light INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2007 of 4210

HEADLAMP (HI) CIRCUITEXL-31

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E11 or E107.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the voltage between the combination lamp connector and ground.

Are the voltage readings as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000005146642

Regarding Wiring Diagram information, refer to EXL-56, "Wiring Diagram".

1.CHECK HEADLAMP (HI) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

(+) (−)Voltage

Connector Terminal

LH E11 6 Ground Battery voltage

RH E107 6

ALLIA0852ZZ

AB Continuity

Connector Terminal Connector Terminal

LH E123 55

E11 6

Ye s

RH 56E107 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E11 2

Ground Yes

RH E107 2

ALLIA0854ZZ

Revision: April 20092010 QX56

Page 2008 of 4210

EXL-32

< COMPONENT DIAGNOSIS >

HEADLAMP (HI) CIRCUIT

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (HI) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E6 or E108.

3. Turn the ignition switch ON.

4. Turn the high beam headlamps ON.

5. With the high beam headlamps ON, check the voltage between the combination lamp connector and ground.

Are the voltage readings as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (HI) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector E123.

3. Check continuity between the IPDM E/R harness connector (A) and the front combination lamp harness connector (B).

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (HI) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO - RH>>Repair the harness.

NO - LH >>Inspect daytime light rela y. If OK, repair harness. If NG,

replace the daytime light relay.

Unit LocationFuse No.Capacity

Headlamp HI (LH) IPDM E/R3510A

Headlamp HI (RH) IPDM E/R3410A

(+)

(−)Voltage

Connector Terminal

LH E6 6 GroundBattery voltage

RH E108 6

ALLIA0852ZZ

AB

Continuity

Connector Terminal Connector Terminal

LH E123 55

E66

Ye s

RH 56E108 6

AWLIA1371ZZ

Connector Terminal —Continuity

LH E6 2

Ground Yes

RH E108 2

ALLIA0854ZZ

Revision: April 20092010 QX56

Page 2009 of 4210

HEADLAMP (LO) CIRCUITEXL-33

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

DescriptionINFOID:0000000005146643

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM via the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 40 and 41, located in the IPDM E/R. Power then flows to the front combination lamps to

the headlamp low beam.

Component Function CheckINFOID:0000000005146644

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT-III

1. Start IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the headlamp is turned ON. NOTE:

HI/LO is repeated 1 second each when using the IPDM E/R auto active test.

CONSULT-III

1. Select "EXTERNAL LAMPS" of IPDM E/R active test item.

2. With the test items operating, c heck that the headlamp is turned ON.

Is the headlamp turned ON?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-33, "

Diagnosis Procedure - Without Daytime Light System", EXL-34, "Diagnosis

Procedure - With Daytime Light System".

Diagnosis Procedure - Without Daytime Light SystemINFOID:0000000005146645

Regarding Wiring Diagram information, refer to EXL-52, "Wiring Diagram".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE Lo : Headlamp ON

Off : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp LO (LH) IPDM E/R4015A

Headlamp LO (RH) IPDM E/R4115A

Revision: April 20092010 QX56

Page 2010 of 4210

EXL-34

< COMPONENT DIAGNOSIS >

HEADLAMP (LO) CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector.

3. Turn the ignition switch ON.

4. Turn the low beam headlamps ON.

5. With the low beam headlamps ON, check the voltage betweenthe combination lamp connector and ground.

Is voltage reading as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and

the front combination lamp harness connector.

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000005146646

Regarding Wiring Diagram information, refer to EXL-56, "Wiring Diagram".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

(+) (−)V olt a ge

Connector Terminal

LH E11 5

Ground Battery voltage

RH E107 5

ALLIA0855ZZ

AB

Continuity

Connector Terminal Connector Terminal

LH E123 52

E11 5

Ye s

RH 54E107 5

AWLIA1372ZZ

Connector Terminal —Continuity

LH E11 1

Ground Yes

RH E107 1

ALLIA0856ZZ

Revision: April 20092010 QX56

Page 2011 of 4210

HEADLAMP (LO) CIRCUITEXL-35

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector.

3. Turn the ignition switch ON.

4. Turn the low beam headlamps ON.

5. With the low beam headlamps ON, check the voltage between the combination lamp connector and ground.

Is voltage reading as specified?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK HEADLAMP (LO) CIRCUIT FOR OPEN

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between the IPDM E/R harness connector and the front combination lamp harness connector.

Does continuity exist?

YES >> GO TO 4.

NO >> Repair the harnesses or connectors.

4.CHECK FRONT COMBINATION LAMP (LO) GROUND CIRCUIT

Check continuity between the front combination lamp harness con-

nector terminal and ground.

Does continuity exist?

YES >> Inspect the headlamp bulb.

NO - RH>>Repair the harness.

NO - LH>>Inspect the daytime light relay. If OK, repair harness. If

NG, replace the daytime light relay.

Unit LocationFuse No.Capacity

Headlamp LO (LH) IPDM E/R4015A

Headlamp LO (RH) IPDM E/R4115A

(+)

(−)Voltage

Connector Terminal

LH E6 5

Ground Battery voltage

RH E108 5

ALLIA0855ZZ

AB

Continuity

Connector Terminal Connector Terminal

LH E123 52

E6 5

Ye s

RH 54E108 5

AWLIA1372ZZ

Connector Terminal —Continuity

LH E6 1

Ground Yes

RH E108 1

ALLIA0856ZZ

Revision: April 20092010 QX56

Page 2014 of 4210

EXL-38

< COMPONENT DIAGNOSIS >

PARKING LAMP CIRCUIT

PARKING LAMP CIRCUIT

DescriptionINFOID:0000000005146650

The IPDM E/R (intelligent power distribution module engine room) controls the tail lamp relay based on inputs

from the BCM via the CAN communication lines. When the tail lamp relay is energized, power flows through

fuse 37, located in the IPDM E/R. Power then flows to the front and rear combination lamps.

Component Function CheckINFOID:0000000005146651

1.CHECK PARKING LAMP OPERATION

WITHOUT CONSULT-III

1. Activate IPDM E/R auto active test. Refer to PCS-12, "

Diagnosis Description".

2. Check that the parking lamp is turned ON.

CONSULT-III

1. Select "EXTERNAL LAMPS" of IPDM E/R active test item.

2. With operating the test items, check that the parking lamp is turned ON.

Is the parking lamp turned ON?

YES >> Parking lamp circuit is normal.

NO >> Refer to EXL-38, "

Diagnosis Procedure - Without Daytime Light System", EXL-41, "Diagnosis

Procedure - With Daytime Light System".

Diagnosis Procedure - Wit hout Daytime Light SystemINFOID:0000000005146652

Regarding Wiring Diagram information, refer to EXL-84, "Wiring Diagram".

1.CHECK PARKING LAMP FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK TAIL LAMP RELAY OUTPUT (VOLTAGE)

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector, rear combination lamp connector and license plate

lamp connector.

3. Turn the ignition switch ON.

4. Turn the parking lamps ON. TAIL : Parking lamp ON

Off : Parking lamp OFF

Unit

LocationFuse No.Capacity

Parking lamps IPDM E/R3710A

Revision: April 20092010 QX56

Page 2017 of 4210

PARKING LAMP CIRCUITEXL-41

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

3. Check continuity between the license plate lamp harness con- nectors and ground.

Does continuity exist?

YES >> Inspect the parking lamp bulb.

NO >> Repair the harness.

Diagnosis Procedure - With Daytime Light SystemINFOID:0000000005146653

Regarding Wiring Diagram information, refer to EXL-84, "Wiring Diagram".

1.CHECK PARKING LAMP FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not open.

Is the fuse open?

YES >> Repair the harness and replace the fuse.

NO >> GO TO 2.

2.CHECK TAIL LAMP RELAY OUTPUT (VOLTAGE)

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector, rear combination lamp connector and license plate

lamp connector.

3. Turn the ignition switch ON.

4. Turn the parking lamps ON.

5. With the parking lamps ON, check voltage between the front combination lamp connectors and ground.

6. With the parking lamps ON, check voltage between the rear combination lamp connectors and ground.

Connector Terminal —Continuity

D703 2Ground Yes

WKIA4615E

Unit LocationFuse No.Capacity

Parking lamps IPDM E/R3710A

(+)

(−)V olt a g e

Connector Terminal

LH E6 3Ground Battery voltage

RH E108

ALLIA0857ZZ

(+) (−)V olt a g e

Connector Terminal

LH B70 3Ground Battery voltage

RH B130

AWLIA1622ZZ

Revision: April 20092010 QX56

Page 2020 of 4210

EXL-44

< COMPONENT DIAGNOSIS >

TURN SIGNAL LAMP CIRCUIT

TURN SIGNAL LAMP CIRCUIT

DescriptionINFOID:0000000005146654

The BCM monitors inputs from the combination switch (lighting and turn signal switch) to determine when to

activate the turn signals. The BCM outputs voltage direction to the left and right turn signals during turn signal

operation or both during hazard warning operation. The BCM sends a turn signal indicator request to the com-

bination meter via the CAN communication lines.

The BCM performs the fast flasher operation (fail-safe) if any bulb or harness of the turn signal lamp circuit is

open.

NOTE:

Turn signal lamp blinks at normal speed when using the hazard warning lamp.

Component Function CheckINFOID:0000000005146655

1.CHECK TURN SIGNAL LAMP

CONSULT-III

1. Select "FLASHER" of BCM (FLASHER) active test item.

2. With operating the test items, check that the turn signal lamp blinks.

Does the turn signal lamp blink?

YES >> Turn signal lamp circuit is normal.

NO >> Refer to EXL-44, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005146656

Regarding Wiring Diagram information, refer to EXL-77, "Wiring Diagram".

1.CHECK TURN SIGNAL LAMP BULB

Check the applicable lamp bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 2.

NO >> Replace the bulb.

2.CHECK TURN SIGNAL LAMP OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front turn/fog lamp connector or the rear combi- nation lamp connector.

3. Turn the ignition switch ON.

4. With turn signal switch operating, check the voltage between the BCM harness connector M20 and ground.LH : Turn signal lamp LH blinking

RH : Turn signal lamp RH blinking

Off : The turn signal lamp OFF

(+)

(−) Voltage

Connector Terminal

ALLIA0896ZZ

Revision: April 20092010 QX56

Page 2023 of 4210

OPTICAL SENSOREXL-47

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

OPTICAL SENSOR

DescriptionINFOID:0000000005146657

The optical sensor converts the outside brightness (lux) to voltage and transmits the optical sensor signal to

the BCM.

Component Function CheckINFOID:0000000005146658

1.CHECK OPTICAL SENSOR SIGNAL BY CONSULT-III

CONSULT-III

1. Turn the ignition switch ON.

2. Select "OPTICAL SENSOR" of BC M (HEAD LAMP) DATA MONITOR item.

3. Turn the lighting switch to AUTO.

4. With the optical sensor illuminat ing, check the monitor status.

*: Illuminates the optical sensor. The value may be less than the standard value if brightness is weak.

Is the item status normal?

YES >> Optical sensor is normal.

NO >> Refer to EXL-47, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005146659

Regarding Wiring Diagram information, refer to EXL-62, "Wiring Diagram".

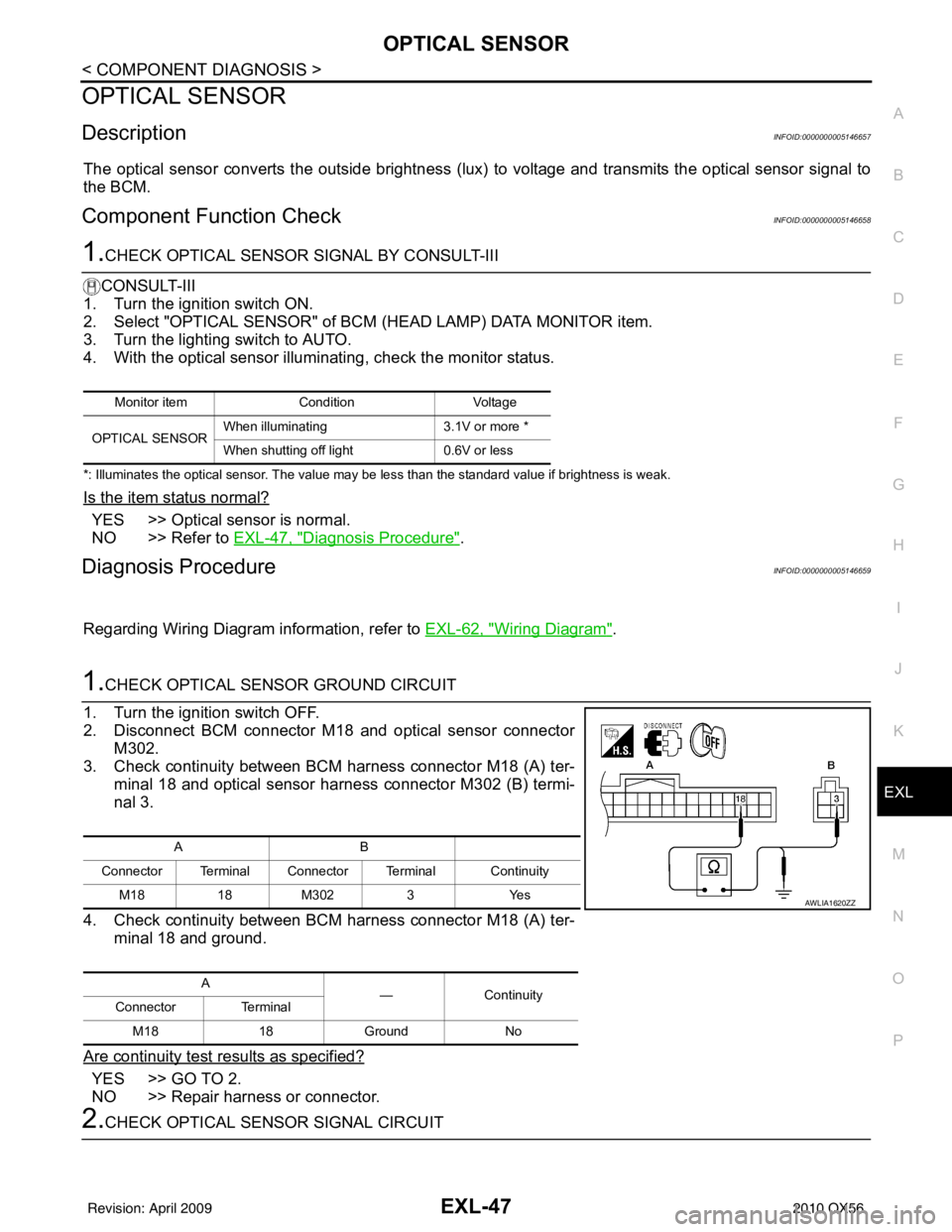

1.CHECK OPTICAL SENSOR GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect BCM connector M18 and optical sensor connector M302.

3. Check continuity between BCM harness connector M18 (A) ter-

minal 18 and optical sensor harness connector M302 (B) termi-

nal 3.

4. Check continuity between BCM harness connector M18 (A) ter- minal 18 and ground.

Are continuity test results as specified?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK OPTICAL SENSOR SIGNAL CIRCUIT

Monitor item ConditionVoltage

OPTICAL SENSOR When illuminating

3.1V or more *

When shutting off light 0.6V or less

AB

Connector Terminal Connector Terminal Continuity M181 8M3023 Y es

A —Contin u it y

Connector Terminal

M18 18Ground No

AWLIA1620ZZ

Revision: April 20092010 QX56

Page 2025 of 4210

HEADLAMP AIMING SWITCHEXL-49

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP AIMING SWITCH

DescriptionINFOID:0000000005146660

The manual headlamp aiming system uses a headlamp aiming switch to adjust the axis of the headlamp aim-

ing motor. The headlamp aiming switch has four settings, each with a different resistance value. The head-

lamp aiming motor adjusts to the proper axis based off the position of the headlamp aiming switch.

Diagnosis Procedure - Without Daytime Light SystemINFOID:0000000005146661

Regarding Wiring Diagram information, refer to EXL-69, "Wiring Diagram".

1.CHECK HEADLAMP AIMING SWITCH SIGNAL FOR OPEN OR SHORT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect headlamp aiming switch connector M148 (A), headlamp aiming motor LH connector E11 and

headlamp aiming motor RH connector E107 (B).

3. Check continuity between the headlamp aiming switch connec-

tor M148 terminal 1 (A) and headlamp aiming motor LH E11 and

RH E107 terminal 7 (B).

4. Check continuity between the headlamp aiming switch connec- tor M148 terminal 1 and ground.

Are the continuity test results as specified?

YES >> GO TO 2.

NO >> Repair the harness or connector.

2.CHECK HEADLAMP AIMING SWITCH

1. Check resistance between the headlamp aiming switch termi- nals 1 and 2 in each switch position.

Are the resistance check results as specified?

YES >> GO TO 3.

NO >> Replace the headlamp aiming switch.

3.CHECK HEADLAMP AIMING SWITCH GROUND CIRCUIT

Connector Terminal Connector Terminal Continuity

M148 1E11

7Y es

E107

Connector Terminal —Continuity

M148 1Ground No

AWLIA1093ZZ

Component Terminal Switch Position Resistance

Headlamp

aiming switch 12 06

04 Ω

13 24 Ω

21 91 Ω

31 30 Ω

AWLIA1027ZZ

Revision: April 20092010 QX56