coolant INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2715 of 4210

PERIODIC MAINTENANCEMA-11

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

(1) If towing a trailer, or using a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every

30,000 miles

(48,000 km) or 24 months. Using automatic transmission fluid other than Ge nuine NISSAN Matic S ATF or Matic J ATF will cause

deterioration in drive ability and automatic transmission durability, and may damage the automatic transmission, which is not

covered by the INFINITI new vehicle limited warranty.

(2) Refer to “Tire rotation” under the “General maintenance” heading earlier in this section.

Schedule 2INFOID:0000000005145937

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Ins pect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item. For service procedures, go to FL section.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and inte rvals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY MAINTENANCE

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section

- Page or

- Content

Title

Perform at number of miles, kilometers or

months, whichever comes first. Miles x

1,000(km x

1,000)

Months 33.75

(54)

27 37.5

(60)

30 41.25

(66)

33 45

(72)

36 48.75

(78)

39 52.5

(84)

42 56.25

(90)

45 60

(96)

48

Brake lines and cables IIMA-34

Brake pads and rotors IIIIMA-35

Automatic transmission fluid, transfer fluid and

differential gear oil NOTE (1)

IIMA-29,

MA-30

,

MA-32

Steering gear and linkage, axle and suspen-

sion parts IIII

MA-36,

MA-37

Tire Rotation NOTE (2) MA-34

Drive shaft boots and propeller shaft (4WD)IIIIMA-31

Exhaust system IIIIMA-26

In-cabin microfilter RRMA-26

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti- tle

Perform at number of miles, kilometers

or months, whichever comes first. Miles x 1,000

(km x 1,000) Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Drive belts NOTE (1) I*MA-15

Air cleaner filter [R][R]MA-20

EVAP vapor lines I*I*MA-25

Fuel lines I*I*MA-19

Fuel filter NOTE (2) MA-19

Engine coolantNOTE (3) R*MA-17

Engine oil R R R R R R R R MA-22

Engine oil filter (Use Genuine NISSAN

oil filter or equivalent)RRRR RRR R

MA-22

Spark plug (Iridium - tipped type) Replace every 105,000 miles (169,000 km).MA-24

Intake and exhaust valve clearance* NOTE (4) EM-18

Revision: April 20092010 QX56

Page 2717 of 4210

RECOMMENDED FLUIDS AND LUBRICANTSMA-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000005145938

*1: For further details, refer to

MA-14, "Engine Oil Recommendation".

*2: If Genuine NISSAN Matic S ATF is not ava ilable, Genuine Matic J ATF may also be used. Using automatic transmission fluid

other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration in drive ability and automatic transmission

durability, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited warranty.

*3: DEXRON

TM VI type ATF may also be used.

*4: Available in mainland U.S.A. through an INFINITI dealer.

*5: For further details, see “Air conditioner specification label”.

*6: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0° C (32° F).

*7: For improved vehicle performance, INFINITI recommends the use of unleaded premium gasoline with an octane rating of at leas t 91

AKI (RON 96). For furt her details, refer to GI-27, "

Precaution for Fuel (Unleaded Premium Gasoline Required)",

*8: See an INFINITI dealer for service for synthetic oil.

*9: Using fluid other than Genuin e NISSAN Matic D ATF may cause deterioration in drive ability and transfer durability, and may damage

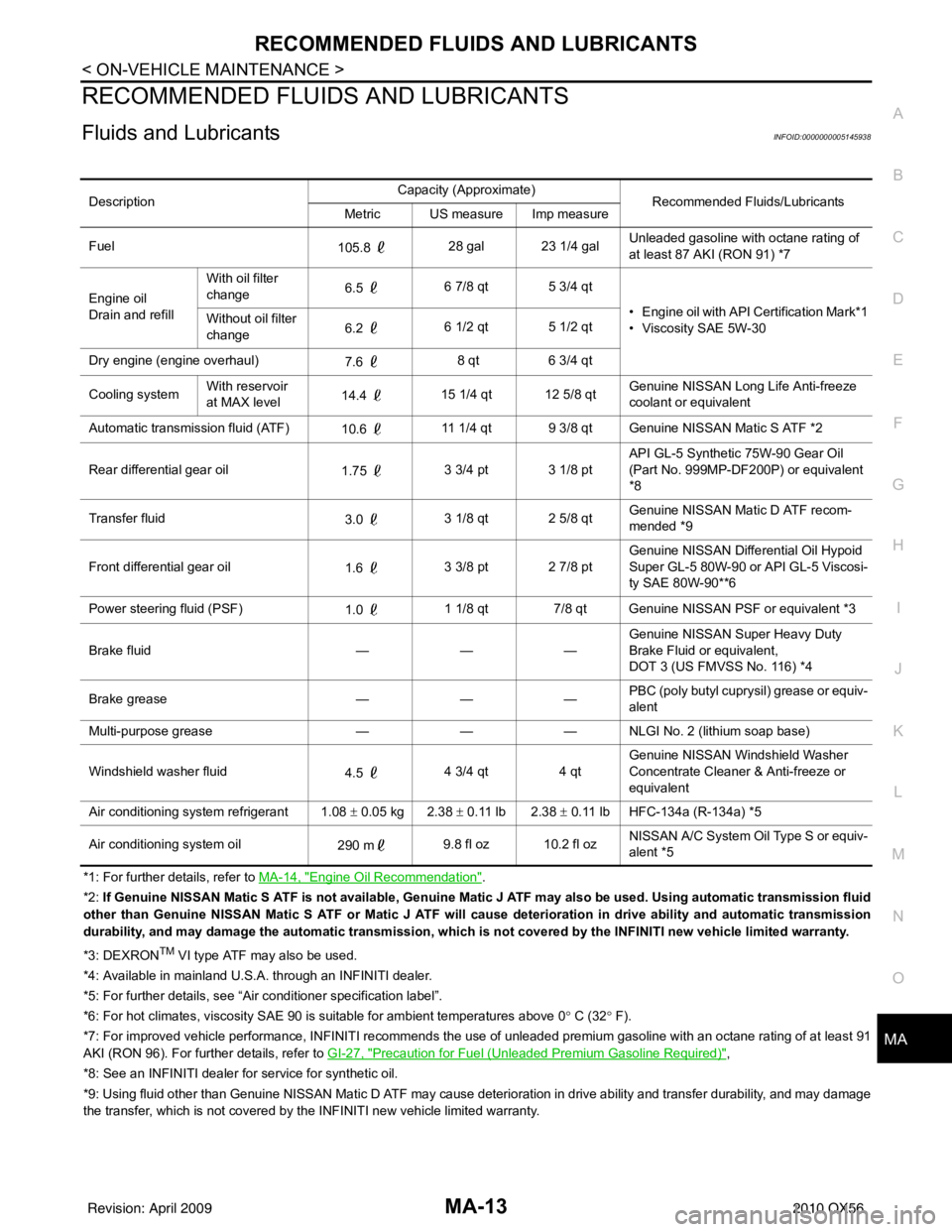

the transfer, which is not covered by the INFINITI new vehicle limited warranty. Description

Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal Unleaded gasoline with octane rating of

at least 87 AKI (RON 91) *7

Engine oil

Drain and refill With oil filter

change

6.5

6 7/8 qt 5 3/4 qt

• Engine oil with API Certification Mark*1

• Viscosity SAE 5W-30

Without oil filter

change

6.2

6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt

6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt Genuine NISSAN Long

Life Anti-freeze

coolant or equivalent

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt Genuine NISSAN Matic S ATF *2

Rear differential gear oil 1.75 3 3/4 pt 3 1/8 pt API GL-5 Synthetic 75W-90 Gear Oil

(Part No. 999MP-DF200P) or equivalent

*8

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt Genuine NISSAN Matic D ATF recom-

mended *9

Front differential gear oil 1.6 3 3/8 pt 2 7/8 pt Genuine NISSAN Differ

ential Oil Hypoid

Super GL-5 80W-90 or API GL-5 Viscosi-

ty SAE 80W-90**6

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt Genuine NISSAN PSF or equivalent *3

Brake fluid ———Genuine NISSAN S

uper Heavy Duty

Brake Fluid or equivalent,

DOT 3 (US FMVSS No. 116) *4

Brake grease ———PBC (poly butyl cuprysil) grease or equiv-

alent

Multi-purpose grease ——— NLGI No. 2 (lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt

4 qtGenuine NISSAN Wind

shield Washer

Concentrate Cleaner & Anti-freeze or

equivalent

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz NISSAN A/C System Oil Type S or equiv-

alent *5

Revision: April 20092010 QX56

Page 2718 of 4210

MA-14

< ON-VEHICLE MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

Engine Oil Recommendation

INFOID:0000000005145939

NISSAN recommends the use of an energy conserving oil in order to

improve fuel economy. Select only engine oils that meet the Ameri-

can Petroleum Institute (API) certification and International Lubricant

Standardization and Approval Committee (ILSAC) certification and

SAE viscosity standard (2). These oils have the API certification

mark (1) on the front of the container. Oils which do not have the

specified quality label should not be used as they could cause

engine damage.

ANTI-FREEZE COOLANT MIXTURE RATIO

The engine cooling system is filled at the factory with a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and co rrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to use only Genuine NISSAN Long Life Anti-freeze cool-

ant or equivalent with the proper mixture ratio of 50% anti-freeze and 50% demineralized water or

distilled water.

• Other types of coolant solution s may damage your cooling system.

ALPIA0001ZZ

For outside temperatures down to: Anti-freeze coolant mixture ratio

° C ° F Genuine NISSAN Long Life

Antifreeze coolant Demineralized water or distilled

water

– 35 ° – 30° 50 % 50 %

Revision: April 20092010 QX56

Page 2719 of 4210

ENGINE MAINTENANCEMA-15

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

ENGINE MAINTENANCE

DRIVE BELTS

DRIVE BELTS : Exploded ViewINFOID:0000000005403131

DRIVE BELTS : Checking Drive BeltsINFOID:0000000005403132

WARNING:

Be sure to perform when the engine is stopped.

1. Remove air duct and resonator assembly when inspecting drive belt.

2. Make sure that indicator (single line notch) of eac

h auto tensioner is within the allowable working range

(between three line notches).

NOTE:

• Check the drive belt auto tensioner indication when the engine is cold.

• The indicator notch is located on the moving side of the drive belt auto tensioner.

3. Visually check entire belt for wear, damage or cracks.

4. If the indicator is out of allowable working range or belt is damaged, replace the belt. Refer to MA-15

.

DRIVE BELT TENSION

There is no manual drive belt tension adjustment. The driv e belt tension is automatically adjusted by the drive

belt auto tensioner.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000005403133

LEVEL CHECK

1. Drive belt 2. Power steering pump pulley 3. Generator pulley

4. Crankshaft pulley 5. A/C compressor6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley9. Drive belt auto tensioner

A. Allowable working range

LBIA0391E

Revision: April 20092010 QX56

Page 2720 of 4210

MA-16

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

• Check if the engine coolant reservoir tank level is within MIN toMAX level when engine is cool.

• Adjust engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

WARNING:

Never remove the radiator or reservoir cap when th e engine is hot. Serious burns could occur from

high-pressure engine coolant escaping from the radiator or reservoir.

• To check for leakage, apply pressure to the cooling system at the

reservoir filler neck using suitable tool and Tool.

CAUTION:

Higher pressure than specified may cause radiator damage.

NOTE:

In case that engine coolant decreases, replenish cooling system

with engine coolant.

• If any concerns are found, repair or replace damaged parts.

CHECKING RESERVOIR CAP

• Check reservoir cap relief pressure using suitable tool and Tool.

NOTE:

Apply engine coolant to the cap seal.

• Replace the reservoir cap if there is any damage in the negative- pressure valve, or if the open-valve pressure is outside of the limit.

CHECKING RADIATOR CAP

Inspect the radiator cap.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy resi-

due or foreign material.

• Replace the cap if the metal plunger cannot be seen around theedge of the black rubber gasket.

• Replace the cap if deposits of waxy residue or other foreign mate- rial are on the black rubber gasket or the metal retainer.

SMA412B

Tool number : EG17650301 (J-33984-A)

Leakage test pressure : 137 kPa (1.4 kg/cm, 20 psi)

WBIA0612E

Tool number : EG17650301 (J-33984-A)

Standard : 95 - 125 kPa (0.97 - 1.28 kg/cm

2, 14 - 18 psi)

WBIA0611E

PBIC2816E

Revision: April 20092010 QX56

Page 2721 of 4210

ENGINE MAINTENANCEMA-17

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• Pull negative-pressure valve to open it and make sure that it closes

completely when released.

• Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

• Make sure that there are no unusualness in the opening and clos- ing conditions of negative-pressure valve.

ENGINE COOLANT : Chang ing Engine CoolantINFOID:0000000005403134

WARNING:

• To avoid being scalded, never change the coolant when the engine is hot.

• Wrap a thick cloth around the cap to carefully remo ve the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine front undercover using power tool.

3. Open the radiator drain plug at the bottom of the radiator, and remove the radiator filler cap. This is the only step required

when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

4. When draining all of the coolant in the system for engine removal or repair, it is necessary to drain the cylinder block.

Remove the RH cylinder block drain plug to drain the right bank

and the oil cooler hose to drain the left bank as shown.

SMA967B

WBIA0391E

PBIC0146E

WBIA0392E

Revision: April 20092010 QX56

Page 2722 of 4210

MA-18

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flush the engine cooling system. Refer to MA-17, "

ENGINE COOLANT :

Changing Engine Coolant".

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir tank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants".

2. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

3. Remove the vented reservoir cap and replace it with a non-vented reservoir cap before filling the cooling

system.

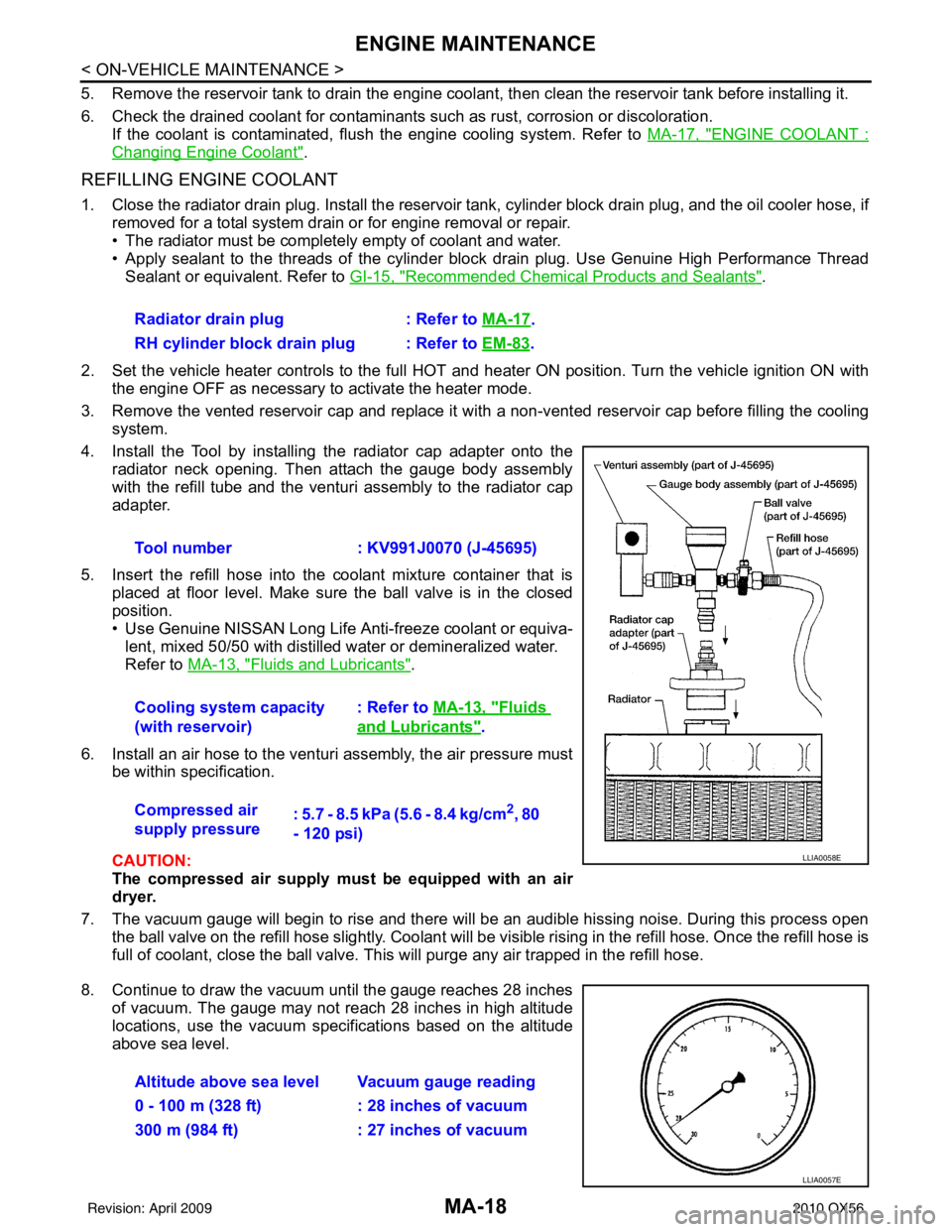

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-13, "

Fluids and Lubricants".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.Radiator drain plug

: Refer to MA-17

.

RH cylinder block drain plug : Refer to EM-83

.

Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir) : Refer to

MA-13, "

Fluids

and Lubricants".

Compressed air

supply pressure : 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2, 80

- 120 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

LLIA0057E

Revision: April 20092010 QX56

Page 2723 of 4210

ENGINE MAINTENANCEMA-19

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

9. When the vacuum gauge has reached the specified

amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening and install the radiator cap.

12. Remove the non-vented reservoir cap.

13. Fill the cooling system reservoir tank to the specified level. Run the engine to warm up the cooling system and top up the system as necessary befor e installing the vented reservoir cap.

FLUSHING COOLING SYSTEM

1. Drain the water from the engine cooling system. Refer to MA-17, "ENGINE COOLANT : Changing Engine

Coolant".

2. Fill the radiator and the reservoir tank (to the “MAX” line), with water. Reinstall the radiator cap and leave

the vented reservoir cap off.

3. Run the engine until it reaches normal operating temperature.

4. Press the engine accelerator two or three times under no-load.

5. Stop the engine and wait until it cools down.

6. Drain the water from the engine cooling system. Refer to MA-17, "

ENGINE COOLANT : Changing Engine

Coolant".

7. Repeat steps 2 through 6 until clear water begins to drain from the radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005403135

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

FUEL FILTER

FUEL FILTER : Changing Fuel FilterINFOID:0000000005259654

The fuel filter is part of the fuel level sensor unit, fuel filter and fuel pump assembly and cannot be replaced

separately. Refer to FL-7, "

Removal and Installation".

WARNING:

Before replacing the fuel filter, release the fuel pressure from the fuel system. Refer to EC-489, "

Fuel

Pressure Check".

AIR CLEANER FILTER

500 m (1,641 ft): 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

SMA803A

Revision: April 20092010 QX56

Page 2725 of 4210

ENGINE MAINTENANCEMA-21

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair the broken

parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

•Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Put the selector lever in the Park “P” position.

1. Check the engine oil level. Refer to MA-20, "

ENGINE OIL : Inspection".

2. Remove engine front undercover using power tool.

3. Disconnect the oil pressure switch harness connector.

4. Remove the oil pressure switch (A).

5. Install Tools.

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load.

Engine oil pressure [Engine oil temperature at 80 °C (175 °F)]

Unit: kPa (kg/cm2, psi)

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

WBIA0791E

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine Speed Approximate Discharge Oil Pressure

Idle speed More than 98 (1.0, 14)

2,000 rpm More than 294 (3.0, 43)

Revision: April 20092010 QX56

Page 2763 of 4210

MWI

MWI-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION MWI

A

O P

CONTENTS

METER, WARNING LAMP & INDICATOR

BASIC INSPECTION ....... .............................4

DIAGNOSIS AND REPAIR WORKFLOW ..... .....4

Work Flow ........................................................... ......4

FUNCTION DIAGNOSIS ...............................5

METER SYSTEM ............................................ .....5

METER SYSTEM .........................................................5

METER SYSTEM : System Diagram ........................5

METER SYSTEM : System Description ....................5

METER SYSTEM : Arrangem ent of Combination

Meter ................................................................... ......

6

METER SYSTEM : Component Parts Location ........7

METER SYSTEM : Component Description ....... ......7

SPEEDOMETER ..........................................................8

SPEEDOMETER : System Diagram ................... ......8

SPEEDOMETER : System Description .....................8

SPEEDOMETER : Component Parts Location .........9

SPEEDOMETER : Component Description ........ ......9

TACHOMETER ...................................................... ......9

TACHOMETER : System Diagram ...........................9

TACHOMETER : System De scription .....................10

TACHOMETER : Component Parts Location ..... ....10

TACHOMETER : Component Description ..............10

ENGINE COOLANT TEMPERATURE GAUGE .... ....10

ENGINE COOLANT TEMPERATURE GAUGE :

System Diagram ......................................................

11

ENGINE COOLANT TEMPERATURE GAUGE :

System Description .................................................

11

ENGINE COOLANT TEMPERATURE GAUGE :

Component Parts Location ......................................

11

ENGINE COOLANT TEMPERATURE GAUGE :

Component Description ...........................................

12

FUEL GAUGE ........................................................ ....12

FUEL GAUGE : System Diagram ...........................12

FUEL GAUGE : System Description .......................12

FUEL GAUGE : Component Parts Location ...........12

FUEL GAUGE : Component Description ............. ....13

ENGINE OIL PRESSURE GAUGE ............................13

ENGINE OIL PRESSURE GAUGE : System Dia-

gram .................................................................... ....

13

ENGINE OIL PRESSURE GAUGE : System De-

scription ...................................................................

13

ENGINE OIL PRESSURE GAUGE : Component

Parts Location ..........................................................

14

ENGINE OIL PRESSURE GAUGE : Component

Description ...............................................................

14

VOLTAGE GAUGE ................................................ ....14

VOLTAGE GAUGE : System Diagram ....................15

VOLTAGE GAUGE : System Description ................15

VOLTAGE GAUGE : Component Parts Location ....15

VOLTAGE GAUGE : Component Description .........16

ODO/TRIP METER ................................................. ....16

ODO/TRIP METER : System Diagram ....................16

ODO/TRIP METER : System Description ................16

ODO/TRIP METER : Component Parts Location ....16

ODO/TRIP METER : Component Description .........17

SHIFT POSITION INDICATOR .............................. ....17

SHIFT POSITION INDICATOR : System Diagram ....17

SHIFT POSITION INDICATOR : System Descrip-

tion ...........................................................................

17

SHIFT POSITION INDICATOR : Component

Parts Location ..........................................................

18

SHIFT POSITION INDICATOR : Component De-

scription ............................................................... ....

18

WARNING LAMPS/INDICATOR LAMPS .............. ....18

WARNING LAMPS/INDICATOR LAMPS : System

Diagram ............................................................... ....

18

WARNING LAMPS/INDICATOR LAMPS : System

Description ........................................................... ....

19

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Parts Location ..............................................

19

WARNING LAMPS/INDICATOR LAMPS : Com-

ponent Description ...................................................

19

Revision: April 20092010 QX56