low beam INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 382 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-8

< FUNCTION DIAGNOSIS >[BCM]

COMBINATION SWITCH READING SYSTEM

Combination switch circuit

Combination switch INPUT-OUTPUT system list

NOTE:

Headlamp has a dual system switch.

COMBINATION SWITCH INFINITI QX56 2009 Factory Service Manual

BCS-8

< FUNCTION DIAGNOSIS >[BCM]

COMBINATION SWITCH READING SYSTEM

Combination switch circuit

Combination switch INPUT-OUTPUT system list

NOTE:

Headlamp has a dual system switch.

COMBINATION SWITCH](/img/42/57031/w960_57031-381.png)

BCS-8

< FUNCTION DIAGNOSIS >[BCM]

COMBINATION SWITCH READING SYSTEM

Combination switch circuit

Combination switch INPUT-OUTPUT system list

NOTE:

Headlamp has a dual system switch.

COMBINATION SWITCH READING FUNCTION

Description

BCM reads the status of the combination switch at 10 ms interval normally.

NOTE:

BCM reads the status of the combination switch at 20 ms interval when BCM is controlled at low power con-

sumption control mode.

BCM operates as follows and judges the status of the combination switch.

- INPUT 1 - 5 outputs the voltage waveforms of 5 systems simultaneously.

- It operates the transistor on OUTPUT side in the following order: OUTPUT 5 → 4 → 3 → 2 → 1.

System OUTPUT 1 OUTPUT 2 OUTPUT 3 OUTPUT 4 OUTPUT 5

INPUT 1 — FR WASHER FR WIPER LOW TURN LH TURN RH

INPUT 2 FR WIPER HI — FR WIPER INT PASSING HEADLAMP 1

INPUT 3 INT VOLUME 1 RR WASHER — HEADLAMP 2 HI BEAM

INPUT 4 RR WIPER INT INT VOLUME 3 AUTO LIGHT — TAIL LAMP

INPUT 5 INT VOLUME 2 RR WIPER — FR FOG —

LIIA0760E

JPMIA0067GB

Revision: December 20092009 QX56

Page 396 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-22

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000003776394

WORK SUPPORT

*: Factory setting

DATA MONITOR INFINITI QX56 2009 Factory Service Manual

BCS-22

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000003776394

WORK SUPPORT

*: Factory setting

DATA MONITOR](/img/42/57031/w960_57031-395.png)

BCS-22

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000003776394

WORK SUPPORT

*: Factory setting

DATA MONITOR

Monitor Item

[Unit] Description

IGN ON SW [ON/OFF] Ignition switch (ON) status judged from IGN signal (ignition power supply)

HI BEAM SW [ON/OFF]

Each switch status that BCM judges from the combination switch reading function

H/L SW POS [ON/OFF]

LIGHT SW 1ST [ON/OFF]

PASSING SW [ON/OFF]

AUTO LIGHT SW [ON/OFF]

FR FOG SW [ON/OFF]

DOOR SW-DR [ON/OFF] The switch status input from front door switch LH

AUT LIGHT SYS [ON/OFF] Auto light

system status that BCM judges from the vehicle condition

Test Item Operation Description

TA I L L A M P ON

Transmits the position light reques

t signal to IPDM E/R with CAN com-

munication to turn the tail lamp ON.

OFF Stops the tail lamp request signal transmission.

HEAD LAMP HI

Transmits the high beam request signal with CAN communication to turn

the headlamp (HI).

LO Transmits the low beam request signal with CAN communication to turn

the headlamp (LO).

OFF Stops the high & low beam request signal transmission.

FR FOG LAMP ON

Transmits the front fog lights request signal to IPDM E/R with CAN com-

munication to turn the front fog lamp ON.

OFF Stops the front fog lights request signal transmission.

DAYTIME RUNNING LIGHT ON

Transmits the day time running light request signal to IPDM E/R with

CAN communication to turn the each lamps ON.

OFF Stops the day time running light request signal transmission.

Work Item Setting

Item Description

WIPER SPEED

SETTING ON*

With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wiper intermittent dial position)

OFF Without vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial position)

Monitor Item

[Unit] Description

IGN ON SW [ON/OFF] Ignition switch ON status judged from ignition power supply

Revision: December 20092009 QX56

Page 398 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-24

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR CONDITIONER : CONSULT-III Func tion (BCM - AUTO AIR CONDITIONER)

INFOID:0000000003776396

DATA MONITOR

INTELLIGENT KEY

INTELLIGENT KEY : C INFINITI QX56 2009 Factory Service Manual

BCS-24

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR CONDITIONER : CONSULT-III Func tion (BCM - AUTO AIR CONDITIONER)

INFOID:0000000003776396

DATA MONITOR

INTELLIGENT KEY

INTELLIGENT KEY : C](/img/42/57031/w960_57031-397.png)

BCS-24

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR CONDITIONER : CONSULT-III Func tion (BCM - AUTO AIR CONDITIONER)

INFOID:0000000003776396

DATA MONITOR

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT-III Function (BCM - INTELLIGENT KEY)INFOID:0000000003776397

DATA MONITOR

COMB SW

COMB SW : CONSULT-III Fu nction (BCM - COMB SW)INFOID:0000000003776398

DATA MONITOR

Monitor Item

[Unit] Contents

IGN ON SW [ON/OFF] Display [ignition switch position (On)/(Off), ACC position (Off)] status as judged from ignition

switch signal

FAN ON SIG [ON/OFF] Display [FAN (On)/FAN (Off)] st atus as judged form blower fan motor switch signal

AIR COND SW [ON/OFF] Display [COMP (On)/COMP (Off)] status as judged form air conditioner switch signal

Monitor Item [Unit] Condition

PUSH SW [ON/OFF] Indicates condition of ignition knob switch

I-KEY LOCK [ON/OFF] Indicate s condition of lock signal from Intelligent Key

I-KEY UNLOCK [ON/OFF] I ndicates [condition of unlock signal from Intelligent Key

I-KEY PW DWN [ON/OFF] Indicates condition of al l power window signal from Intelligent Key

I-KEY TRUNK [ON/OFF] Indicates condition of trunk open signal from Intelligent Key

I-KEY PANIC [ON/OFF] Indicates condition of panic signal from Intelligent Key

Monitor Item

[Unit] Description

TURN SIGNAL R

[OFF/ON] Displays the status of

the TURN RH switch in combination switch ju dged by BCM with the combination switch

reading function

TURN SIGNAL L

[OFF/ON] Displays the status of

the TURN LH switch in combin ation switch judged by BCM with th e combination switch

reading function

HI BEAM SW

[OFF/ON] Displays the status of the HI BEAM switch in combination switch judged by BCM with the combination switch

reading function

HEADLAMP SW1

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

HEADLAMP SW2

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

LIGHT SW 1ST

[OFF/ON] Displays the status of the HEADLAMP switch in combination switch judged by BCM with the combination

switch reading function

PASSING SW

[OFF/ON] Displays the status of the PASSING sw

itch in combination switch judged by BCM with the combination switch

reading function

AUTO LIGHT SW

[OFF/ON] Displays the status of the AUTO LIGHT switch in combination switch judged by BCM with the combination

switch reading function

FR FOG SW

[OFF/ON] Displays the status of the FR FOG switch in combination switch judged by BCM with the combination switch

reading function

FR WIPER HI

[OFF/ON] Displays the status of the FR WIPER HI switch in combination switch judged by BCM with the combination

switch reading function

Revision: December 20092009 QX56

Page 410 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-36

< COMPONENT DIAGNOSIS >[BCM]

COMBINATION SWITCH

COMBINATION SWITCH

DescriptionINFOID:0000000003776418

COMBINATION SWITCH MATRIX

Combination switch consists of INPUT circuit and OUTPUT circuit. INFINITI QX56 2009 Factory Service Manual

BCS-36

< COMPONENT DIAGNOSIS >[BCM]

COMBINATION SWITCH

COMBINATION SWITCH

DescriptionINFOID:0000000003776418

COMBINATION SWITCH MATRIX

Combination switch consists of INPUT circuit and OUTPUT circuit.](/img/42/57031/w960_57031-409.png)

BCS-36

< COMPONENT DIAGNOSIS >[BCM]

COMBINATION SWITCH

COMBINATION SWITCH

DescriptionINFOID:0000000003776418

COMBINATION SWITCH MATRIX

Combination switch consists of INPUT circuit and OUTPUT circuit.

Combination switch circuit

Combination switch INPUT-OUTPUT system list

NOTE:

Headlamp has a dual system switch.

Diagnosis ProcedureINFOID:0000000003776419

1. CHECK LIGHT & TURN SIGNAL SWITCH

Check operation with normal light and turn signal switch installed.

Does it operate normally?

YES >> Replace light and turn signal switch. Refer to EXL-152, "Removal and Installation".

NO >> GO TO 2

2. CHECK WIPER & WASHER SWITCH

Check operation with normal wiper and washer switch installed.

Does it operate normally?

YES >> Replace wiper and washer switch. Refer to WW-80, "Wiper and Washer Switch".

System OUTPUT 1 OUTPUT 2 OUTPUT 3 OUTPUT 4 OUTPUT 5

INPUT 1 — FR WASHER FR WIPER LOW TURN LH TURN RH

INPUT 2 FR WIPER HI — FR WIPER INT PASSING HEADLAMP 1

INPUT 3 INT VOLUME 1 RR WASHER — HEADLAMP 2 HI BEAM

INPUT 4 RR WIPER INT INT VOLUME 3 AUTO LIGHT — TAIL LAMP

INPUT 5 INT VOLUME 2 RR WIPER — FR FOG —

LIIA0760E

Revision: December 20092009 QX56

Page 427 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS

COMBINATION SWITCH SYSTEM SYMPTOMSBCS-53

< SYMPTOM DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003776426

1. Per INFINITI QX56 2009 Factory Service Manual

BCS

COMBINATION SWITCH SYSTEM SYMPTOMSBCS-53

< SYMPTOM DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003776426

1. Per](/img/42/57031/w960_57031-426.png)

BCS

COMBINATION SWITCH SYSTEM SYMPTOMSBCS-53

< SYMPTOM DIAGNOSIS > [BCM]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYMPTOM DIAGNOSIS

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003776426

1. Perform the data monitor of CONSULT-II

I to check for any malfunctioning item.

2. Check the malfunction combinations.

Malfunction item: ×

3. Identify the malfunctioning part from the agreed combination and repair or replace the part.

Data monitor item

Malfunction combi-nation

TURN SIGNAL R

TURN SIGNAL L HI BEAM SW

HEADLAMP SW 1

HEADLAMP SW 2 TAIL LAMP SWPASSING SW

AUTO LIGHT SW FR FOG SW

FR WIPER HI

FR WIPER LOW FR WIPER INT

FR WASHER SW INT VOLUME

RR WIPER ON

RR WIPER INT

RR WASHER SW

×× × × A

×××× B

×× × × C

×× ×× D

××× E

××× F

××× × G

××× H

×××× I

×××× J

Combinations other than those above K All Items L

If only one item is detected or the item is not applicable to the combinations A to L M

Malfunction

combination Malfunctioning part Repair or replace

A Combination switch INPUT 1 circuit

Inspect the combination switch input circuit applicable to the malfunctioning

part. Refer to BCS-33, "Diagnosis Procedure"

.

B Combination switch INPUT 2 circuit

C Combination switch INPUT 3 circuit

D Combination switch INPUT 4 circuit E Combination switch INPUT 5 circuitF Combination switch OUTPUT 1 circuit

Inspect the combination switch output circuit applicable to the malfunction-

ing part. Refer to BCS-35, "Diagnosis Procedure"

.

G Combination switch OUTPUT 2 circuit

H Combination switch OUTPUT 3 circuit I Combination switch OUTPUT 4 circuit

J Combination switch OUTPUT 5 circuit

K Light and turn signal switch or front wip-

er and washer switch Refer to

BCS-36, "Description"

.

L BCM Replace BCM. Refer to BCS-56, "Removal and Installation"

.

M Light and turn signal switch or front wip-

er and washer switch Replace the switch that cannot be operated.

Revision: December 20092009 QX56

Page 633 of 4171

BODY REPAIRBRM-37

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

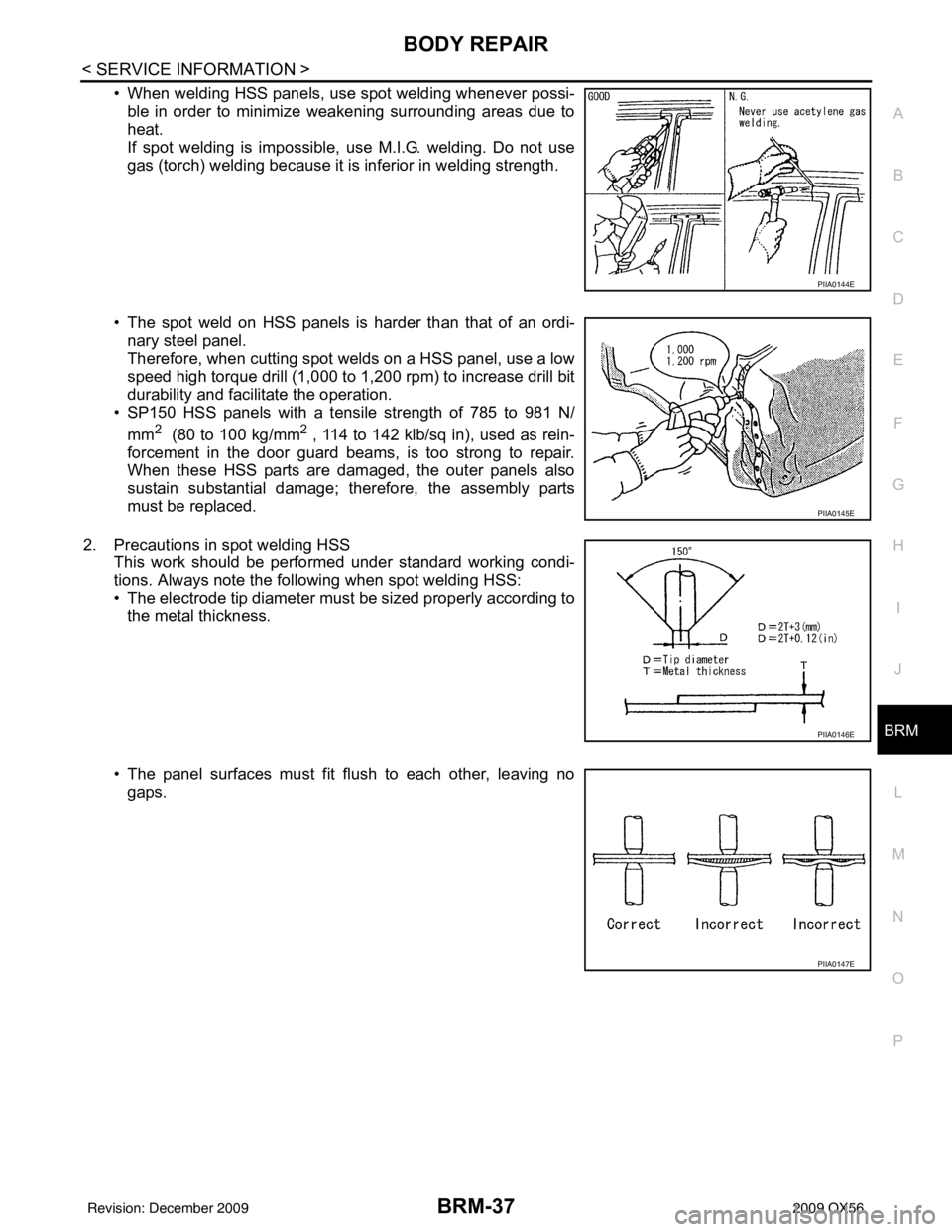

• When welding HSS panels, use spot welding whenever possi- ble in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use M.I.G. welding. Do not use

gas (torch) welding because it is inferior in welding strength.

• The spot weld on HSS panels is harder than that of an ordi- nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

• SP150 HSS panels with a tensile strength of 785 to 981 N/

mm

2 (80 to 100 kg/mm2 , 114 to 142 klb/sq in), used as rein-

forcement in the door guard beams, is too strong to repair.

When these HSS parts are damaged, the outer panels also

sustain substantial damage; therefore, the assembly parts

must be replaced.

2. Precautions in spot welding HSS This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according tothe metal thickness.

• The panel surfaces must fit flush to each other, leaving no gaps.

PIIA0144E

PIIA0145E

PIIA0146E

PIIA0147E

Revision: December 20092009 QX56

Page 652 of 4171

CCS-1

CRUISE CONTROL

C

DE

F

G H

I

J

K L

M B

CCS

SECTION CCS

N

P A

CONTENTS

CRUISE CONTROL SYSTEM

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

5

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

5

LASER BEAM AIMING ADJUSTMENT ................ ......5

LASER BEAM AIMING ADJUSTMENT : Outline

of Laser Beam Aiming Adjustment Procedure ..........

5

LASER BEAM AIMING ADJUSTMENT : Prepara-

tion ...................................................................... ......

5

LASER BEAM AIMING ADJUSTMENT : Setting

up the ICC Target Board ...........................................

6

LASER BEAM AIMING ADJUSTMENT : Sensor

Adjustment ................................................................

7

ACTION TEST ....................................................... ......8

ACTION TEST : ICC System Running Test ..............8

FUNCTION DIAGNOSIS ..............................12

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ........................................................... ....

12

System Description ............................................. ....12

INTELLIGENT CRUISE CONTROL SYSTEM ....13

System Diagram .................................................. ....13

System Description .................................................13

Component Parts Location ......................................15

Component Description ...........................................16

DIAGNOSIS SYSTEM (ICC SENSOR INTE-

GRATED UNIT) ..................................................

17

Diagnosis Description ......................................... ....17

CONSULT-III Function (ICC) ............................... ....18

COMPONENT DIAGNOSIS .........................22

DTC 11 CONTROL UNIT ..................................22

DTC 11 CONTROL UNIT .................................... ....22

DTC 12 VDC CONTROL UNIT ..........................23

DTC 12 VDC CONTROL UNIT ................................23

DTC 20 CAN COMM CIRCUIT ..........................24

DTC 20 CAN COMM CIRCUIT ................................24

DTC 31 POWER SUPPLY CIR1, DTC 34

POWER SUPPLY CIR2 .....................................

25

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER

SUPPLY CIR2 .........................................................

25

DTC 41 VHCL SPEED SE CIRC .......................26

DTC 41 VHCL SPEED SE CIRC .............................26

DTC 43 VDC/TCS/ABS CIRC ...........................27

DTC 43 VDC/TCS/ABS CIRC .................................27

DTC 45 BRAKE SW/STOP L SW .....................28

DTC 45 BRAKE SW/STOP L SW ............................28

DTC 46 OPERATION SW CIRC .......................30

DTC 46 OPERATION SW CIRC ......................... ....30

DTC 74 LASER BEAM OFF CNTR ..................31

DTC 74 LASER BEAM OFF CNTR .........................31

DTC 90 STOP LAMP RLY FIX ..........................32

DTC 90 STOP LAMP RLY FIX ................................32

DTC 92 ECM CIRCUIT ......................................37

DTC 92 ECM CIRCUIT ............................................37

DTC 96 NP RANGE ..........................................38

DTC 96 NP RANGE ............................................ ....38

DTC 97 AT CIRCUIT .........................................39

DTC 97 AT CIRCUIT ...............................................39

Revision: December 20092009 QX56

Page 656 of 4171

CCS

INSPECTION AND ADJUSTMENTCCS-5

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

N P A

INSPECTION AND ADJUSTMENT

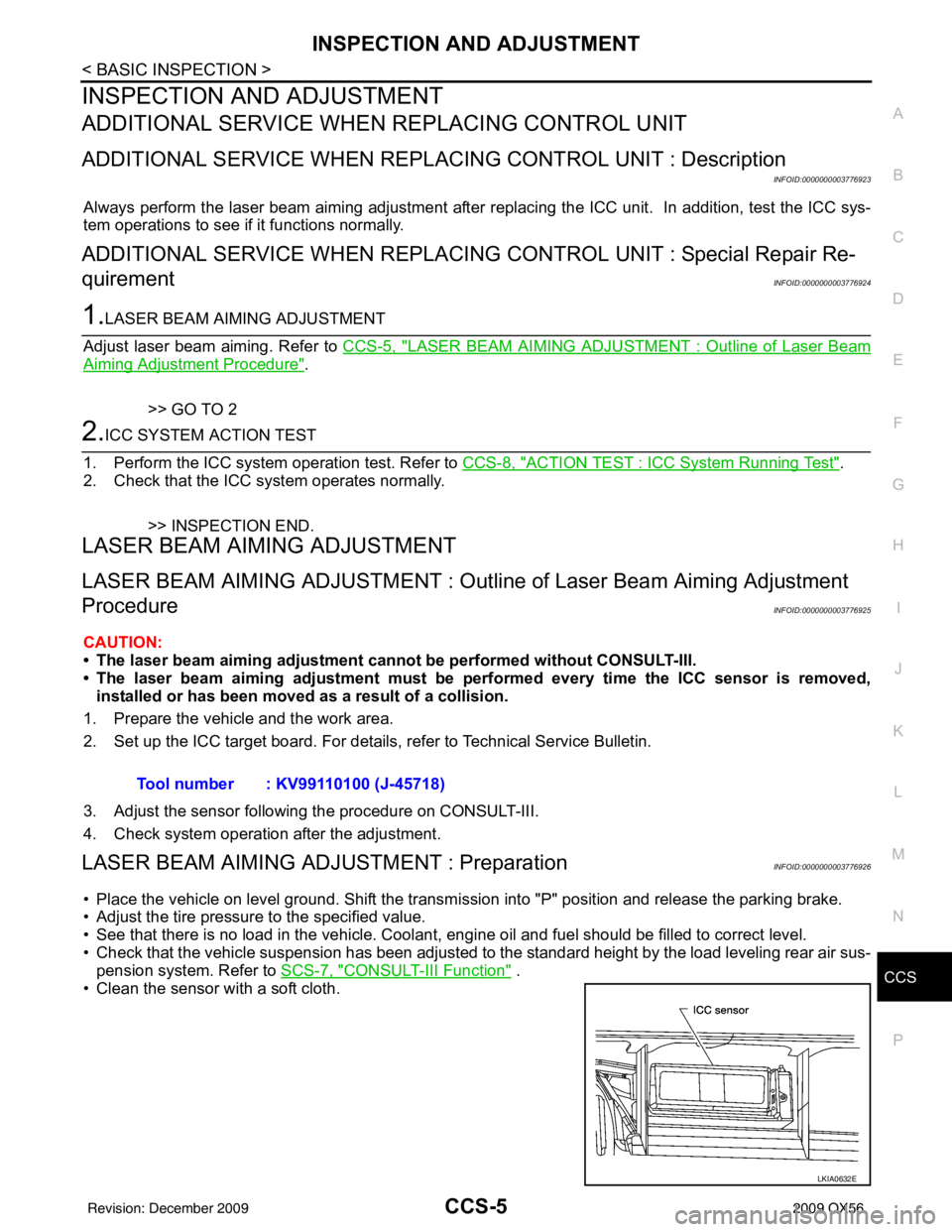

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000003776923

Always perform the laser beam aiming adjustment after repl acing the ICC unit. In addition, test the ICC sys-

tem operations to see if it functions normally.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000003776924

1.LASER BEAM AIMING ADJUSTMENT

Adjust laser beam aiming. Refer to CCS-5, "

LASER BEAM AIMING ADJUSTMENT : Outline of Laser Beam

Aiming Adjustment Procedure".

>> GO TO 2

2.ICC SYSTEM ACTION TEST

1. Perform the ICC system operation test. Refer to CCS-8, "

ACTION TEST : ICC System Running Test".

2. Check that the ICC system operates normally.

>> INSPECTION END.

LASER BEAM AIMI NG ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT : Outlin e of Laser Beam Aiming Adjustment

Procedure

INFOID:0000000003776925

CAUTION:

• The laser beam aiming adjustment can not be performed without CONSULT-III.

• The laser beam aiming adjustment must be performed every time the ICC sensor is removed,

installed or has been moved as a result of a collision.

1. Prepare the vehicle and the work area.

2. Set up the ICC target board. For details, refer to Technical Service Bulletin.

3. Adjust the sensor following the procedure on CONSULT-III.

4. Check system operation after the adjustment.

LASER BEAM AIMING ADJU STMENT : PreparationINFOID:0000000003776926

• Place the vehicle on level ground. Shift the transmi ssion into "P" position and release the parking brake.

• Adjust the tire pressure to the specified value.

• See that there is no load in the vehicle. Coolant , engine oil and fuel should be filled to correct level.

• Check that the vehicle suspension has been adjusted to the standard height by the load leveling rear air sus-

pension system. Refer to SCS-7, "

CONSULT-III Function" .

• Clean the sensor with a soft cloth. Tool number : KV99110100 (J-45718)

LKIA0632E

Revision: December 20092009 QX56

Page 659 of 4171

CCS-8

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

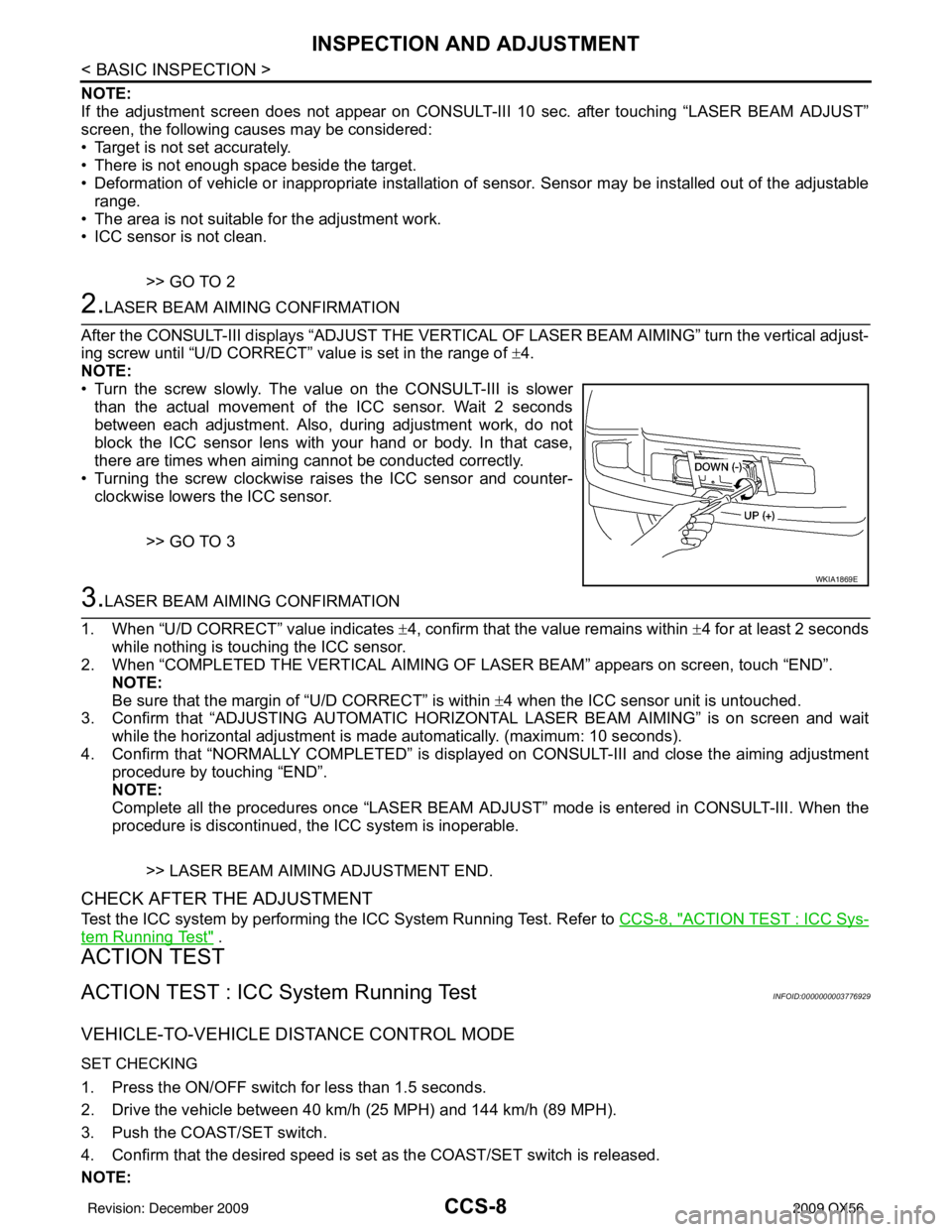

NOTE:

If the adjustment screen does not appear on CONSULT-III 10 sec. after touching “LASER BEAM ADJUST”

screen, the following causes may be considered:

• Target is not set accurately.

• There is not enough space beside the target.

• Deformation of vehicle or inappropriate installation of sensor. Sensor may be installed out of the adjustablerange.

• The area is not suitable for the adjustment work.

• ICC sensor is not clean.

>> GO TO 2

2.LASER BEAM AIMING CONFIRMATION

After the CONSULT-III displays “ADJ UST THE VERTICAL OF LASER BEAM AIMING” turn the vertical adjust-

ing screw until “U/D CORRECT” value is set in the range of ±4.

NOTE:

• Turn the screw slowly. The value on the CONSULT-III is slower

than the actual movement of the ICC sensor. Wait 2 seconds

between each adjustment. Also, during adjustment work, do not

block the ICC sensor lens with your hand or body. In that case,

there are times when aiming cannot be conducted correctly.

• Turning the screw clockwise raises the ICC sensor and counter- clockwise lowers the ICC sensor.

>> GO TO 3

3.LASER BEAM AIMING CONFIRMATION

1. When “U/D CORRECT” value indicates ±4, confirm that the value remains within ±4 for at least 2 seconds

while nothing is touching the ICC sensor.

2. When “COMPLETED THE VERTICAL AIMING OF LASER BEAM” appears on screen, touch “END”.

NOTE:

Be sure that the margin of “U/D CORRECT” is within ±4 when the ICC sensor unit is untouched.

3. Confirm that “ADJUSTING AUTOMATIC HORIZONTAL LASER BEAM AIMING” is on screen and wait

while the horizontal adjustment is made automatically. (maximum: 10 seconds).

4. Confirm that “NORMALLY COMPLETED” is displayed on CONSULT-III and close the aiming adjustment procedure by touching “END”.

NOTE:

Complete all the procedures once “LASER BEAM AD JUST” mode is entered in CONSULT-III. When the

procedure is discontinued, the ICC system is inoperable.

>> LASER BEAM AIMING ADJUSTMENT END.

CHECK AFTER THE ADJUSTMENT

Test the ICC system by performing the ICC System Running Test. Refer to CCS-8, "ACTION TEST : ICC Sys-

tem Running Test" .

ACTION TEST

ACTION TEST : ICC System Running TestINFOID:0000000003776929

VEHICLE-TO-VEHICLE DISTANCE CONTROL MODE

SET CHECKING

1. Press the ON/OFF switch for less than 1.5 seconds.

2. Drive the vehicle between 40 km/h (25 MPH) and 144 km/h (89 MPH).

3. Push the COAST/SET switch.

4. Confirm that the desired speed is set as the COAST/SET switch is released.

NOTE:

WKIA1869E

Revision: December 20092009 QX56

Page 669 of 4171

CCS-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (ICC SENSOR INTEGRATED UNIT)

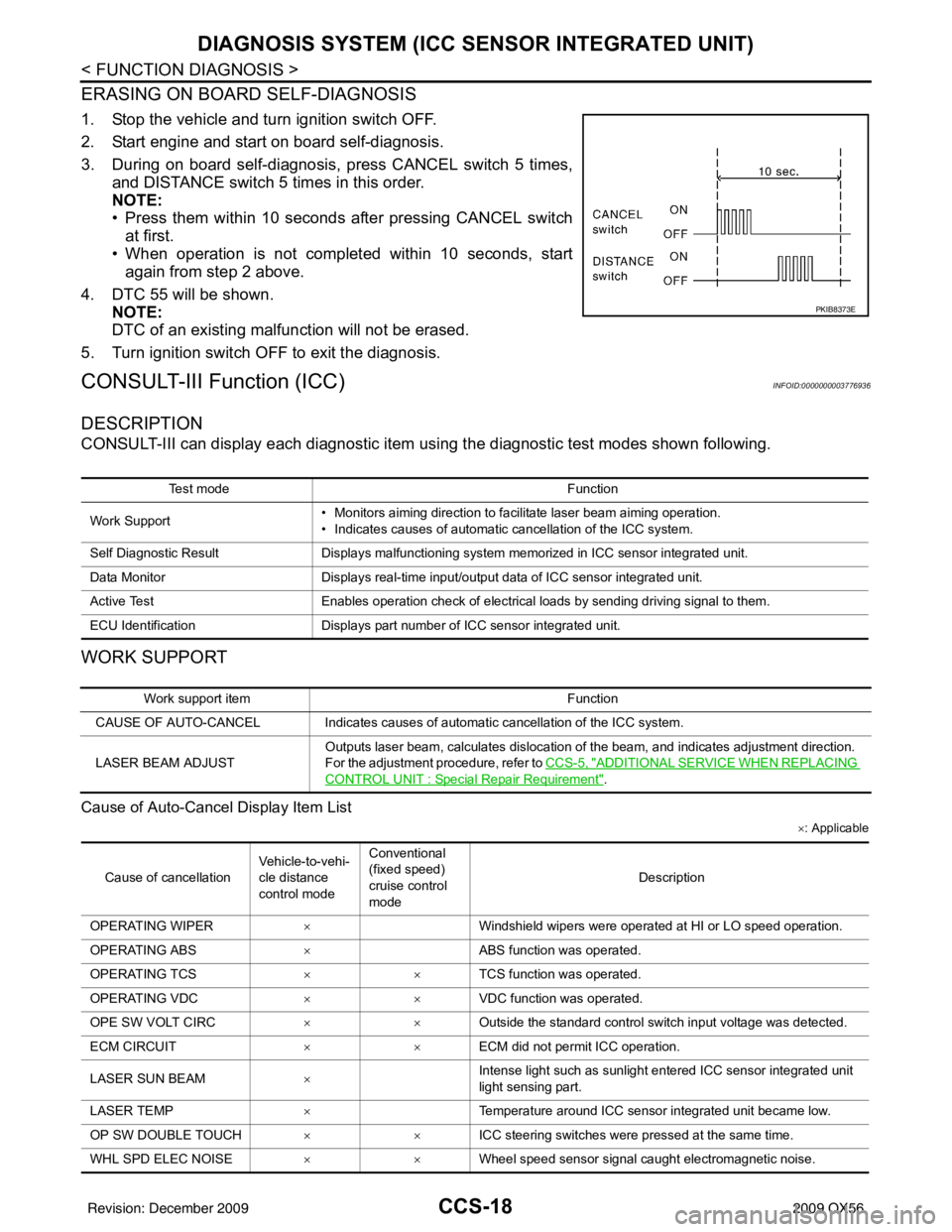

ERASING ON BOARD SELF-DIAGNOSIS

1. Stop the vehicle and turn ignition switch OFF.

2. Start engine and start on board self-diagnosis.

3. During on board self-diagnosis, press CANCEL switch 5 times,

and DISTANCE switch 5 times in this order.

NOTE:

• Press them within 10 seconds after pressing CANCEL switch

at first.

• When operation is not completed within 10 seconds, start again from step 2 above.

4. DTC 55 will be shown. NOTE:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

CONSULT-III Function (ICC)INFOID:0000000003776936

DESCRIPTION

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

WORK SUPPORT

Cause of Auto-Cancel Display Item List

×: Applicable

PKIB8373E

Test mode Function

Work Support • Monitors aiming direction to facilitate laser beam aiming operation.

• Indicates causes of automatic cancellation of the ICC system.

Self Diagnostic Result Displays malfunctioning system memorized in ICC sensor integrated unit.

Data Monitor Displays real-time input/output data of ICC sensor integrated unit.

Active Test Enables operation check of electrical loads by sending driving signal to them.

ECU Identification Displays part number of ICC sensor integrated unit.

Work support item Function

CAUSE OF AUTO-CANCEL Indicates causes of automatic cancellation of the ICC system.

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction.

For the adjustment procedure, refer to

CCS-5, "

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement".

Cause of cancellationVehicle-to-vehi-

cle distance

control modeConventional

(fixed speed)

cruise control

mode

Description

OPERATING WIPER ×Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ×ABS function was operated.

OPERATING TCS ××TCS function was operated.

OPERATING VDC ××VDC function was operated.

OPE SW VOLT CIRC ××Outside the standard control switch input voltage was detected.

ECM CIRCUIT ××ECM did not permit ICC operation.

LASER SUN BEAM ×Intense light such as sunlight entered ICC sensor integrated unit

light sensing part.

LASER TEMP ×Temperature around ICC sensor integrated unit became low.

OP SW DOUBLE TOUCH ××ICC steering switches were pressed at the same time.

WHL SPD ELEC NOISE ××Wheel speed sensor signal caught electromagnetic noise.

Revision: December 20092009 QX56