engine overheat INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 696 of 4171

CCS

DTC109 LASER HIGH TEMPCCS-45

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B

N P A

DTC109 LASER HIGH TEMP

DTC 109 LASER HIGH TEMPINFOID:0000000003776955

1.CHECK SYMPTOM

Inspect engine cooling system.

Did the engine overheat?

YES >> • Repair cooling system. • Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test". Then perform self-diagnosis of ICC system again.

NO >> • Replace ICC sensor and adjust laser beam aiming. Refer to CCS-71, "

ICC Sensor".

• Erase DTC, then perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test". Then perform self-diagnosis of ICC system again.

Revision: December 20092009 QX56

Page 745 of 4171

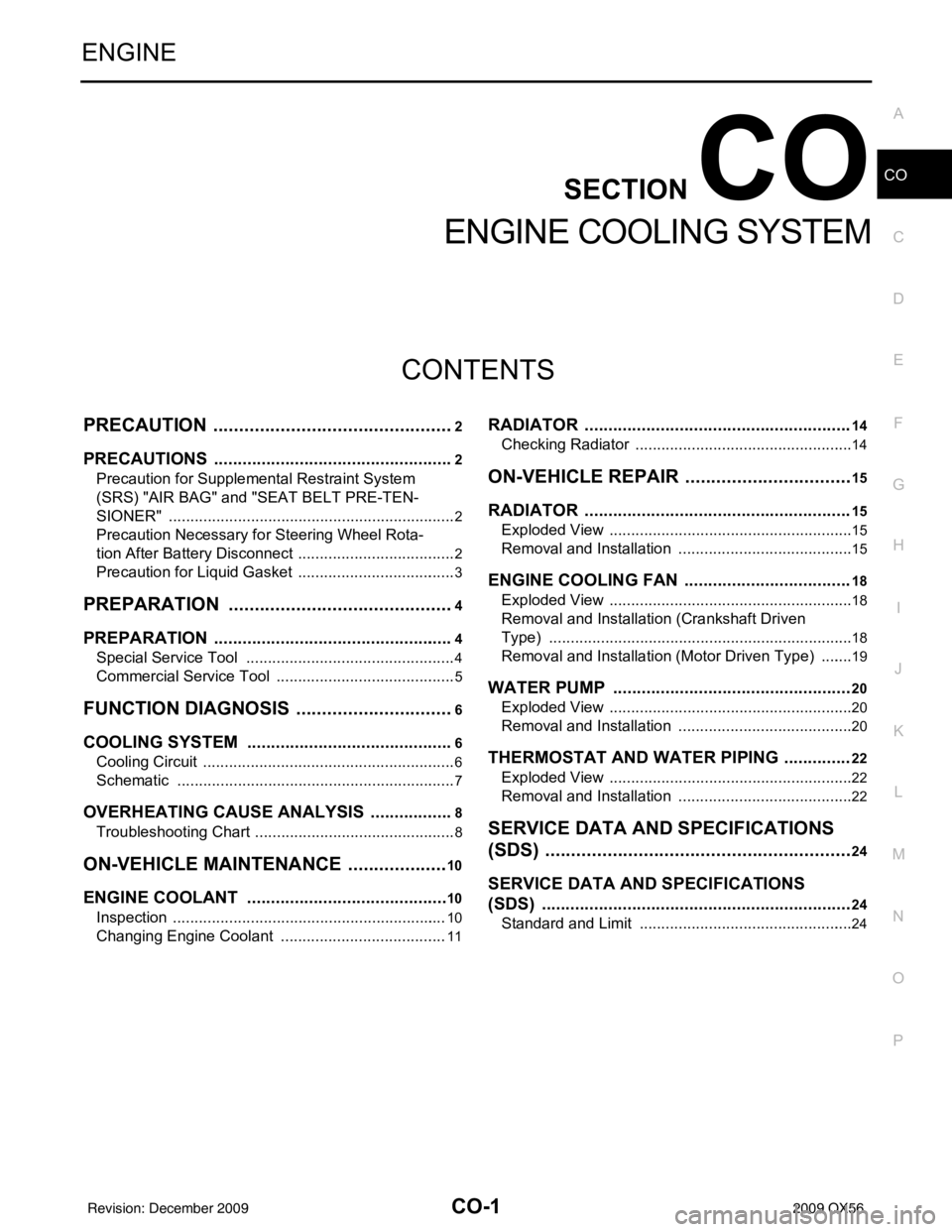

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

COOLING SYSTEM ....................................... .....6

Cooling Circuit ..................................................... ......6

Schematic .................................................................7

OVERHEATING CAUSE ANALYSIS ..................8

Troubleshooting Chart ...............................................8

ON-VEHICLE MAINTENA NCE ....................10

ENGINE COOLANT ....................................... ....10

Inspection ............................................................ ....10

Changing Engine Coolant .......................................11

RADIATOR ........................................................14

Checking Radiator ............................................... ....14

ON-VEHICLE REPAIR .................................15

RADIATOR ....... .................................................15

Exploded View ..................................................... ....15

Removal and Installation .........................................15

ENGINE COOLING FAN ...................................18

Exploded View .........................................................18

Removal and Installation (Crankshaft Driven

Type) .......................................................................

18

Removal and Installation (Motor Driven Type) ........19

WATER PUMP ..................................................20

Exploded View .........................................................20

Removal and Installation .........................................20

THERMOSTAT AND WATER PIPING ..............22

Exploded View .........................................................22

Removal and Installation .........................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

24

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

24

Standard and Limit .............................................. ....24

Revision: December 20092009 QX56

Page 752 of 4171

CO-8

< FUNCTION DIAGNOSIS >

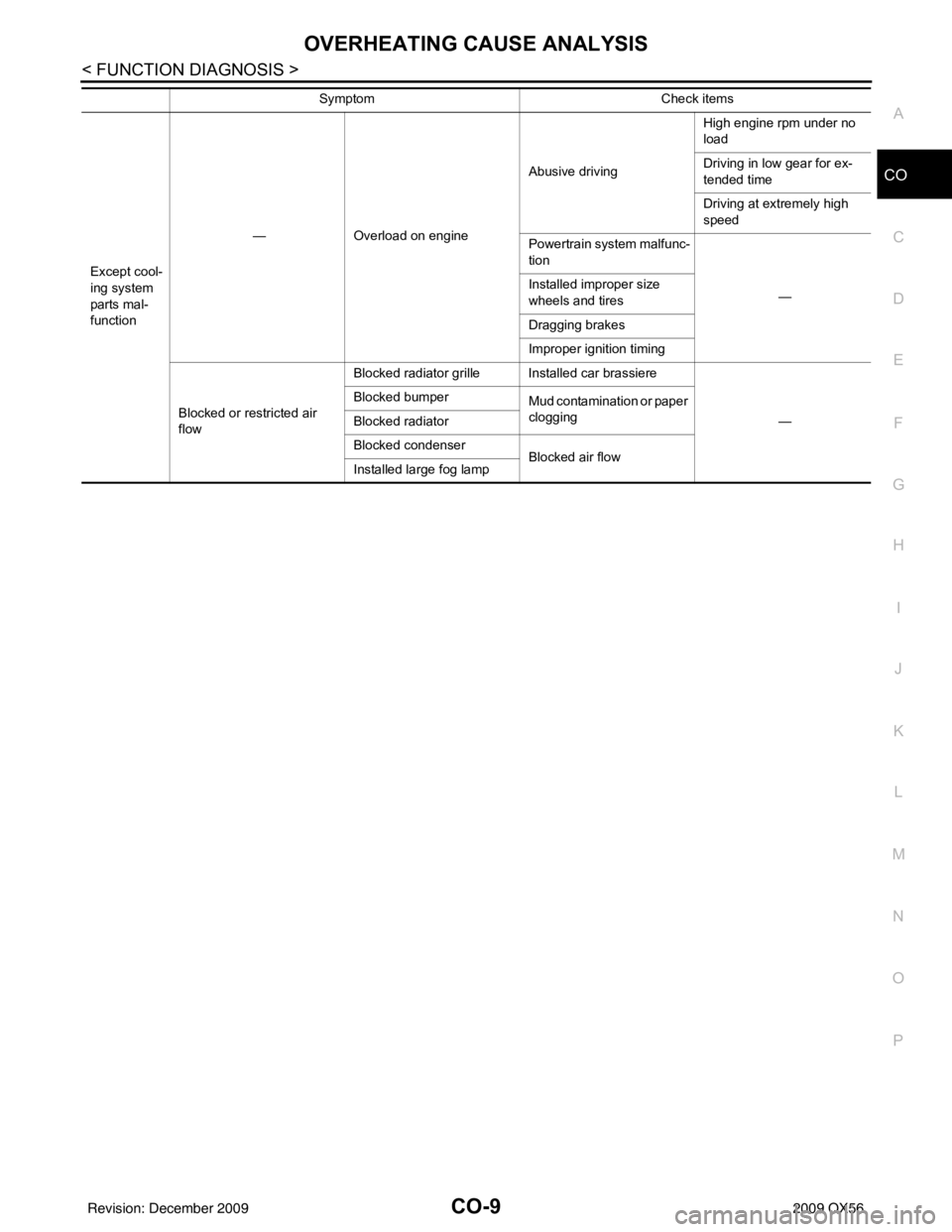

OVERHEATING CAUSE ANALYSIS

OVERHEATING CAUSE ANALYSIS

Troubleshooting ChartINFOID:0000000003771283

SymptomCheck items

Cooling sys-

tem parts

malfunction Poor heat transfer

Water pump malfunction Worn or loose drive belt

—

Thermostat stuck closed Coolant circulation

Damaged fins

Dust contamination or pa-

per clogging

Physical damage

Clogged radiator cooling

tube Excess foreign material

(rust, dirt, sand, etc.)

Water cut valve malfunction Excess foreign material

(rust, dirt, sand, etc.), phys-

ical damage

Reduced air flow Cooling fan does not oper-

ate

Fan assembly —

High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud —Radiator shroud —

Improper engine coolant

mixture ratio —

Engine coolant viscosity —

Poor engine coolant quality —Engine coolant density —

Insufficient engine coolant Engine coolant leaksCooling hose

Loose clamp

Cracked hose

Water pump Poor sealing

Radiator cap Loose

Poor sealing

Radiator O-ring for da

mage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tank Exhaust gas leaks into cool-

ing system Cylinder head deterioration

Cylinder head gasket deteri-

oration

Revision: December 20092009 QX56

Page 753 of 4171

OVERHEATING CAUSE ANALYSISCO-9

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked radiator grille Installed car brassiere

—

Mud contamination or paper

clogging

Blocked bumper

Blocked radiator

Blocked condenser

Blocked air flow

Installed large fog lamp

Symptom

Check items

Revision: December 20092009 QX56

Page 1332 of 4171

EC-5

C

DE

F

G H

I

J

K L

M

EC A

N

O P

On Board Diagnosis Logic ..................................

..

295

P1211 TCS CONTROL UNIT ...........................296

Description .......................................................... ..296

On Board Diagnosis Logic ....................................296

DTC Confirmation Procedure ................................296

Diagnosis Procedure .............................................296

P1212 TCS COMMUNICATION LINE ..............297

Description .......................................................... ..297

On Board Diagnosis Logic ....................................297

DTC Confirmation Procedure ................................297

Diagnosis Procedure .............................................297

P1217 ENGINE OVER TEMPERATURE .........298

On Board Diagnosis Logic .................................. ..298

Overall Function Check .........................................298

Diagnosis Procedure .............................................299

Main 13 Causes of Overheating ............................300

P1225 TP SENSOR ..........................................302

Component Description ....................................... ..302

On Board Diagnosis Logic ....................................302

DTC Confirmation Procedure ................................302

Diagnosis Procedure .............................................302

P1226 TP SENSOR ..........................................304

Component Description ....................................... ..304

On Board Diagnosis Logic ....................................304

DTC Confirmation Procedure ................................304

Diagnosis Procedure .............................................304

P1421 COLD START CONTROL .....................306

Description .......................................................... ..306

On Board Diagnosis Logic ....................................306

DTC Confirmation Procedure ................................306

Diagnosis Procedure .............................................306

P1550 BATTERY CURRENT SENSOR ...........308

Component Description ....................................... ..308

On Board Diagnosis Logic ....................................308

DTC Confirmation Procedure ................................308

Diagnosis Procedure .............................................308

Component Inspection ..........................................310

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

312

Component Description ....................................... ..312

On Board Diagnosis Logic ....................................312

DTC Confirmation Procedure ................................312

Diagnosis Procedure .............................................312

Component Inspection ..........................................314

P1553 BATTERY CURRENT SENSOR ...........316

Component Description ....................................... ..316

On Board Diagnosis Logic ....................................316

DTC Confirmation Procedure ................................316

Diagnosis Procedure .............................................316

Component Inspection ..........................................318

P1554 BATTERY CURRENT SENSOR ...........320

Component Description ....................................... ..320

On Board Diagnosis Logic .....................................320

Overall Function Check .........................................320

Diagnosis Procedure .............................................321

Component Inspection ...........................................322

P1564 ICC STEERING SWITCH .....................324

Component Description .........................................324

On Board Diagnosis Logic .....................................324

DTC Confirmation Procedure ................................324

Diagnosis Procedure .............................................324

Component Inspection ...........................................326

P1564 ASCD STEERING SWITCH .................328

Component Description .........................................328

On Board Diagnosis Logic .....................................328

DTC Confirmation Procedure ................................328

Diagnosis Procedure .............................................328

Component Inspection ...........................................330

P1568 ICC FUNCTION ....................................332

On Board Diagnosis Logic .....................................332

DTC Confirmation Procedure ................................332

Diagnosis Procedure .............................................332

P1572 ICC BRAKE SWITCH ..........................333

Component Description .........................................333

On Board Diagnosis Logic .....................................333

DTC Confirmation Procedure ................................333

Diagnosis Procedure .............................................334

Component Inspection ...........................................337

P1572 ASCD BRAKE SWITCH ......................339

Component Description .........................................339

On Board Diagnosis Logic .....................................339

DTC Confirmation Procedure ................................339

Diagnosis Procedure .............................................340

Component Inspection ...........................................343

P1574 ICC VEHICLE SPEED SENSOR .........344

Component Description .........................................344

On Board Diagnosis Logic .....................................344

DTC Confirmation Procedure ................................344

Diagnosis Procedure .............................................344

P1574 ASCD VEHICLE SPEED SENSOR .....346

Component Description .........................................346

On Board Diagnosis Logic .....................................346

DTC Confirmation Procedure ................................346

Diagnosis Procedure .............................................346

P1805 BRAKE SWITCH .................................348

Description .............................................................348

On Board Diagnosis Logic .....................................348

DTC Confirmation Procedure ................................348

Diagnosis Procedure .............................................348

Component Inspection ...........................................350

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

351

Component Description .........................................351

Revision: December 20092009 QX56

Page 1398 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-71

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overh INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-71

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overh](/img/42/57031/w960_57031-1397.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-71

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: Leaving cooling fan OFF with CONSULT-III while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to

EC-456, "DTC Index".

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION Engine: Return to the original

trouble condition

Change the amount of fuel injec-

tion using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

Harness and connectors

Fuel injector

Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING Engine: Return to the original

trouble condition

Timing light: Set

Retard the ignition timing using

CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

Perform Idle Air Volume Learning.

POWER BAL-

ANCE Engine: After warming up, idle the

engine.

A/C switch: OFF

Selector lever: P or N

Cut off each injector signal one at a time using CONSULT-III. Engine runs rough or dies.

Harness and connectors

Compression

Fuel injector

Power transistor

Spark plug

Ignition coil

COOLING FAN* Ignition switch: ON

Turn the cooling fan HI and OFF

using CONSULT-III. Cooling fan moves and stops. Harness and connectors

Cooling fan motor

IPDM E/R

ENG COOLANT

TEMP Engine: Return to the original

trouble condition

Change the engine coolant tem- perature using CONSULT-III. If trouble symptom disappears, see

CHECK ITEM. Harness and connectors

Engine coolant temperature sen-

sor

Fuel injector

FUEL PUMP RE-

LAY Ignition switch: ON

(Engine stopped)

Turn the fuel pump relay ON and OFF using CONSULT-III and lis-

ten to operating sound. Fuel pump relay makes the operat-

ing sound.

Harness and connectors

Fuel pump relay

PURG VOL

CONT/V Engine: After warming up, run en-

gine at 1,500 rpm.

Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-III. Engine speed changes according to

the opening percent.

Harness and connectors

Solenoid valve

FUEL/T TEMP

SEN Change the fuel tank temperature using CONSULT-III.

VENT CON-

TROL/V Ignition switch: ON

(Engine stopped)

Turn solenoid valve ON and OFF with the CONSULT-III and listen

to operating sound. Solenoid valve makes an operating

sound.

Harness and connectors

Solenoid valve

V/T ASSIGN AN-

GLE Engine: Return to the original

trouble condition

Change intake valve timing using

CONSULT-III. If trouble symptom disappears, see

CHECK ITEM.

Harness and connectors

Intake valve timing control sole-

noid valve

ALTERNATOR

DUTY Engine: Idle

Change duty ratio using CON-

SULT-III. Battery voltage changes. Harness and connectors

IPDM E/R

Alternator

Revision: December 20092009 QX56

Page 1455 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-128

< COMPONENT DIAGNOSIS >[VK56DE]

P0125 ECT SENSOR

P0125 ECT SENSOR

Component DescriptionINFOID:0000000003771384

The engine coolant temperature sens

or is used to detect the engine

coolant tempe INFINITI QX56 2009 Factory Service Manual

EC-128

< COMPONENT DIAGNOSIS >[VK56DE]

P0125 ECT SENSOR

P0125 ECT SENSOR

Component DescriptionINFOID:0000000003771384

The engine coolant temperature sens

or is used to detect the engine

coolant tempe](/img/42/57031/w960_57031-1454.png)

EC-128

< COMPONENT DIAGNOSIS >[VK56DE]

P0125 ECT SENSOR

P0125 ECT SENSOR

Component DescriptionINFOID:0000000003771384

The engine coolant temperature sens

or is used to detect the engine

coolant temperature. The sensor modifies a voltage signal from the

ECM. The modified signal returns to the ECM as the engine coolant

temperature input. The sensor uses a thermistor which is sensitive to

the change in temperature. The elec trical resistance of the ther-

mistor decreases as temperature increases.

*: This data is reference value and is measured between ECM terminal 73 (Engine

coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring in put/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground ot her than ECM terminals, such as the ground.

On Board Diagnosis LogicINFOID:0000000003771385

DTC Confirmation ProcedureINFOID:0000000003771386

CAUTION:

Be careful not to overheat engine.

NOTE:

If DTC P0125 is displayed with P0117 or P0118, first perform the trouble diagnosis for DTC P0117,

P0118. Refer to EC-121, "DTC Confirmation Procedure"

.

If DTC P0125 is displayed with P0116, first perf orm the trouble diagnosis for DTC P011. Refer to EC-

117, "DTC Confirmation Procedure".

1. If DTC Confirmation Procedure has been previously conducted, always perform the following before con-

ducting the next step.

a. Turn ignition switch OFF and wait at least 10 seconds.

b. Turn ignition switch ON.

c. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Select “DATA MONITOR” mode with CONSULT-III.

SEF594K

Engine coolant temperature °C ( °F)] Voltage* (V) Resistance (k

Ω)

–10 (14) 4.4 7.0 - 11.4 20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0125

0125 Insufficient engine coolant

temperature for closed loop

fuel control Voltage sent to ECM from the sensor is not

practical, even when some time has passed

after starting the engine.

Engine coolant temperature is insufficient for closed loop fuel control. Harness or connectors

(High resistance in the circuit)

Engine coolant temperature sensor

Thermostat

Revision: December 20092009 QX56

Page 1516 of 4171

![INFINITI QX56 2009 Factory Service Manual

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307, INFINITI QX56 2009 Factory Service Manual

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307,](/img/42/57031/w960_57031-1515.png)

P0300, P0301, P0302, P0303, P0304, P0305, P0306, P0307, P0308 MISFIRE

EC-189

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0300, P0301, P0302, P0303, P0304,

P0305, P0306, P0307, P0308 MIS-

FIRE

On Board Diagnosis LogicINFOID:0000000003771454

When a misfire occurs, engine speed will fluctuate. If the engine speed fluctuates enough to cause the crank-

shaft position (CKP) sensor (POS) signal to vary , ECM can determine that a misfire is occurring.

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage) On the 1st trip, when a misfire condition occurs that can damage the three way catalyst (TWC) due to

overheating, the MIL will blink.

When a misfire condition occurs, the ECM monitors the CKP sensor signal every 200 engine revolutions

for a change.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC on a second trip, the MIL will blink.

When the misfire condition decreases to a level t hat will not damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC, the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration) For misfire conditions that will not damage the TWC (but will affect vehicle emissions), the MIL will only

light when the misfire is detected on a second trip. Du ring this condition, the ECM monitors the CKP sen-

sor signal every 1,000 engine revolutions.

A misfire malfunction can be detected on any one cylinder or on multiple cylinders.

DTC Confirmation ProcedureINFOID:0000000003771455

CAUTION:

Always drive vehicle in safe manner according to traf fic conditions and obey all traffic laws when driv-

ing.

NOTE:

If DTC Confirmation Procedure has been previously conduc ted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

Sensor Input signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0300

0300 Multiple cylinder misfire

detected

Multiple cylinder misfire.

Improper spark plug

Insufficient compression

Incorrect fuel pressure

The injector circuit is open or shorted

Fuel injector

Intake air leak

The ignition signal circuit is open or short-ed

Lack of fuel

Signal plate

Air fuel ratio (A/F) sensor 1

Incorrect PCV hose connection

P0301

0301

No.1 cylinder misfire de-

tected

No. 1 cylinder misfires.

P0302

0302 No. 2 cylinder misfire

detected

No. 2 cylinder misfires.

P0303

0303 No. 3 cylinder misfire

detected

No. 3 cylinder misfires.

P0304

0304 No. 4 cylinder misfire

detected

No. 4 cylinder misfires.

P0305

0305 No. 5 cylinder misfire

detected

No. 5 cylinder misfires.

P0306

0306 No. 6 cylinder misfire

detected

No. 6 cylinder misfires.

P0307

0307 No. 7 cylinder misfire

detected

No. 7 cylinder misfires.

P0308

0308 No. 8 cylinder misfire

detected

No. 8 cylinder misfires.

Revision: December 20092009 QX56

Page 1625 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or INFINITI QX56 2009 Factory Service Manual

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or](/img/42/57031/w960_57031-1624.png)

EC-298

< COMPONENT DIAGNOSIS >[VK56DE]

P1217 ENGINE OVER TEMPERATURE

P1217 ENGINE OVER TEMPERATURE

On Board Diagn

osis LogicINFOID:0000000003771589

NOTE:

If DTC P1217 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-86

.

If DTC P1217 is displayed with DTC P0607, first pe rform the trouble diagnosis for DTC P0607. Refer

to EC-284

.

If the cooling fan or another component in the coo ling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnorma lly high temperature condition, a malfunction is

indicated.

This self-diagnosis has the one trip detection logic.

CAUTION:

When a malfunction is indicated, be su re to replace the coolant. Refer to CO-11, "Changing Engine

Coolant". Also, replace the engine oil. Refer to LU-9, "Changing Engine Oil".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to CO-10

.

2. After refilling coolant, run engine to en sure that no water-flow noise is emitted.

Overall Function CheckINFOID:0000000003771590

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING:

Never remove the radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

be caused by high pressure fluid escaping fr om the radiator and/or reservoir tank.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-III

1. Check the coolant level in the reservoir tank and radiator. Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-388,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-388,

"Diagnosis Procedure".

3. Turn ignition switch ON.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217 Engine over tempera-

ture (Overheat) Cooling fan does not operate properly (Over-

heat).

Cooling fan system does not operate proper-

ly (Overheat).

Engine coolant was not added to the system using the proper filling method.

Engine coolant is not within the specified range. Harness or connectors

(The cooling fan circuit is open or short-

ed.)

Cooling fan

Cooling fan (crankshaft diven)

IPDM E/R (Cooling fan relay)

Radiator hose

Radiator

Radiator cap

Reservoir tank

Reservoir tank cap

Water pump

Thermostat

For more informat ion, refer to EC-300,

"Main 13 Causes of Overheating".

SEF621W

Revision: December 20092009 QX56

Page 1626 of 4171

![INFINITI QX56 2009 Factory Service Manual

P1217 ENGINE OVER TEMPERATUREEC-299

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

5. If the results are NG, INFINITI QX56 2009 Factory Service Manual

P1217 ENGINE OVER TEMPERATUREEC-299

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

5. If the results are NG,](/img/42/57031/w960_57031-1625.png)

P1217 ENGINE OVER TEMPERATUREEC-299

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

5. If the results are NG, go to

EC-388, "Diagnosis Procedure"

.

WITH GST

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool befo re checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-388,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-388,

"Diagnosis Procedure".

3. Disconnect engine coolant temper ature sensor harness connec-

tor.

4. Connect 150 Ω resistor to engine coolant temperature sensor

harness connector.

5. Start engine and make sure that cooling fan operates. CAUTION:

Be careful not to overheat engine.

6. If NG, go to EC-388, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000003771591

1.CHECK COOLING FAN (CRANKSHAFT DRIVEN) OPERATION

1. Start engine and let it idle.

2. Make sure that cooling fan (crankshaft driven) operates normally.

OK or NG

OK (With CONSULT-III)>>GO TO 2.

OK (Without CONSULT-III)>>GO TO 3.

NG >> Check cooling fan (crankshaft driven). Refer to CO-18, "Removal and Installation (Crankshaft

Driven Type)".

2.CHECK COOLING FAN MOTOR OPERATION

With CONSULT-III

1. Start engine and let it idle.

2. Select “COOLING FAN” in “A CTIVE TEST” mode with CONSULT-III.

3. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control ci rcuit. (Go to "PROCEDURE A".)

3.CHECK COOLING FAN MOTOR OPERATION

Without CONSULT-III

1. Disconnect engine coolant temperature sensor harness connector.

2. Connect 150 Ω resistor to engine coolant temperature sensor harness connector.

3. Start engine and let it idle.

SEF621W

SEF882V

Revision: December 20092009 QX56