ignition INFINITI QX56 2009 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 124 of 4171

ADP-110

< ECU DIAGNOSIS >

DRIVER SEAT CONTROL UNIT

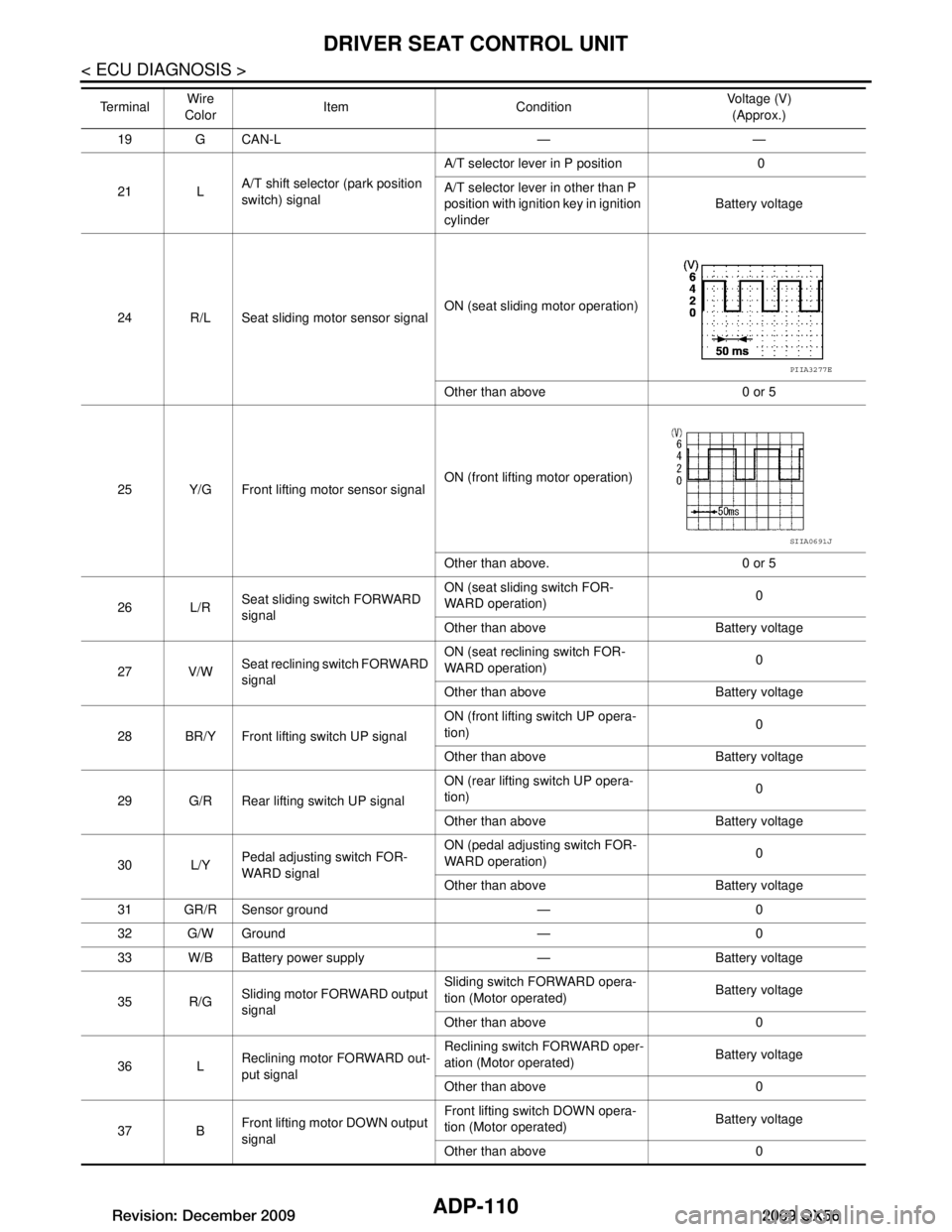

19 G CAN-L — —

21 LA/T shift selector (park position

switch) signal A/T selector lever in P position 0

A/T selector lever in other than P

position with ignition key in ignition

cylinder

Battery voltage

24 R/L Seat sliding motor sensor signal ON (seat sliding motor operation)

Other than above 0 or 5

25 Y/G Front lifting motor sensor signal ON (front lifting motor operation)

Other than above. 0 or 5

26 L/R Seat sliding switch FORWARD

signal ON (seat sliding switch FOR-

WARD operation)

0

Other than above Battery voltage

27 V/W Seat reclining switch FORWARD

signal ON (seat reclining switch FOR-

WARD operation)

0

Other than above Battery voltage

28 BR/Y Front lifting switch UP signal ON (front lifting switch UP opera-

tion)

0

Other than above Battery voltage

29 G/R Rear lifting switch UP signal ON (rear lifting switch UP opera-

tion)

0

Other than above Battery voltage

30 L/Y Pedal adjusting switch FOR-

WARD signal ON (pedal adjusting switch FOR-

WARD operation)

0

Other than above Battery voltage

31 GR/R Sensor ground — 0

32 G/W Ground — 0

33 W/B Battery power supply — Battery voltage

35 R/G Sliding motor FORWARD output

signal Sliding switch FORWARD opera-

tion (Motor operated)

Battery voltage

Other than above 0

36 L Reclining motor FORWARD out-

put signal Reclining switch FORWARD oper-

ation (Motor operated)

Battery voltage

Other than above 0

37 B Front lifting motor DOWN output

signal Front lifting switch DOWN opera-

tion (Motor operated)

Battery voltage

Other than above 0

Te r m i n a l

Wire

Color Item Condition Voltage (V)

(Approx.)

PIIA3277E

SIIA0691J

Revision: December 20092009 QX56

Page 141 of 4171

DRIVER SEAT CONTROL UNITADP-127

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

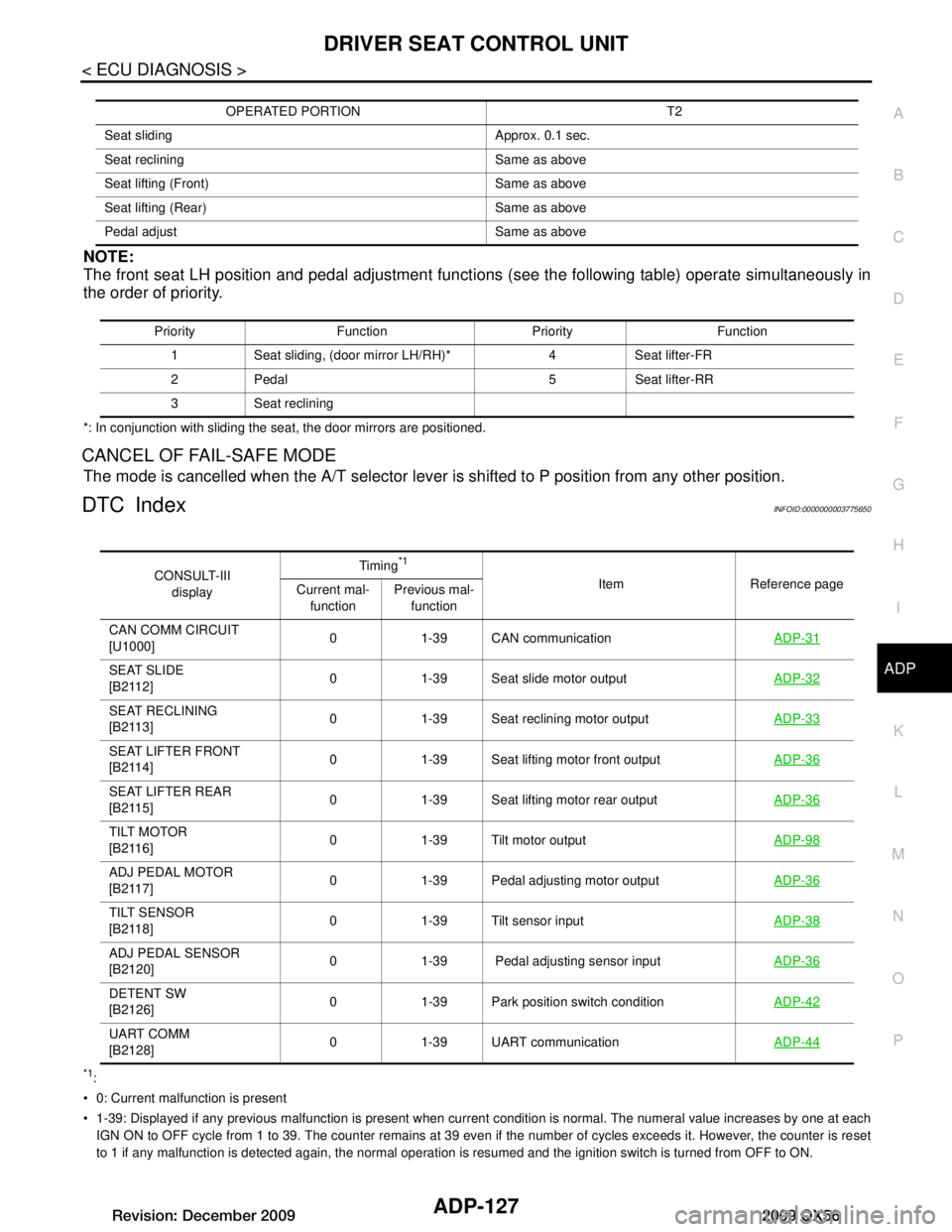

NOTE:

The front seat LH position and pedal adjustment functi ons (see the following table) operate simultaneously in

the order of priority.

*: In conjunction with sliding the seat, the door mirrors are positioned.

CANCEL OF FAIL-SAFE MODE

The mode is cancelled when the A/T selector lever is shifted to P position from any other position.

DTC IndexINFOID:0000000003775650

*1:

0: Current malfunction is present

1-39: Displayed if any previous malfunction is present when current condition is normal. The numeral value increases by one at each

IGN ON to OFF cycle from 1 to 39. The counter remains at 39 even if the number of cycles exceeds it. However, the counter is re set

to 1 if any malfunction is detected again, the normal operation is resumed and the ignition switch is turned from OFF to ON. OPERATED PORTION T2

Seat sliding Approx. 0.1 sec.

Seat reclining Same as above

Seat lifting (Front) Same as above

Seat lifting (Rear) Same as above

Pedal adjust Same as above

Priority Function Priority Function1 Seat sliding, (door mirro r LH/RH)* 4 Seat lifter-FR

2 Pedal 5 Seat lifter-RR

3Seat reclining

CONSULT-III display Timing

*1

Item Reference page

Current mal-

function Previous mal-

function

CAN COMM CIRCUIT

[U1000] 0 1-39 CAN communication

ADP-31

SEAT SLIDE

[B2112]0 1-39 Seat slide motor output

ADP-32

SEAT RECLINING

[B2113]0 1-39 Seat reclining motor output

ADP-33

SEAT LIFTER FRONT

[B2114]0 1-39 Seat lifting motor front output

ADP-36

SEAT LIFTER REAR

[B2115]0 1-39 Seat lifting motor rear output

ADP-36

TILT MOTOR

[B2116]0 1-39 Tilt motor output

ADP-98

ADJ PEDAL MOTOR

[B2117]0 1-39 Pedal adjusting motor output

ADP-36

TILT SENSOR

[B2118]0 1-39 Tilt sensor input

ADP-38

ADJ PEDAL SENSOR

[B2120]0 1-39 Pedal adjusting sensor input

ADP-36

DETENT SW

[B2126]0 1-39 Park position switch condition

ADP-42

UART COMM

[B2128]0 1-39 UART communication

ADP-44

Revision: December 20092009 QX56

Page 161 of 4171

BCM (BODY CONTROL MODULE)ADP-147

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

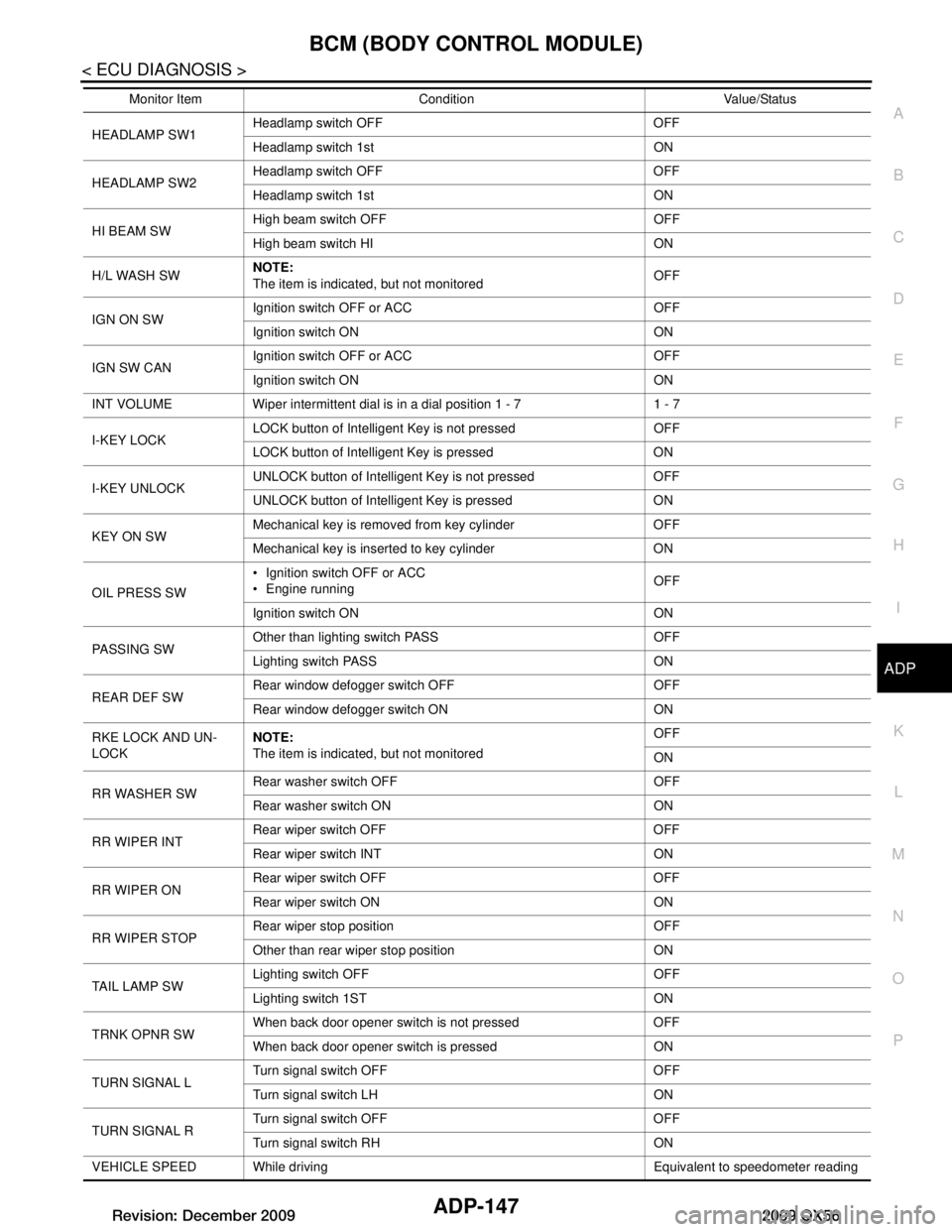

HEADLAMP SW1 Headlamp switch OFF OFF

Headlamp switch 1st ON

HEADLAMP SW2 Headlamp switch OFF OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF OFF

High beam switch HI ON

H/L WASH SW NOTE:

The item is indicated, but not monitored OFF

IGN ON SW Ignition switch OFF or ACC OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed OFF

UNLOCK button of Intelligent Key is pressed ON

KEY ON SW Mechanical key is removed from key cylinder OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW Ignition switch OFF or ACC

Engine running

OFF

Ignition switch ON ON

PASSING SW Other than lighting switch PASS OFF

Lighting switch PASS ON

REAR DEF SW Rear window defogger switch OFF OFF

Rear window defogger switch ON ON

RKE LOCK AND UN-

LOCK NOTE:

The item is indicated, but not monitored OFF

ON

RR WASHER SW Rear washer switch OFF OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position OFF

Other than rear wiper stop position ON

TAIL LAMP SW Lighting switch OFF OFF

Lighting switch 1ST ON

TRNK OPNR SW When back door opener switch is not pressed OFF

When back door opener switch is pressed ON

TURN SIGNAL L Turn signal switch OFF OFF

Turn signal switch LH ON

TURN SIGNAL R Turn signal switch OFF OFF

Turn signal switch RH ON

VEHICLE SPEED While driving Equiv alent to speedometer reading

Monitor Item Condition Value/Status

Revision: December 20092009 QX56

Page 163 of 4171

BCM (BODY CONTROL MODULE)ADP-149

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

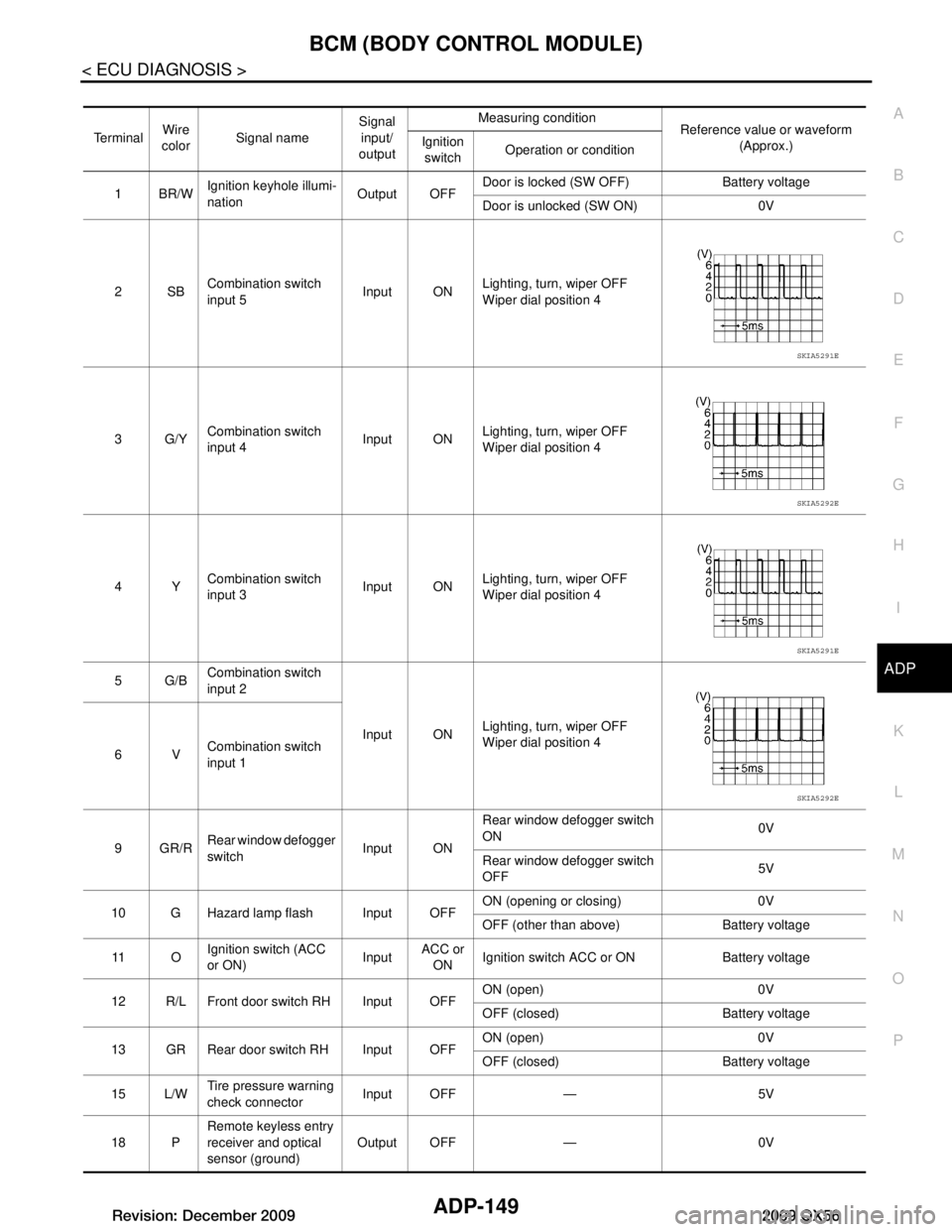

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF) Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing) 0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON Battery voltage

12 R/L Front door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open) 0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF — 5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF — 0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56

Page 164 of 4171

ADP-150

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

19 V/WRemote keyless entry

receiver (power sup-

ply) Output OFF Ignition switch OFF

20 G/W Remote keyless entry

receiver (signal) Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

22 W/V BUS — — Ignition switch ON or power

window timer operates

23 G/O Security indicator

lamp Output OFF

Goes OFF

→ illuminates (Ev-

ery 2.4 seconds) Battery voltage

→ 0V

25 BR NATS antenna amp. Input OFF

→

ON Ignition switch (OFF

→ ON) Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then return to battery voltage.

26 Y/L Rear wiper auto stop

switch 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Fluctuating

27 W/R Compressor ON sig-

nal Input ONA/C switch OFF 5V

A/C switch ON 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Revision: December 20092009 QX56

Page 165 of 4171

BCM (BODY CONTROL MODULE)ADP-151

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

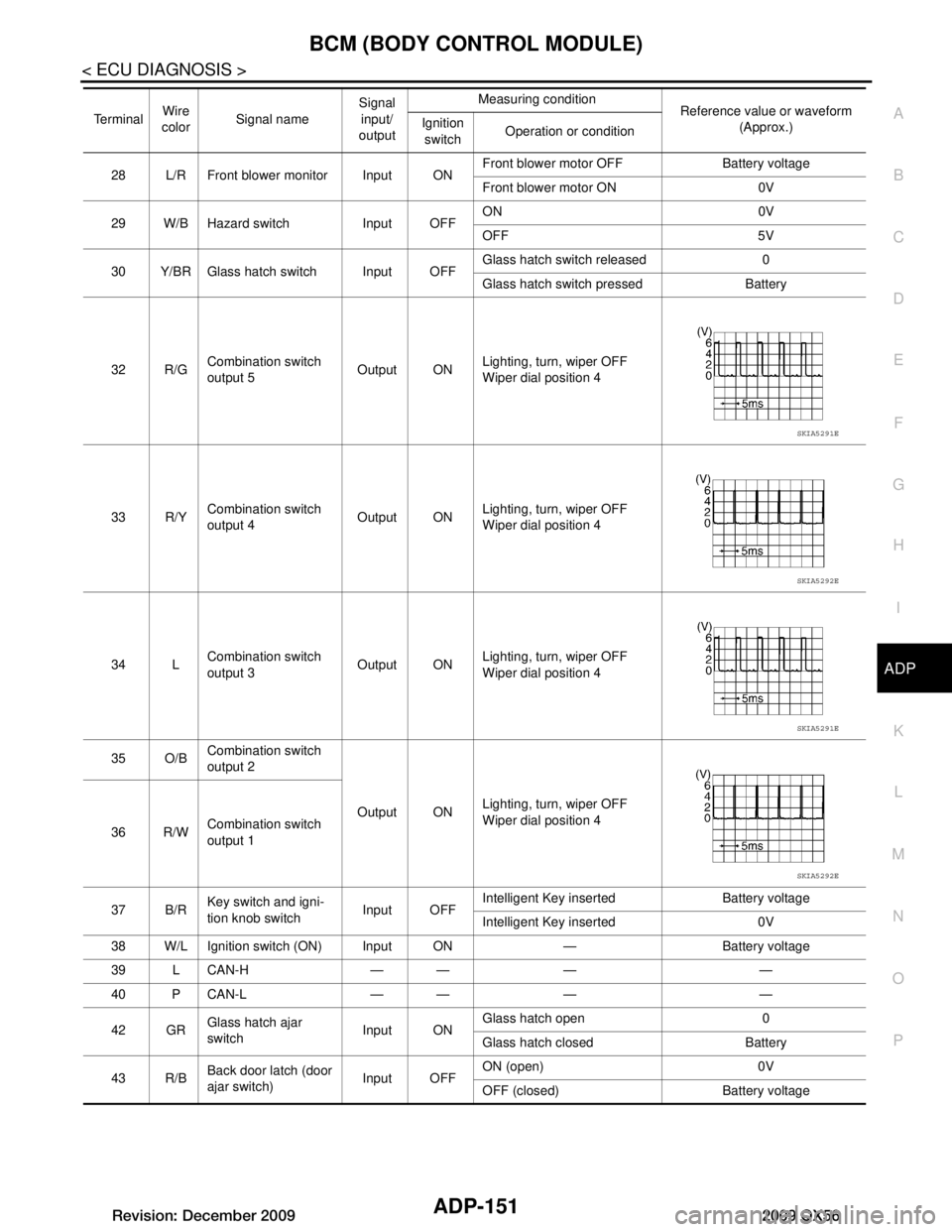

28 L/R Front blower monitor Input ON Front blower motor OFF Battery voltage

Front blower motor ON 0V

29 W/B Hazard switch Input OFF ON 0V

OFF 5V

30 Y/BR Glass hatch switch Input OFF Glass hatch switch released 0

Glass hatch switch pressed Battery

32 R/G Combination switch

output 5

Output ONLighting, turn, wiper OFF

Wiper dial position 4

33 R/Y Combination switch

output 4 Output ONLighting, turn, wiper OFF

Wiper dial position 4

34 L Combination switch

output 3 Output ON

Lighting, turn, wiper OFF

Wiper dial position 4

35 O/B Combination switch

output 2

Output ONLighting, turn, wiper OFF

Wiper dial position 4

36 R/W Combination switch

output 1

37 B/R Key switch and igni-

tion knob switch Input OFFIntelligent Key inserted Battery voltage

Intelligent Key inserted 0V

38 W/L Ignition switch (ON) Input ON — Battery voltage

39 L CAN-H — — — —

40 P CAN-L — — — —

42 GR Glass hatch ajar

switch Input ONGlass hatch open 0

Glass hatch closed Battery

43 R/B Back door latch (door

ajar switch) Input OFFON (open) 0V

OFF (closed) Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: December 20092009 QX56

Page 166 of 4171

ADP-152

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

44 ORear wiper auto stop

switch 1 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) Battery voltage

Forward sweep (counterclock-

wise direction) Fluctuating

B Position (full counterclock-

wise stop position) 0V

Reverse sweep (clockwise di-

rection) Fluctuating

47 SB Front door switch LH Input OFF ON (open) 0V

OFF (closed) Ba

ttery voltage

48 R/Y Rear door switch LH Input OFF ON (open) 0V

OFF (closed) Ba

ttery voltage

49 R Cargo lamp Output OFF Any door open (ON) 0V

All doors closed (OFF) Battery voltage

51 G/Y Trailer turn signal

(right) Output ON Turn right ON

52 G/B Trailer turn signal (l eft) Output ON Turn left ON

53 L/W Glass hatch lock actu-

ator

Output OFFGlass hatch switch released 0

Glass hatch switch pressed Battery

54 Y Rear wiper output cir-

cuit 2 Input ONRise up position (rear wiper

arm on stopper)

0V

A Position (full clockwise stop

position) 0V

Forward sweep (counterclock-

wise direction) 0V

B Position (full counterclock-

wise stop position) Battery voltage

Reverse sweep (clockwise di-

rection) Battery voltage

55 SB Rear wiper output cir-

cuit 1 Output ONOFF 0

ON Battery voltage

56 R/G Battery saver output Output OFF

30 minutes after ignition

switch is turned OFF 0V

ON — Battery voltage

57 Y/R Battery power supply Input OFF — Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: December 20092009 QX56

Page 167 of 4171

BCM (BODY CONTROL MODULE)ADP-153

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

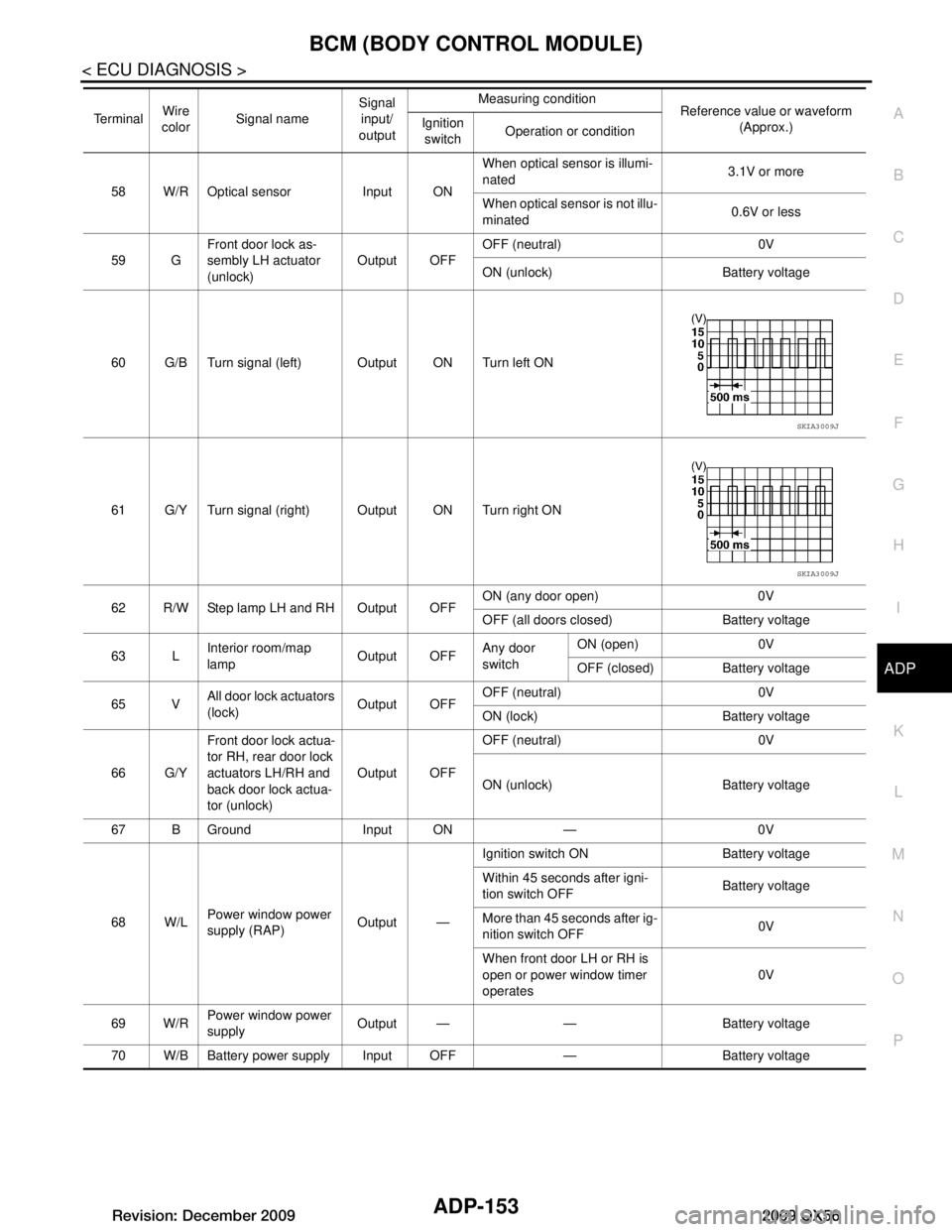

58 W/R Optical sensor Input ON When optical sensor is illumi-

nated

3.1V or more

When optical sensor is not illu-

minated 0.6V or less

59 G Front door lock as-

sembly LH actuator

(unlock) Output OFF

OFF (neutral) 0V

ON (unlock) Battery voltage

60 G/B Turn signal (left) Output ON Turn left ON

61 G/Y Turn signal (right) Output ON Turn right ON

62 R/W Step lamp LH and RH Output OFF ON (any door open) 0V

OFF (all doors closed) Battery voltage

63 L Interior room/map

lamp Output OFFAny door

switchON (open) 0V

OFF (closed) Battery voltage

65 V All door lock actuators

(lock) Output OFFOFF (neutral) 0V

ON (lock) Battery voltage

66 G/Y Front door lock actua-

tor RH, rear door lock

actuators LH/RH and

back door lock actua-

tor (unlock) Output OFF

OFF (neutral) 0V

ON (unlock) Battery voltage

67 B Ground Input ON — 0V

68 W/L Power window power

supply (RAP) Output —Ignition switch ON Battery voltage

Within 45 seconds after igni-

tion switch OFF

Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69 W/R Power window power

supply

Output — — Battery voltage

70 W/B Battery power supply Input OFF — Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

SKIA3009J

SKIA3009J

Revision: December 20092009 QX56

Page 176 of 4171

ADP-162

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005848468

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851835

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 177 of 4171

PRECAUTIONSADP-163

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for WorkINFOID:0000000003775660

When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

Protect the removed parts with a shop cloth and keep them.

Replace a deformed or damaged clip.

If a part is specified as a non-reusable part, always replace it with new one.

Be sure to tighten bolts and nuts securely to the specified torque.

After re-installation is completed, be sure to check that each part works normally.

Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

For genuine leather seats, use a genuine leather seat cleaner.

Revision: December 20092009 QX56