width INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 7 of 4171

QUICK REFERNCE CHART: QX56

2010

*2: Verify the vehicle height. If vehicle height is not within ± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure.

Brake SpecificationsINFOID:0000000005987157

Unit: mm (in)

Brake PedalINFOID:0000000005987158

Unit: mm (in)

CAUTION:

When equipped with adjustable pedal, the pedal must be in th e forward most position (closest to the floor) for pedal height

adjustment. Front brake Brake model AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.181)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 50.8 (2.00)

Rear brake Brake model AD14VE Rotor outer diameter × thickness 320 x 14 (12.60 x 0.551)

Pad Length × width × thickness 83.0 x 33.0 x 12.0 (3.268 x 1.299 x 0.472)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Pedal free height (H) with pedal in forward most position 182.3 - 192.3 (7.18 - 7.57)

Pedal travel (T) 153.3 (6.04)

Stop lamp switch and ASCD cancel switch threaded end to brake pedal bracket gap 0.74 - 1.96 (0.029 - 0.077)

ALFIA0149ZZ

Page 339 of 4171

![INFINITI QX56 2009 Factory Service Manual AV

DVD PLAYERAV-153

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

DVD PLAYER

Reference ValueINFOID:0000000003776897

PHYSICAL VALUES

ALNIA0665GB

Te r m i n a l

(Wire color) Description INFINITI QX56 2009 Factory Service Manual AV

DVD PLAYERAV-153

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

DVD PLAYER

Reference ValueINFOID:0000000003776897

PHYSICAL VALUES

ALNIA0665GB

Te r m i n a l

(Wire color) Description](/img/42/57031/w960_57031-338.png)

AV

DVD PLAYERAV-153

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

DVD PLAYER

Reference ValueINFOID:0000000003776897

PHYSICAL VALUES

ALNIA0665GB

Te r m i n a l

(Wire color) Description

ConditionReference value

(Approx.)

+ – Signal nameInput/

Output

1

(W) 2

(B) DVD audio signal LH Output Ignition

switch ON With operation of the DVD

player

3—Shield —— — —

5

(B) Ground Ground

—Ignition

switch

ON —0

V

6

(BR) Ground Illumination control (pulse

width modulated)

— — With lighting switch ON

—

7

(W/L) Ground Can communication Input/

Output Ignition

switch ON ——

9

(SB) Ground Video monitor power sup-

ply OutputIgnition

switch ON With DVD player operation

Battery voltage

10

(G/Y) Ground Switch power

OutputIgnition

switch

ON With DVD player operation

5V

12

(B/W) Ground VTR (+)

OutputIgnition

switch ON With DVD player operation

—

13

(L) Ground VTR (-)

OutputIgnition

switch ON With DVD player operation

—

14

(B/W) Ground Display ground

—Ignition

switch

ON With DVD player operation

0V

16

(Y) — Data receive

Input —— —

SKIB3609E

Revision: December 20092009 QX56

Page 475 of 4171

SERVICE DATA AND SPECIFICATIONS (SDS)BR-45

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

G H

I

J

K L

M A

B

BR

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000004181524

Unit: mm (in)

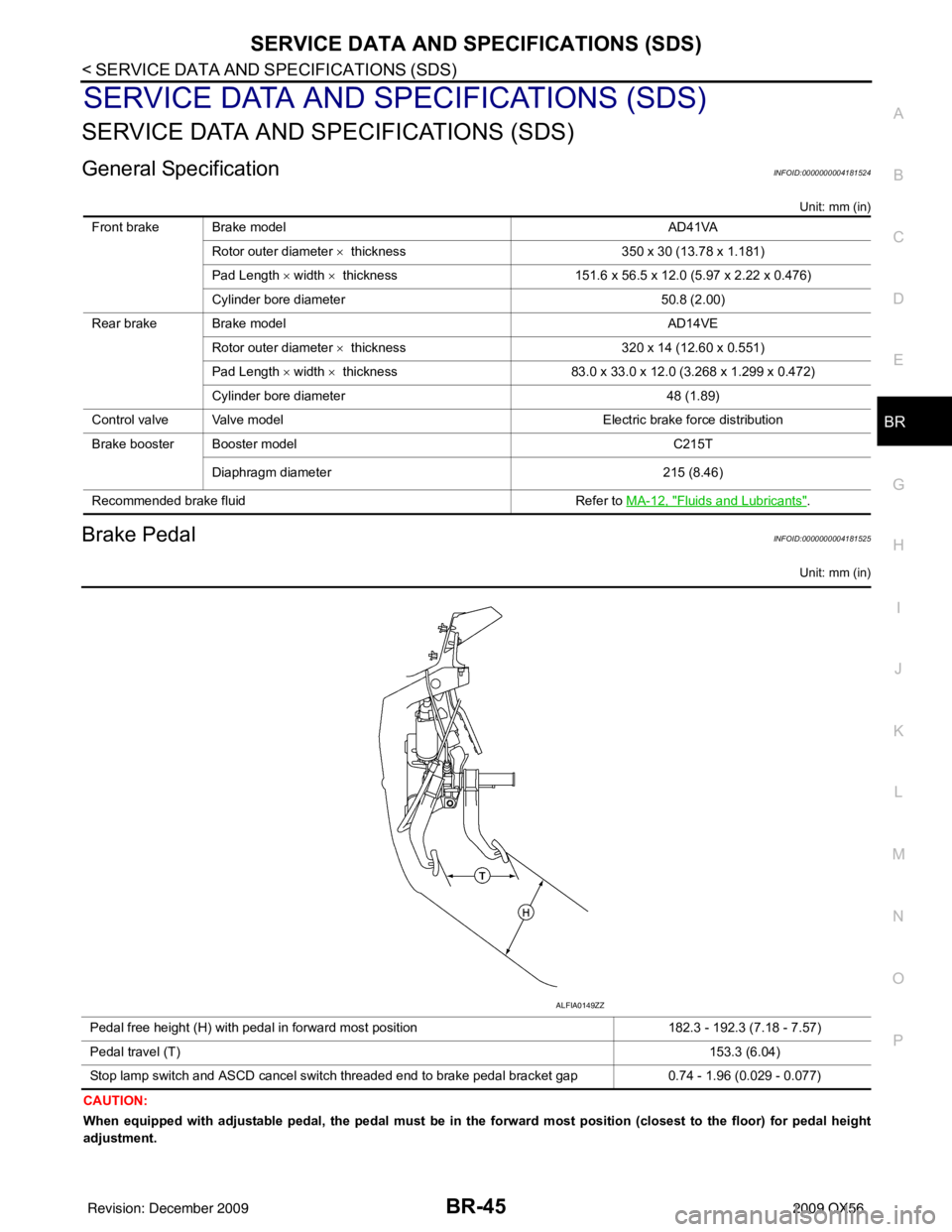

Brake PedalINFOID:0000000004181525

Unit: mm (in)

CAUTION:

When equipped with adjustable pedal, the pedal must be in the forward most position (closest to the floor) for pedal height

adjustment. Front brake Brake model

AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.181)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 50.8 (2.00)

Rear brake Brake model AD14VE

Rotor outer diameter × thickness 320 x 14 (12.60 x 0.551)

Pad Length × width × thickness 83.0 x 33.0 x 12.0 (3.268 x 1.299 x 0.472)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Recommended brake fluid Refer to MA-12, "

Fluids and Lubricants".

Pedal free height (H) with pedal in forward most position 182.3 - 192.3 (7.18 - 7.57)

Pedal travel (T) 153.3 (6.04)

Stop lamp switch and ASCD cancel switch threaded end to brake pedal bracket gap 0.74 - 1.96 (0.029 - 0.077)

ALFIA0149ZZ

Revision: December 20092009 QX56

Page 730 of 4171

CHG

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

CHG-7

< FUNCTION DIAGNOSIS >

C

D E

F

G H

I

J

K L

B A

O P

N

POWER GENERATION VOLTAG

E VARIABLE CONTROL SYSTEM

System DiagramINFOID:0000000003776545

System DescriptionINFOID:0000000003776546

Power generation variable voltage control system has been adopted. By varying the voltage to the generator,

engine load due to power generation of the generator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generat ion variable voltage control system, power generation

is performed according to the characterist ic of the IC regulator in the generator.

Component DescriptionINFOID:0000000003776547

ALMIA0057GB

Component part Description

Battery current sensor The battery current sensor is installed on the battery cable at the

negative terminal. The battery current sensor detects the charg-

ing/discharging current of the battery and sends a voltage signal

to the ECM according to the current value detected.

ECM The battery current sensor detects the charging/discharging cur-

rent of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power

generation voltage variable control according to the battery condi-

tion.

When performing the power generation voltage variable control,

the ECM calculates the target power generation voltage according

to the battery condition and sends the calculated value as the pow-

er generation command value to the IPDM E/R.

IPDM E/R The IPDM E/R converts the received power generation command

value into a pulse width modulated (PWM) command signal and

sends it to the IC regulator.

Generator (IC regulator) The IC regulator controls the power generation voltage by the tar-

get power generation voltage based on the received PWM com-

mand signal.

When there is no PWM command signal, the generator performs

the normal power generation according to the characteristic of the

IC regulator.

Revision: December 20092009 QX56

Page 1356 of 4171

![INFINITI QX56 2009 Factory Service Manual

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides t INFINITI QX56 2009 Factory Service Manual

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides t](/img/42/57031/w960_57031-1355.png)

MULTIPORT FUEL INJECTION SYSTEMEC-29

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system prov

ides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-136

. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, t he air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

Deceleration and acceleration

High-load, high-speed operation

Malfunction of A/F sensor 1 or its circuit

Insufficient activation of A/F sensor 1 at low engine coolant temperature

High engine coolant temperature

During warm-up

After shifting from N to D

When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM cont rols the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mi xture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation ca rried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

PBIB3020E

Revision: December 20092009 QX56

Page 1357 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-30

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinde INFINITI QX56 2009 Factory Service Manual

EC-30

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinde](/img/42/57031/w960_57031-1356.png)

EC-30

< FUNCTION DIAGNOSIS >[VK56DE]

MULTIPORT FUEL INJECTION SYSTEM

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl

e according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all eight cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The eight fuel injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speed.

PBIB0122E

Revision: December 20092009 QX56

Page 1358 of 4171

![INFINITI QX56 2009 Factory Service Manual

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This sig INFINITI QX56 2009 Factory Service Manual

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This sig](/img/42/57031/w960_57031-1357.png)

ELECTRIC IGNITION SYSTEMEC-31

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ELECTRIC IGNITION SYSTEM

System DescriptionINFOID:0000000003771304

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 8 - 7 - 3 - 6 - 5 - 4 -2

The ignition timing is controlled by the ECM to maintain

the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Comput-

ing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revi sed by the ECM according to the other data stored in

the ECM.

At starting

During warm-up

At idle

At low battery voltage

During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed*

2

Piston position

Ignition timing

controlPower transistor

Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Knock sensor Engine knocking

TCM Gear position

Battery

Battery voltage*

2

Wheel sensor

Vehicle speed*1

Revision: December 20092009 QX56

Page 1394 of 4171

![INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-67

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: The item is the same as that of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

� INFINITI QX56 2009 Factory Service Manual

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-67

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: The item is the same as that of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

�](/img/42/57031/w960_57031-1393.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEMEC-67

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: The item is the same as that of 1st trip freeze frame data.

DATA MONITOR MODE

Monitored Item

×

: Applicable

INT/A TEMP SE

[° C] or [ °F] The intake air temperature at the moment a malfunction is detected is displayed.

INT MANI PRES [kPa] Always a certain value is displayed.

These items are not efficient JA60 models.

COMBUST CONDI-

TION Freeze frame data

item* Description

Monitored item

[Unit] ECM IN-

PUT SIG-

NALS MAIN

SIGNALS Description Remarks

ENG SPEED [rpm] ×× Indicates the engine speed computed

from the signal of the crankshaft position

sensor (POS) and camshaft position

sensor (PHASE). Accuracy becomes poor if engine

speed drops below the idle rpm.

If the signal is interrupted while the en-

gine is running, an abnormal value may

be indicated.

MAS A/F SE-B1 [V] ×× The signal voltage of the mass air flow

sensor is displayed. When the engine is stopped, a certain

value is indicated.

When engine is running specification range is indicated in “SPEC”.

B/FUEL SCHDL

[msec] ×× Base fuel schedule indicates the fuel in-

jection pulse width programmed into

ECM, prior to any learned on board cor-

rection. When engine is running specification

range is indicated in “SPEC”.

A/F ALPHA-B1 [%] The mean value of the air-fuel ratio feed-back correction factor per cycle is indi-

cated. When the engine is stopped, a certain

value is indicated.

When engine is running specification range is indicated in “SPEC”.

This data also includes the data for the

air-fuel ratio learning control.

A/F ALPHA-B2 [%]

COOLAN TEMP/S

[

° C] or [ °F] ×× The engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is dis-

played. When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the

ECM is displayed.

A/F SEN1 (B1) [V] ××

The A/F signal computed from the input

signal of the A/F sensor 1 is displayed.

A/F SEN1 (B2) [V] ××

HO2S2 (B1) [V] ××

The signal voltage of the heated oxygen

sensor 2 is displayed.

HO2S2 (B2) [V] ××

HO2S2 MNTR (B1)

[RICH/LEAN] ×

Display of heated oxygen sensor 2 sig-

nal:

RICH: means the amount of oxygen after

three way catalyst is relatively small.

LEAN: means the amount of oxygen af-

ter three way catalyst is relatively large. When the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN] ×

VHCL SPEED SE

[km/h] or [mph] ×× The vehicle speed computed from the

vehicle speed signal sent from combina-

tion meter is displayed.

BATTERY VOLT [V] The power supply voltage of ECM is dis-

played.

ACCEL SEN 1 [V] The accelerator pedal position sensor

signal voltage is displayed. ACCEL SEN 2 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

ACCEL SEN 2 [V]

Revision: December 20092009 QX56

Page 1395 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM inte INFINITI QX56 2009 Factory Service Manual

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM inte](/img/42/57031/w960_57031-1394.png)

EC-68

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

TP SEN 1-B1 [V]

××

The throttle position sensor signal volt-

age is displayed. TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

TP SEN 2-B1 [V]

××

FUEL T/TMP SE

[ ° C] or [ °F] The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A TEMP SE

[ ° C] or [ °F] ×× The intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

EVAP SYS PRES

[V] The signal voltage of EVAP control sys-

tem pressure sensor is displayed.

FUEL LEVEL SE [V] × The signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF] Indicates start signal status [ON/OFF]

computed by the ECM according to the

signals of engine speed and battery volt-

age. After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF] ×× Indicates idle position [ON/OFF] comput-

ed by ECM according to the accelerator

pedal position sensor signal.

AIR COND SIG

[ON/OFF] ×× Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF] ××

Indicates [ON/OFF] condition from the

transmission range signal.

PW/ST SIGNAL

[ON/OFF] ×× [ON/OFF] condition of the power steering

system (determined by the signal voltage

of the power steering pressure sensor

signal) is indicated.

LOAD SIGNAL [ON/

OFF] ×× Indicates [ON/OFF] condition from the

electrical load signal.

ON: Rear window defogger switch is ON

and/or lighting switch is in 2nd position.

OFF: Both rear window defogger switch

and lighting switch are OFF.

IGNITION SW

[ON/OFF] ×× Indicates [ON/OFF] condition from igni-

tion switch signal.

HEATER FAN SW

[ON/OFF] ×

Indicates [ON/OFF] condition from heat-

er fan switch signal.

BRAKE SW

[ON/OFF] Indicates [ON/OFF] condition from the

stop lamp switch signal.

INJ PULSE-B1

[msec] Indicates the actual fuel injection pulse

width compensated by ECM according to

the input signals. When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

IGN TIMING [BT-

DC] Indicates the ignition timing computed by

ECM according to the input signals. When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE [%]

“Calculated load value” indicates the val- ue of the current air flow divided by peak

air flow.

MASS AIRFLOW

[g·m/s] Indicates the mass air flow computed by

ECM according to the signal voltage of

the mass air flow sensor.

Monitored item

[Unit] ECM IN-

PUT SIG-

NALS MAIN

SIGNALS Description Remarks

Revision: December 20092009 QX56

Page 1401 of 4171

![INFINITI QX56 2009 Factory Service Manual

EC-74

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003771320

The specification (SP) val INFINITI QX56 2009 Factory Service Manual

EC-74

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003771320

The specification (SP) val](/img/42/57031/w960_57031-1400.png)

EC-74

< COMPONENT DIAGNOSIS >[VK56DE]

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

COMPONENT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003771320

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode with CONSULT-III during normal operation of the Engine Control System. When the value in

“SPEC” of “DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When

the value in “SPEC” of “DATA MONITOR” mode is NO T within the SP value, the Engine Control System may

have one or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

B/FUEL SCHDL (The fuel injection pulse width progr ammed into ECM prior to any learned on board correc-

tion)

A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionINFOID:0000000003771321

Vehicle driven distance: More than 5,000 km (3,107 miles)

Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2 , 14.25 - 15.12 psi)

Atmospheric temperature: 20 - 30 °C (68 - 86 °F)

Engine coolant temperature: 75 - 95 °C (167 - 203 °F)

Engine speed: Idle

Transmission: Warmed-up

- After the engine is warmed up to normal operating temper ature, drive vehicle until “ATF TEMP SE 1” (A/T

fluid temperature sensor signal) indicates more than 60 °C (140 °F).

Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

Inspection ProcedureINFOID:0000000003771322

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform EC-13, "Basic Inspection"

.

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2” and “MAS A/F SE-B1” in “SPEC” of “DATA

MONITOR” mode with CONSULT-III.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-75, "Diagnosis Procedure"

.

Revision: December 20092009 QX56