engine and throttle valve being closed to reduce engine torque by

the control unit. Further more, throttle position is continuously controlled to ensure the optimum engine

torque at all times.

• During TCS operation, it inform s driver of system operation by flashing SLIP indicator lamp.

• Electrical system diagnosis by CONSULT-III is available.

AWFIA0065GB

Revision: December 20092009 QX56

Page 588 of 4171

![INFINITI QX56 2009 Factory User Guide PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba INFINITI QX56 2009 Factory User Guide PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba](/img/42/57031/w960_57031-587.png)

PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000003772632

CAUTION:

• Always use recommended brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosen e. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF and remove the connector of the ABS actuator and electric unit (con trol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

Refer to BR-30, "

Brake Burnishing Procedure" (front disc brake) or BR-35, "Brake Burnishing Proce-

dure" (rear disc brake).

WARNING:

• Clean brake pads and shoes with a waste cl oth, then wipe with a dust collector.

Precaution for Brake ControlINFOID:0000000003772633

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine

compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer (what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check boos ter operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near control module, ABS function may have a malfunction or

error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

• If the following components are replaced with non-genuine components or modified, the VDC OFF indicator lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorbers, struts, springs , bushings, etc.), tires, wheels (exclude specified

size), components related to brake system (pads, roto rs, calipers, etc.), components related to engine (muf-

fler, ECM, etc.), components related to body reinforcement (roll bar, tower bar, etc.).

• Driving with broken or excessively worn suspensi on components, tires or brake system components may

cause the VDC OFF indicator lamp and the SLIP indicator lamp to turn on, and the VDC system may not

operate properly.

• When the TCS or VDC is activated by sudden acceleration or sudden turn, some noise may occur. The noise is a result of the normal operation of the TCS and VDC.

• When driving on roads which have extreme slopes (such as mountainous roads) or high banks (such as sharp curves on a freeway), the VDC may not operate no rmally, or the VDC warning lamp and the SLIP indi-

cator lamp may turn on. This is not a problem if normal operation can be resumed after restarting the engine.

SBR686C

Revision: December 20092009 QX56

Page 590 of 4171

![INFINITI QX56 2009 Factory User Guide PREPARATIONBRC-113

< PREPARATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003772635

The actual shapes of Kent-Moore tools may differ INFINITI QX56 2009 Factory User Guide PREPARATIONBRC-113

< PREPARATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003772635

The actual shapes of Kent-Moore tools may differ](/img/42/57031/w960_57031-589.png)

PREPARATIONBRC-113

< PREPARATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003772635

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003772636

Tool number

(Kent-Moore No.)

Tool name Description

KV991J0080

(J-45741)

ABS active wheel sensor tester Checking operation of ABS active wheel sen-

sors

WFIA0101E

Tool name

Description

1. Flare nut crowfoot

2. Torque wrench Removing and installing brake piping

a: 10 mm (0.39 in)/12 mm (0.47 in)

S-NT360

Revision: December 20092009 QX56

Page 593 of 4171

![INFINITI QX56 2009 Factory User Guide BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005855796

REMOVAL

1. Disconnect the INFINITI QX56 2009 Factory User Guide BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005855796

REMOVAL

1. Disconnect the](/img/42/57031/w960_57031-592.png)

BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000005855796

REMOVAL

1. Disconnect the battery negative terminal. Refer to

PG-76, "Removal and Installation".

2. Remove the air cleaner and air duct assembly. Refer to EM-25, "

Exploded View".

3. Drain the brake fluid. Refer to BR-17, "

Drain and Refill".

4. Disconnect the actuator harness connector from t he ABS actuator and electric unit (control unit).

CAUTION:

• To remove the brake tubes, use a flare nut wrench to prevent the flare nuts and brake tubes from

being damaged.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed on painted areas, wash it away with water immediately.

5. Disconnect the brake tubes.

6. Remove the three bolts and remove the ABS actuator and electric unit (control unit).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• To install, use a flare nut crowfoot and torque wrench (commercial service tools).

1. To rear left caliper

13.0 N·m (1.3 kg-m, 10 ft-lb) 2. To rear right caliper

13.0 N·m (1.3 kg-m, 10 ft-lb) 3. To front left caliper

13.0 N·m (1.3 kg-m, 10 ft-lb)

4. To front right caliper 13.0 N·m (1.3 kg-m, 10 ft-lb) 5. From the master cylinder secondary side

18.2 N·m (1.9 kg-m, 13 ft-lb) 6. From the master cylinder primary side

18.2 N·m (1.9 kg-m, 13 ft-lb)

7. ABS actuator and electric unit (control unit) 8. Actuator harness connector

WFIA0375E

Revision: December 20092009 QX56

Page 633 of 4171

BODY REPAIRBRM-37

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

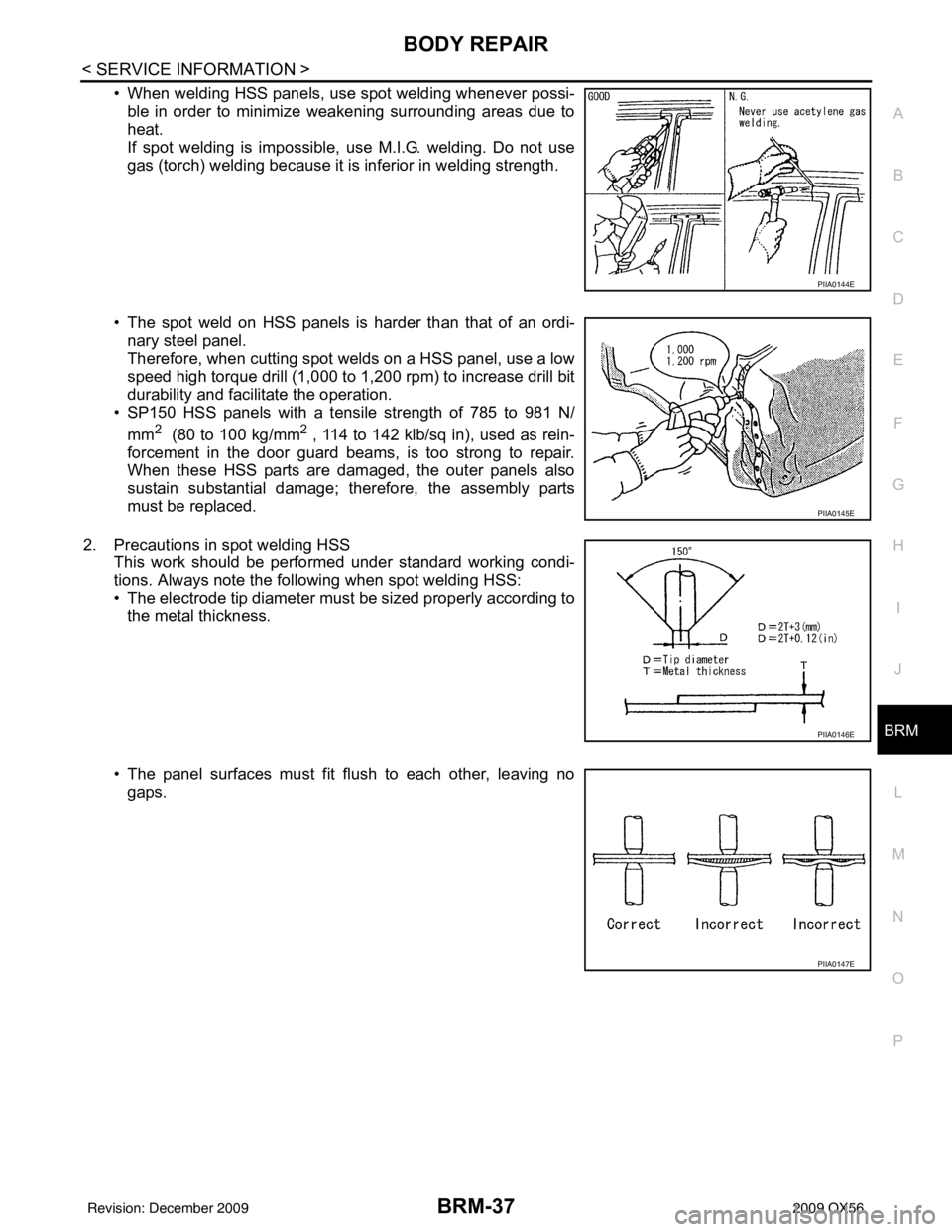

• When welding HSS panels, use spot welding whenever possi- ble in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use M.I.G. welding. Do not use

gas (torch) welding because it is inferior in welding strength.

• The spot weld on HSS panels is harder than that of an ordi- nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

• SP150 HSS panels with a tensile strength of 785 to 981 N/

mm

2 (80 to 100 kg/mm2 , 114 to 142 klb/sq in), used as rein-

forcement in the door guard beams, is too strong to repair.

When these HSS parts are damaged, the outer panels also

sustain substantial damage; therefore, the assembly parts

must be replaced.

2. Precautions in spot welding HSS This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according tothe metal thickness.

• The panel surfaces must fit flush to each other, leaving no gaps.

PIIA0144E

PIIA0145E

PIIA0146E

PIIA0147E

Revision: December 20092009 QX56