stop start INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3462 of 4210

![INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-111

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

26 P/L Headlamp aiming mo-

tors

Output —Lightin INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-111

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

26 P/L Headlamp aiming mo-

tors

Output —Lightin](/img/42/57032/w960_57032-3461.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-111

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

26 P/L Headlamp aiming mo-

tors

Output —Lighting

switch 2nd

position or

AUTO, head-

lamp aiming

switch in po-

sition OFF

0V

ON Battery voltage

27 W/B Fuse 38

(With trailer tow)

Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

30 W Fuse 53 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

32 L Wiper low speed sig-

nal

OutputON or

START Wiper switch OFF

Battery voltage

LO or INT 0V

35 L/B Wiper high speed sig-

nal

OutputON or

START Wiper switch OFF, LO, INT Battery voltage

HI 0V

37 Y Power generation

command signal Output —Ignition switch ON

6.3 V

40% is set on "Active test,"

"ALTERNATOR DUTY" of

"ENGINE" 3.8 V

40% is set on "Active test,"

"ALTERNATOR DUTY" of

"ENGINE" 1.4 V

38 B Ground Input ——0V

39 L CAN-H — ON— —

40 P CAN-L — ON— —

41 Y/B Hood switch Input —Hood closed OFF

0V

Hood open ON Battery voltage

42 GR Oil pressure switch Input — Engine running

Battery voltage

Engine stopped 0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

JPMIA0001GB

JPMIA0002GB

JPMIA0003GB

Revision: April 20092010 QX56

Page 3463 of 4210

![INFINITI QX56 2010 Factory Service Manual SEC-112

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery INFINITI QX56 2010 Factory Service Manual SEC-112

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery](/img/42/57032/w960_57032-3462.png)

SEC-112

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery voltage

44 BR Daytime light relay

control

(Canada only) Input ONDaytime light system active

0V

Daytime light system inactive Battery voltage

45 G/W Horn relay control Input ON When door locks are operated

using Intelligent Key (OFF

→

ON)* Battery voltage

→ 0V

46 GR Fuel pump relay con-

trol Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

47 O Throttle control motor

relay control Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

48 B/R Starter relay (inhibit

switch) Input

ON or

START Selector lever in "P" or "N"

0V

Selector lever any other posi-

tion Battery voltage

49 R/L Trailer tow relay

(With trailer tow)

Illumination

(Without trailer tow) Output ONLighting

switch must

be in the 1st

position OFF

0V

ON Battery voltage

50 W/R Front fog lamp (LH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

51 W/R Front fog lamp (RH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

52 L LH low beam head-

lamp

Output — Lighting switch in 2nd position Battery voltage

54 R/Y RH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

55 G LH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

56 Y

(With

DTRL)

L/W

(Without DTRL) RH high beam head-

lamp

Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position

Battery voltage

57 R/LPa

rking, license, and

tail lamp Output ONLighting

switch 1st po-

sition OFF

0V

ON Battery voltage

59 B Ground Input ——0V

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

Revision: April 20092010 QX56

Page 3464 of 4210

![INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-113

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

*: When horn reminder is ON

Fail SafeINFOID:00000 INFINITI QX56 2010 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-113

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

*: When horn reminder is ON

Fail SafeINFOID:00000](/img/42/57032/w960_57032-3463.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-113

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

*: When horn reminder is ON

Fail SafeINFOID:0000000005282721

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible, IPDM E/R performs fail-s afe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop posit ion by a front wiper auto stop signal.

60 B/WRear window defog-

ger relay

OutputON or

START Rear defogger switch ON

Battery voltage

Rear defogger switch OFF 0V

61 BR Fuse 32

(With trailer tow) Output OFF

—Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

Control part

Fail-safe in operation

Cooling fan • Turns ON the cooling fan relay when the ignition switch is turned ON

• Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part

Fail-safe in operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high LH/RH relays OFF

•Parking lamps

• License plate lamps

• Tail lamps • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper • The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

• The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wipe r is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relayTail lamp relay

ON ON —

OFF OFF —

Revision: April 20092010 QX56

Page 3465 of 4210

![INFINITI QX56 2010 Factory Service Manual SEC-114

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R st INFINITI QX56 2010 Factory Service Manual SEC-114

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R st](/img/42/57032/w960_57032-3464.png)

SEC-114

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

DTC IndexINFOID:0000000005282722

NOTE:

The details of TIME display are as follows.

• CRNT: The malfunctions that are detected now

• 1 - 39: The number is indicated when it is normal at present and a malfunction was detected in the past. It

increases like 0 → 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF → ON. It is

fixed to 39 until the self-diagnosis results are erased if it is over 39. It returns to 0 when a malfunction is

detected again in the process.

Ignition switch Front wiper switch Auto stop signal

ON OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

CONSULT-III display Fail-safe

TIMENOTERefer to

No DTC is detected.

further testing

may be required. ————

U1000: CAN COMM CIRCUIT ×CRNT 1 – 39 PCS-17

Revision: April 20092010 QX56

Page 3466 of 4210

![INFINITI QX56 2010 Factory Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E STA INFINITI QX56 2010 Factory Service Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E STA](/img/42/57032/w960_57032-3465.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E START FUNCTION SYMPTOMS

Symptom TableINFOID:0000000005147148

NOTE:

• Before performing the diagnosis in the following table, check “ SEC-4, "

Work Flow"”.

• Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and check each symptom.

• Engine cranking is enabled when the shift lever is in the "Park" position, and in the "Neutral" position only if the brake pedal is depressed.

• If the following symptoms are detec ted, check systems shown in the “Diagnosis/service procedure” column

in this order.

CONDITIONS OF VEHICLE (OPERATING CONDITIONS)

• Engine start function is ON when setting on CONSULT-III.

• Mechanical key is not inserted in key cylinder.

• One or more of Intelligent Keys with registered Intelligent Key ID is in the vehicle.

Symptom Diagnosis/service procedureReference

page

Ignition switch does not turn on with Intelligent Key.

[LCD displays "KEY DETECTED"] 1. Check steering lock solenoid.

DLK-99

2. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with Intelligent Key.

[LCD does not display "PUSH" with arrow toward key

cylinder] 1. Check Intelligent Key unit power supply and ground circuit.

DLK-682. Check ignition knob switch.DLK-116

3. Check key switch (BCM input).DLK-115

4. Check key switch (Intelligent Key unit input).DLK-113

5. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with Intelligent Key.

[LCD displays " NO KEY"] 1a. Check center console area antenna (rear).

DLK-60

1b. Check luggage area antenna.DLK-62

1c. Check center console area antenna (front).DLK-64

1d. Check overhead console area antenna.DLK-68

2. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with mechanical key1. Check key switch (BCM input).

DLK-1152. Check key switch (Intelligent Key unit input).DLK-113

Engine cannot be cranked with transmission in "Park"

or in "Neutral" position with brake pedal depressed.1. Check transmission signal.

TM-45

2. Check stop lamp switch.EXL-91

Revision: April 20092010 QX56

Page 3716 of 4210

A/T CONTROL SYSTEMTM-21

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

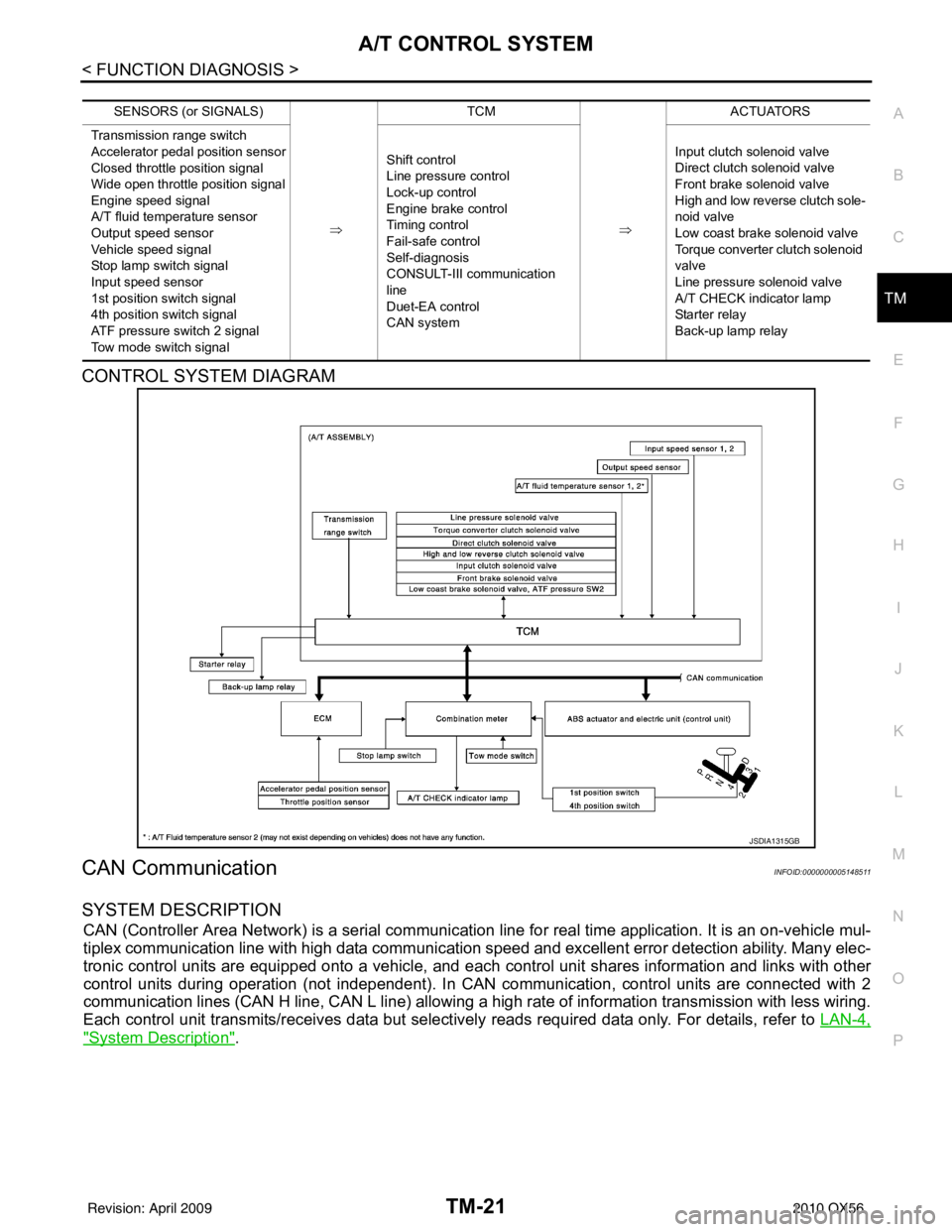

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005148511

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-4,

"System Description".

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Output speed sensor

Vehicle speed signal

Stop lamp switch signal

Input speed sensor

1st position switch signal

4th position switch signal

ATF pressure switch 2 signal

Tow mode switch signal Shift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

JSDIA1315GB

Revision: April 20092010 QX56

Page 3717 of 4210

TM-22

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

Input/Output Signal of TCM

INFOID:0000000005148512

*1: Spare for output speed sensor

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: CAN comm unications

*5: Used as a condition for starting self-diagnostics; if self-diagnostics are not started, it is judged that there is some kin d of error.

*6: A/T fluid temperature sensor 2 does not have any function.

Line Pressure ControlINFOID:0000000005148513

• When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the TCM

controls the line pressure solenoid.

Control item Line

pres- sure

control Vehicle

speed

control S h i f t

control Lock-up

control Engine

brake

control Fail-safe

function (*3) Self-diag-

nostics

function

Input Accelerator pedal position signal

(*4)XXXXX X X

Output speed sensor X X X X X X

Vehicle speed signal

(*1) (*4)XXXX X

Closed throttle position signal

(*4)(*2) X (*2) X X (*2) X(*5) X

Wide open throttle position signal

(*4)(*2) X (*2) X (*2) X(*5) X

Input speed sensor 1 X XXX X

Input speed sensor 2

(for 4th speed only) XX X

X X

Engine speed signals

(*4)XX

Transmission range switch X X X X X X X

Stop lamp switch signal

(*4)XXX (*5) X

A/T fluid temperature sensors 1, 2 (*6) X X X X X X X

ASCD Operation signal

(*4)XXXX

Overdrive cancel sig-

nal

(*4)XXX

TCM power supply voltage signal X X X X X X

Output Direct clutch solenoid

X XX X

Input clutch solenoid X XX X

High and low reverse clutch solenoid X XX X

Front brake solenoid X XX X

Low coast brake solenoid (ATF pressure

switch 2) XX X X X

Line pressure solenoid X X X X X X X

TCC solenoid XX X

Starter relay XX

Revision: April 20092010 QX56

Page 3726 of 4210

ON BOARD DIAGNOSTIC (OBD) SYSTEMTM-31

< FUNCTION DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

• If the battery cable is disconnected, the diagnostic trouble code will be lost within 24 hours.

• When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-42, "

Emission-related Diagnostic Information".

• Diagnostic trouble codes (DTC)

• 1st trip diagnostic trouble codes (1st trip DTC)

• Freeze frame data

• 1st trip freeze frame data

• System readiness test (SRT) codes

• Test values

HOW TO ERASE DTC (WITH CONSULT-III)

1. The emission related diagnostic information in the TCM and ECM can be er\

ased by selectioning "ALL

ERASE" in the "Description" of "F INAL CHECK" mode with CONSULT-III.

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Select Mode 4 with the Generic Scan Tool (GST). For details refer to EC-72, "

Generic Scan Tool (GST)

Function".

HOW TO ERASE DTC (NO TOOLS)

1. Disconnect battery for 24 hours.

2. Reconnect battery.

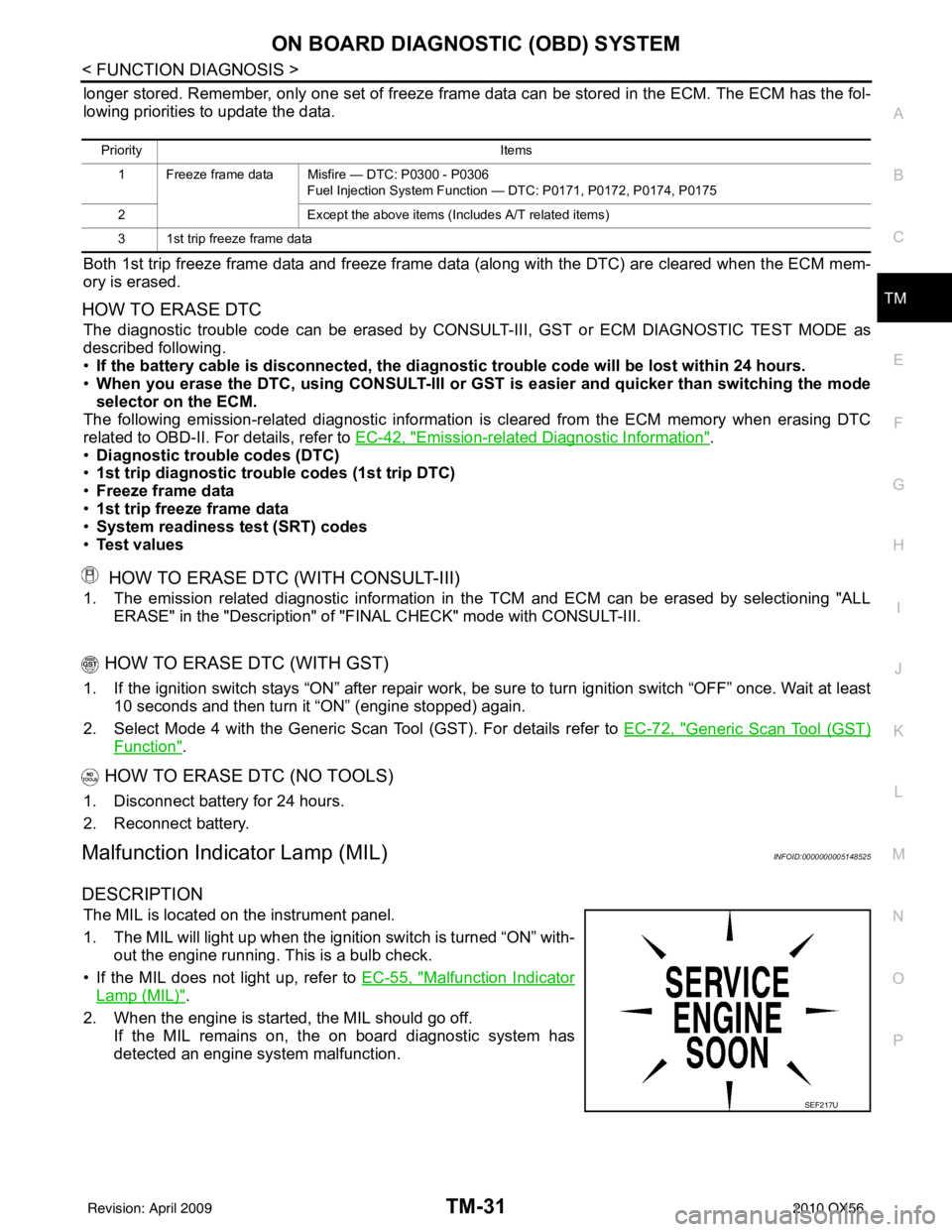

Malfunction Indicator Lamp (MIL)INFOID:0000000005148525

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned “ON” with-

out the engine running. This is a bulb check.

• If the MIL does not light up, refer to EC-55, "

Malfunction Indicator

Lamp (MIL)".

2. When the engine is start ed, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306 Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

SEF217U

Revision: April 20092010 QX56

Page 3733 of 4210

TM-38

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (TCM)

Does A/T CHECK indicator lamp come on for about 2 seconds?

YES >> GO TO 2.

NO >> GO TO TM-121, "

Symptom Table".

2.JUDGMENT PROCEDURE STEP 1

1. Turn ignition switch OFF.

2. Keep pressing shift lock release button.

3. Move selector lever from “P” to “D” position.

4. Release accelerator pedal. (Set the closed throttle position signal “ON”.)

5. Depress brake pedal. (Stop lamp switch signal “ON”.)

6. Turn ignition switch ON. (Do not start engine.)

7. Wait 3 seconds.

8. Move the selector lever from “D” to “3” position.

9. Release brake pedal. (Stop lamp switch signal “OFF”.)

10. Move the selector lever from “3” to “2” position.

11. Depress brake pedal. (Stop lamp switch signal “ON”.)

12. Depress accelerator pedal fully and release it.

>> GO TO 3.

3.CHECK SELF-DIAGNOSIS CODE

Check A/T CHECK indicator lamp.

Refer to "Judgment Self-diagnosis Code".

If the system does not go into self-diagnostics. Refer to TM-45, "

Diagnosis Procedure", TM-96, "Diagnosis

Procedure", TM-97, "Diagnosis Procedure".

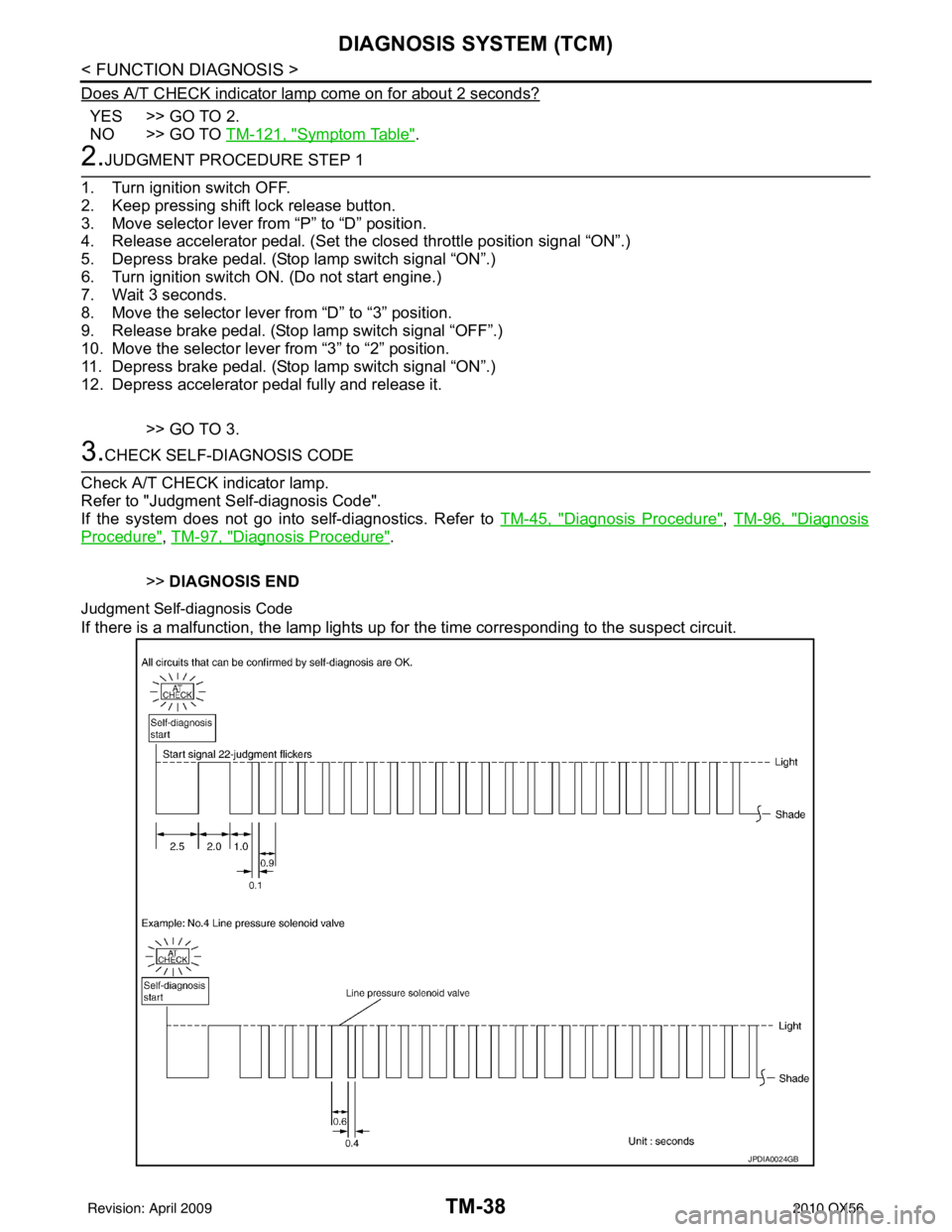

>> DIAGNOSIS END

Judgment Self-diagnosis Code

If there is a malfunction, the lamp lights up for the time corresponding to the suspect circuit.

JPDIA0024GB

Revision: April 20092010 QX56

Page 3750 of 4210

P0731 1GR INCORRECT RATIOTM-55

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0731 1GR INCORRECT RATIO

DescriptionINFOID:0000000005148568

This malfunction is detected when the A/T does not shift into 1GR position as instructed by TCM. This is not

only caused by electrical malfunction (circuits open or shorted) but also by mechanical malfunction such as

control valve sticking, improper solenoid valve operation.

On Board Diagnosis LogicINFOID:0000000005148569

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0731 1GR INCORRECT RATIO” is detected when TCM detects any inconsis-

tency in the actual gear ratio.

Possible CauseINFOID:0000000005148570

• Harness or connectors (Solenoid circuits are open or shorted.)

• Input clutch solenoid valve

• Front brake solenoid valve

• Direct clutch solenoid valve

• High and low reverse clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005148571

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start the engine and select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that “ATF TEMP 1” is within the following range. ATF TEMP 1: 20 °C – 140 °C

If out of range, drive vehicle to warm ATF or stop engine to cool ATF.

3. Select “1ST GR FNCTN P0731” of “DTC WO RK SUPPORT” mode for “TRANSMISSION” with CON-

SULT-III.

4. Drive vehicle and maintain the following conditions. VEHICLE SPEED: 10 km/h (6 MPH) or more

ACCELE POSI: 0.6/8 or more

ENGINE SPEED: INPUT SPEED − 50 rpm or more

INPUT SPEED: 300 rpm or more

GEAR: “1” position

MANU MODE SW: ON

5. Keep the current driving status for at least 5 consecutive seconds if CONSULT-III screen changes from “OUT OF CONDITION” to “TESTING”.

CAUTION:

If “TESTING” does not appear on CONSULT-III for a long time, select “SELF-DIAG RESULTS”. In

case a 1st trip DTC other than P0731 is shown, refer to “ TM-119, "

DTC No. Index"”.

If “COMPLETED RESULT NG” is detected, go to TM-56, "

Diagnosis Procedure".

If “STOP VEHICLE” is detec ted, go to the following step.

6. Stop vehicle.

7. Drive vehicle in “D” position allowing it to shift from 1GR to 5GR and check shift timing and shift shock.

- Touch “OK” to complete the inspection when normally shifted from the 1GR to 5GR.

- Touch “NG” when an unusual shift shock, etc. occurs in spite of shifting from the 1GR to 5GR. Go to TM-

159, "Description".

-Perform TM-32, "

CONSULT-III Functi on (TRANSMISSION)" when not shifted from the 1GR to 5GR. (Nei-

ther “OK” nor “NG” are indicated.)

Revision: April 20092010 QX56